A method for preparing vanadium dioxide film with high resistance change rate on silicon substrate

A technology based on vanadium dioxide and silicon substrates, applied in circuits, electrical components, gaseous chemical plating, etc., can solve the problems of complex epitaxy process, difficult control, buffer layer thickness, etc., achieve high film quality and reduce phase transition Relaxation time and the effect of improving the resistance change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings. It should be noted that the present invention is not limited to the embodiments.

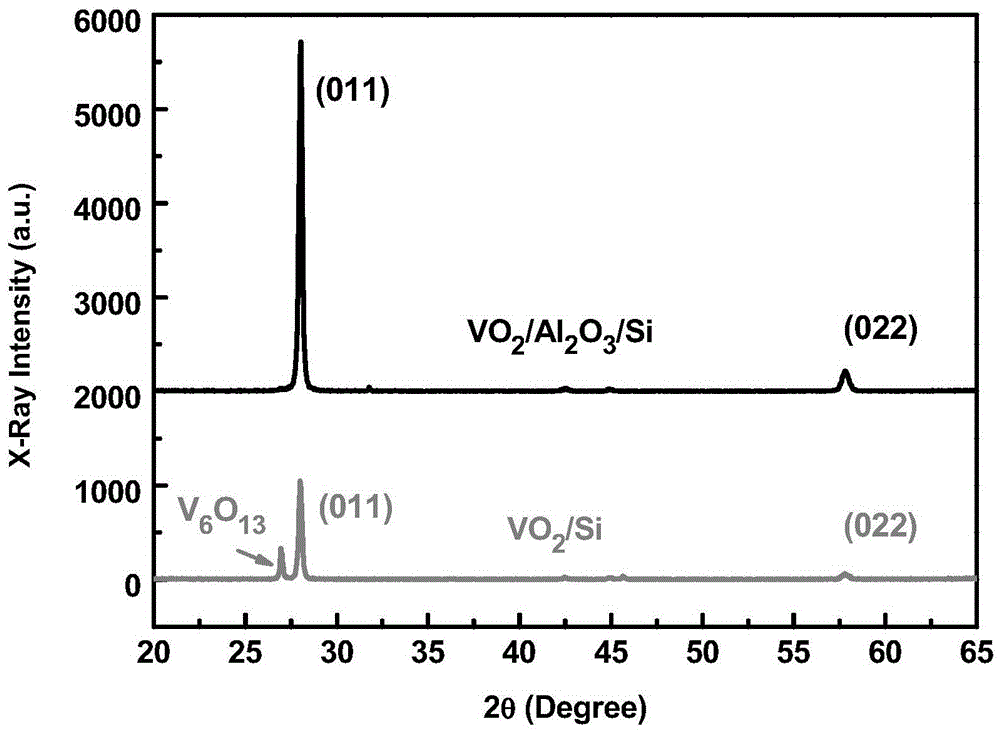

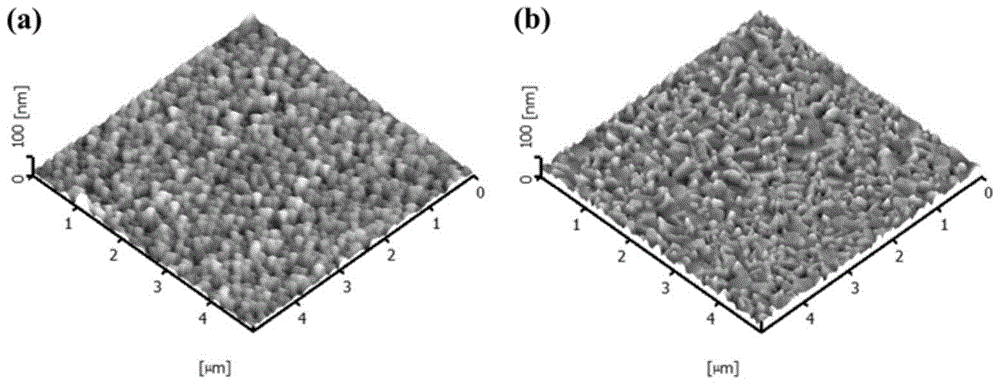

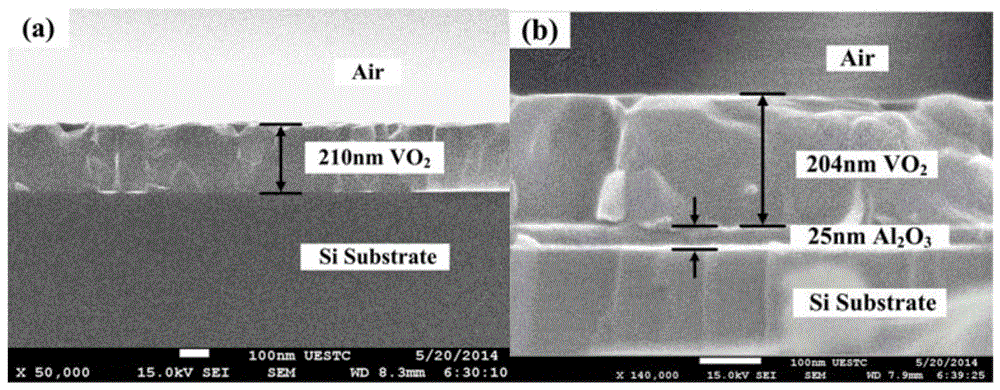

[0023] A kind of VO with obvious preferred orientation and high resistivity change rate prepared on silicon substrate 2 A thin film method comprising the steps of:

[0024] Step 1. First select a double-sided polished Si substrate, and then clean the substrate. Soak the silicon substrate in self-prepared acid solution for 20 minutes to remove organic pollutants on the surface; rinse with a large amount of deionized water and then soak the silicon substrate with 25% HF solution for 10 minutes to remove the silicon oxide layer formed on the surface ; Rinse with deionized water; then ultrasonically clean with acetone for 10 minutes, then ultrasonically clean with alcohol for 10 minutes, finally clean with deionized water, and dry with nitrogen for later use.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com