Micro-tapered fiber for producing ultra-narrow linewidth fiber laser, and laser

A fiber laser and ultra-narrow linewidth technology, applied in the field of lasers, can solve problems such as difficult implementation, difficult doping concentration, weak signal, etc., and achieve the effect of achieving Rayleigh gain accumulation, improving output signal strength, and improving signal strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

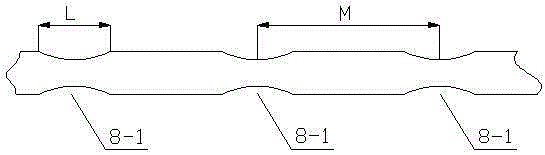

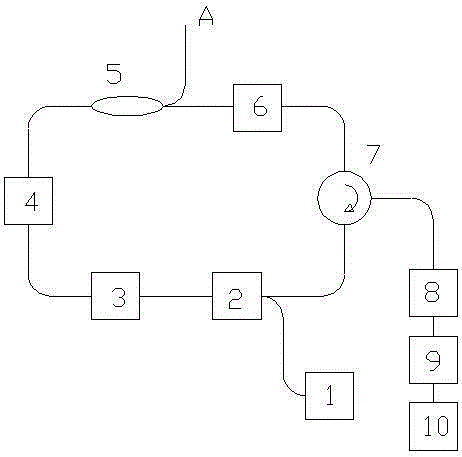

[0017] A kind of micro-tapered fiber for making ultra-narrow-linewidth fiber lasers, the micro-tapered fiber is made of ordinary single-mode fiber through a tapered process: through multiple taper operations, the ordinary single-mode fiber is formed A plurality of tapered regions 8-1; the micro-tapered optical fiber is integrated into the laser, so that the resonant cavity length of the laser is greater than or equal to 80m, and the multiple tapered regions 8-1 on the ordinary single-mode fiber can effectively suppress the distribution The Rayleigh gain ensures the stability of the single-frequency operation of the laser. At the same time, the long-length resonator can meet the needs of a large accumulation of Rayleigh gain and improve the signal strength.

[0018] Axial length of a single tapered zone 8-1 (see figure 1 The range indicated by the middle mark L) is 1.5~2cm.

[0019] Each tapered area 8-1 is arranged at equal intervals, and the axial centers of two adjacent tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com