Anti-scratch branching device

A wire-splitting device and anti-scratch technology, applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve problems such as affecting the quality of aluminum wires leaving the factory, scratches, loss of reputation of manufacturers in use experience, etc., to solve the problem of wire body scratches problems, reducing scratch problems, and the effect of finished product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

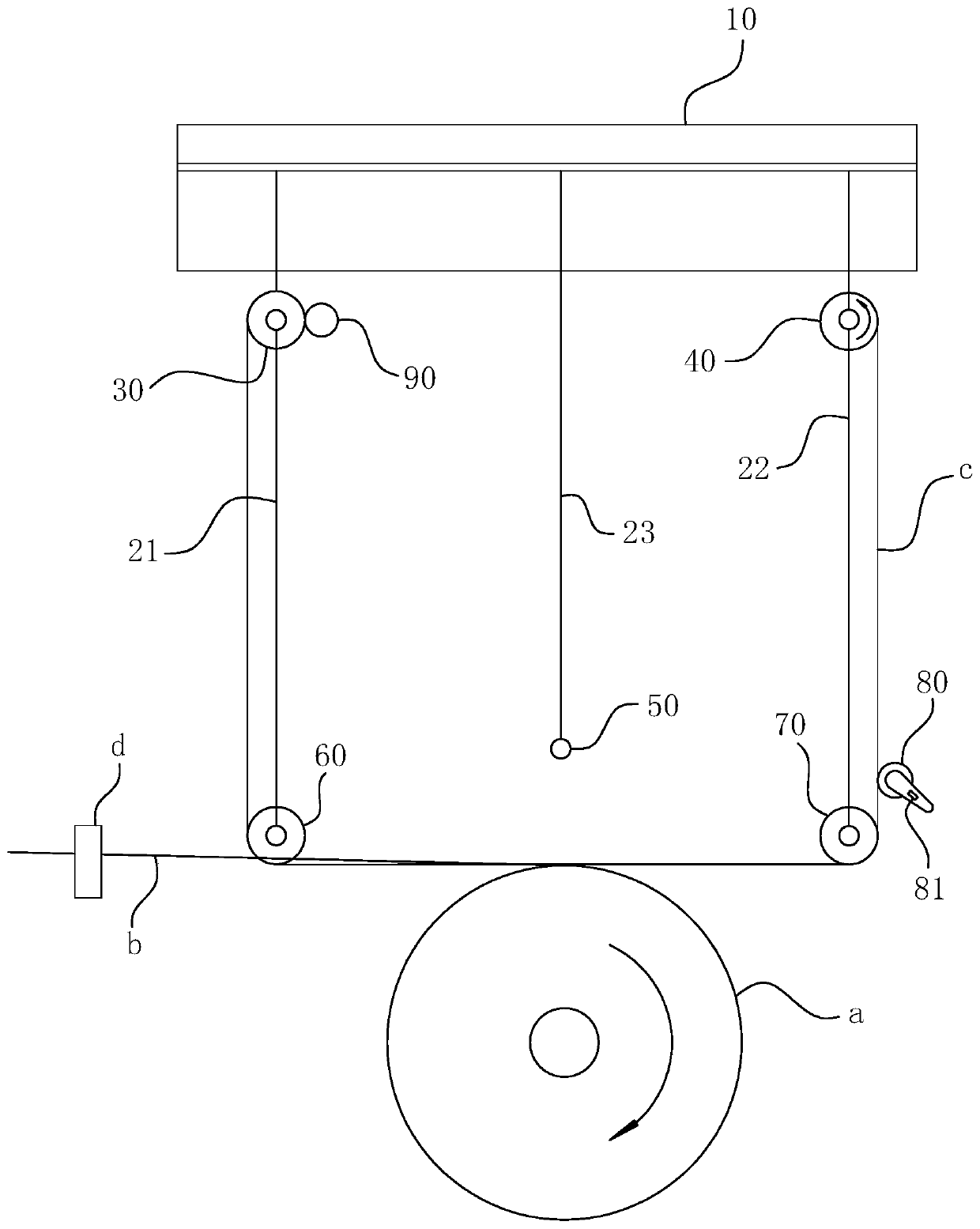

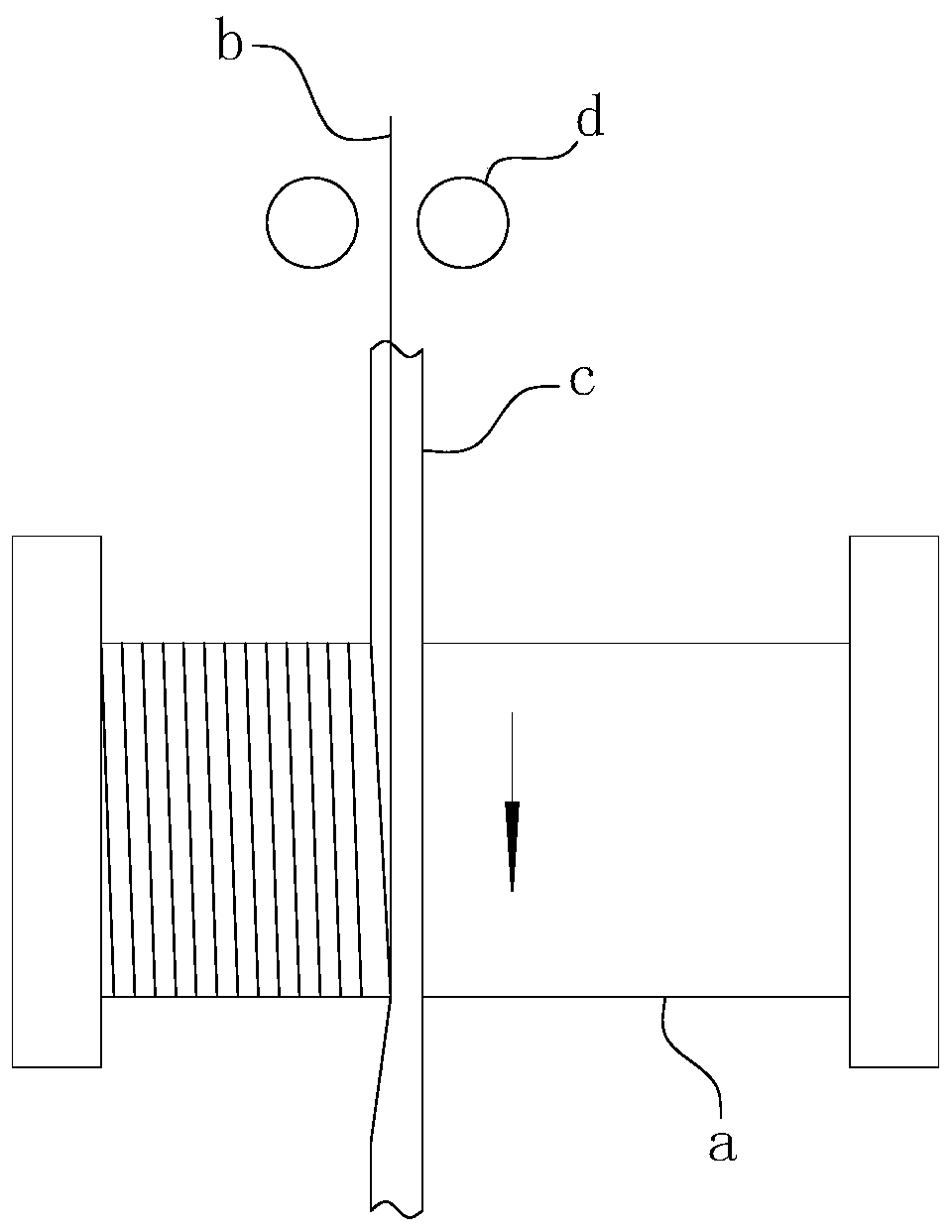

[0028] For ease of understanding, combined here Figure 1-2 , the concrete structure and working mode of the present invention are further described as follows:

[0029] The specific embodiment structure of the present invention can refer to Figure 1-2 As shown, its main structure includes a suspension frame 10, an extension rod, a tape release roller 30, a tape pressure roller 90, a first direction change wheel 60, a second direction change wheel 70, a tension wheel 80, a tape collection roller 40 and a monitoring system. sensor 50. in:

[0030] The suspension frame 10 is actually a common XY-axis double-action platform. Specifically, the suspension frame 10 is split into a horizontal action platform that can move horizontally along the axial direction of the take-up roller a, and a vertical action platform that can move vertically along the vertical direction and is arranged on the moving block of the horizontal action platform. action platform. In actual operation, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com