Patents

Literature

40results about How to "Ensure monitoring reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monitoring system for crack growth conditions of pressure vessel containing vertical internal crack defects

ActiveCN105259180AImprove efficiency and reliabilityImprove accuracy and reliabilityOptically investigating flaws/contaminationUsing mechanical meansEngineeringMonitoring system

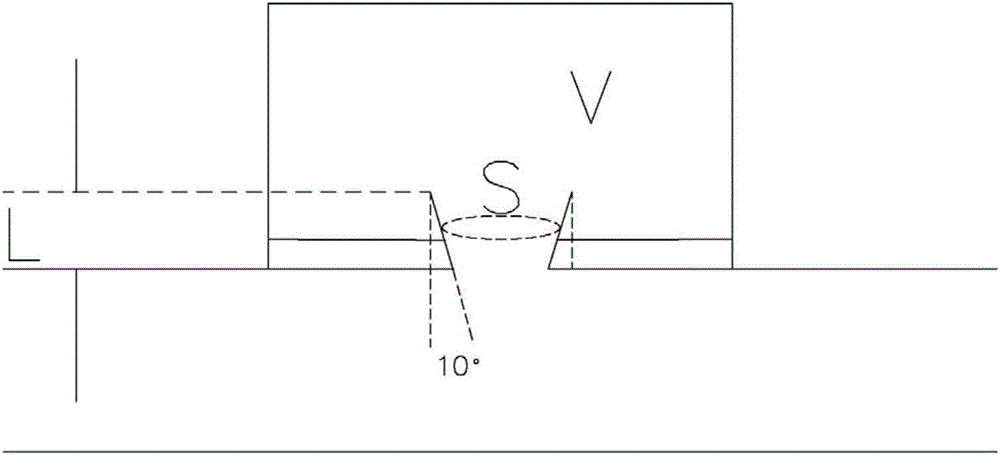

The invention discloses a monitoring system for crack growth conditions of a pressure vessel containing vertical internal crack defects, which belongs to the technical field of safety analysis of pressure vessels. The monitoring system comprises a sensor unit and an arithmetic unit. The sensor unit is connected with the arithmetic unit and sends monitored information to the arithmetic unit. The arithmetic unit comprises a strain value calculation module, which is connected with the sensor unit, acquires the data of the outer surface of the container detected by the sensor unit and calculates a corresponding strain value according to the data; a depth calculation module, which is connected with the strain value calculation module, acquires the strain value and calculates the depth of an internal crack of the container according to the strain value; a stress intensity factor calculation module, which is connected with the depth calculation module, acquires the value of the crack depth and calculates the value of a stress intensity factor at the tip of the crack according to the value of the crack depth; and a determination module, which is connected with the stress intensity factor calculation module, acquires the value of the stress intensity factor at the tip of the crack and compares the value with a fracture toughness value of a material from which the pressure vessel is made; wherein comparison results output by the determination module characterize the state of the crack and indicate whether the pressure vessel should be on service. According to the invention, the growth state of the crack is obtained through rational detection and calculation; and the safe service situation of the pressure vessel is determined, and high reliability is obtained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

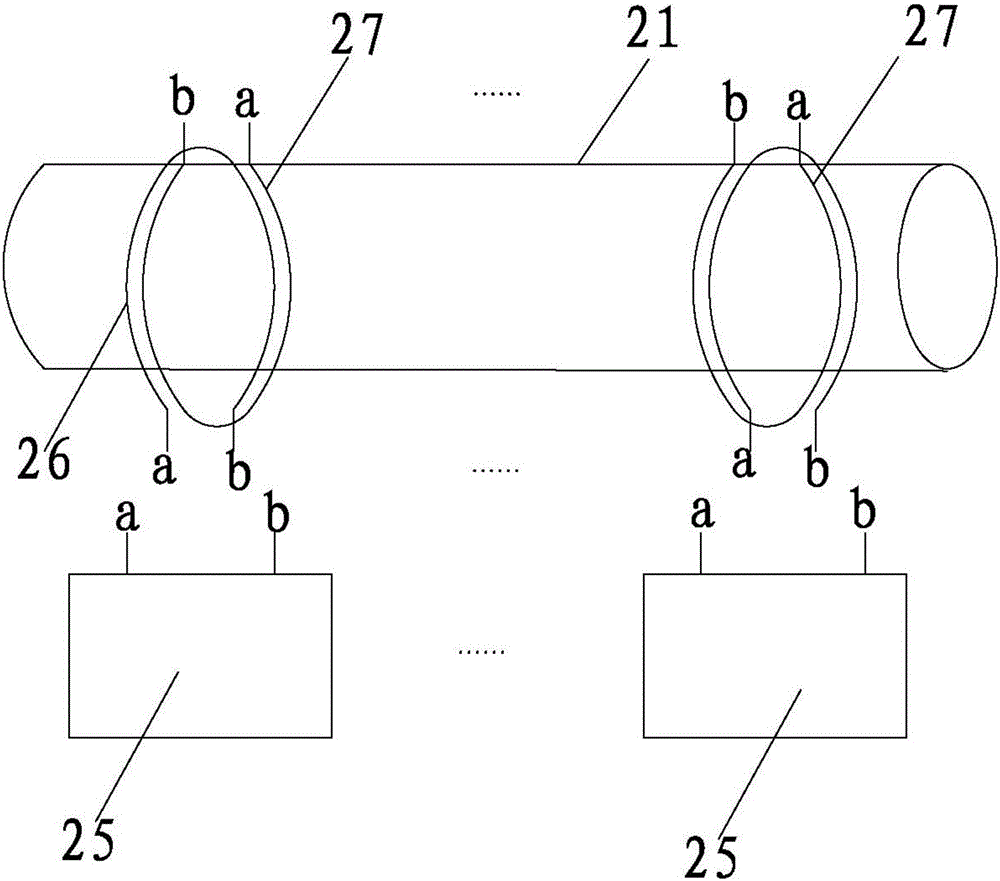

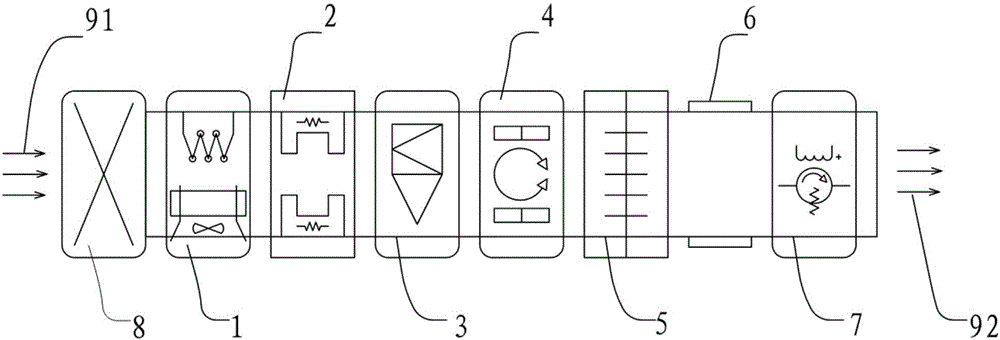

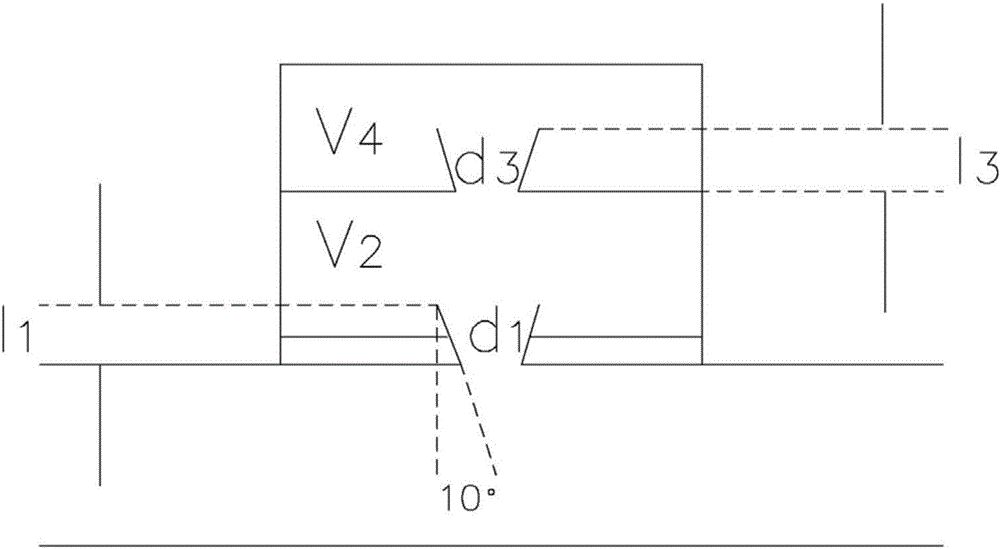

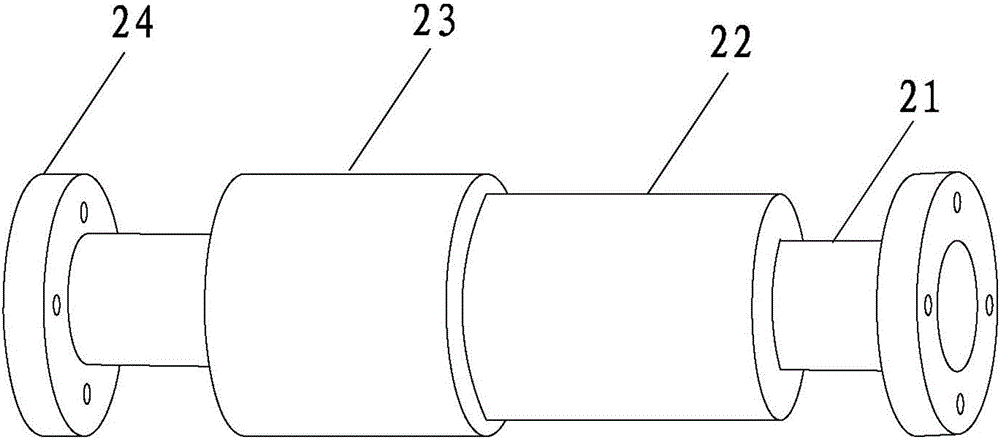

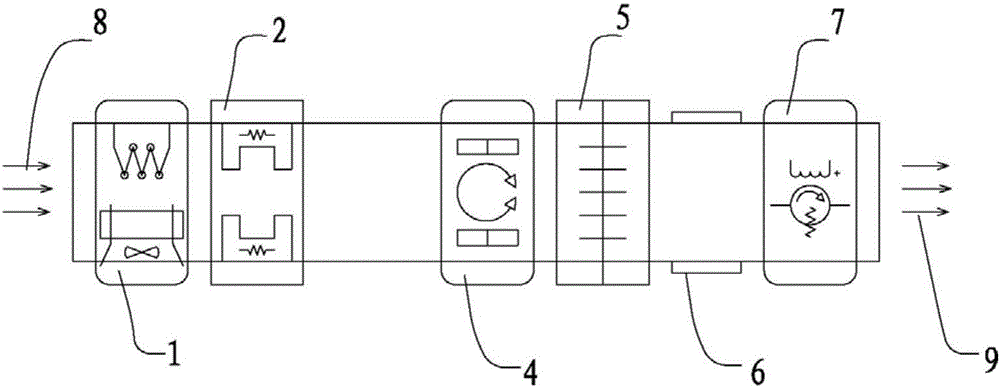

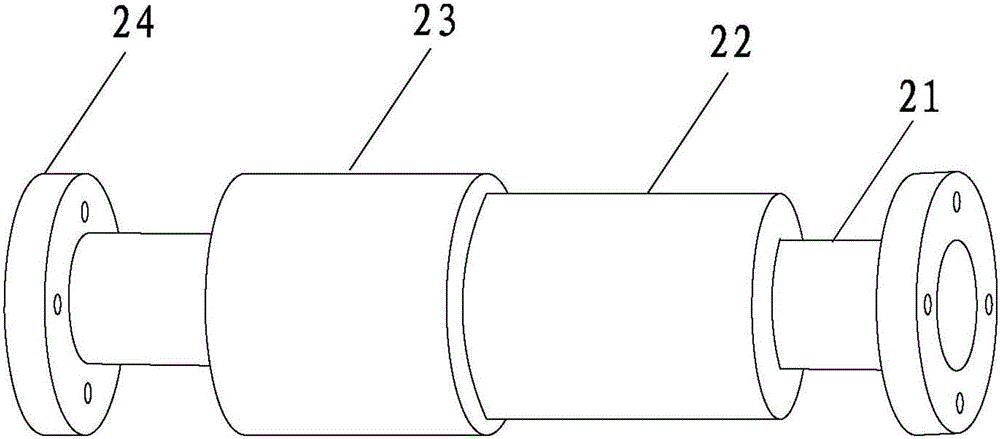

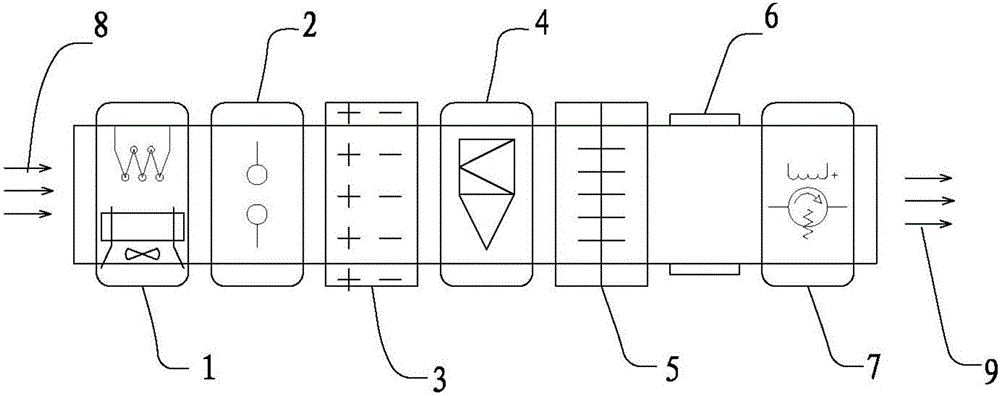

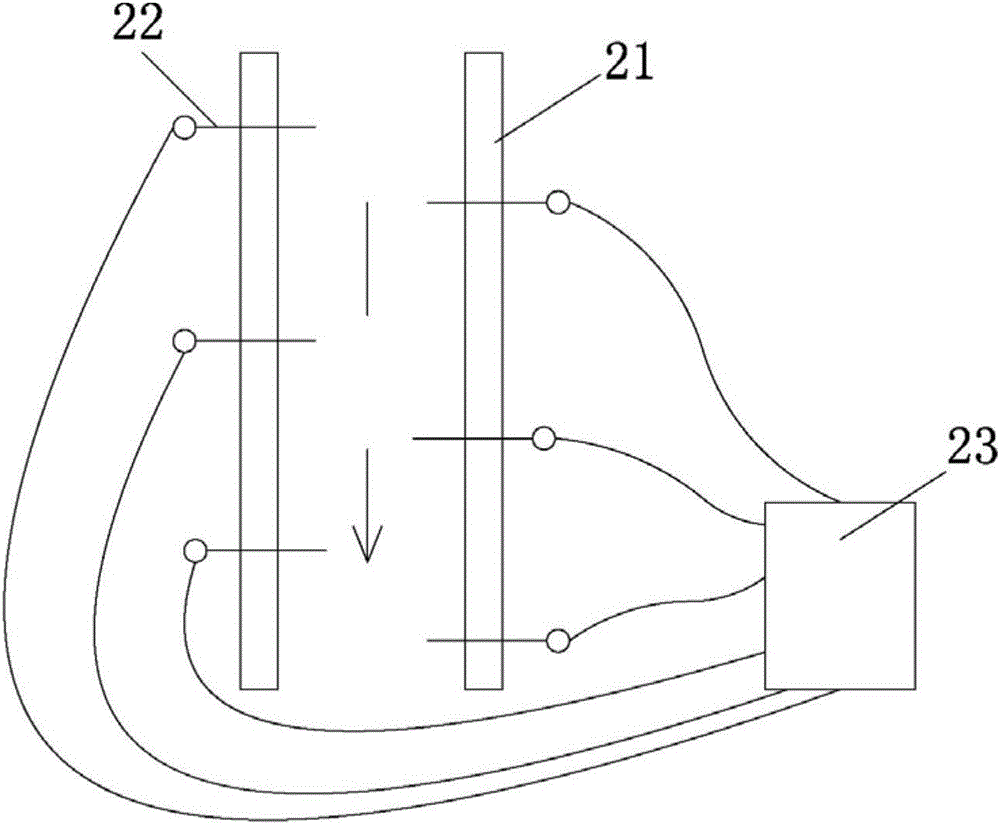

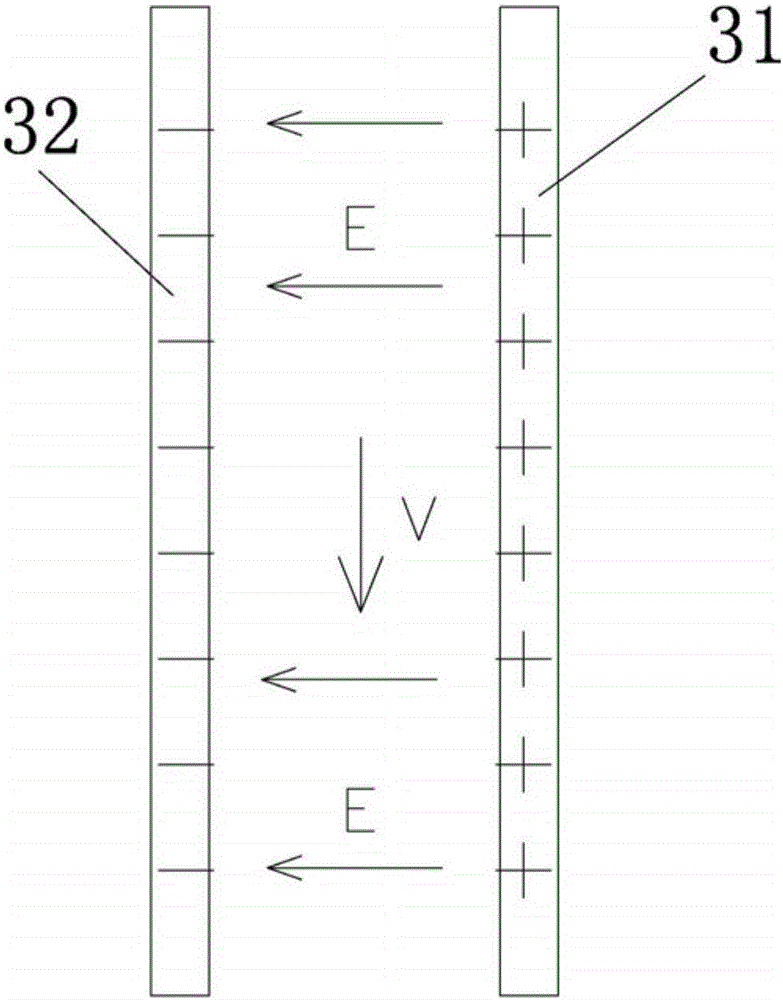

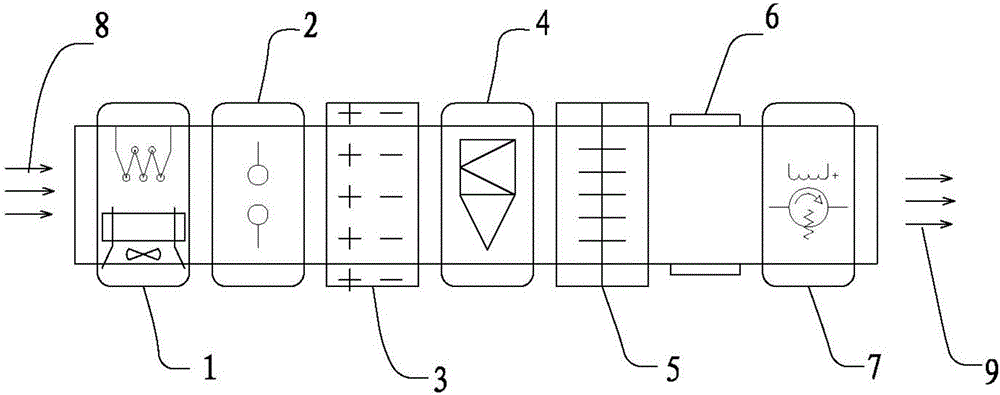

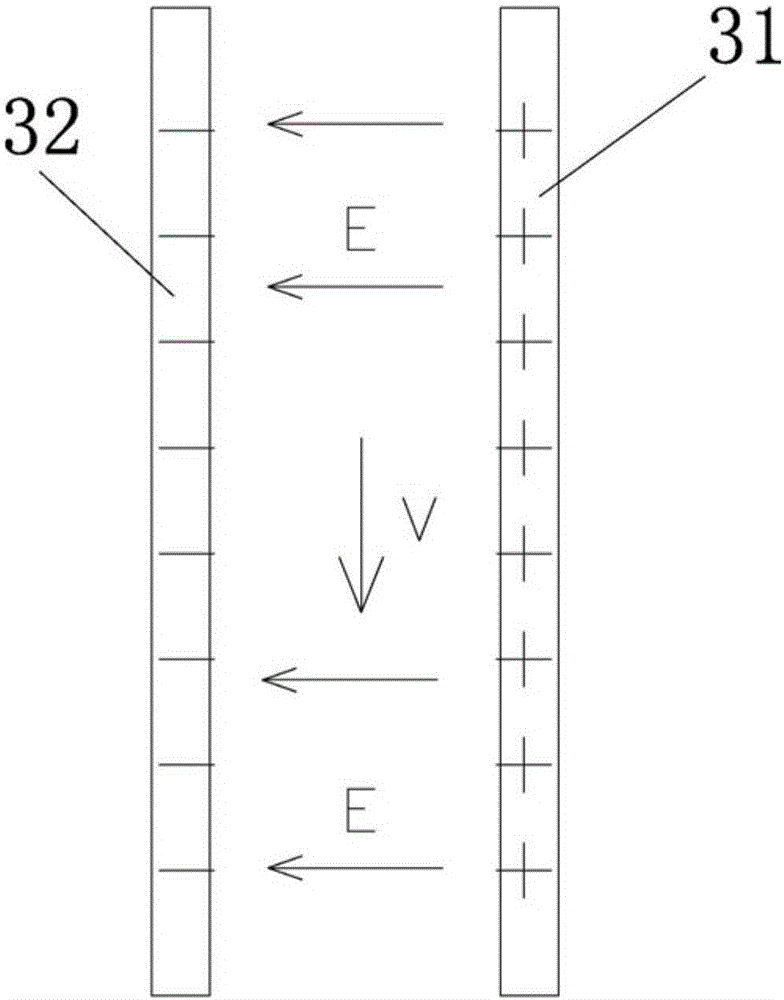

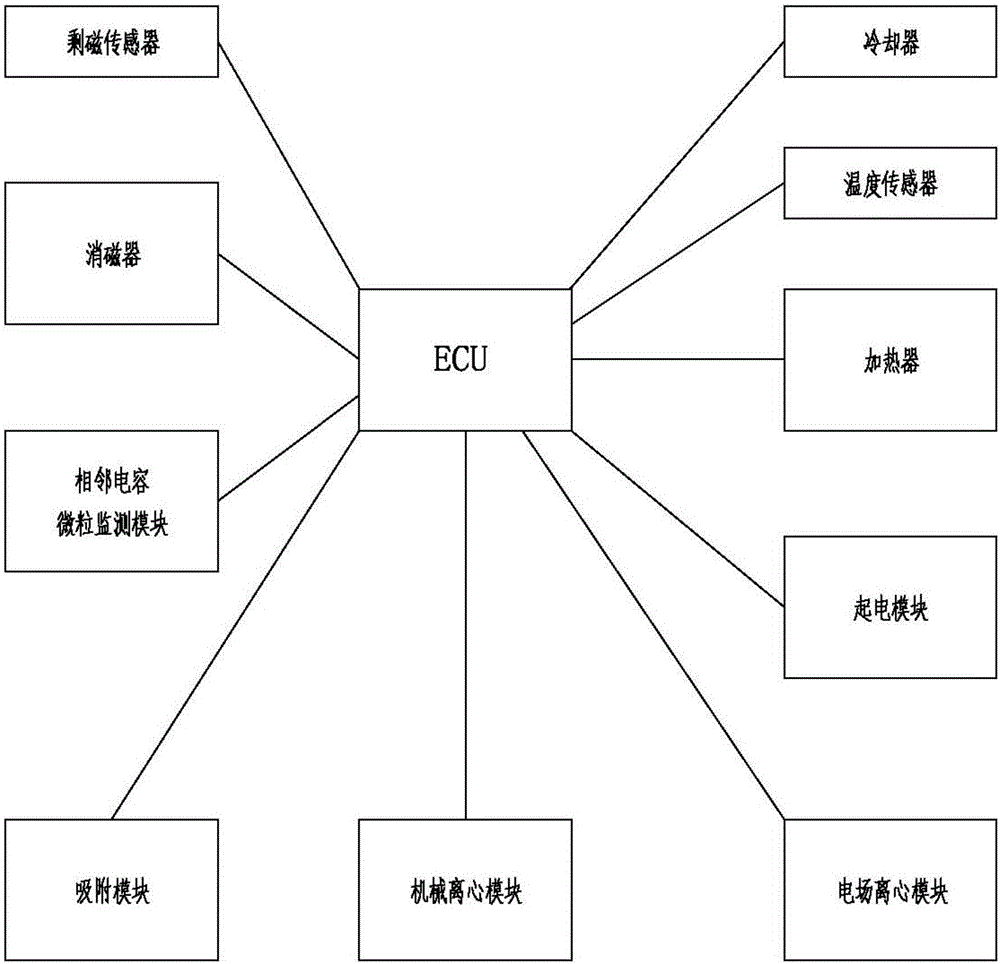

Method for online wear particle monitoring by adoption of electrification, electric control loop adsorption and adjacent capacitance

InactiveCN105864152AIncrease output signal strengthHigh dielectric constantFluid-pressure actuator testingEdge effectsEngineering

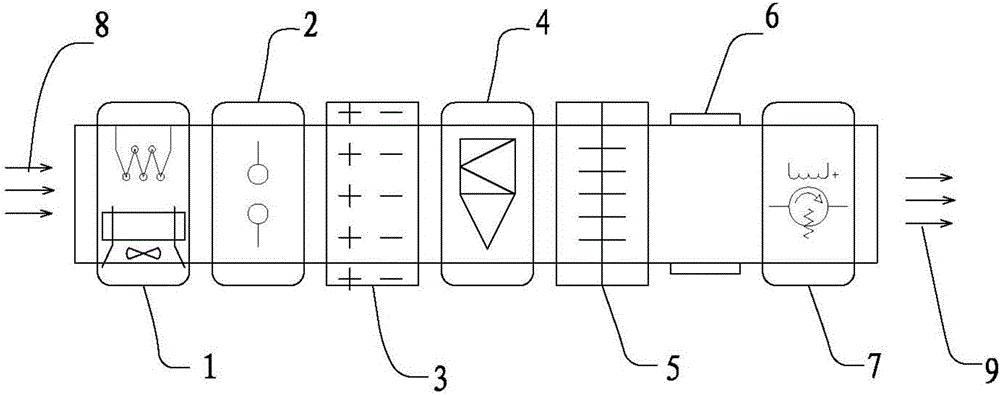

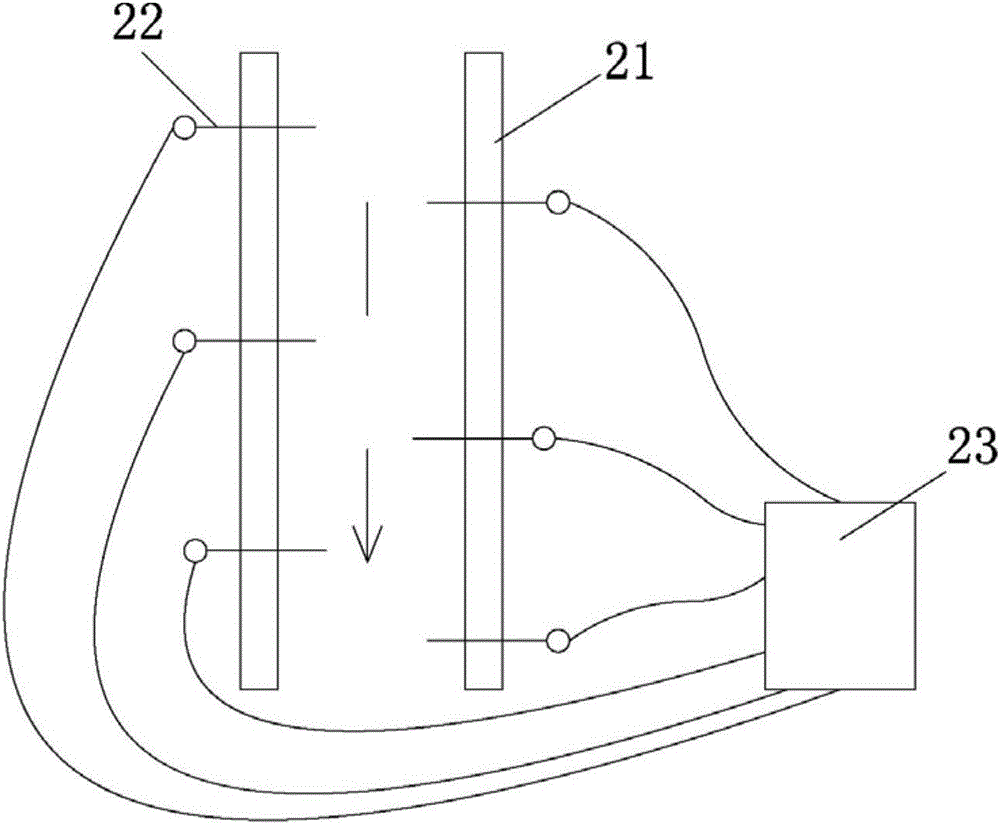

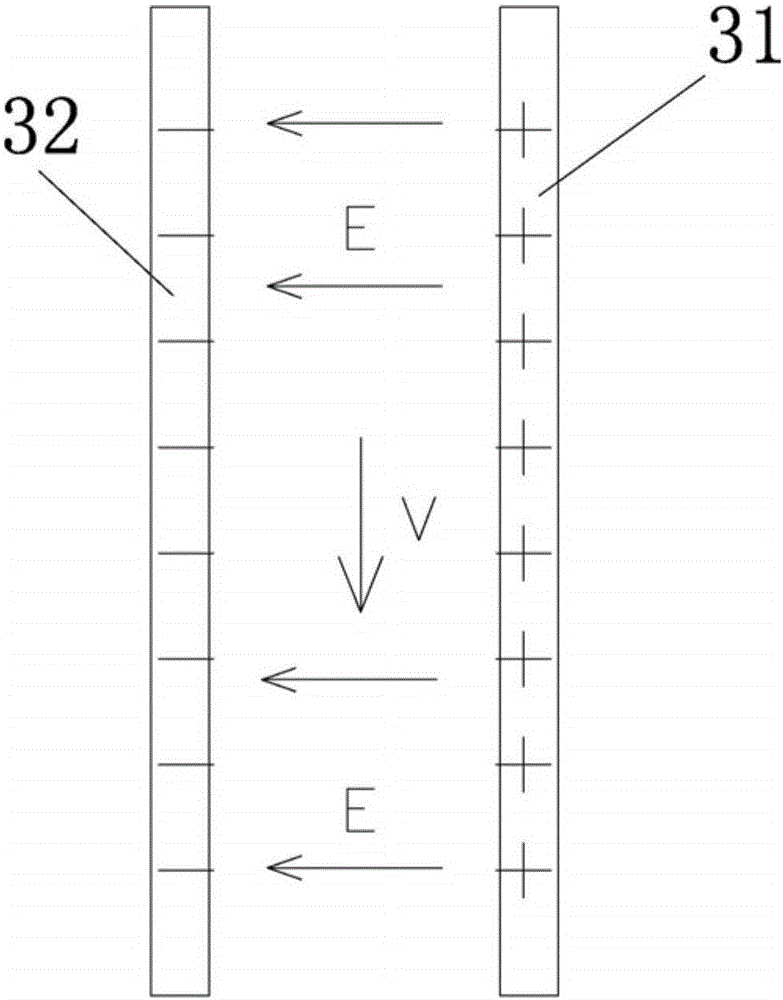

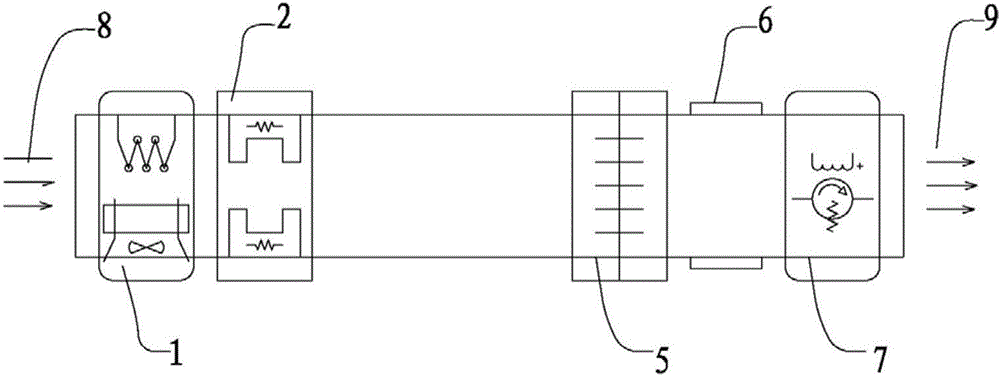

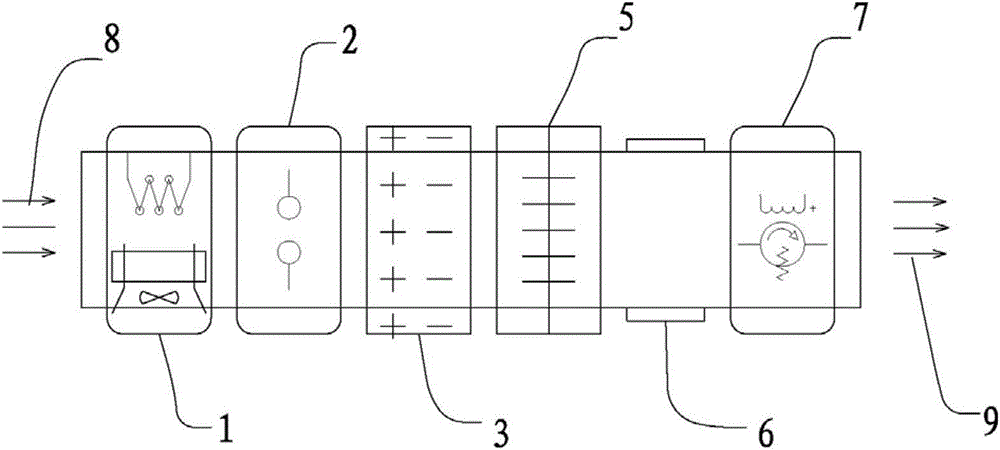

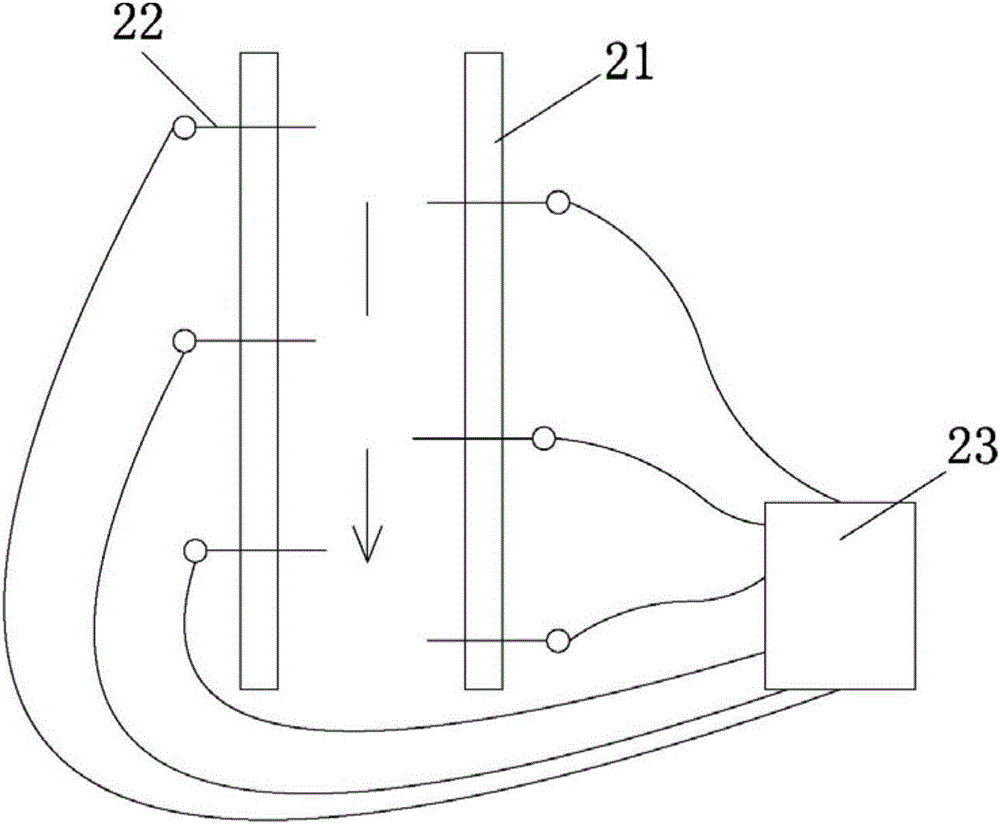

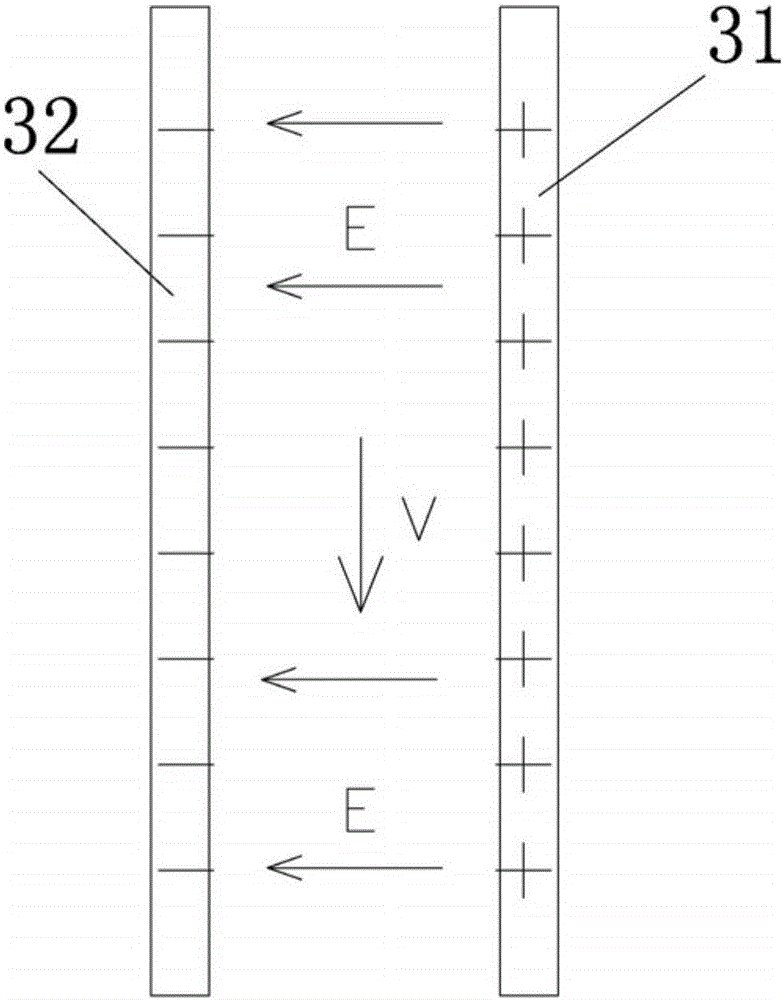

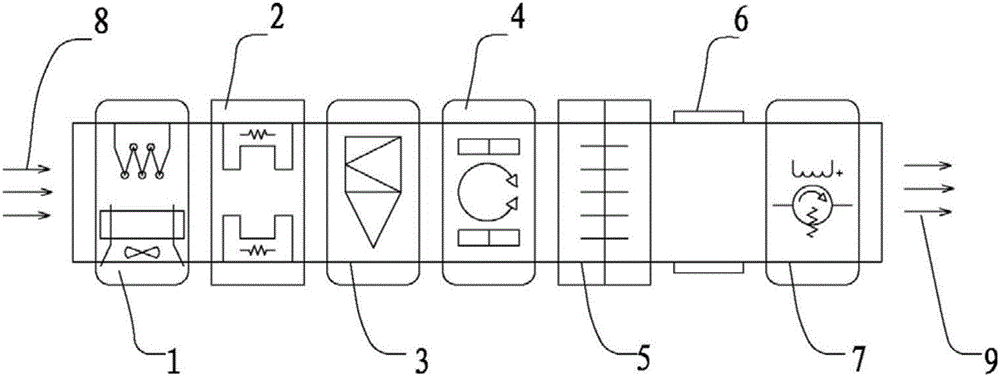

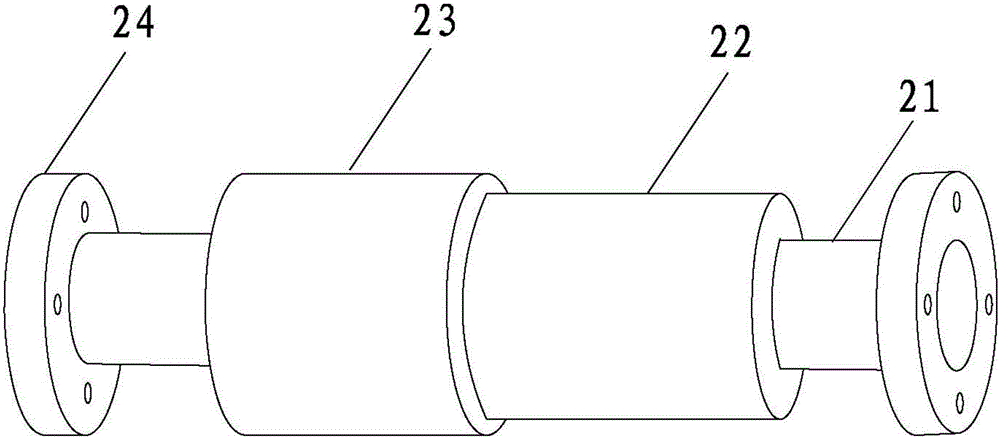

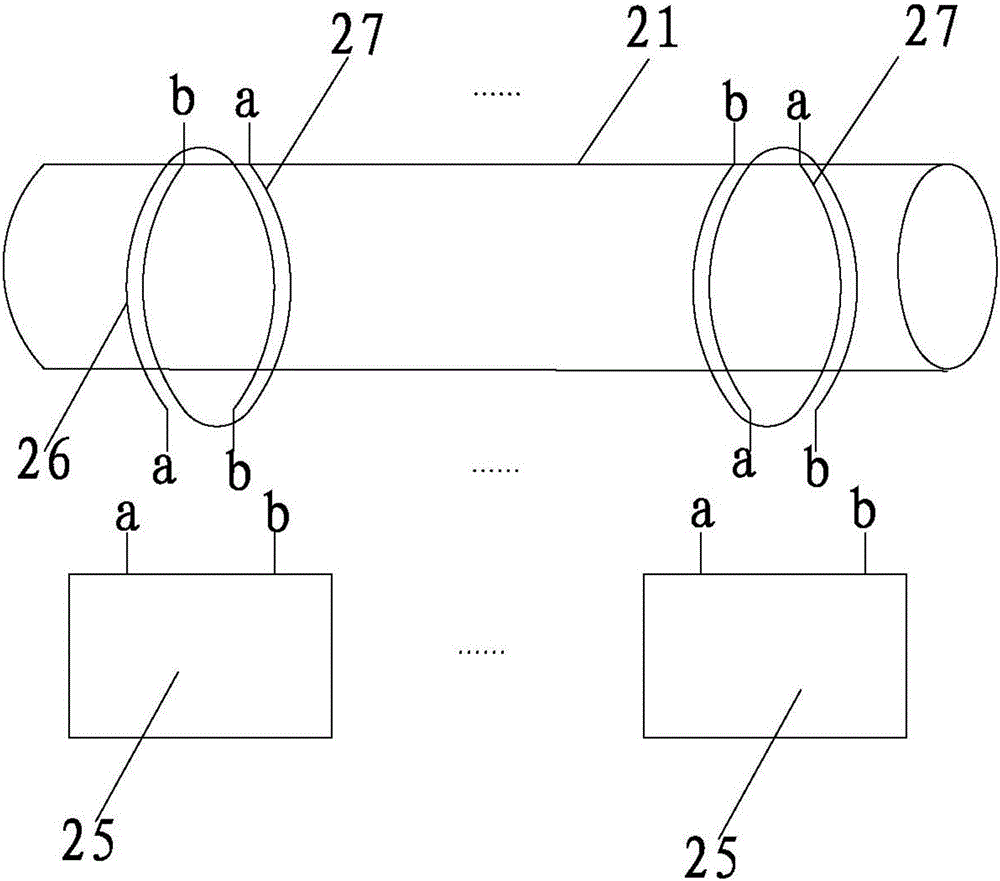

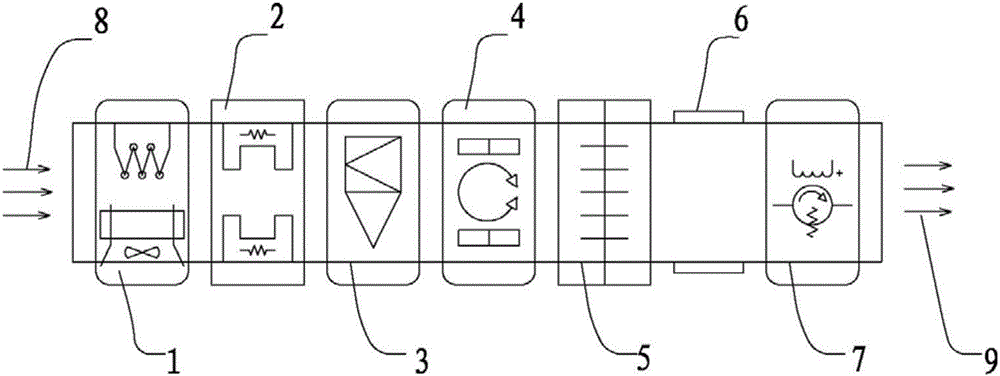

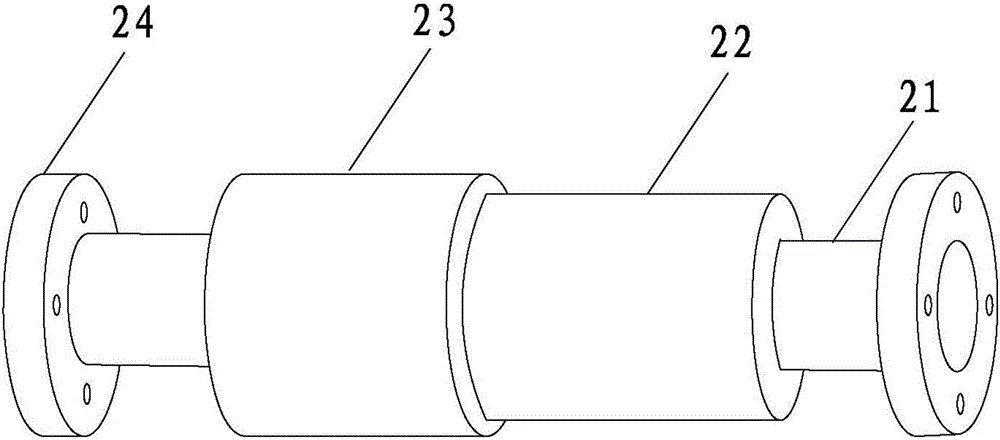

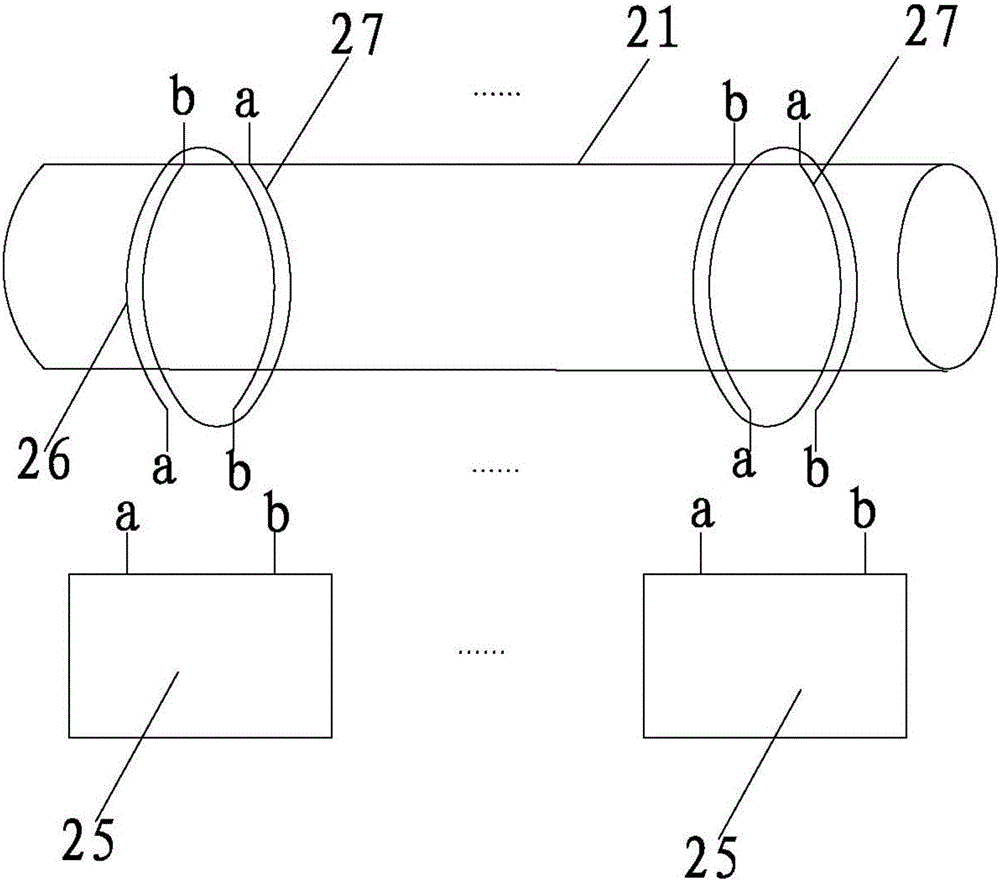

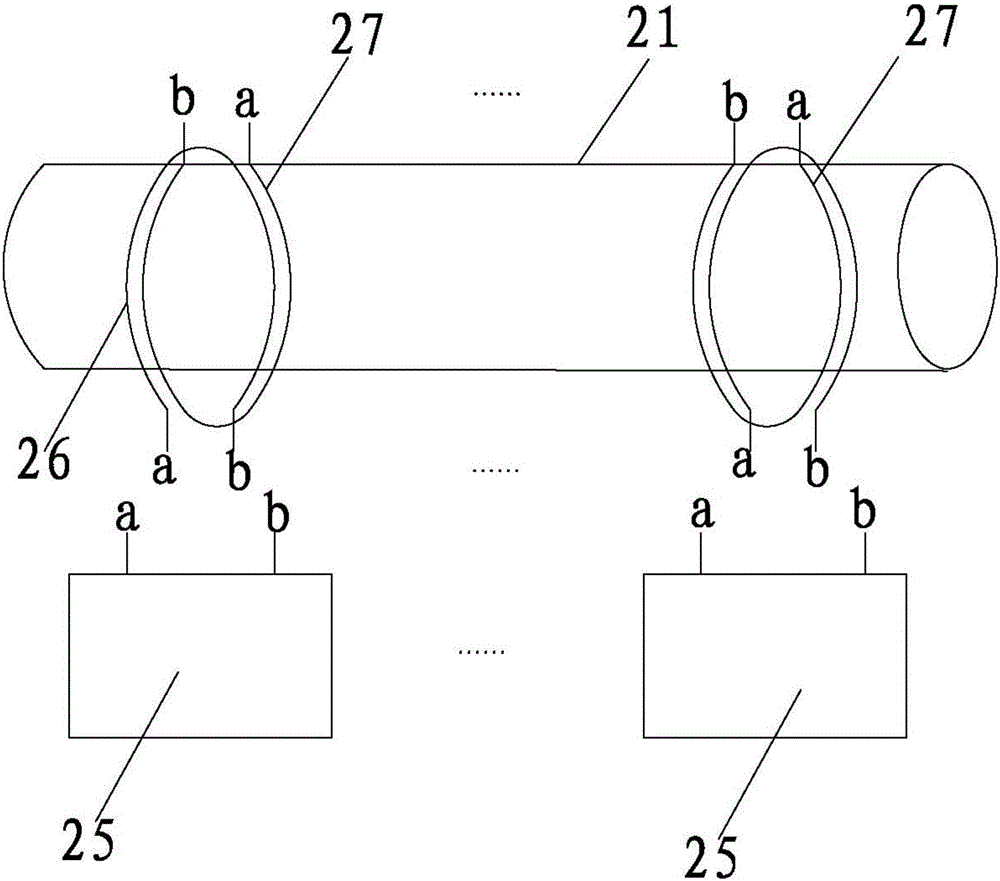

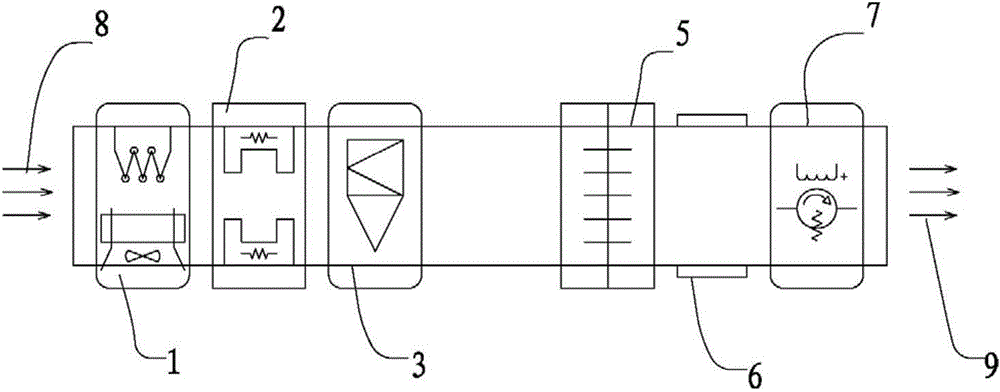

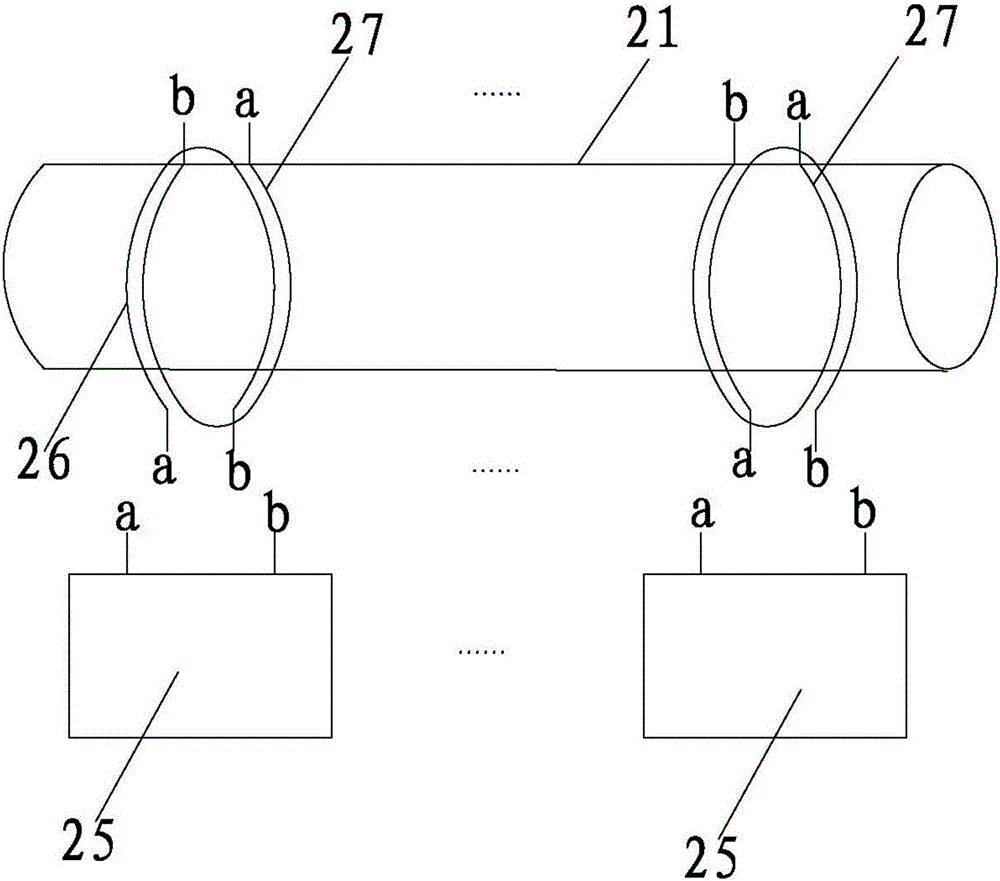

The invention relates to an on-line monitoring method of wear particles using electrification, electric control ring adsorption and adjacent capacitors, which sequentially passes through a temperature control module, an electrification module, an electric field centrifugal module, a mechanical centrifugal module, an adsorption module, and adjacent capacitor particles The monitoring module and the degaussing module perform on-line monitoring of wear particles; one end of the temperature control module is provided with an oil inlet; the adsorption module is specifically a homopolar adjacent type adsorption ring. The invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through electrification, electric field centrifugation and mechanical centrifugation modules, the wear particles in the oil are aggregated into large particles and move to the pipe wall Adjacent and adsorbed by the adsorption module to increase the output monitoring signal strength of the adjacent capacitive sensor; through the temperature control module and the rational design of the adjacent capacitive sensor plate layer structure, suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device.

Owner:张国云

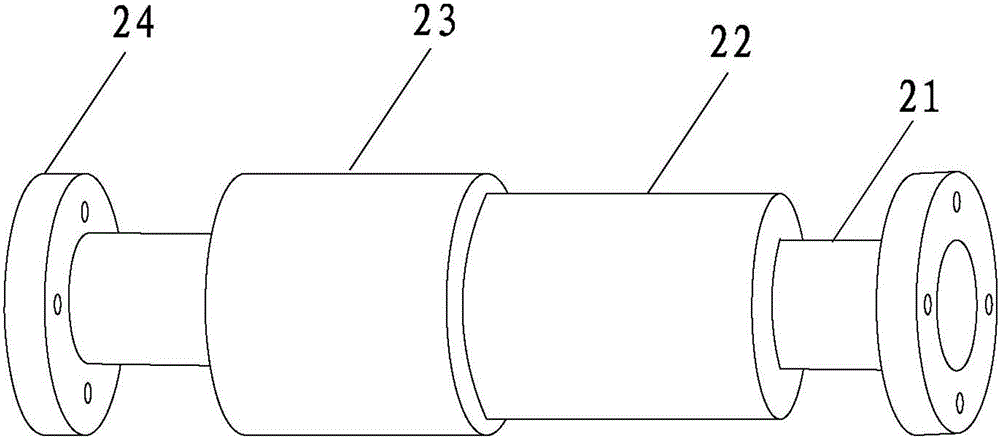

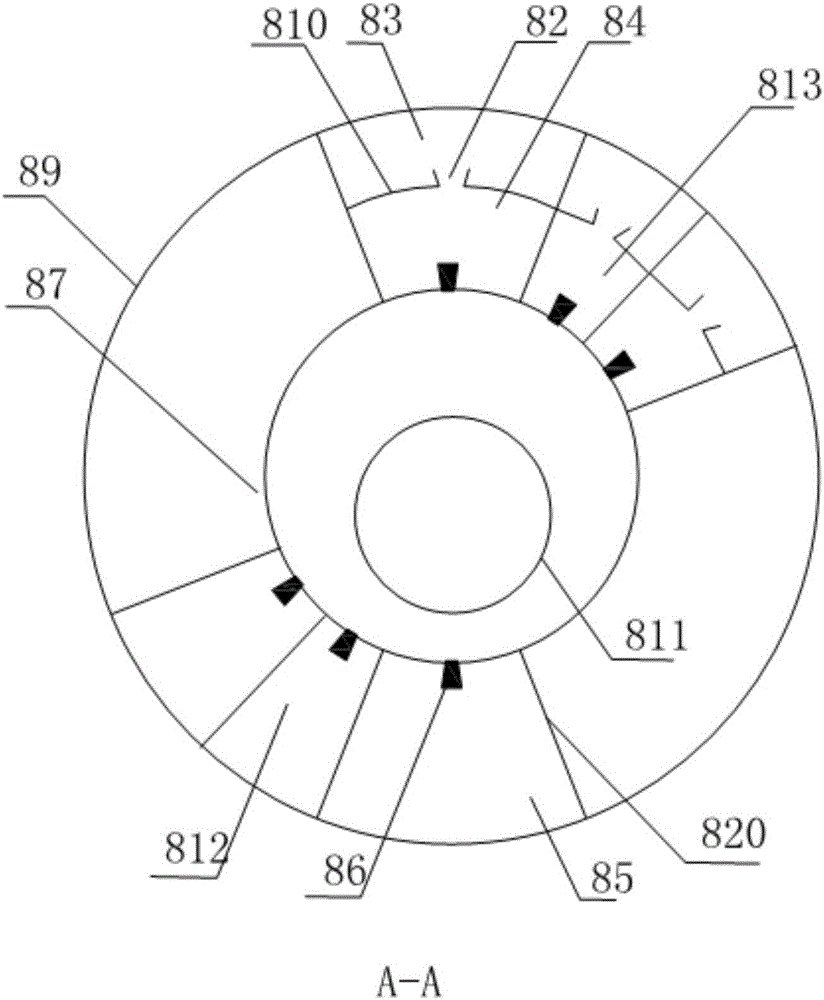

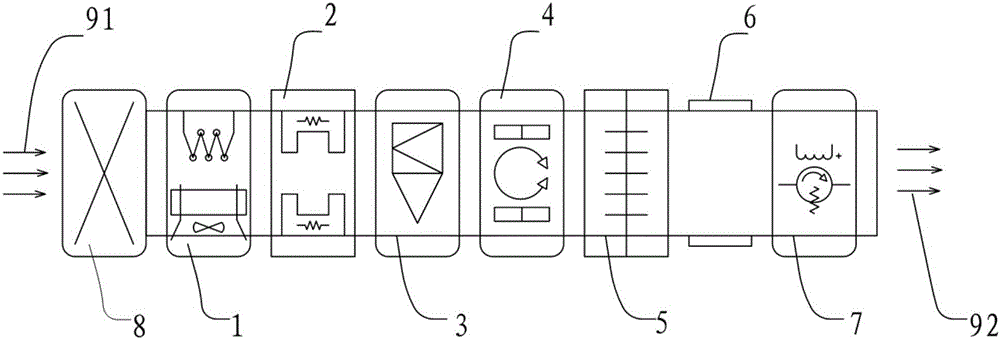

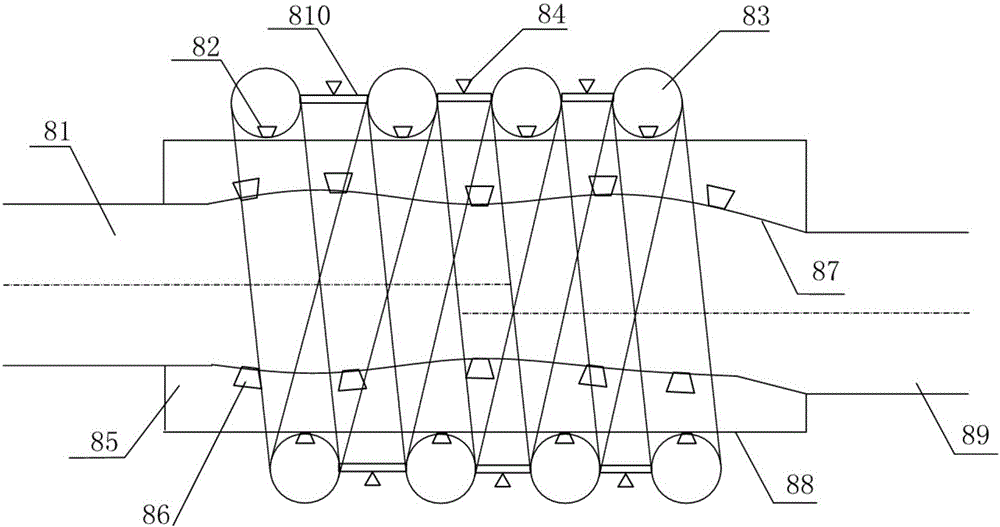

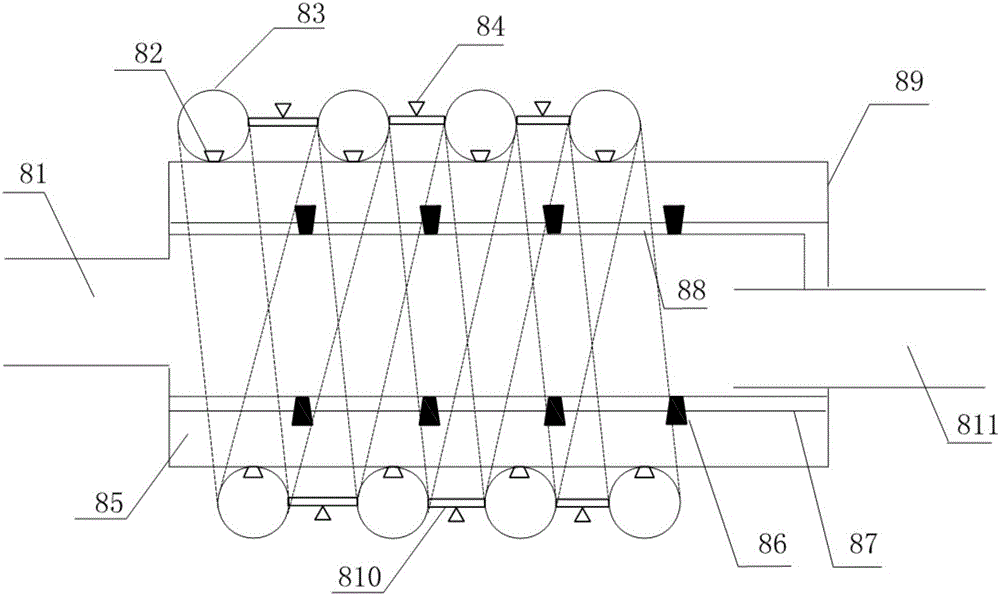

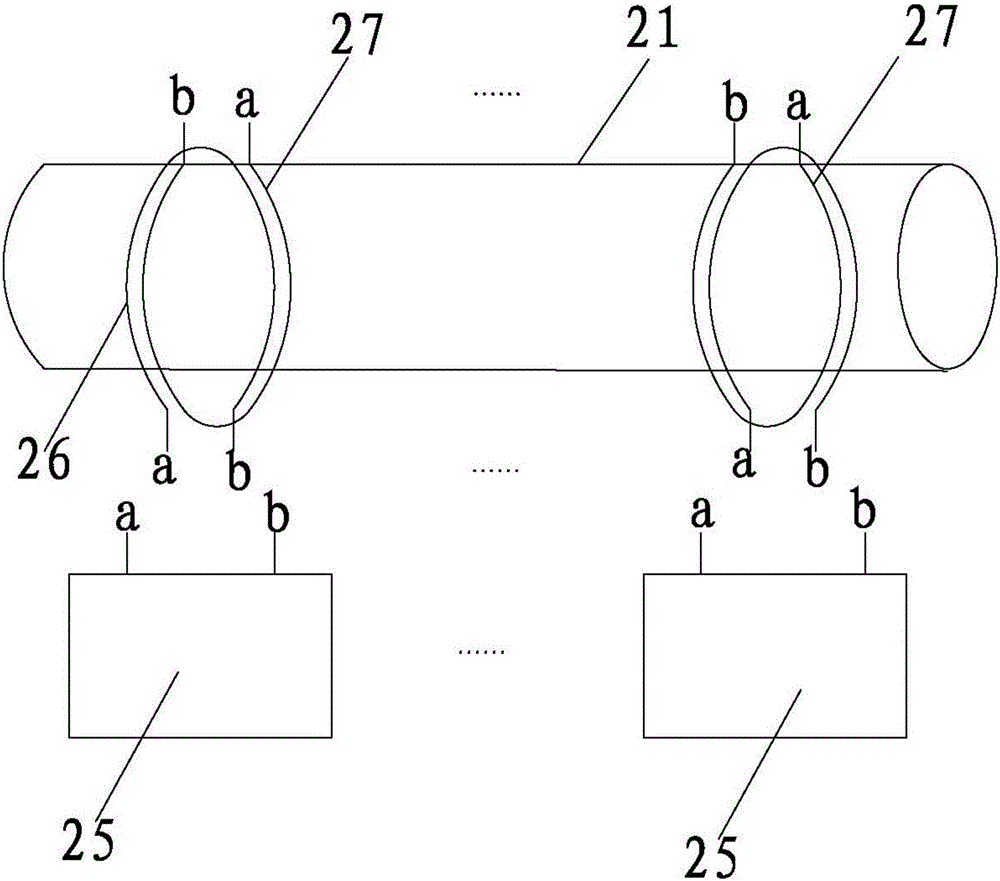

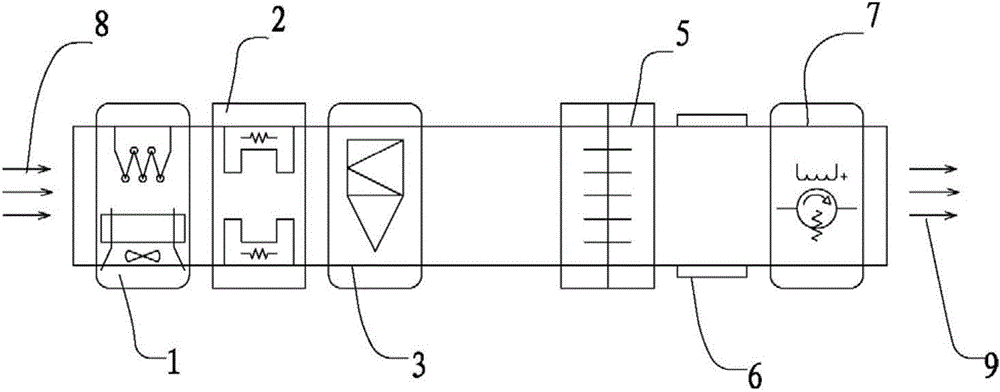

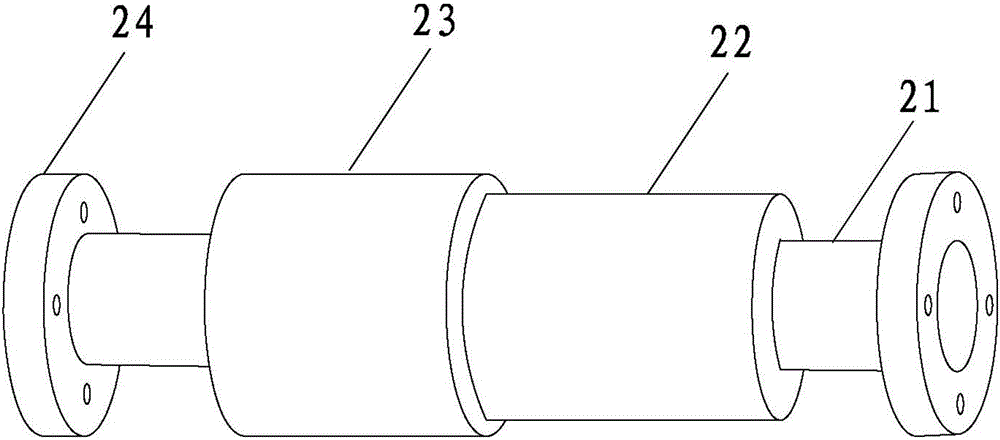

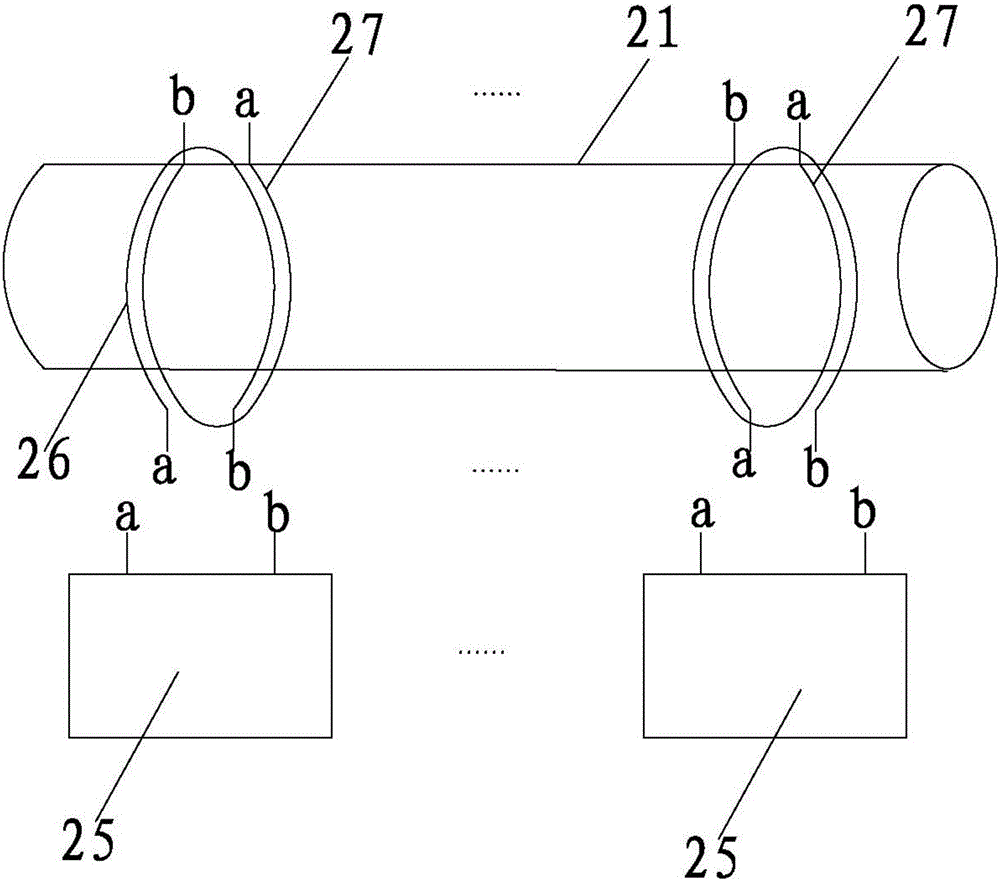

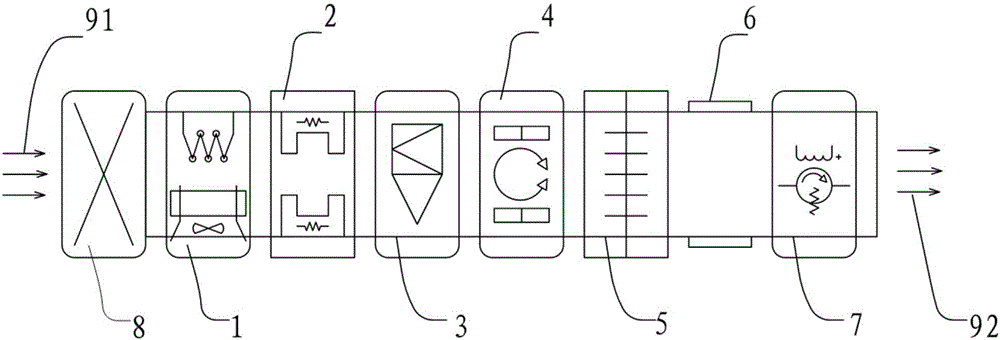

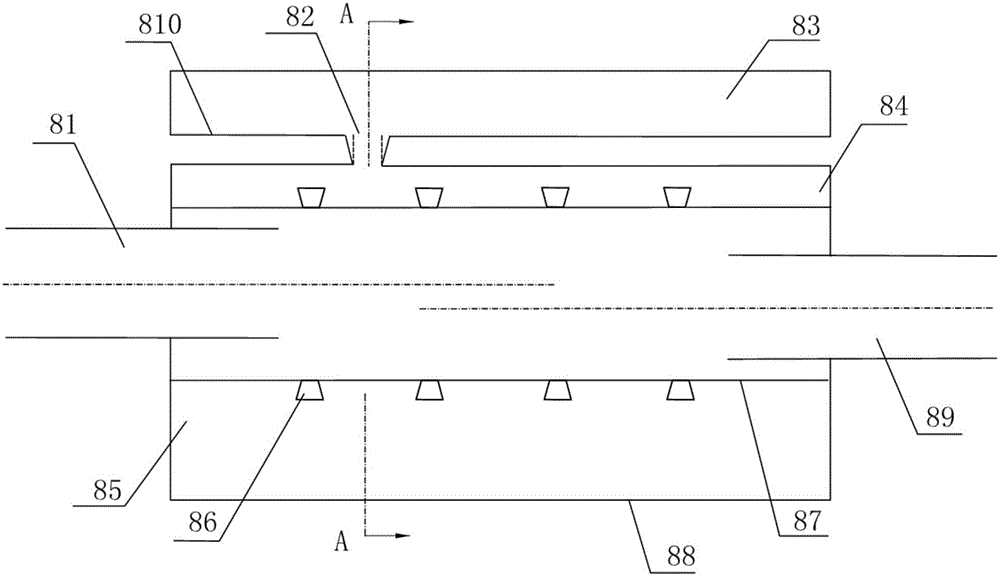

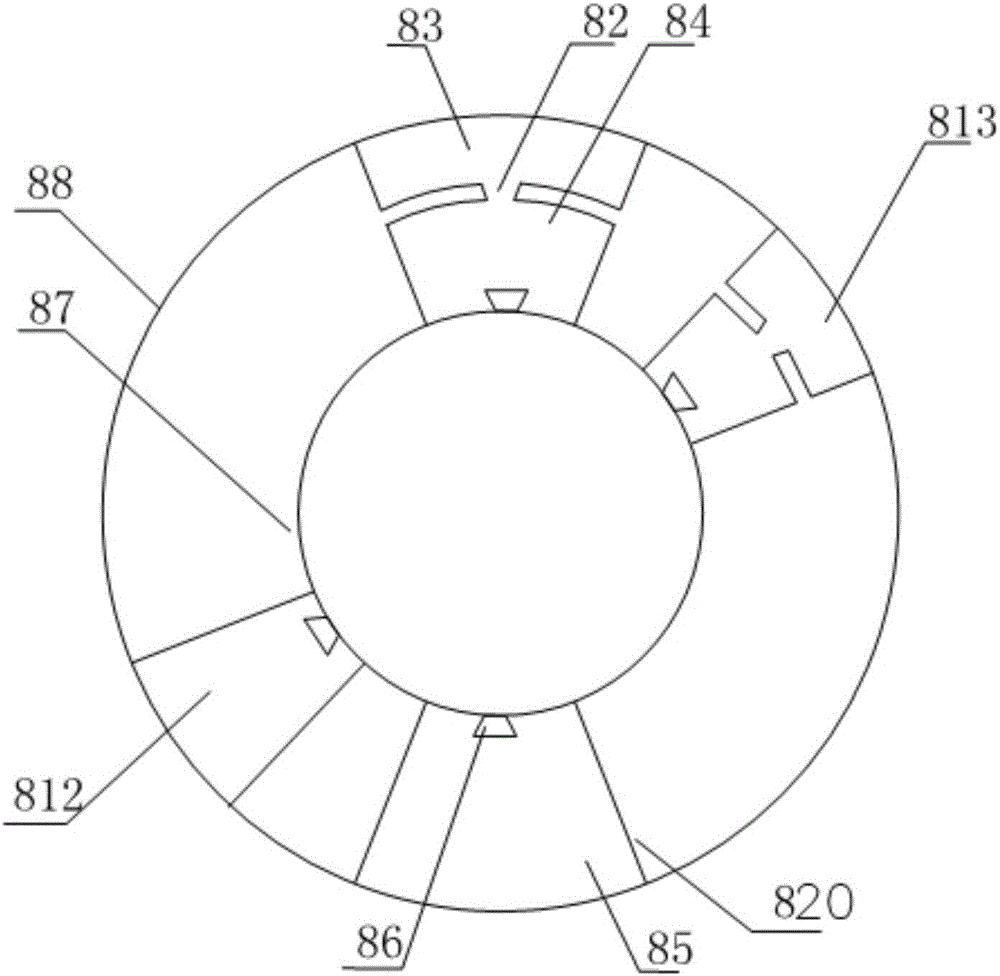

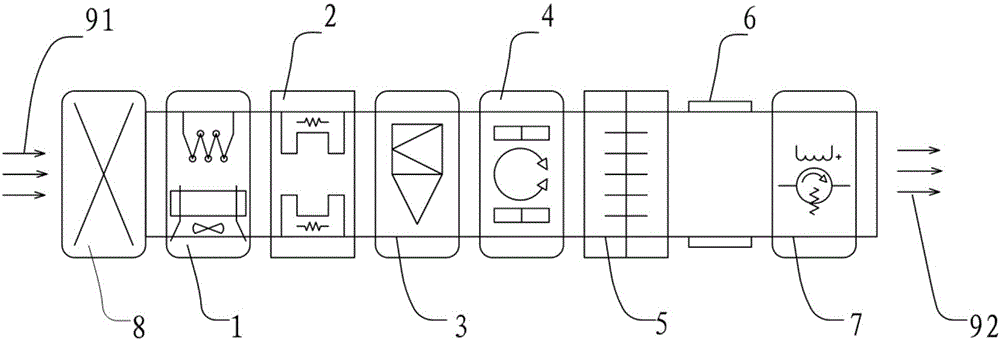

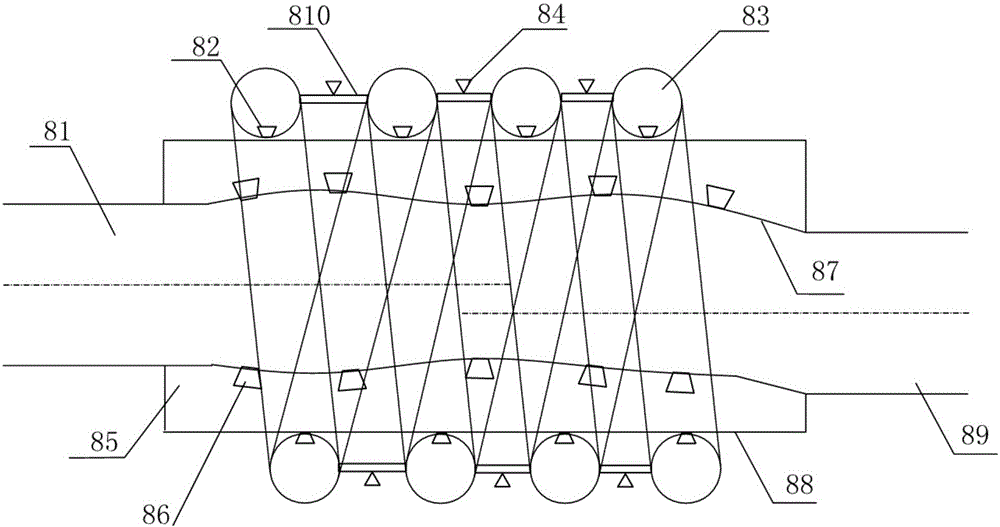

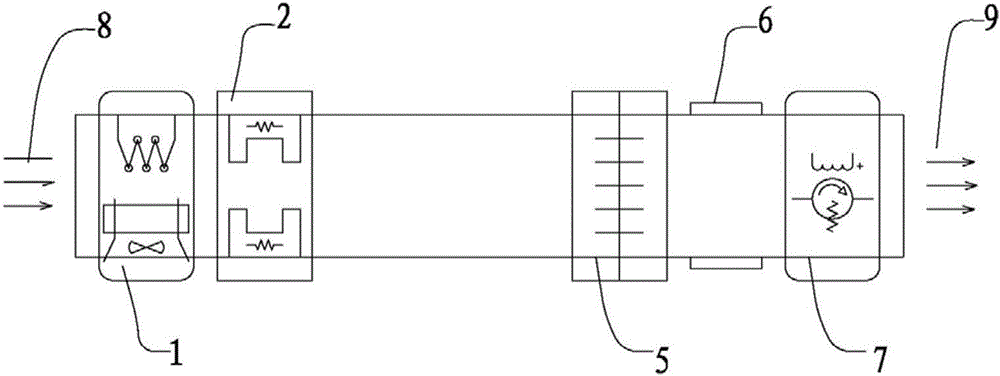

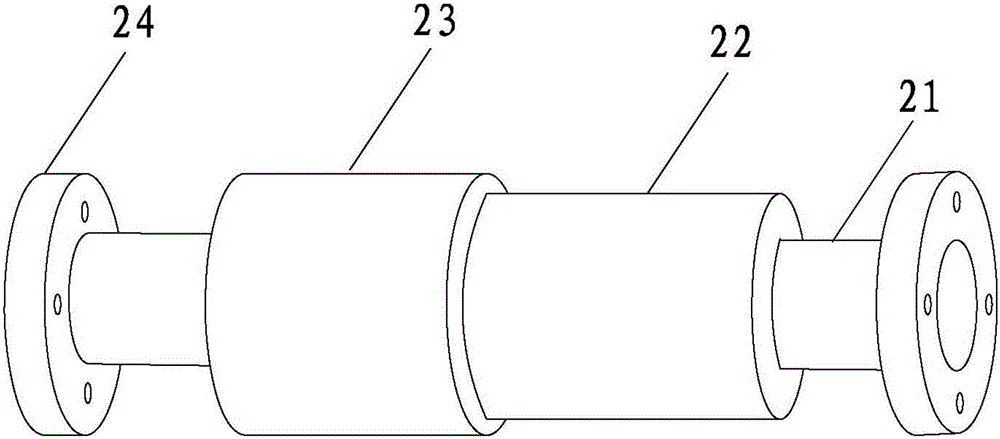

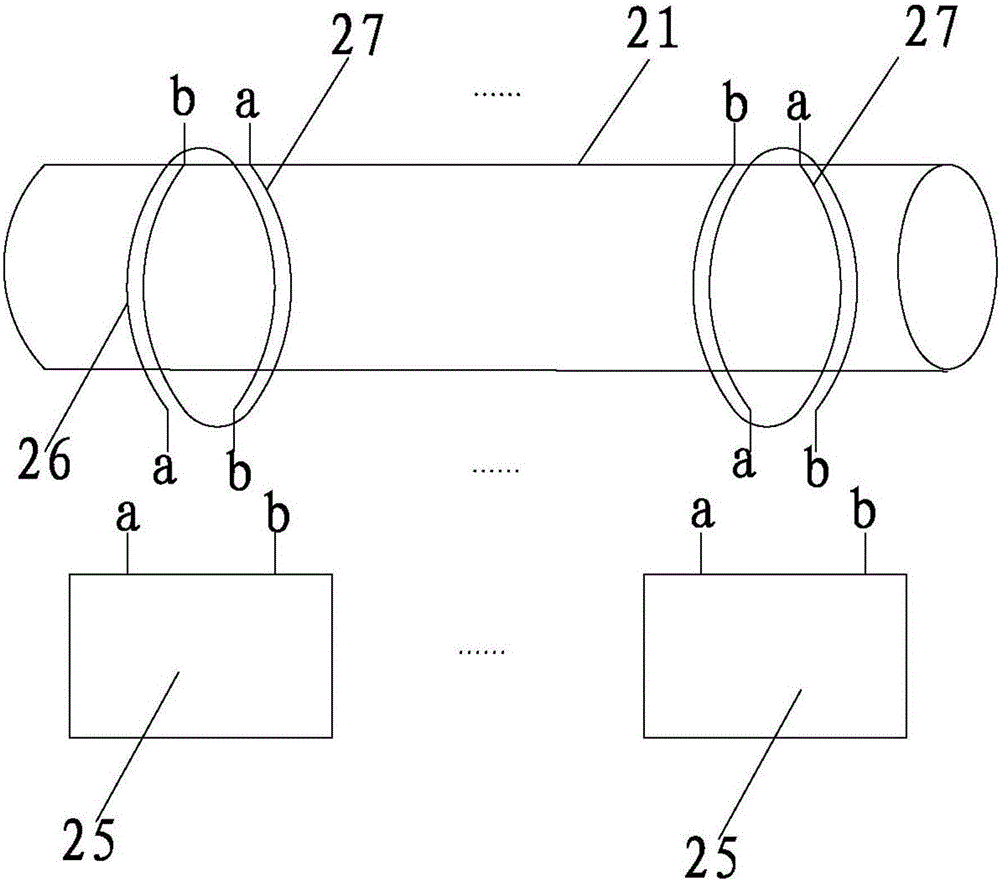

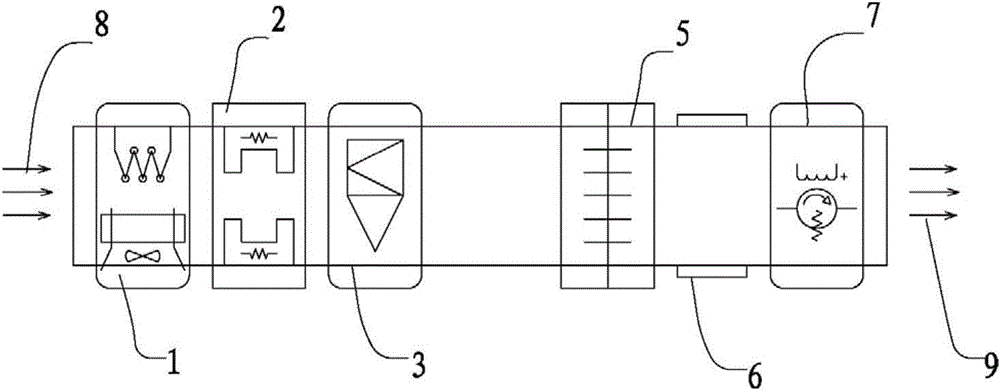

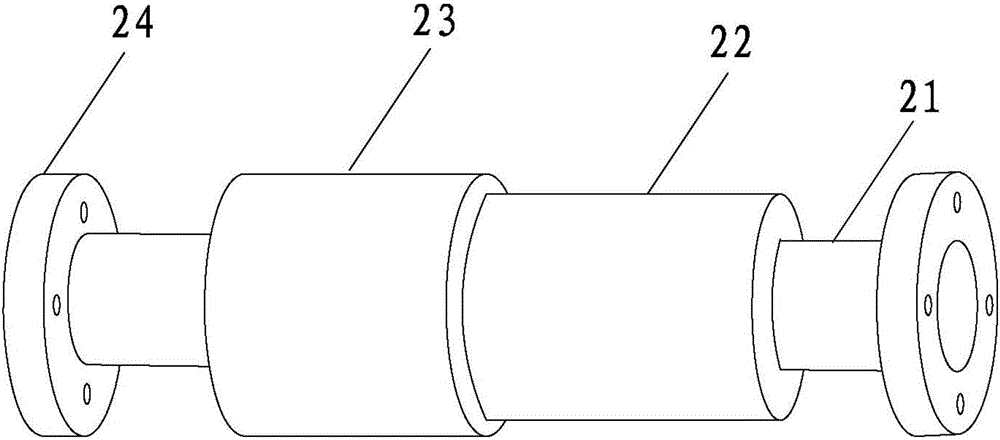

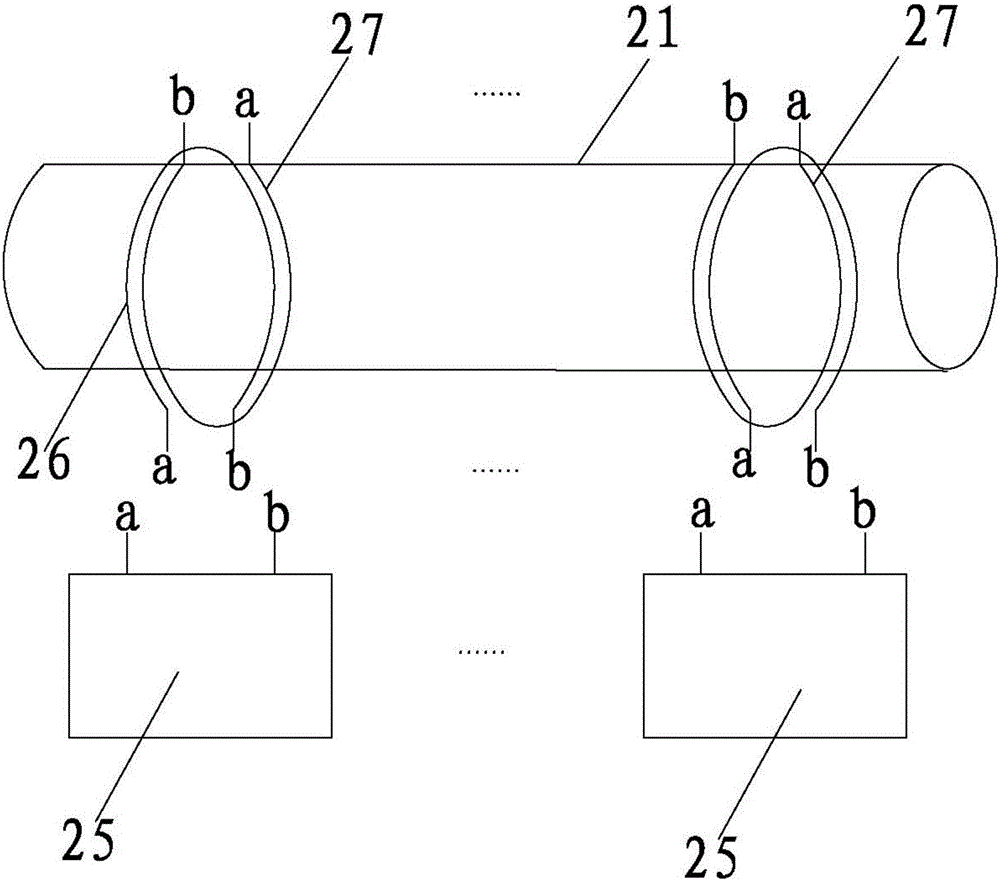

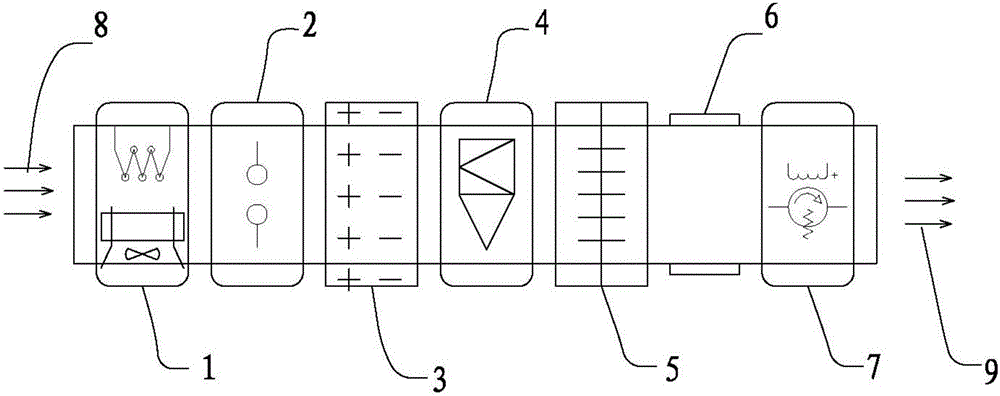

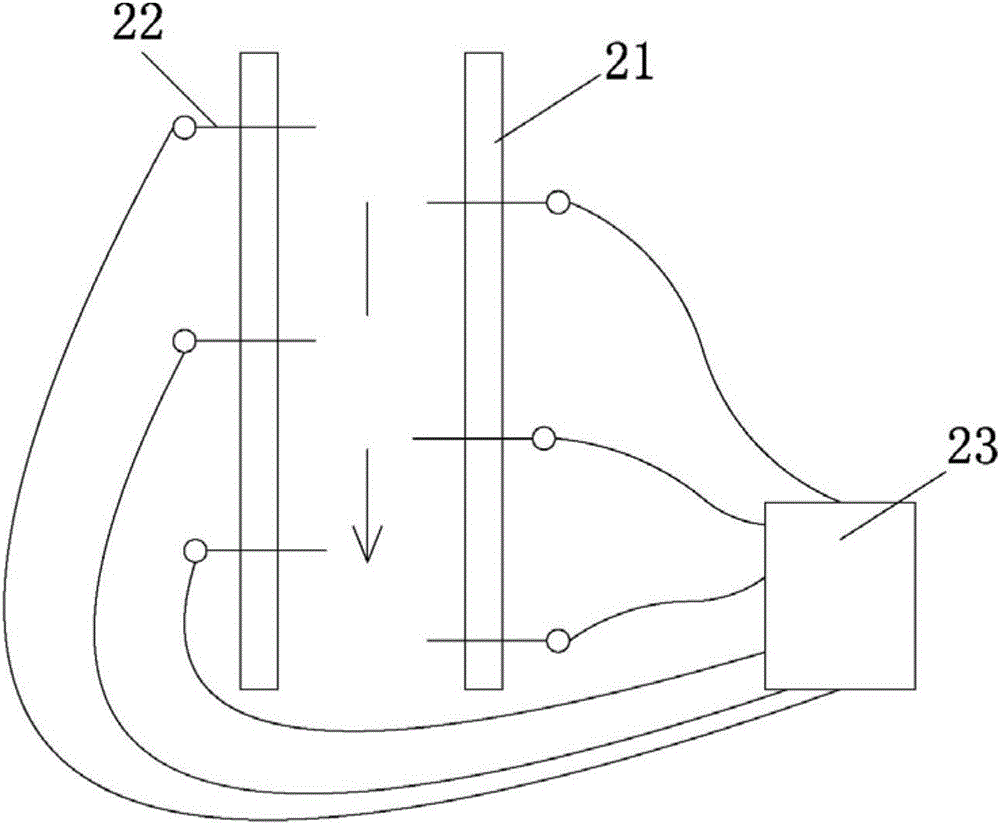

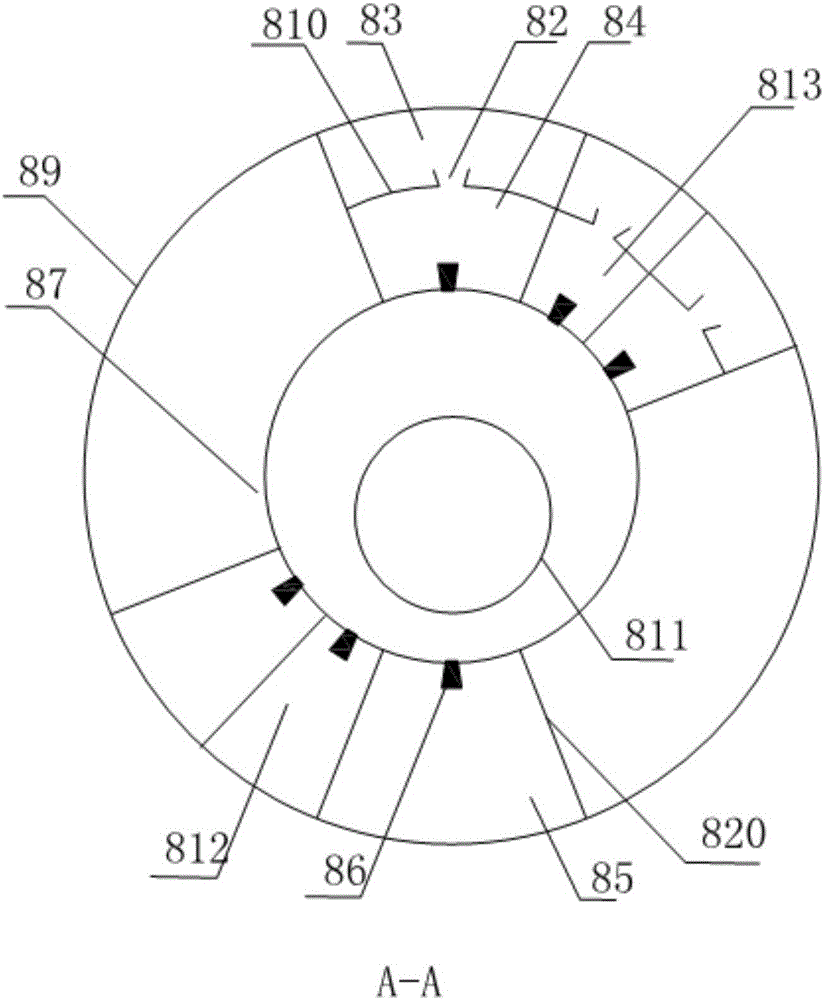

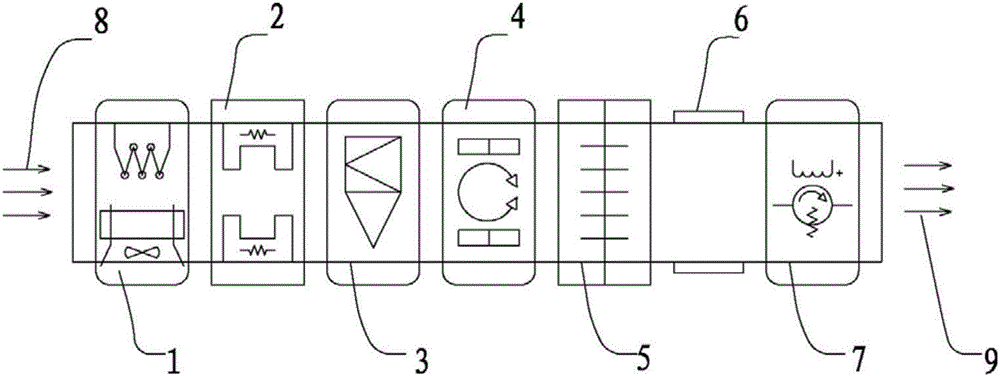

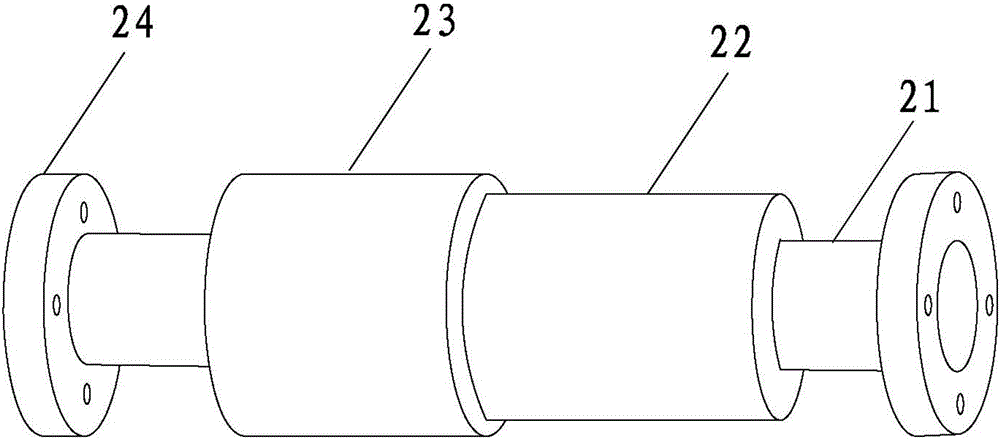

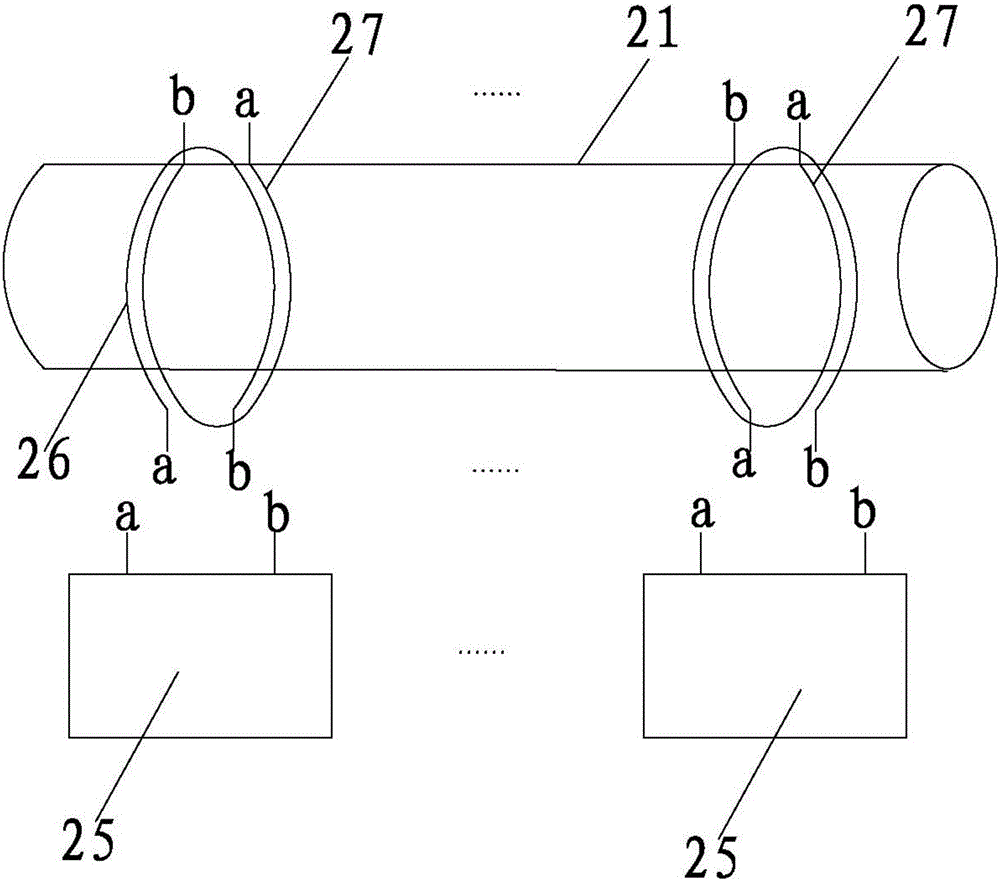

Wear particle online monitoring device adopting adsorption and adjacent capacitance

InactiveCN105864151AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingMaterial capacitanceTemperature controlWear particle

The invention relates to an on-line monitoring device for wear particles using adsorption and adjacent capacitors, in which a temperature control module, a magnetization module, an adsorption module, an adjacent capacitor particle monitoring module and a degaussing module are connected in sequence; one end of the temperature control module is provided with Oil inlet; One end of the degaussing module is provided with an oil outlet, which is composed of a residual magnetic sensor and a degausser. The present invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through the magnetization module, the wear particles in the oil are magnetized and adsorbed by the adsorption module to improve the output of adjacent capacitive sensors Monitor signal strength; suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device through the temperature control module and reasonable design of the plate layer structure of the adjacent capacitive sensor.

Owner:SHAOXING UNIVERSITY

A Crack Propagation Monitoring System for Pressure Vessels Containing Longitudinal Internal Crack Defects

ActiveCN105259180BImprove reliabilityImprove efficiencyUsing mechanical meansOptically investigating flaws/contaminationStress intensity factorMonitoring system

The invention discloses a monitoring system for crack growth conditions of a pressure vessel containing vertical internal crack defects, which belongs to the technical field of safety analysis of pressure vessels. The monitoring system comprises a sensor unit and an arithmetic unit. The sensor unit is connected with the arithmetic unit and sends monitored information to the arithmetic unit. The arithmetic unit comprises a strain value calculation module, which is connected with the sensor unit, acquires the data of the outer surface of the container detected by the sensor unit and calculates a corresponding strain value according to the data; a depth calculation module, which is connected with the strain value calculation module, acquires the strain value and calculates the depth of an internal crack of the container according to the strain value; a stress intensity factor calculation module, which is connected with the depth calculation module, acquires the value of the crack depth and calculates the value of a stress intensity factor at the tip of the crack according to the value of the crack depth; and a determination module, which is connected with the stress intensity factor calculation module, acquires the value of the stress intensity factor at the tip of the crack and compares the value with a fracture toughness value of a material from which the pressure vessel is made; wherein comparison results output by the determination module characterize the state of the crack and indicate whether the pressure vessel should be on service. According to the invention, the growth state of the crack is obtained through rational detection and calculation; and the safe service situation of the pressure vessel is determined, and high reliability is obtained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

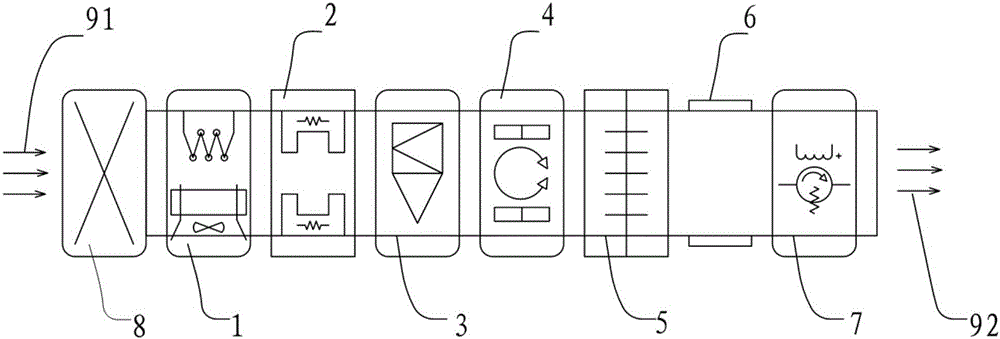

Method for monitoring wear particles on line by virtue of filtration, electromagnetic centrifugation and adjacent capacitance

InactiveCN105973777AGrowth inhibitionIncrease output signal strengthParticle suspension analysisEdge effectsFiltration

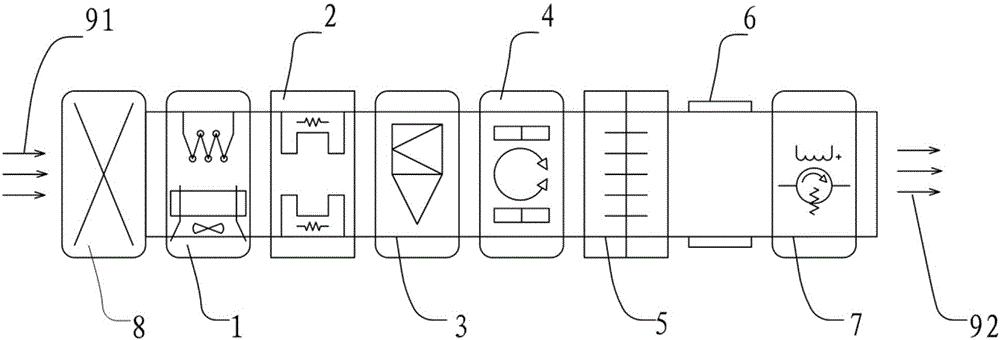

The invention relates to a method for monitoring wear particles on line by virtue of filtration, electromagnetic centrifugation and adjacent capacitance. The wear particles are monitored on line sequentially through a filter, a temperature control module, a magnetization module, a cyclone centrifugation module, a rotating magnetic field centrifugation module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetization module, wherein an oil inlet is formed in one end of the filter; an oil outlet is formed in one end of the demagnetization module. According to the method, a capacitance edge effect-based adjacent capacitance sensor technology is introduced to implement nonintrusive and unconstrained monitoring of the wear particles; the wear particles in oil are magnetized and aggregated into large particles through the magnetization, cyclone centrifugation and rotating magnetic field centrifugation modules, move to the vicinity of tube walls and are adsorbed by the adsorption module, so that the output monitoring signal strength of an adjacent capacitance sensor is improved; by the temperature control module and a reasonably designed adjacent capacitance sensor plate layer structure, noise is suppressed, and the overall performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:李伟波

Wear particle detecting method adopting electrification, electric control loop adsorption and adjacent capacitance

InactiveCN105889192AIncrease output signal strengthHigh dielectric constantFluid-pressure actuator componentsEngineeringElectric control

The invention relates to a wear particle detecting method adopting electrification, electric control loop adsorption and adjacent capacitance. Wear particle online monitoring is carried out by virtue of a temperature control module, an electrification module, an electric field centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module; one end of the temperature control module is provided with an oil inlet; and the adsorption module is specifically a homopolar adjacent type adsorption ring. According to the wear particle detecting method, an adjacent capacitance sensor technology based on a capacitance edge effect is introduced, so that non-intrusive and non-restriction monitoring of the wear particles is realized; wear particles in an oil liquid are polymerized into large particles by electrification and electrical field centrifugation and are moved to positions near a tube wall for being adsorbed by the adsorption module, so that output monitoring signal strength of the adjacent capacitance sensor is improved; and by virtue of the temperature control module and a reasonably designed polar plate structure of the adjacent capacitance sensor, noises are restrained, and the overall performance of the adjacent capacitor sensor monitoring device is optimized.

Owner:张国云

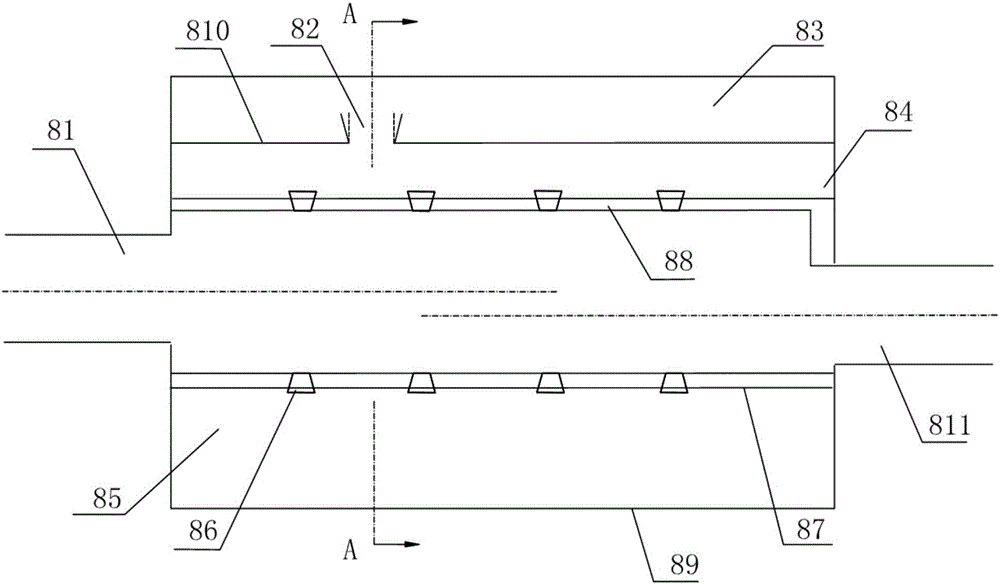

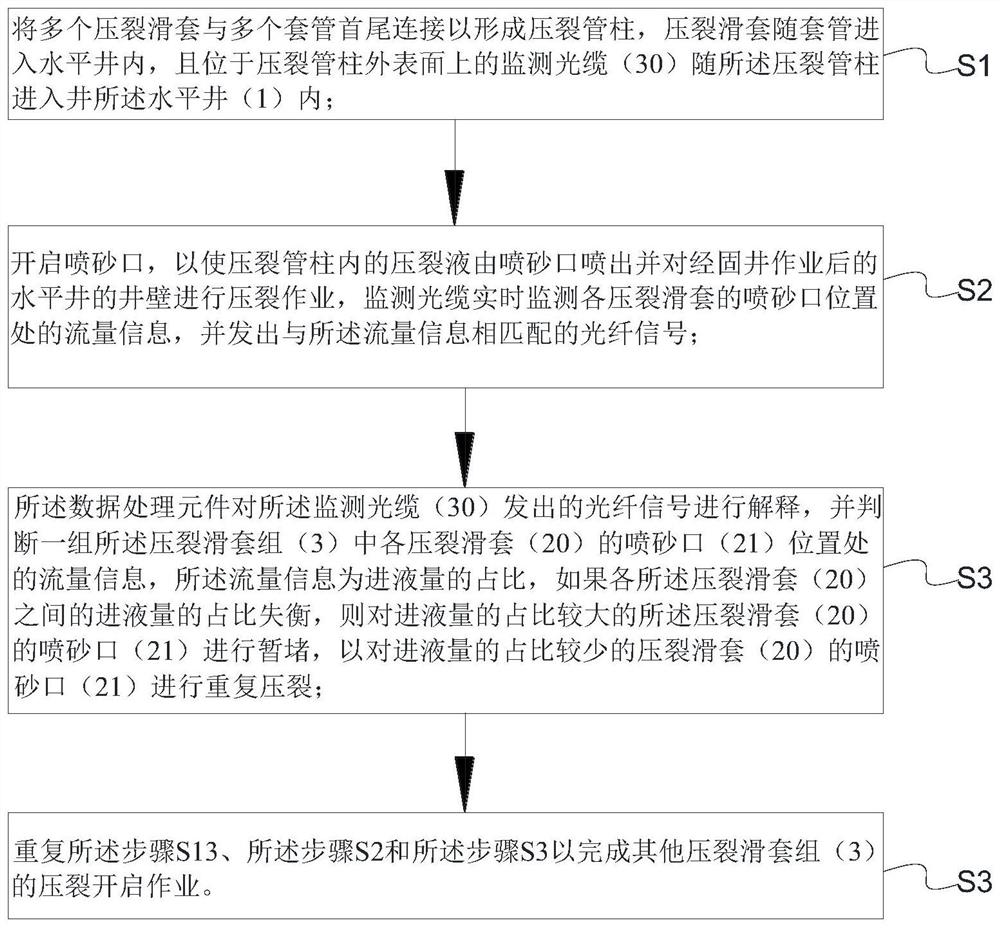

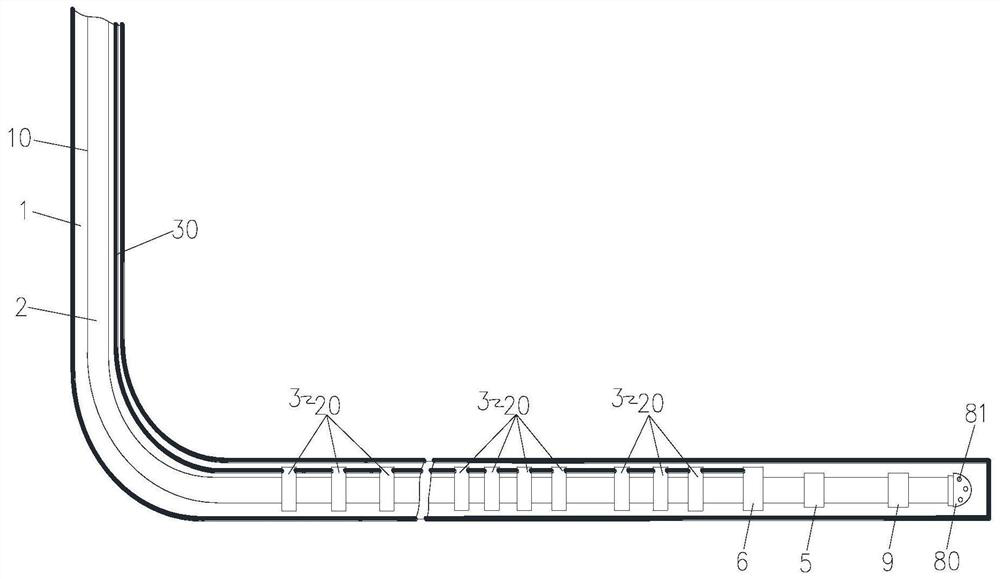

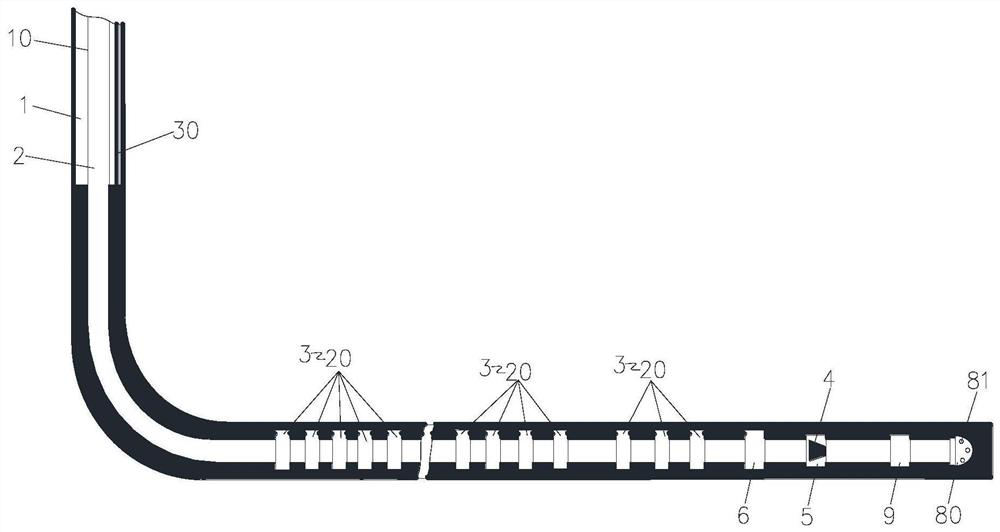

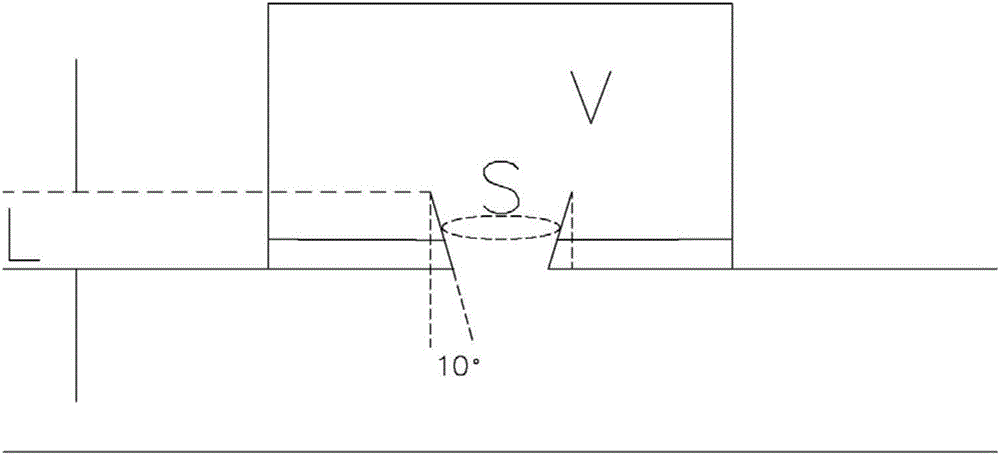

Horizontal well cementation sliding sleeve partial pressure pipe outer optical fiber system and monitoring method thereof

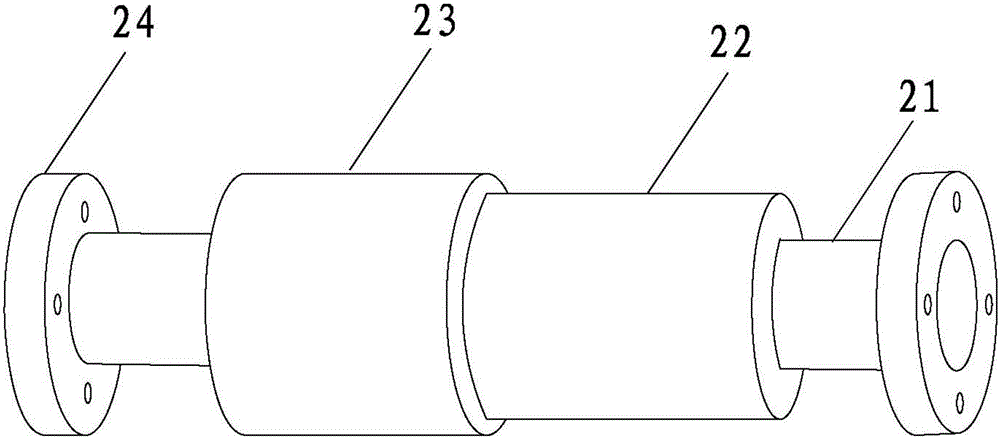

ActiveCN112253069AFully fracturedObtain the fracturing effect in timeConstructionsGeothermal energy generationThermodynamicsSand blasting

The invention provides a horizontal well cementation sliding sleeve partial pressure pipe outer optical fiber system and a monitoring method thereof. The horizontal well cementation sliding sleeve partial pressure pipe outer optical fiber system comprises a plurality of casing pipes, a plurality of fracturing sliding sleeves and a monitoring optical cable, the casing pipes are connected with the fracturing sliding sleeves, the multiple casing pipes and the multiple fracturing sliding sleeves are connected end to end to form a fracturing string, the fracturing sliding sleeves are provided withsand blasting openings, the sand blasting openings are opened so that fracturing fluid in the fracturing string is sprayed out from the sand blasting openings, and fracturing operation is conducted ona target reservoir of a horizontal well after well cementation operation. The monitoring optical cable is arranged on the outer surface of the fracturing string so as to enter the horizontal well along with the fracturing string and monitor flow information at the position of the sand blasting opening of each fracturing sliding sleeve in real time. The problems that in the prior art, in the process of conducting subdivision cutting and volume fracturing operation on a horizontal well, flow information at the position of a sand blasting opening of a fracturing sliding sleeve cannot be obtained, and the fracturing effect cannot be evaluated are solved.

Owner:PETROCHINA CO LTD

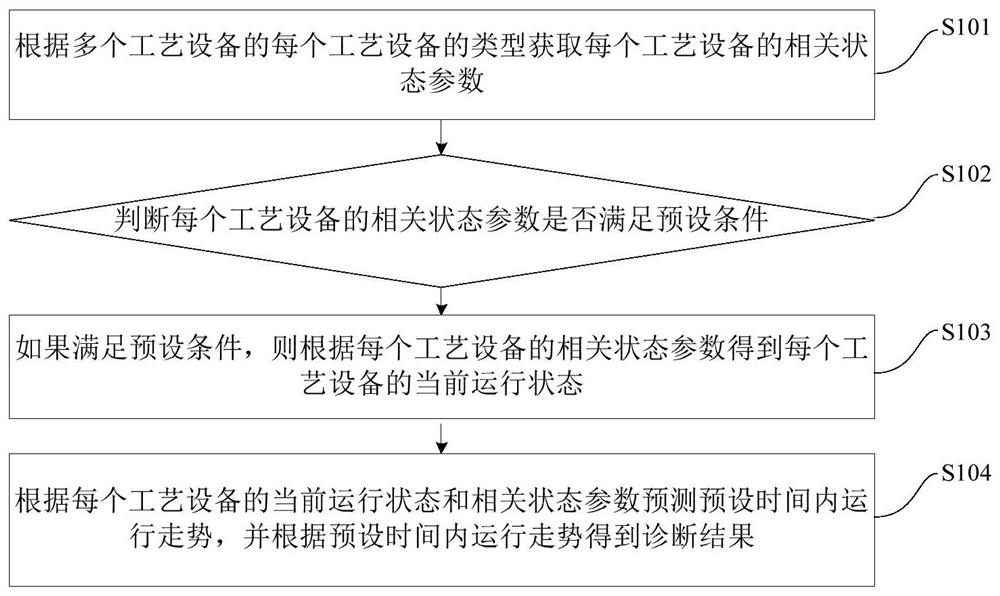

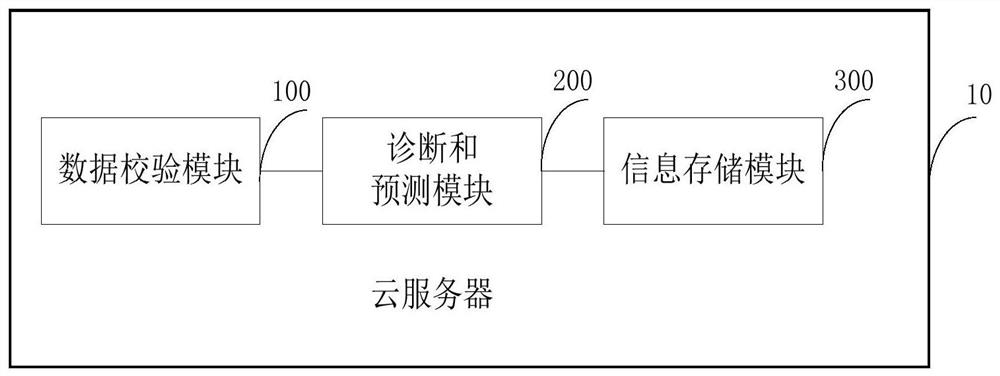

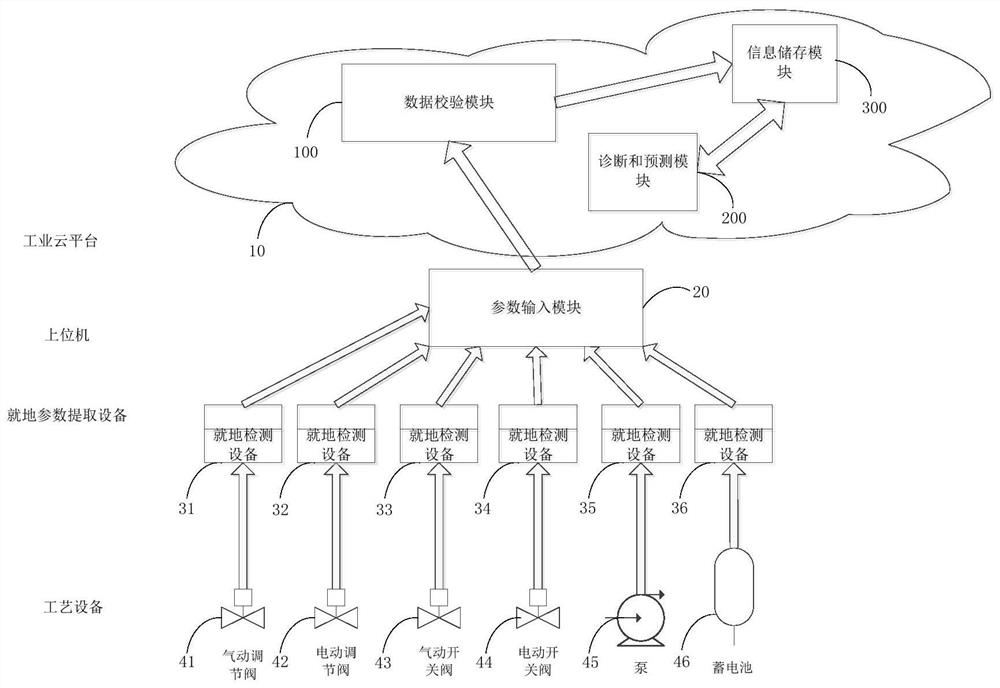

Diagnosis method, cloud server and system for ubiquitous energy station equipment

ActiveCN107505884BReduce operating costsHigh precisionProgramme controlData processing applicationsProcess equipmentServer

The invention discloses a diagnosis method, a cloud server and a system of a universal energy station equipment, wherein the method includes: obtaining the relevant state parameters of each process equipment according to the type of each process equipment of a plurality of process equipment; judging each process equipment Whether the relevant status parameters of the equipment meet the preset conditions; if the preset conditions are met, the current operating status of each process equipment is obtained according to the relevant status parameters of each process equipment; according to the current operating status of each process equipment and related status parameters Predict the running trend within the preset time, and get the diagnosis result according to the running trend within the preset time. This method can obtain the diagnosis result according to the running trend within the preset time, so that various performance indicators of the equipment can be monitored in real time, and the purpose of online diagnosis of the pan-energy station equipment based on the industrial cloud can be realized, the accuracy of the diagnosis can be improved, and the accuracy of the diagnosis can be improved. The real-time performance can effectively ensure the reliability of monitoring and reduce operating costs.

Owner:ENN ENERGY SERVICE

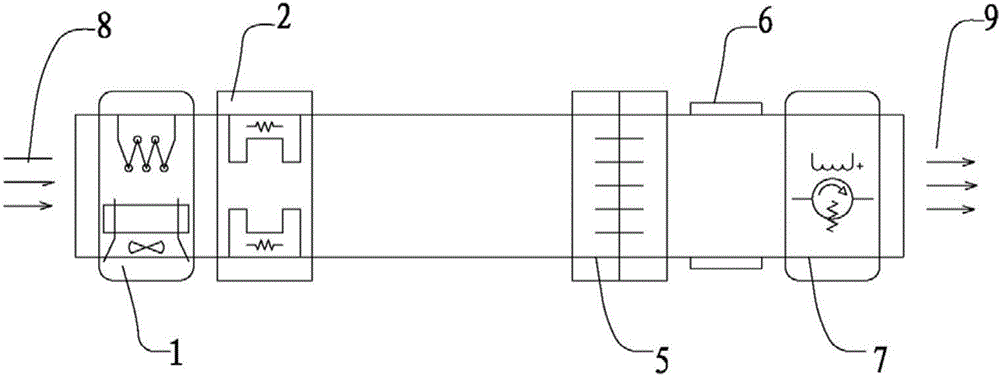

Wear particle monitoring equipment using hydraulic filtration, centrifugation and adjacent capacitance

InactiveCN106015173AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingFluid-pressure actuator componentsAdaptive filterFiltration

The invention relates to a wear particle monitoring device using hydraulic filtering, centrifugal separation and adjacent capacitors, including a filter, a temperature control module, a magnetization module, a mechanical centrifugal module, a rotating magnetic field centrifugal module, an adsorption module, and an adjacent capacitor particle monitoring module It is connected with the degaussing module in turn; the filter adopts a variable structure working condition adaptive filter, and one end of it is provided with an oil inlet; one end of the degaussing module is provided with an oil outlet. The invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through magnetization, mechanical centrifugation and rotating magnetic field centrifugal module, the wear particles in the oil are magnetized, aggregated into large particles and moved to Near the pipe wall and adsorbed by the adsorption module to improve the output monitoring signal strength of the adjacent capacitive sensor; through the temperature control module and the reasonable design of the plate layer structure of the adjacent capacitive sensor, the noise is suppressed and the overall monitoring device of the adjacent capacitive sensor is optimized performance.

Owner:SHAOXING UNIVERSITY

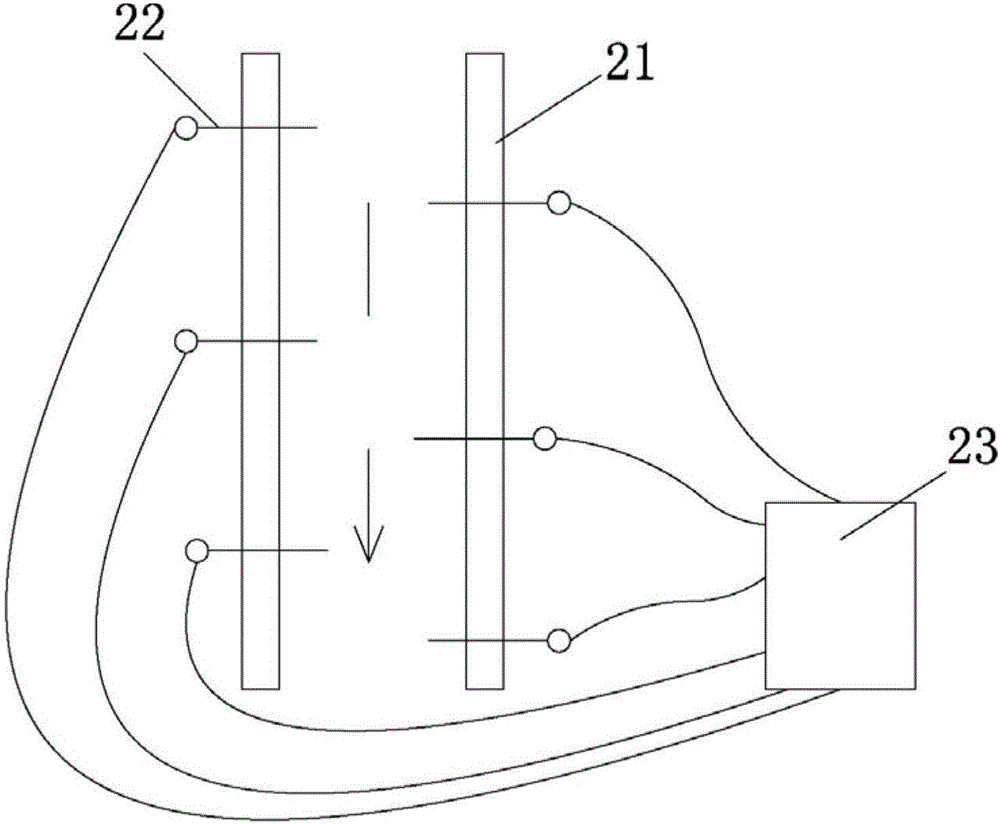

Wear particle online monitoring method using centrifugation, adsorption and adjacent capacitance

InactiveCN106018214AGrowth inhibitionIncrease output signal strengthParticle suspension analysisEdge effectsEngineering

The invention relates to a wear particle online monitoring method using centrifugation, adsorption and adjacent capacitance. Wear particle online monitoring is conduced sequentially by means of a temperature control module, a magnetization module, a mechanical centrifugation module, a rotary magnetic field centrifugation module, an adsorption module, an adjacent capacitance wear particle monitoring module and a demagnetization module. An oil inlet is formed in one end of the temperature control module, an oil outlet is formed in one end of the demagnetization module, and the demagnetization module is composed of a remanence sensor and a demagnetizer. The adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and non-intrusive and unrestricted monitoring of wear particles is achieved. By means of the magnetization, mechanical centrifugation and rotary magnetic field centrifugation modules, wear particles in oil are magnetized and polymerized into large particles and move to the position near a pipe wall to be adsorbed by the adsorption module so that the intensity of output monitoring signals of an adjacent capacitance sensor can be increased. By means of the temperature control module and a reasonably designed polar plate structure of the adjacent capacitance sensor, noise is suppressed, and the overall performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Online abrasion particle monitoring system adopting centrifugation, electric shock hammer adsorption and adjacent capacitance

InactiveCN105954157AGrowth inhibitionIncrease output signal strengthParticle and sedimentation analysisTemperature controlCentrifugation

The invention relates to an online abrasion particle monitoring system adopting centrifugation, electric shock hammer adsorption and adjacent capacitance. A temperature control module, a magnetizing module, a mechanical centrifugal module, a rotary magnetic field centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the system are sequentially connected, wherein an oil inlet is formed in one end of the temperature control module; the adsorption module is a like-pole adjacent type adsorption ring with an electric shock hammer specifically. According to the system, the adjacent capacitance transducer technology based on the capacitance fringe effect is introduced, and non-invasion and unrestraint monitoring of abrasion particles is realized; the abrasion particles in oil are magnetized and aggregated to form large particles through the magnetizing module, the mechanical centrifugal module and the rotary magnetic field centrifugal module, and the large particles move to the vicinity of a tube wall and are adsorbed by the adsorption module, so that the strength of output monitoring signals of adjacent capacitance transducers is improved; by means of a temperature control module and reasonable design of polar plate layer structures of the adjacent capacitance transducers, noise is inhibited, and the overall performance of an adjacent capacitance transducer monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Abrasion particle monitoring equipment using filter waves, electromagnetic centrifugation and adjacent capacitances

InactiveCN105909594AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingTemperature controlEdge effects

The invention relates to abrasion particle monitoring equipment using filter waves, electromagnetic centrifugation and adjacent capacitances. A filter, a temperature control module, a magnetization module, a mechanical centrifugal module, a rotating magnetic field centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetization module of the abrasion particle monitoring equipment are sequentially connected. An oil liquid inlet is formed in one end of the filter. An oil liquid outlet is formed in one end of the demagnetization module. According to the abrasion particle monitoring equipment using the filter waves, electromagnetic centrifugation and the adjacent capacitances, the adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and abrasion particle non-intrusive and unconstrained monitoring is achieved; abrasion particles in oil liquid are magnetized and aggregated into large particles through the magnetization module, the mechanical centrifugal module and the rotating magnetic field centrifugal module and move to the position near a pipe wall to be adsorbed by the adsorption module so that the output monitoring signal strength of an adjacent capacitance sensor can be improved; and through the temperature control module and reasonable design of the polar plate layer structure of the adjacent capacitance sensor, noise is suppressed, and the overall performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Online abraded particle monitoring method adopting electric shock hammer adsorption and adjacent capacitance

InactiveCN105864150AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingTemperature controlMagnetization

The invention relates to an on-line monitoring method of wear particles using electric hammer adsorption and adjacent capacitors, which sequentially conducts online monitoring of wear particles through a temperature control module, a magnetization module, an adsorption module, an adjacent capacitor particle monitoring module, and a degaussing module; One end of the temperature control module is provided with an oil inlet; the adsorption module is specifically a homopolar adjacent adsorption ring with an electric hammer. The present invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through the magnetization module, the wear particles in the oil are magnetized and adsorbed by the adsorption module to improve the output of adjacent capacitive sensors Monitor signal strength; suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device through the temperature control module and reasonable design of the plate layer structure of the adjacent capacitive sensor.

Owner:张国云

Abrasion particle monitoring device using temperature control, electronic control ring adsorption and adjacent capacitance

InactiveCN105937516AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator componentsTemperature controlComputer module

The invention relates to an abrasion particle monitoring device using temperature control, electronic control ring adsorption and adjacent capacitance. A temperature control module, a magnetization module, a mechanical centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetization module of the abrasion particle monitoring device are sequentially connected. An oil inlet is formed in one end of the temperature control module. The adsorption module is particularly a homopolar adjacent type adsorption ring. According to the abrasion particle monitoring device, the adjacent capacitance sensor technology based on the capacitance fringe effect is introduced, and non-invasion and unrestraint monitoring of abrasion particles is achieved; the abrasion particles in oil are magnetized and gathered into large particles through magnetizing and mechanical centrifuging and move to the portion nearby a pipe wall to be adsorbed by the adsorption module, and therefore the output monitoring signal intensity of an adjacent capacitance sensor can be improved; and by arranging the temperature control module and reasonably designing the pole plate layer structure of the adjacent capacitance sensor, noise is restrained and the overall performance of the adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

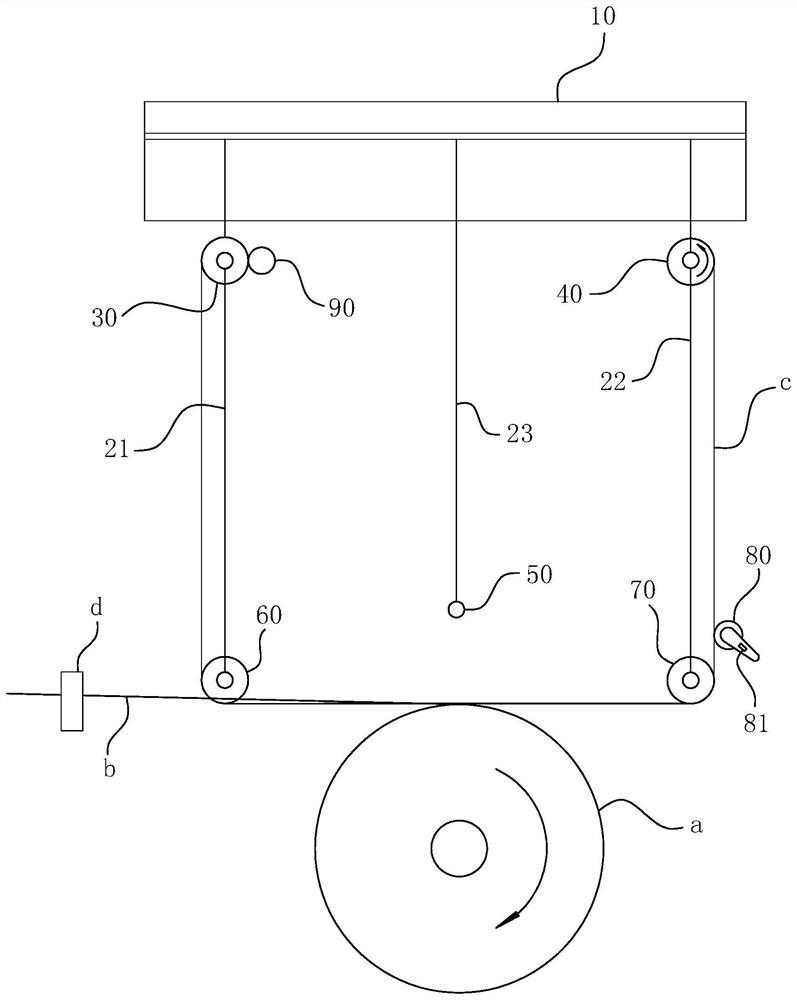

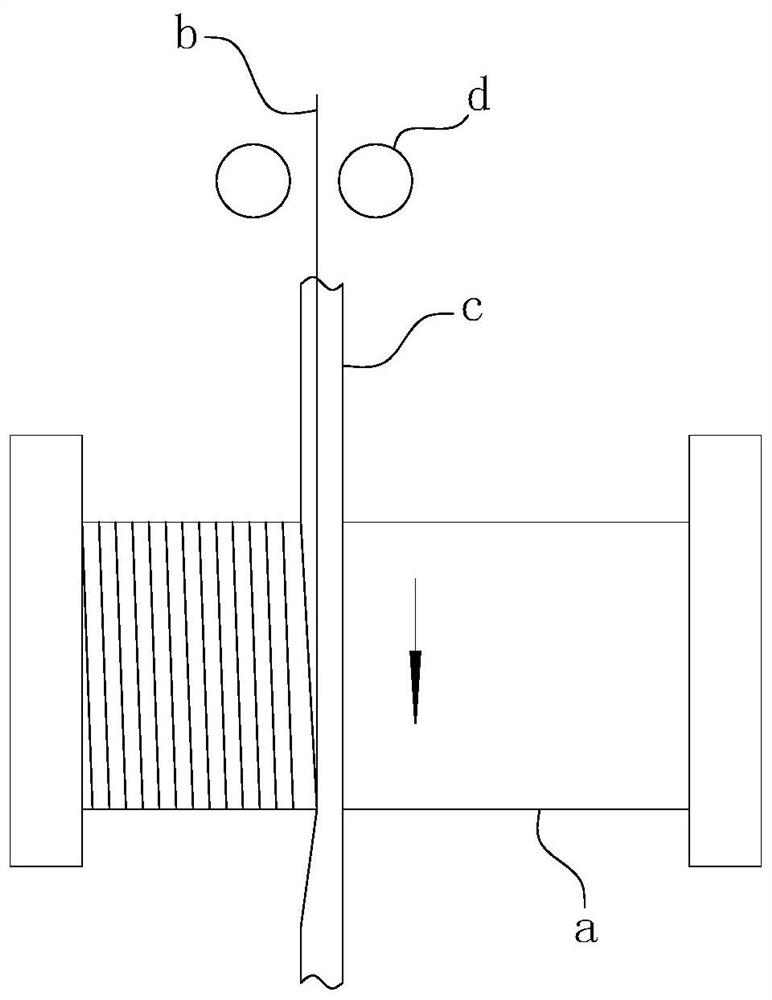

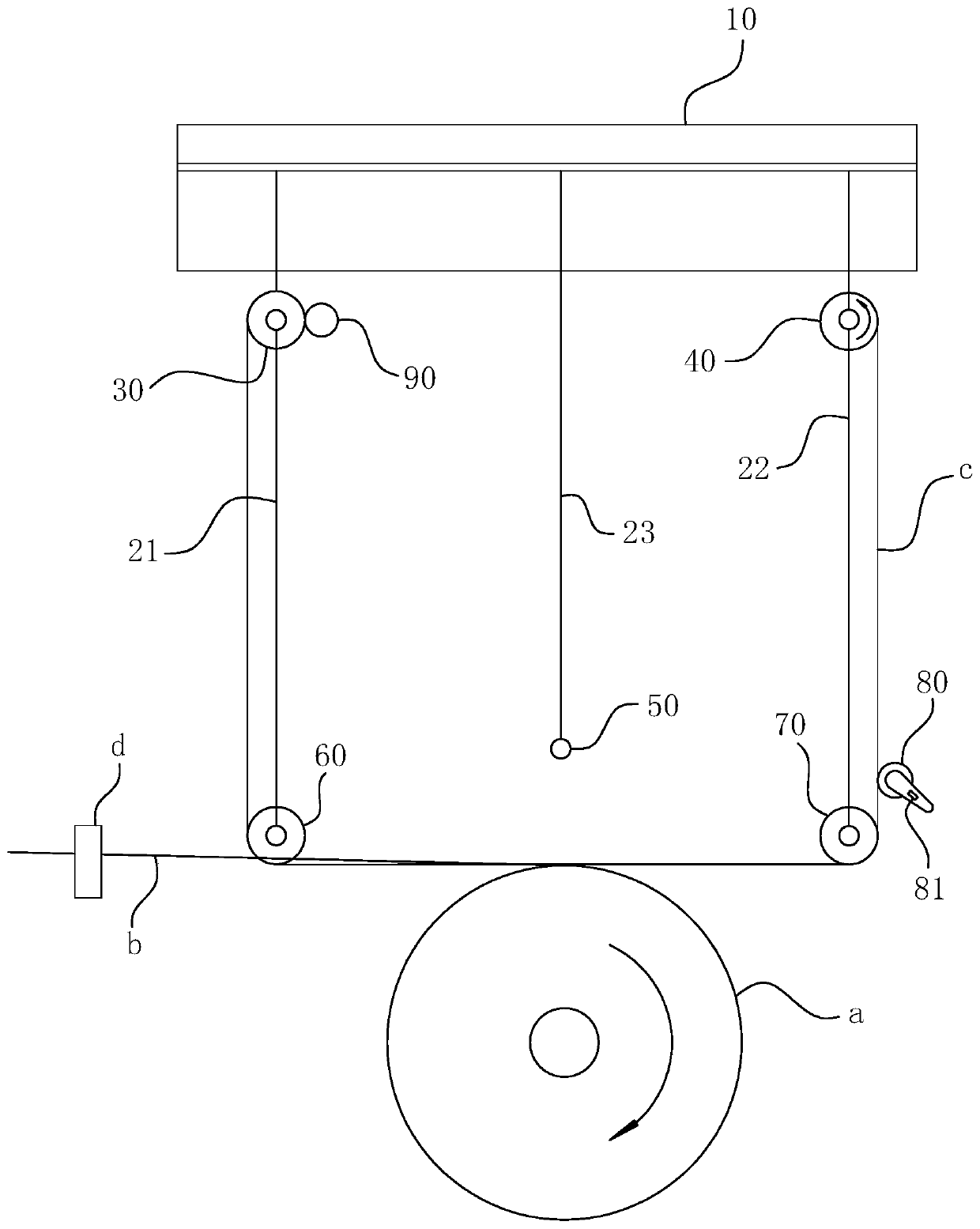

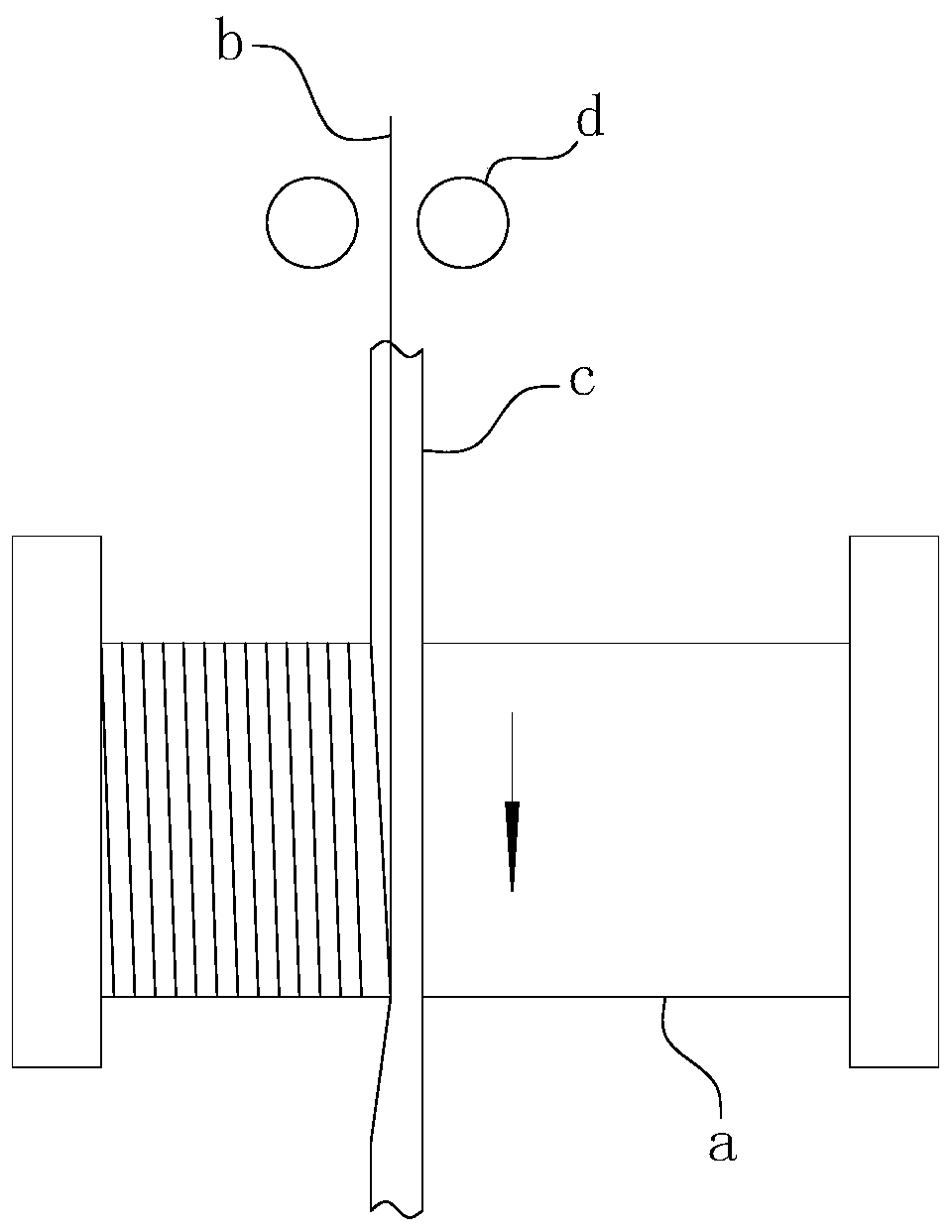

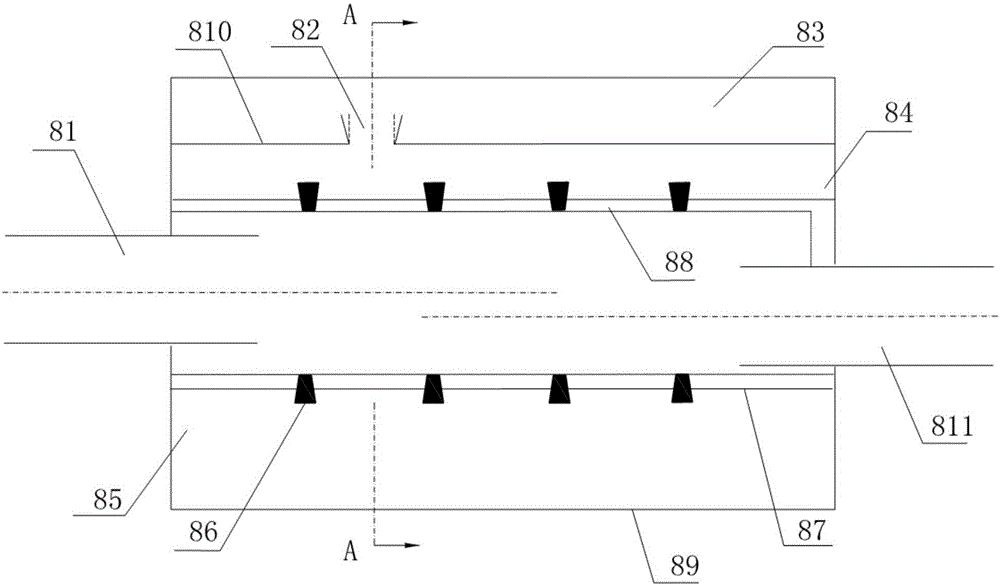

An anti-scratch branching device

The invention belongs to the technical field of bare stranded wire take-up, and particularly relates to an anti-scratch branching device. The device comprises a suspension frame, an adhesive tape releasing roller is rotationally matched with an extension rod located on the wire inlet side of a take-up roller, and an adhesive tape taking-up roller is rotationally matched with an extension rod located on the wire outlet side of the take-up roller; and a take-up tangent point is located on the advancing path of an adhesive tape, the advancing height of the adhesive tape located on the wire inletside of the take-up roller is lower than that of a bare stranded wire, and the advancing speed of the adhesive tape is consistent with that of the bare stranded wire. The device further comprises a monitoring sensor used for monitoring the position of the take-up tangent point, the monitoring sensor sends current take-up tangent point position information, and therefore the controller controls a movable block and a sliding block at a suspension frame to generate corresponding actions so as to keep the take-up tangent point on the advancing path of the adhesive tape all the time. According to the invention, the scratch-free function of bare stranded wires, especially aluminum wires, during take-up can be realized simply, conveniently and quickly; and the device is compact in structure, reliable and stable in work, capable of achieving the purpose of automatic production and beneficial to actual production and application.

Owner:铜陵顶科线材有限公司

Abrasion particle monitoring method based on magnetic field centrifugation, electric shock hammer adsorption and adjacent capacitance

InactiveCN105909593AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator testingFluid-pressure actuator componentsTemperature controlCentrifugation

The invention relates to an abrasion particle monitoring method based on magnetic field centrifugation, electric shock hammer adsorption and adjacent capacitance. According to the abrasion particle monitoring method, online monitoring of abrasion particles is conducted sequentially through a temperature control module, a magnetization module, a rotating magnetic field centrifugation module, an adsorption module, an adjacent capacitive particle monitoring module and a demagnetization module. An oil inlet is formed in one end of the temperature control module. The adsorption module is specifically a homopolar adjacent type adsorption ring provided with an electric shock hammer. According to the abrasion particle monitoring method, an adjacent capacitance sensor technique based on the capacitance fringe effect is introduced, so that non-invasion unconstrained monitoring of the abrasion particles is achieved; the abrasion particles in the oil are magnetized and aggregated into big particles through the magnetization module and the rotating magnetic field centrifugation module, move to the position near the pipe wall, and are adsorbed by the adsorption module, and thus the intensity of a monitoring signal output by an adjacent capacitance sensor is increased; and through the temperature control module and the reasonable design of the structure of an adjacent capacitance sensor polar plate layer, noise is restrained, and the overall performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Anti-scratch branching device

The invention belongs to the technical field of bare stranded wire take-up, and particularly relates to an anti-scratch branching device. The device comprises a suspension frame, an adhesive tape releasing roller is rotationally matched with an extension rod located on the wire inlet side of a take-up roller, and an adhesive tape taking-up roller is rotationally matched with an extension rod located on the wire outlet side of the take-up roller; and a take-up tangent point is located on the advancing path of an adhesive tape, the advancing height of the adhesive tape located on the wire inletside of the take-up roller is lower than that of a bare stranded wire, and the advancing speed of the adhesive tape is consistent with that of the bare stranded wire. The device further comprises a monitoring sensor used for monitoring the position of the take-up tangent point, the monitoring sensor sends current take-up tangent point position information, and therefore the controller controls a movable block and a sliding block at a suspension frame to generate corresponding actions so as to keep the take-up tangent point on the advancing path of the adhesive tape all the time. According to the invention, the scratch-free function of bare stranded wires, especially aluminum wires, during take-up can be realized simply, conveniently and quickly; and the device is compact in structure, reliable and stable in work, capable of achieving the purpose of automatic production and beneficial to actual production and application.

Owner:铜陵顶科镀锡铜线有限公司

Wear particle monitoring system adopting electrification, rotational flow centrifugation, adsorption and adjacent capacitance

InactiveCN105928842AIncrease output signal strengthHigh dielectric constantParticle and sedimentation analysisEngineeringRotational flow

The invention relates to a wear particle monitoring system adopting electrification, rotational flow centrifugation, adsorption and adjacent capacitance. A temperature control module, an electrification module, an electric field centrifugation module, a mechanical centrifugation module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the system are sequentially connected. An oil liquid inlet is formed in one end of the temperature control module. The mechanical centrifugation module is a rotational flow centrifugation module. The adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and wear particles are monitored without invasion or restriction. By means of the electrification module, the electric field centrifugation module and the mechanical centrifugation module, the wear particles in oil liquid are aggregated into large particles, move to the position close to the pipe wall and are adsorbed by the adsorption module, so that the intensity of monitoring signals output by an adjacent capacity sensor is improved. By means of the temperature control module and the adjacent capacitance sensor pole plate layer structure designed reasonably, noise is restrained, and the overall performance of a monitoring device of the adjacent capacitance sensor is optimized.

Owner:SHAOXING UNIVERSITY

Worn particle monitoring system using temperature control, electric shock hammer adsorption and adjacent capacitance

InactiveCN105973766AGrowth inhibitionIncrease output signal strengthParticle and sedimentation analysisTemperature controlEdge effects

The invention relates to a worn particle monitoring system using temperature control, electric shock hammer adsorption and adjacent capacitance. A temperature control module, a magnetizing module, a mechanical centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the worn particle monitoring system using the temperature control, electric shock hammer adsorption and adjacent capacitance are connected in sequence; an oil inlet is formed in one end of the temperature control module; the adsorption module is a homopolar adjacent type adsorption ring with an electric shock hammer specifically. According to the worn particle monitoring system using temperature control, electric shock hammer adsorption and adjacent capacitance, a capacitance edge effect-based adjacent capacitance sensor technology is introduced, and non-intrusive and unrestraint monitoring of worn particles is realized; the worn particles in oil is magnetized and aggregated into large particles through magnetizing and mechanical centrifuging, and the large particles move near a pipe wall and are adsorbed by the adsorption module, so that the output monitoring signal intensity of an adjacent capacitance sensor is improved; noises are restrained and the overall performance of the adjacent capacitance sensor monitoring device is optimized through the temperature control module and by reasonably designing an adjacent capacitance sensor polar plate layer structure.

Owner:SHAOXING UNIVERSITY

Method for monitoring wear particles on line by virtue of electrification, electric hammer adsorption and adjacent capacitance

InactiveCN105973948AIncrease output signal strengthHigh dielectric constantMaterial capacitanceTemperature controlElectricity

The invention relates to an on-line monitoring method of wear particles using electrification, electric hammer adsorption and adjacent capacitors, which sequentially monitors the particles through a temperature control module, an electrification module, an electric field centrifugal module, a mechanical centrifugal module, an adsorption module, and adjacent capacitor particles The module and the degaussing module carry out online monitoring of wear particles; one end of the temperature control module is provided with an oil inlet; the adsorption module is specifically a homopolar adjacent adsorption ring with an electric hammer. The invention introduces adjacent capacitive sensor technology based on capacitive edge effect to realize non-invasive and unconstrained monitoring of wear particles; through electrification, electric field centrifugation and mechanical centrifugation modules, the wear particles in the oil are aggregated into large particles and move to the pipe wall Adjacent and adsorbed by the adsorption module to increase the output monitoring signal strength of the adjacent capacitive sensor; through the temperature control module and the rational design of the adjacent capacitive sensor plate layer structure, suppress noise and optimize the overall performance of the adjacent capacitive sensor monitoring device.

Owner:张国云

Wear particle monitoring method using filtering, electromagnetic centrifugal separation and adjacent capacitance

InactiveCN106018213AGrowth inhibitionIncrease output signal strengthParticle suspension analysisCycloneAdaptive filter

The invention relates to a wear particle monitoring method using filtering, electromagnetic centrifugal separation and adjacent capacitance. Wear particles are monitored by a filter, a temperature control module, a magnetization module, a cyclone centrifugal module, a rotating magnetic field centrifugal module, an adsorption module, an adjacent capacitive particle monitoring module and a degaussing module sequentially; a working condition adaptive filter is used as the filter, and an oil inlet is formed in one end of the filter; an oil outlet is formed in one end of the degaussing module. According to the wear particle monitoring method, an adjacent capacitive sensor technology based on the capacitance edge effect is introduced, and wear particle non-intrusive and unconstrained monitoring is realized; wear particles in oil are magnetized and polymerized into large particles by the magnetization module, the cyclone centrifugal module and the rotating magnetic field centrifugal module, move to the vicinity of a pipe wall and are absorbed by the adsorption module, so that the strength of monitoring signals output by an adjacent capacitive sensor is improved; noise is restrained and the whole performance of the adjacent capacitive sensor monitoring device is optimized by the temperature control module and a reasonably designed adjacent capacitive sensor polar plate layer structure.

Owner:李伟波

Method for monitoring wear particles with hydraulic filtering, centrifugal separation and adjacent capacitors

InactiveCN105842305AGrowth inhibitionIncrease output signal strengthPreparing sample for investigationCentrifugal force sediment separationAdaptive filterMagnetization

The invention relates to a method for monitoring wear particles with hydraulic filtering, centrifugal separation and adjacent capacitors. Monitoring of wear particles is conducted through a filter, a temperature control module, a magnetization module, a mechanical centrifugal module, a rotating magnetic field centrifugal module, an absorption module, an adjacent capacitor particle monitoring module and a degaussing module in sequence; a variable structure work condition self-adapting filter is adopted for the filter, and one end of the filter is provided with an oil liquid inlet; one end of the degaussing module is provided with an oil liquid outlet. An adjacent capacitor sensor technology based on the capacitor edge effect is introduced, and non-intrusive and no-constraint monitoring of the wear particles is achieved; the wear particles in oil liquid are magnetized and aggregated into large particles through the magnetization module, the mechanical centrifugal module and the rotating magnetic field centrifugal module, move to the position near the pipe wall and are absorbed by the absorption module, so that strength of output monitoring signals of adjacent capacitor sensors is improved; the temperature control module is utilized, polar plate layer structures of the adjacent capacitor sensors are designed reasonably, noise is inhibited, and the overall performance of an adjacent capacitor sensor monitoring device is optimized.

Owner:李伟波

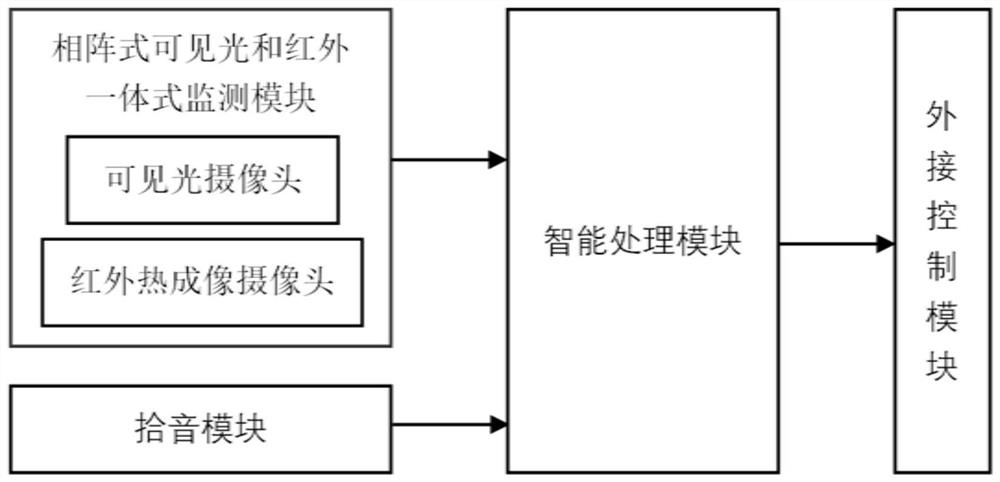

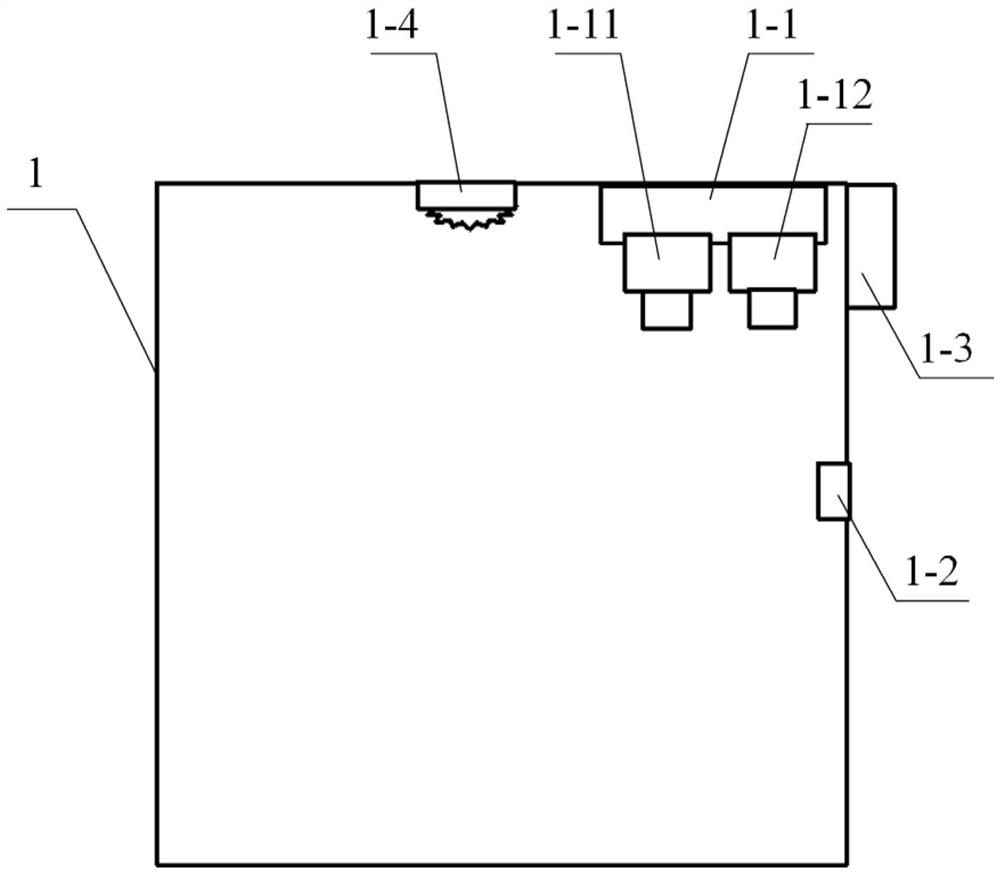

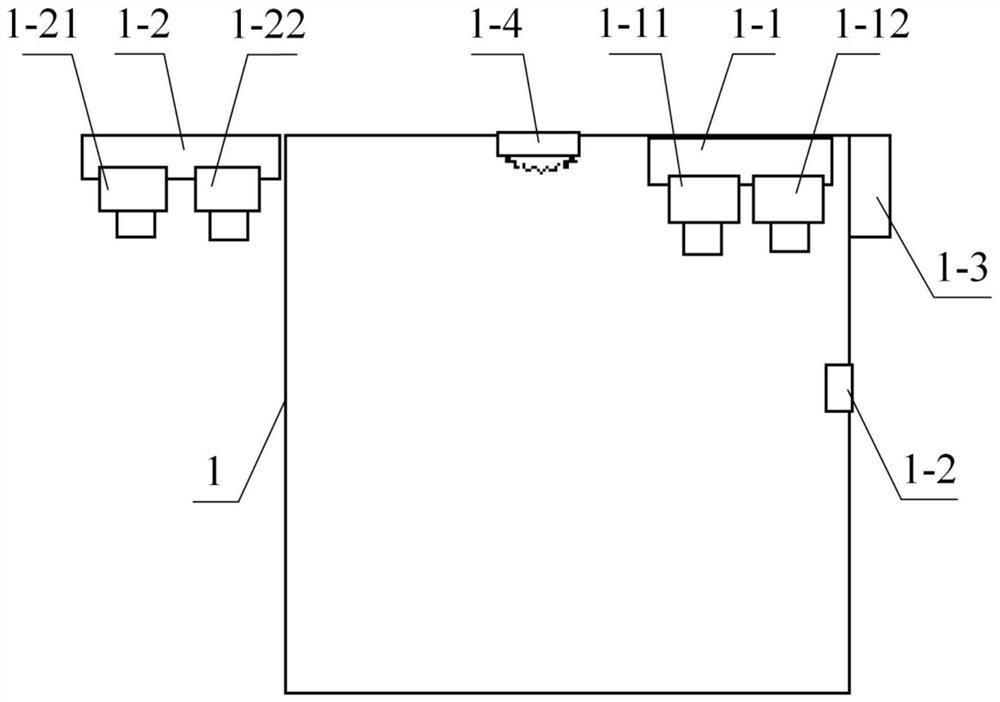

An elevator all-element health and safety monitoring system

ActiveCN111232788BHealth status real-time monitoringControl mutual infectionElevatorsPhysical medicine and rehabilitationIntegrated monitoring

An elevator all-element health and safety monitoring system, characterized in that: the system includes a phased array visible light and infrared integrated monitoring module (1-1), a sound pickup module (1-2), an intelligent processing module (1-2) 3) and an external control module (1‑4); the present invention realizes the identity recognition of the occupants inside the elevator, the detection of fever characteristics, and the changing characteristics of facial expressions and neck dynamics caused by cough symptoms through a phased array visible light and infrared integrated monitoring module , to realize real-time monitoring of the health status of the occupants in the elevator, so as to effectively control the legacy of the virus in the elevator and the mutual infection between the sick people; through the fusion of the cough symptom facial and neck dynamic change characteristics and sound characteristics acquired by the video, Based on the fusion of multi-feature information, the cough symptom assessment of the occupants in the elevator is realized, and the all-factor health assessment of the personnel is realized in combination with the fever characteristics. The assessment accuracy is high and the monitoring reliability is effectively guaranteed.

Owner:江苏弘冉智能科技有限公司

Abrasion particle online monitoring method through adsorption and adjacent capacitance

InactiveCN105909614AGrowth inhibitionIncrease output signal strengthFluid-pressure actuator componentsTemperature controlMagnetization

The invention relates to an abrasion particle online monitoring method through adsorption and adjacent capacitance. Abrasion particle online monitoring is sequentially conducted through a temperature control module, a magnetization module, an adsorption module, an adjacent capacitance abrasion particle monitoring module and a demagnetization module. One end of the temperature control module is provided with an oil inlet. One end of the demagnetization module is provided with an oil outlet, and the demagnetization module is composed of a residual magnetism sensor and a magnetic eraser. The adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and non-intrusive and unconstrained monitoring of abrasion particles is achieved; the abrasion particles in oil are magnetized through the magnetization module and are adsorbed through the adsorption module, so that the intensity of output monitoring signals of adjacent capacitance sensors is improved; and through the temperature control module and the reasonable design of polar plate layer structures of the adjacent capacitance sensors, noise is suppressed, and the whole performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:张国云

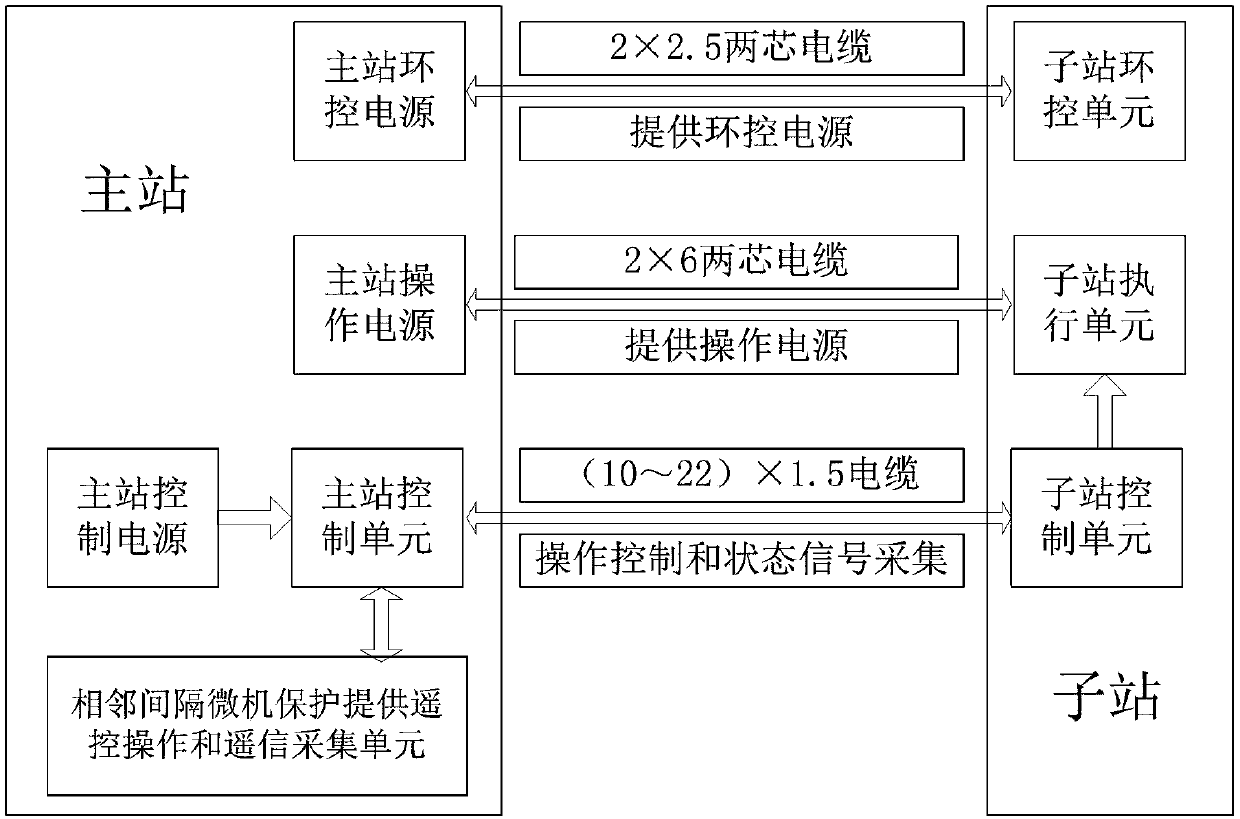

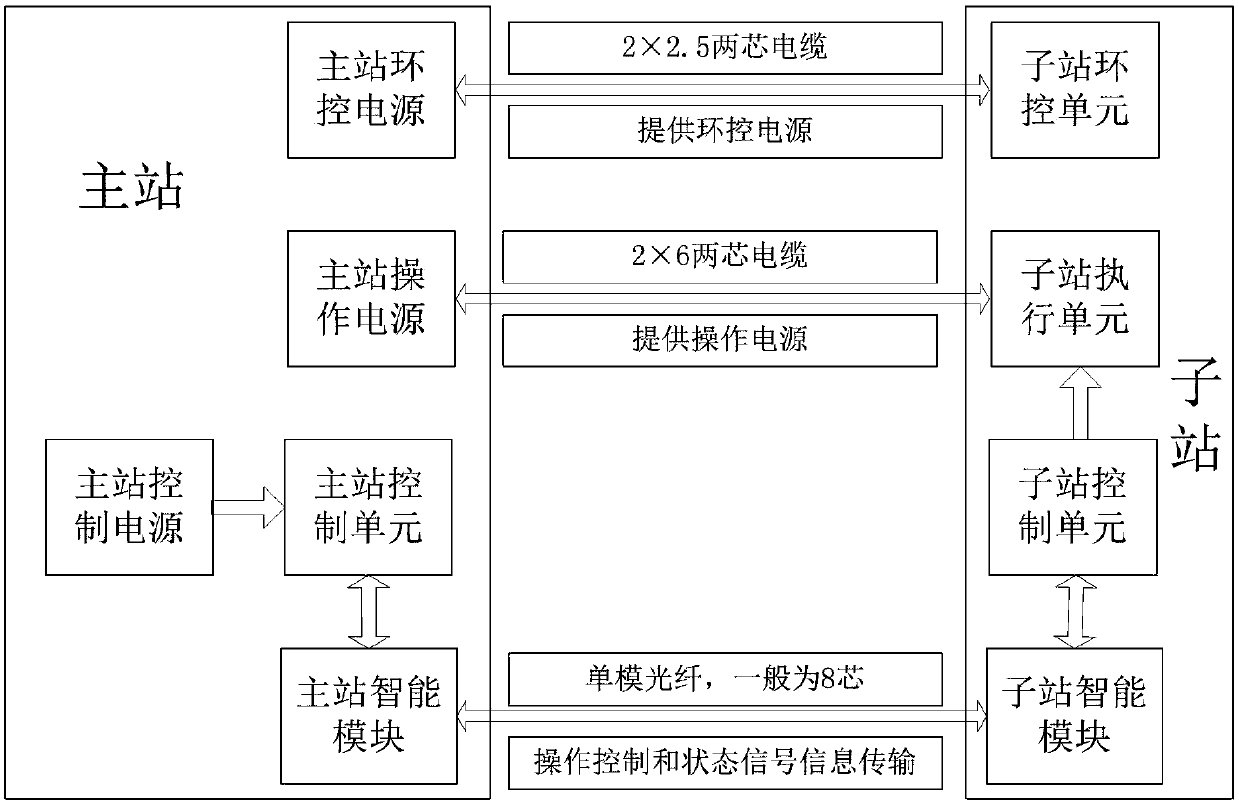

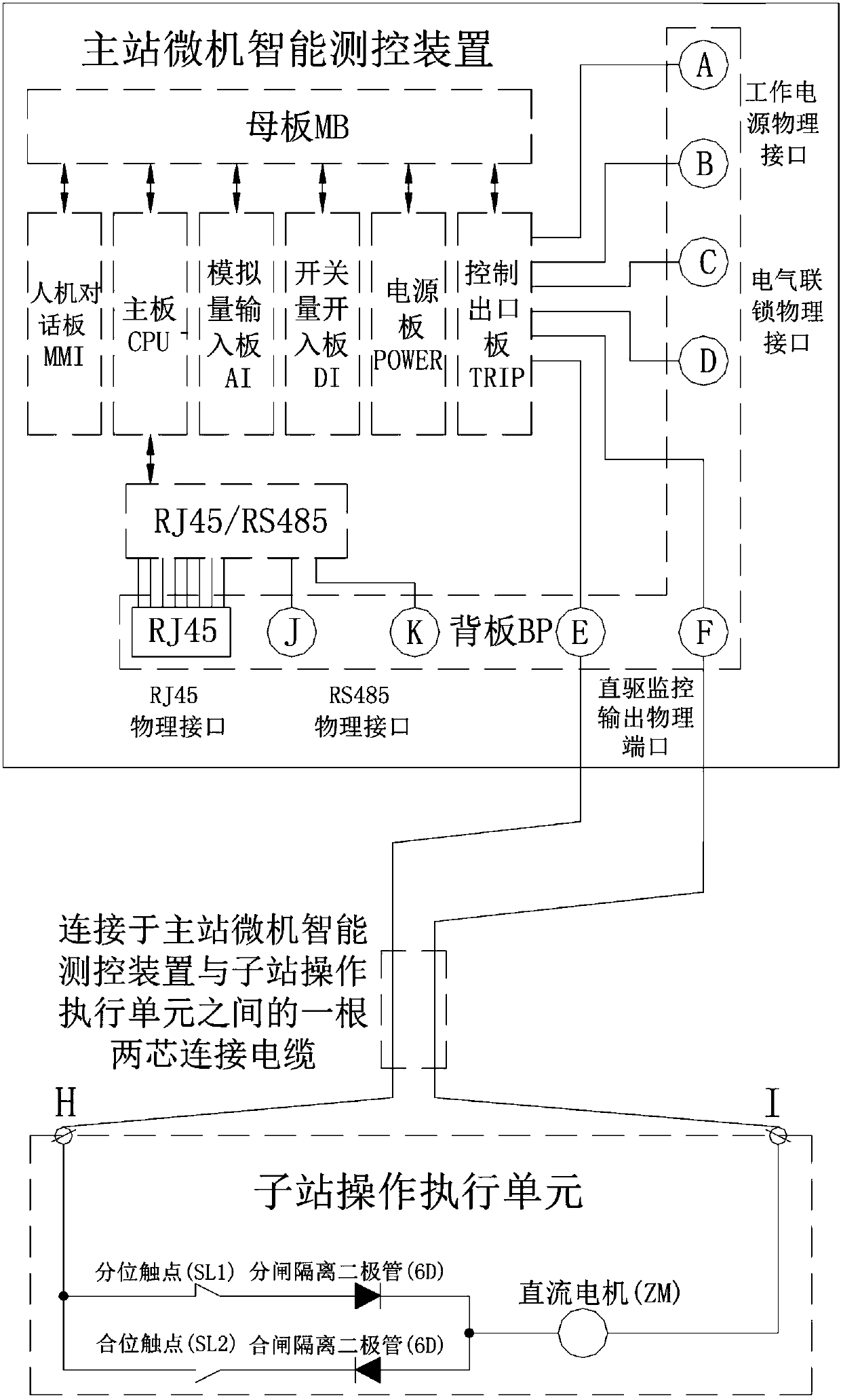

Two-wire direct drive monitoring system of high-voltage electric disconnecting switch

ActiveCN107809141AMonitoring mode innovationComplete monitoring functionCircuit arrangementsMonitor modeFull life cycle

The invention, which relates to the field of high-voltage electrical equipment in the electric power industry, discloses a two-wire direct drive monitoring system of a high-voltage electric disconnecting switch. The monitoring system comprises a master station microcomputer intelligent monitoring device, a substation operation execution unit, and a two-core connection cable connected between the master station microcomputer intelligent monitoring device and the substation operation execution unit. On the basis of monitoring mode innovation, a two-wire direct drive monitoring mode is realized physically and the system construction is simplified. Because of the novel and unique monitoring mode, local monitoring and remote monitoring are realized; the local monitoring includes measurement, signal, protection, control, and full-life-cycle monitoring and the remote monitoring includes telemetering, remote signaling, remote control, and remote regulation. With the monitoring mode, interlocking of the operating power supply and the monitoring power supply as well as real-time monitoring of the operation loop, operating conditions, and three positions is realized. The monitoring mode is the breakthrough of the monitoring mode of the high-voltage electric disconnecting switch and is pioneering; and reliable monitoring and maintenance-free operation and maintenance of high-voltage electric disconnecting switch are realized.

Owner:成都锦城和创电气设备有限公司 +1

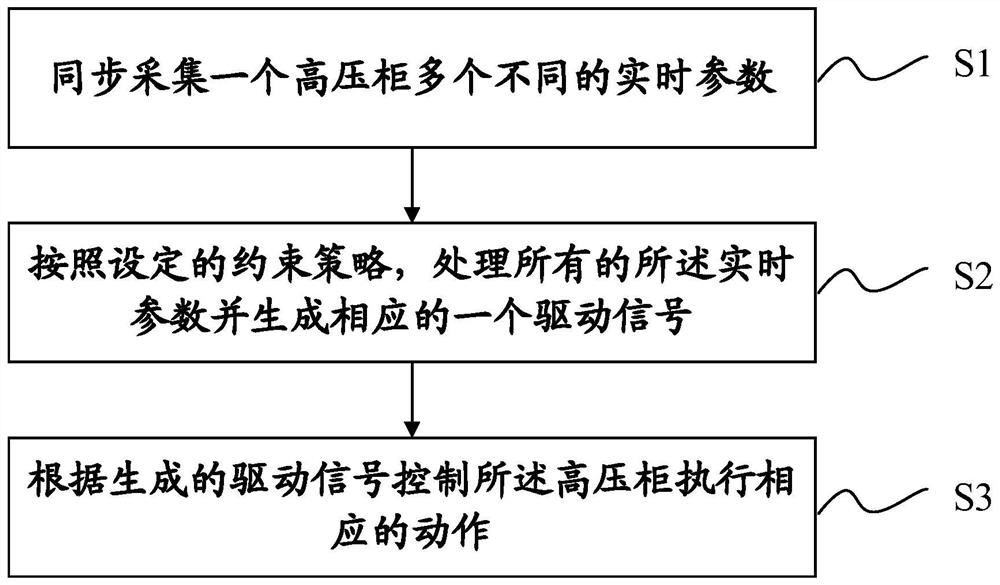

High-voltage cabinet monitoring method based on multiple parameters

PendingCN114243496AEnsure monitoring reliabilityImprove reliabilityCircuit arrangementsSubstation/switching arrangement casingsReliability engineeringVoltage

The embodiment of the invention discloses a high-voltage cabinet monitoring method based on multiple parameters, and relates to the technical field of high-voltage cabinet monitoring, and the method comprises the following steps: synchronously collecting a plurality of different parameters of a high-voltage cabinet; according to a set constraint strategy, processing all the parameters and generating a corresponding driving signal; and controlling the high-voltage cabinet to execute corresponding actions according to the generated driving signal. According to the embodiment of the invention, the high-voltage cabinet can be comprehensively monitored, the control form of the high-voltage cabinet is simplified, the monitoring mode is more scientific, the monitoring reliability and monitoring efficiency of the high-voltage cabinet are improved, the reliable operation of the high-voltage cabinet is ensured, and the probability of power failure of the high-voltage cabinet is reduced.

Owner:HUBEI XIANGKAI POWER EQUIP CO LTD

Abraded micro-particle online monitoring method adopting temperature control, adsorption and adjacent capacitor

InactiveCN105973780AGrowth inhibitionIncrease output signal strengthParticle suspension analysisDemagnetizing deviceTemperature control

The invention relates to an abraded micro-particle online monitoring method adopting temperature control, adsorption and an adjacent capacitor. Abraded micro-particle online monitoring is carried out by adopting a temperature control module, a magnetizing module, a mechanical centrifuging module, an adsorption module, an adjacent capacitor micro-particle monitoring module and a demagnetizing module in sequence; an oil liquid inlet is arranged at one end of the temperature control module; an oil liquid outlet is arranged at one end of the demagnetizing module; the demagnetizing module is composed of a residual magnetism sensor and a demagnetizing device. By introducing an adjacent capacitor sensor technology based on a capacitor edge effect, non-invasion and restriction-free monitoring of abraded micro-particles is realized; the abraded micro-particles in oil liquid are magnetized through magnetizing and mechanical centrifuging and are polymerized into large particles, and the large particles move to the nearby place of a pipe wall and are adsorbed by the adsorption module, so that the intensity of a monitoring signal output by an adjacent capacitor sensor is improved; the temperature control module is adopted and a polar plate layer structure of the adjacent capacitor sensor is reasonably designed, so that noises are inhibited and the whole performance of an adjacent capacitor sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

On-line wear particle monitoring equipment adopting electrification, electric shock hammer adsorption and adjacent capacitance

InactiveCN106018186AIncrease output signal strengthHigh dielectric constantParticle suspension analysisParticle and sedimentation analysisEngineeringElectric shock

The invention relates to on-line wear particle monitoring equipment adopting electrification, electric shock hammer adsorption and adjacent capacitance. A temperature control module, an electrification module, an electric field centrifugation module, a mechanical centrifugation module, an adsorption module, an adjacent capacitance particle monitor module and a demagnetization module of the equipment are sequentially connected; one end of the temperature control module is provided with an oil liquid inlet; the adsorption module particularly is homopolar adjacent type adsorption rings with electric shock hammers. According to the equipment, non-intrusive and unconstrained wear particle monitoring is achieved by introducing an adjacent capacitance sensor technique based on a capacitance edge effect; through the electrification module, the electric field centrifugation module and the mechanical centrifugation module, wear particles in oil liquid are aggregated into large particles and move to the positions near the tube wall to be adsorbed by the adsorption module, so that the output monitoring signal intensity of an adjacent capacitance sensor is improved; by arranging the temperature control module and reasonably designing the structure of a polar plate layer of the adjacent capacitance sensor, noise is inhibited, and the whole performance of an adjacent capacitance sensor monitoring device is optimized.

Owner:SHAOXING UNIVERSITY

Wear particle online monitoring device using filtering, centrifuge and adjacent capacitance

InactiveCN105866198AGrowth inhibitionIncrease output signal strengthMaterial capacitanceTemperature controlEdge effects

The invention relates to a wear particle online monitoring device using filtering, centrifuge and adjacent capacitance. The wear particle online monitoring device using filtering, centrifuge and adjacent capacitance comprises a filter, a temperature control module, a magnetizing module, a mechanical centrifugal module, a rotary magnetic-field centrifugal module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module, which are sequentially connected. The filter is a pressure pulse filter with the full-band hydraulic system. One end of the filter is provided with an oil inlet, and one end of the demagnetizing module is provided with an oil outlet. The wear particle online monitoring device can realize non-intruding and restraint-free monitoring by introducing the adjacent capacitance sensor technology based on capacitance edge effect. Through magnetization, mechanical centrifuge and the rotary magnetic-field centrifugal module, wear particles in oil can be magnetized and gathered to be large particles moving to the pipe wall and to be adsorbed by the adsorption module, so that intensity of output monitoring signals of the adjacent capacitance sensor is improved. Through the temperature control module and the adjacent capacitance sensor plate structure reasonably designed, noise can be suppressed, and the overall performance of the adjacent capacitance sensor-monitoring device can be optimized.

Owner:SHAOXING UNIVERSITY

Wear particle online monitoring device adopting rotational flow centrifugation, adsorption and adjacent capacitance

InactiveCN105928843AGrowth inhibitionIncrease output signal strengthParticle and sedimentation analysisTemperature controlWear particle

The invention relates to a wear particle online monitoring device adopting rotational flow centrifugation, adsorption and adjacent capacitance. A temperature control module, a magnetizing module, a mechanical centrifugation module, a rotary magnetic field centrifugation module, an adsorption module, an adjacent capacitance particle monitoring module and a demagnetizing module of the monitoring device are sequentially connected. An oil liquid inlet is formed in one end of the temperature control module. The mechanical centrifugation module is a rotational flow centrifugation module. The adjacent capacitance sensor technology based on the capacitance edge effect is introduced, and wear particles are monitored without invasion or restriction. By means of the electrification module, the mechanical centrifugation module and the rotary magnetic field centrifugation module, the wear particles in oil liquid are magnetized and aggregated into large particles, move to the position close to the pipe wall and are adsorbed by the adsorption module, so that the intensity of monitoring signals output by an adjacent capacity sensor is improved. By means of the temperature control module and the adjacent capacitance sensor pole plate layer structure designed reasonably, noise is restrained, and the overall performance of the monitoring device of the adjacent capacitance sensor is optimized.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com