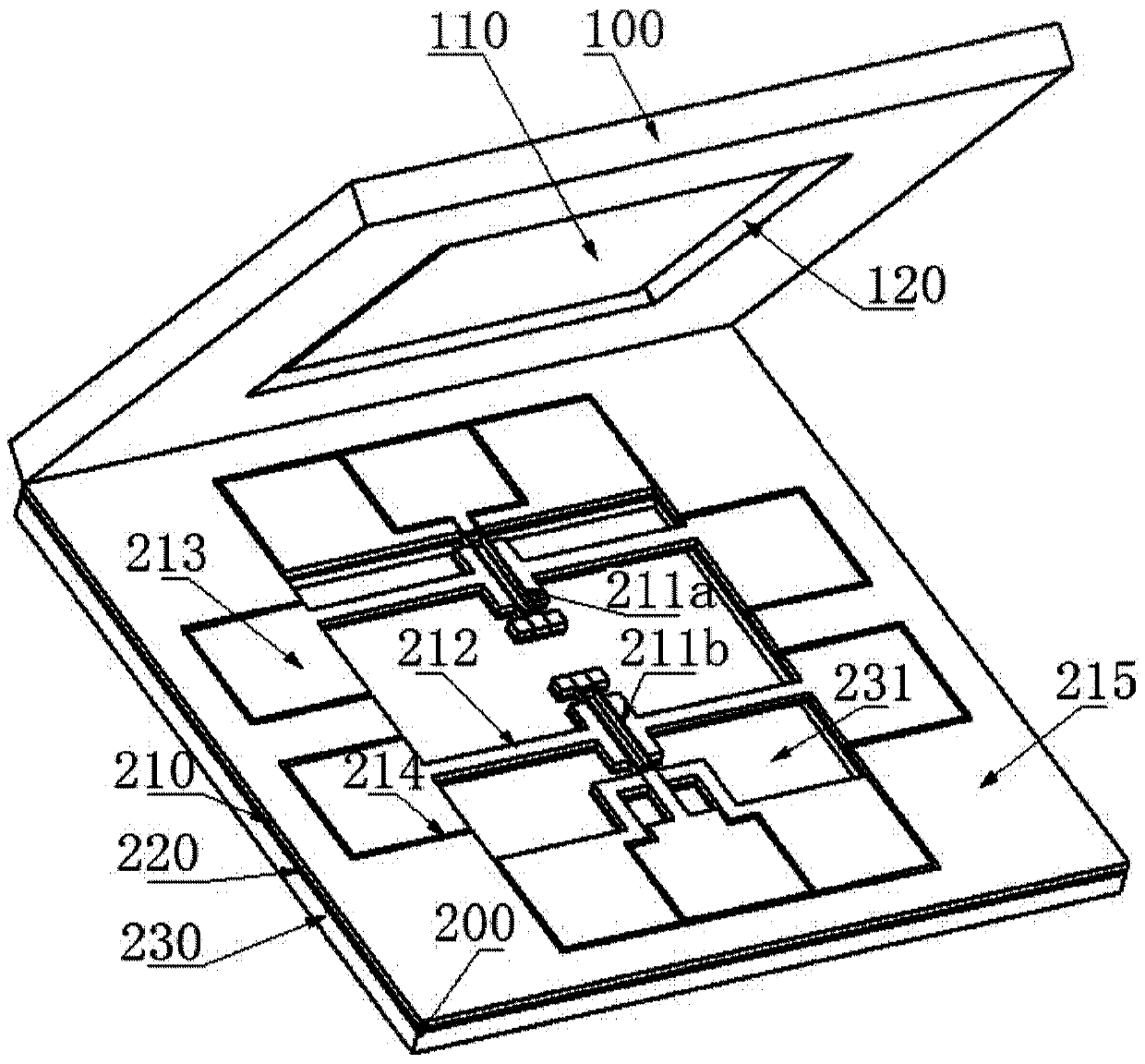

Resonant pressure sensor based on piezoresistive detection and its preparation method

A pressure sensor and piezoresistive detection technology, which is applied in the field of MEMS micro-sensors, can solve problems such as short circuit of electrodes and easy breakage of silicon-aluminum wire materials, and achieve the effects of improving yield, increasing process complexity, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

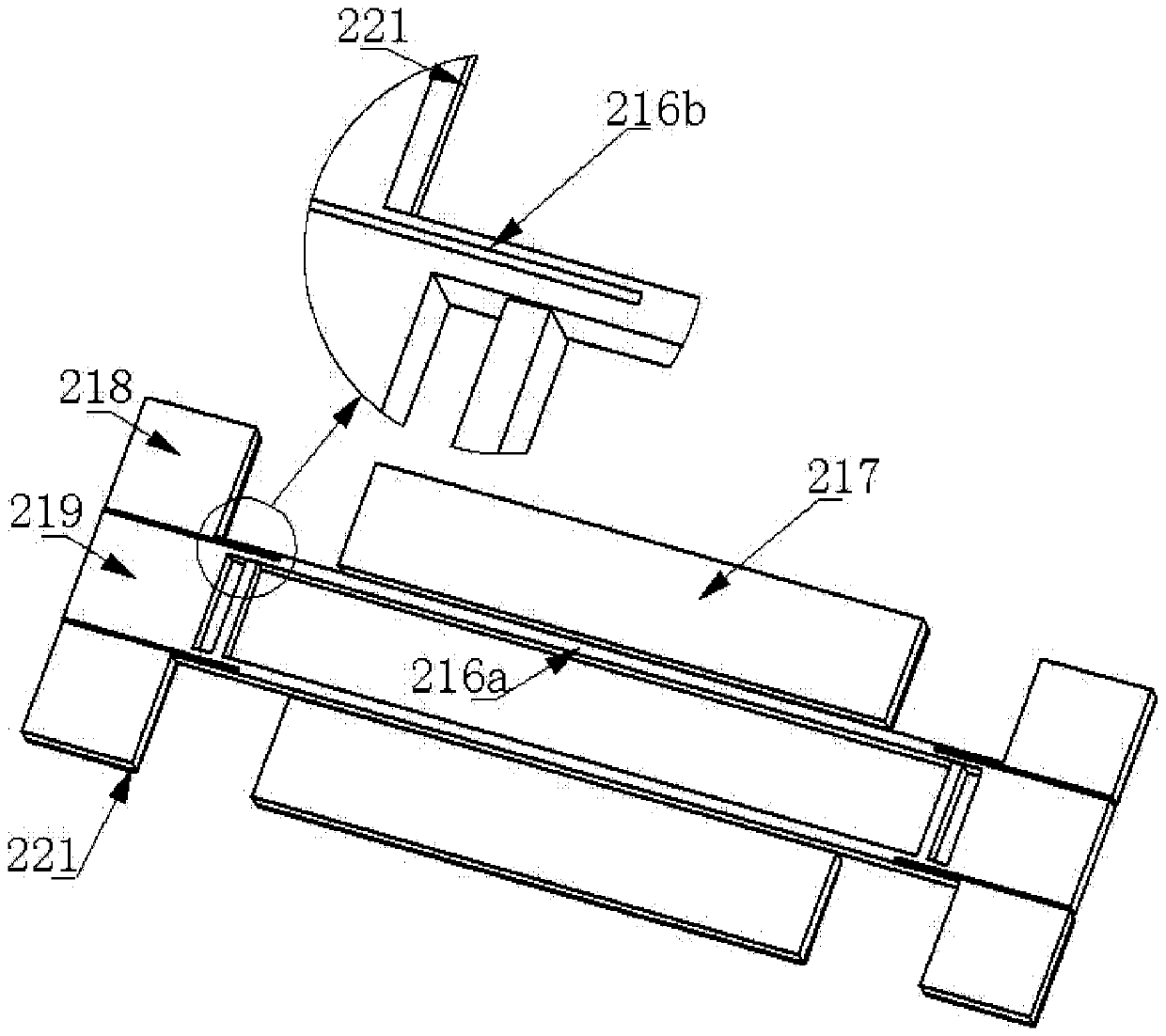

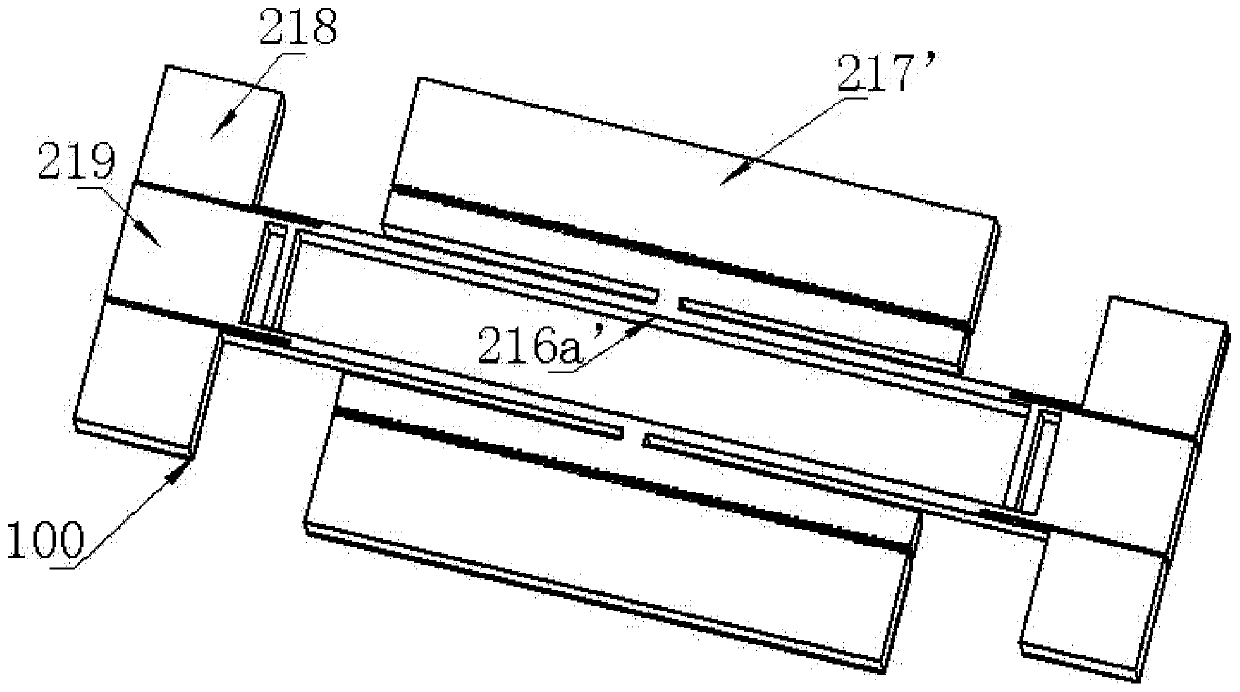

[0057] It should be noted that the directional terms mentioned in the embodiments, such as "up", "down", "front", "rear", "left", "right", etc., are only for referring to the directions of the drawings, not for reference. To limit the protection scope of the present invention. Throughout the drawings, the same elements are indicated by the same or similar reference numerals. For example, in the following, it is as follows figure 1 As shown, the up-down direction is determined based on the plane where the SOI sheet is located, and the horizontal direction is the left-right direction, and the vertical direction is the front-rear direction.

[0058] Aiming at the problems of complex drive structure, small detection signal, difficult temperature compensation and electrode short circuit in excitation and detection, temperature compensation and electrode fabrication of resonant pressure sensors, the present invention provides a resonant pressure sensor based on piezoresistive detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com