Farraginous carbon fiber composite material, preparation method and application thereof

A composite material and carbon fiber technology, applied in fiber processing, fiber chemical characteristics, yarn, etc., can solve problems such as brittle fracture, monitoring accuracy needs to be improved, and material fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

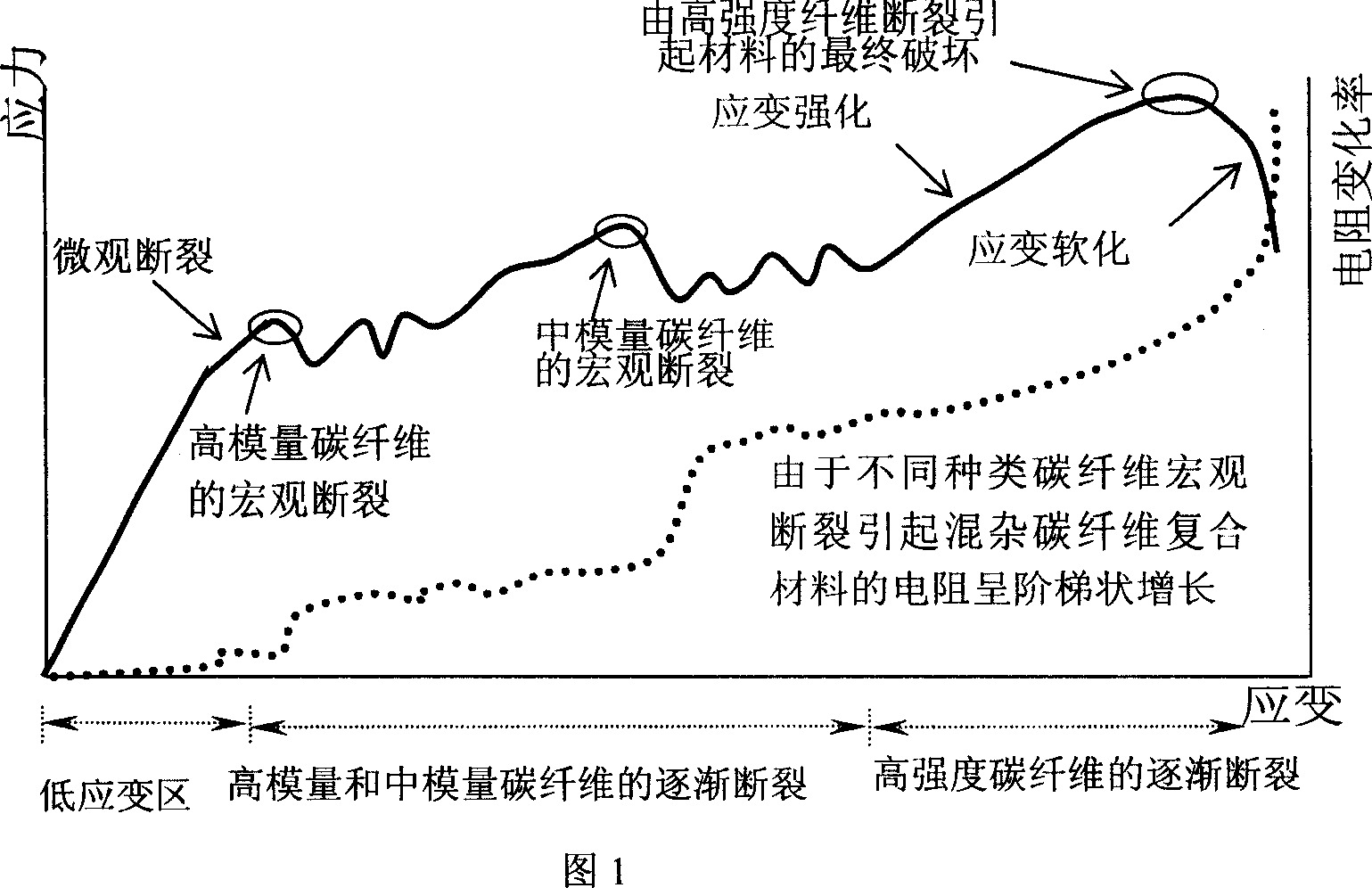

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, hybrid carbon fiber reinforcement

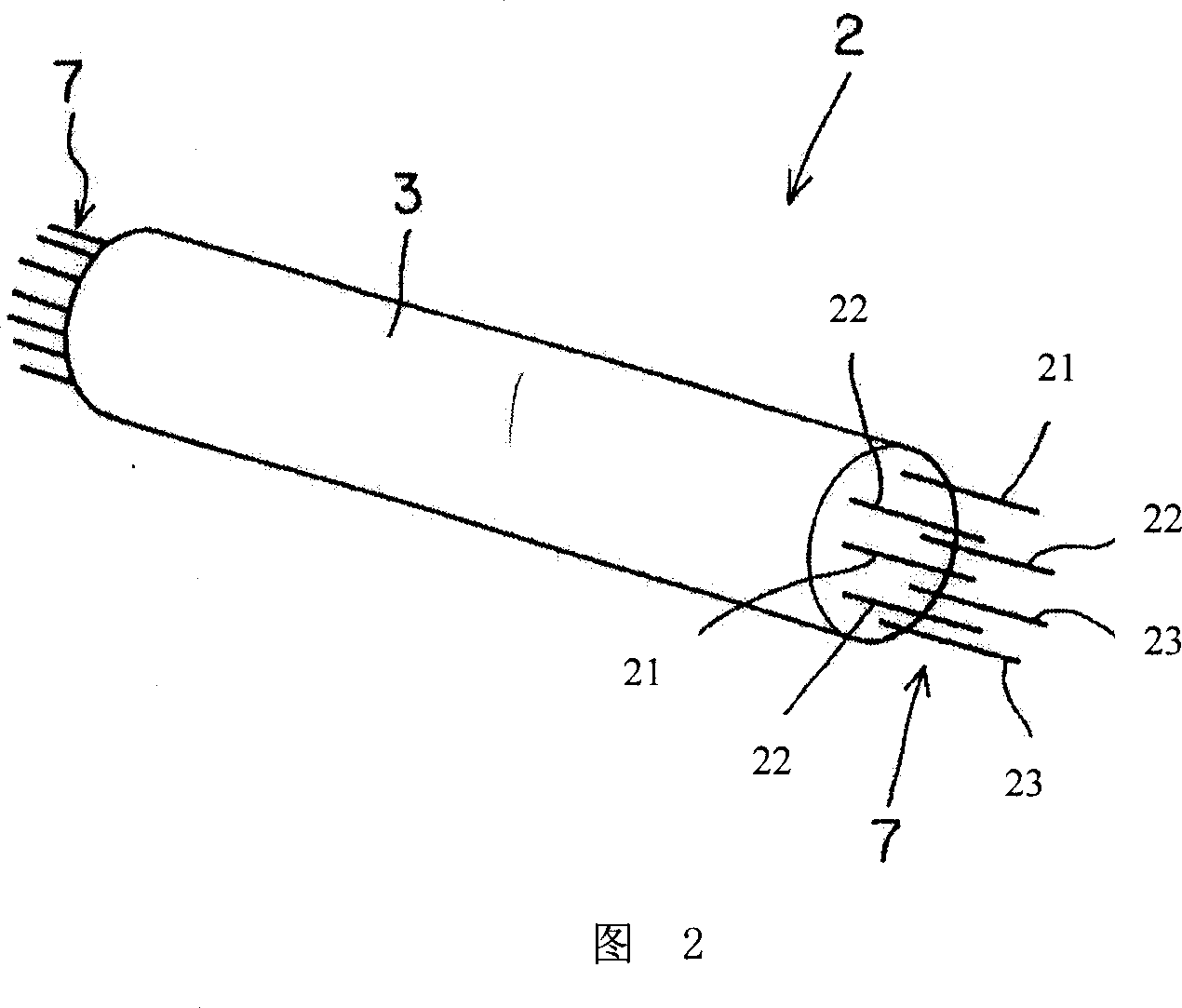

[0028] The structure of the hybrid carbon fiber reinforcement is shown in Figure 2. The hybrid carbon fiber bundle 2 is a mixture of carbon fiber A21 (high elastic modulus carbon fiber), carbon fiber B22 (medium elastic modulus carbon fiber), and carbon fiber C23 (high-strength carbon fiber) with different properties. The resulting aggregates are formed by impregnating these carbon fiber bundles with epoxy resin 3 . The strength, modulus and ductility of carbon fiber A21, carbon fiber B22, and carbon fiber C23 that make up the hybrid carbon fiber bundle 2 are different, and the appropriate ratio can be designed according to the specific use conditions. When the hybrid composite material is used as a structural material and a sensing material, the hybrid The proportion of medium modulus and high strength fibers in the material can be appropriately increased, and if it is mainly used as a sensing material, the volume conte...

Embodiment 2

[0031] Embodiment 2, sheet-like hybrid carbon fiber composite material

[0032] The structure of the sheet-like hybrid carbon fiber composite material is shown in Figure 4. The hybrid carbon fiber sheet 5 can be formed by impregnating and hardening the hybrid carbon fiber bundle 2 with epoxy resin 3, or it can be formed by three kinds of carbon fiber sheets (high-strength carbon fiber, Medium elastic modulus and high elastic modulus carbon fiber sheets) are impregnated, mixed and hardened with epoxy resin by lamination method. The hybrid carbon fiber sheet 5 also has the function of monitoring the strain and damage state of the structure. For example, the sheet-like hybrid carbon fiber material 5 can be pasted to the lower part of the structure along the direction of force with resin and used as a sensing material and a reinforcing material.

[0033] Figure 5 is a schematic diagram of the resistance measurement of a sheet-like hybrid carbon fiber composite material. A tensile ...

Embodiment 3

[0035] Example 3. Application of hybrid carbon fiber bars in strengthening and monitoring the strain state of concrete structures

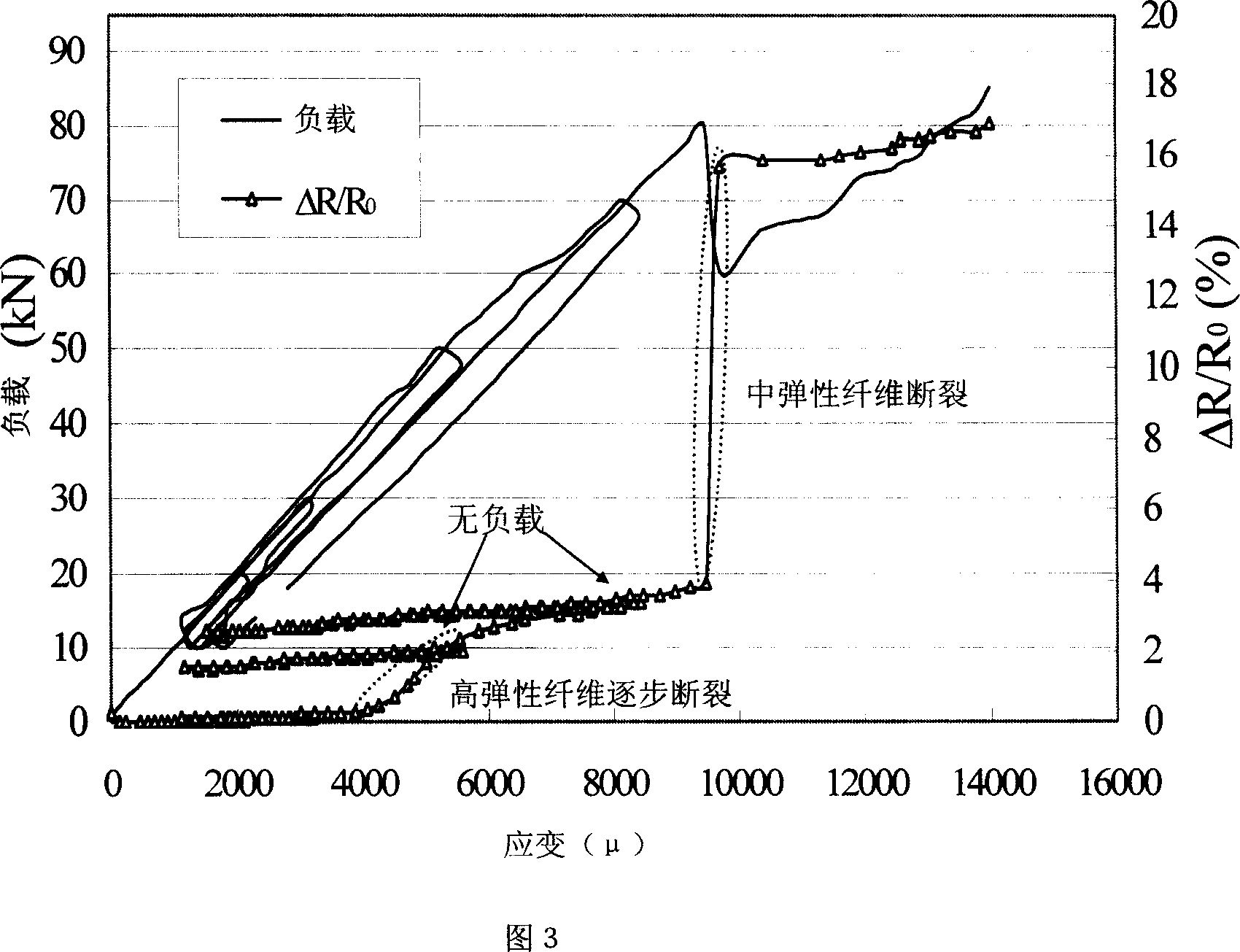

[0036] FIG. 7 is a schematic diagram of applying hybrid carbon fiber bars to concrete structures. There is no reinforcing steel bar in the concrete beam 10, and two hybrid carbon fiber bars 11 are distributed in the concrete beam as shown in FIG. 7 . The hybrid carbon fiber reinforcement 11 can be used as a reinforcing material to enhance the stiffness and bearing capacity of the structure, and can also be used as a sensing material to monitor the strain and damage of the structure 10 . The stress state and damage state inside the structure 10 can be judged by measuring the resistance change rate of 11 . Hybrid carbon fiber reinforcement 11 contains four kinds of fibers, three of which are carbon fibers (high elastic modulus carbon fiber A21 (elastic modulus is 640GPa), medium elastic modulus carbon fiber B22 (elastic modulus is 392GPa) and high-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com