Pressure sensor and production method thereof

A pressure sensor and substrate technology, applied in the field of sensors, can solve the problems of small pressure detection range and achieve the effects of low cost, sensitive response, and improved sensitivity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

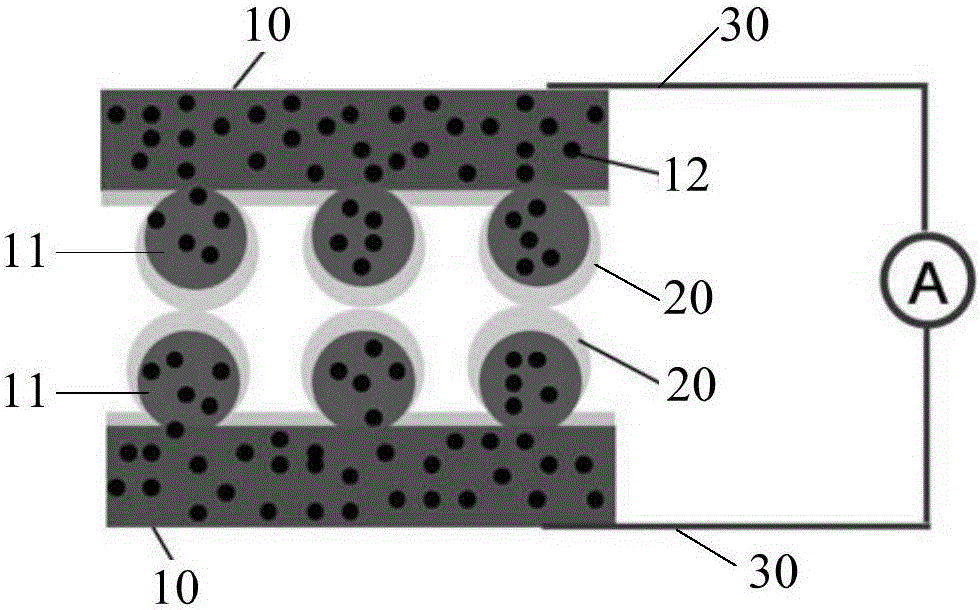

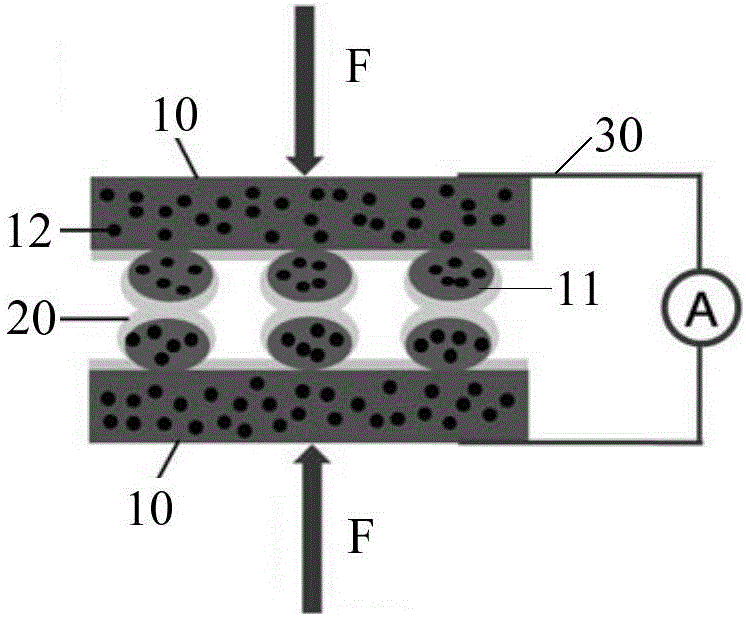

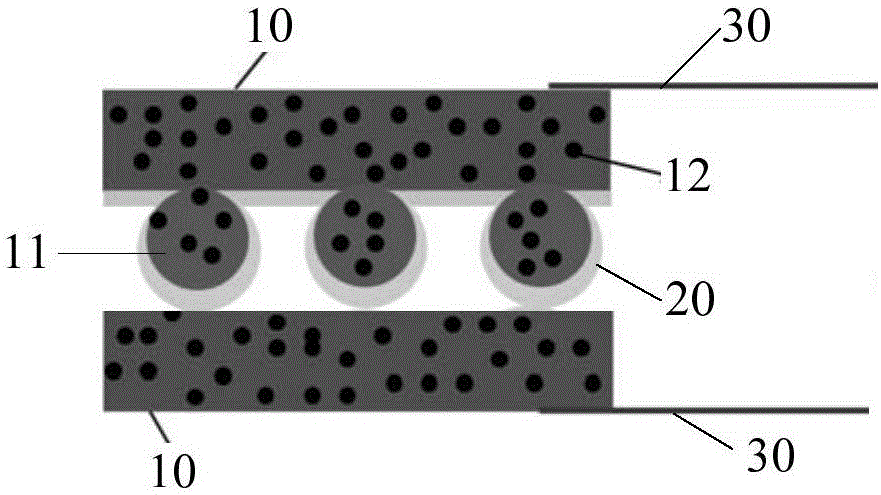

[0038] see figure 1 , the pressure sensor according to the first embodiment of the present invention is proposed, the pressure sensor includes two external electrodes 30 and two oppositely disposed substrates 10, the substrates 10 are elastic and conductive. like figure 1 As shown, there are micro-protrusion structures 11 (or micro-protrusion structures) on the contact surfaces (the opposite sides of the two substrates) of the two substrates 10, and the protrusion structures 11 of the two substrates 10 are preferably the same structure, the protruding structure 11 leads to a convex portion and a concave portion on the contact surface, and the convex portion and the convex portion on the contact surface of the two substrates 10 can be directly contacted, or the convex portion can be directly contacted with the concave portion. The surface of the protruding structure 11 is covered with a conductive layer 20, and each substrate 10 is connected with an external electrode 30 for c...

Embodiment 2

[0053] refer to Figure 4 , propose the preparation method of the pressure sensor of the second embodiment of the present invention, described method comprises the following steps:

[0054] S11. Prepare two elastic and conductive substrates, and at least one of the substrates has a protruding structure on the contact surface.

[0055] In this step S11, two elastic conductive substrates are prepared, and at least one of the substrates has a raised structure on the contact surface, which is the opposite surface when the last two substrates are folded together.

[0056] In the embodiment of the present invention, two substrates with the same raised structure are preferably prepared. In other embodiments, the raised structures on the two substrates may be different, or only one substrate has the raised structure. The raised structure on the contact surface of the substrate can be one or a combination of at least two regular three-dimensional structures such as prisms, pyramids, c...

example 1

[0076] (1) Using the silicon wafer as the substrate, a hemispherical hole array (depression structure array) is processed on the surface of the silicon wafer by MEMS technology, with a diameter of 20 μm, and the processed silicon wafer is used as a micro template.

[0077] (2) Use silver flakes with a particle size of 1-10 μm as the conductive filler, use polydimethylsiloxane (PDMS) as the matrix, and mix the PDMS prepolymer and its curing agent with the silver flakes by mechanical stirring to obtain a flexible Conductive paste (mixture in fluid form). The mass ratio of the PDMS prepolymer to its curing agent is 12:1-5:1, and the mass ratio of the PDMS and its curing agent (total mass of the two) to the silver sheet is 1:1-1:4.

[0078] (3) Deposit the flexible conductive paste made in the above step (2) on the silicon micro-template made in the above step (1) by scraping and printing with a mask plate, and cure the flexible conductive paste by heating at 80°C for 2 hours It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com