Narrow linewidth laser output method based on micro-groove fiber

An output method and micro-groove technology, applied in the laser field, can solve the problems of difficult gain accumulation, weak signal, and inability to achieve single-frequency operation, and achieve the effects of achieving Rayleigh gain accumulation, improving signal strength, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

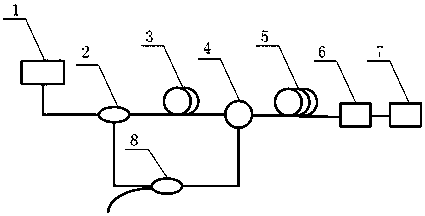

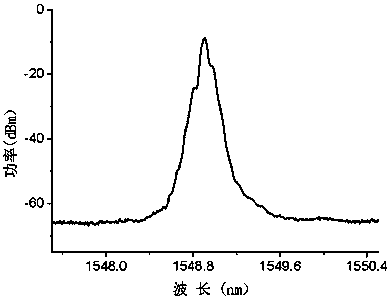

[0018] Such as Figure 1a with Figure 1b As shown, this embodiment includes a 980nm pump laser 1, a wavelength division multiplexer 2, an erbium-doped optical fiber 3 with a length of 2 meters to 10 meters, a three-port circulator 4, a section of micro-groove optical fiber 5, a Variable optical attenuator 6, a fiber Bragg grating 7 with a center wavelength of 1548.839nm, and a 1*2 coupler 8;

[0019] A specific method for realizing narrow linewidth laser output includes the following steps:

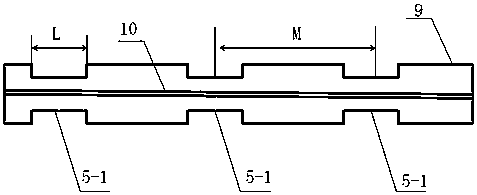

[0020] (1) Select the micro-groove fiber 5 used to realize the ultra-narrow linewidth fiber laser, the micro-groove fiber is made by ordinary single-mode fiber 9 through femtosecond laser micromachining, and the femtosecond laser is used on the single-mode fiber Two symmetrical grooves 5-1 with a depth of 6-7 microns are written on the surface, and 20-22 pairs of micro-groove areas are formed on the common single-mode optical fiber through multiple writing operations. The micro-groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com