Magnetic resistance element, magnetic sensor device and manufacturing method of magnetic resistance element

A technology of a magnetoresistive element and a manufacturing method, which is applied in the manufacture/processing of electromagnetic devices, and a resistor for magnetic field control, etc., can solve the problem that the magnetoresistive film cannot be sufficiently prevented from being oxidized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

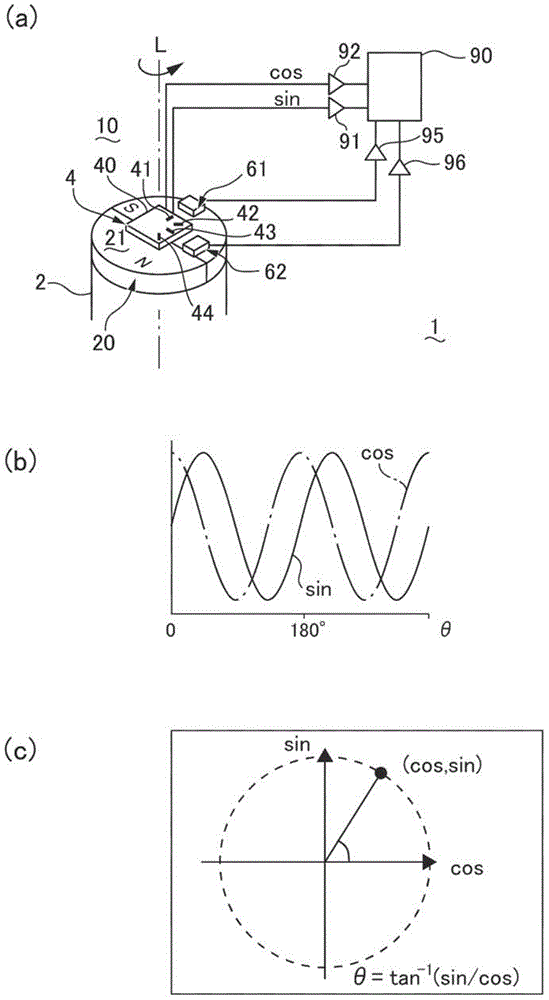

[0044] Hereinafter, embodiments of a magnetoresistive element, a magnetic sensor device, and a rotary encoder to which the present invention is applied will be described with reference to the drawings. In addition, in the rotary encoder, when detecting the rotation of the rotor relative to the stator, a structure in which a magnet is provided in the stator and a reluctance element in the rotor, and a structure in which a reluctance element is provided in the stator and a magnet in the rotor can be employed. In any configuration, in the following description, a configuration in which a magnetic sensor device is provided in a stator and a magnet is provided in a rotor will be mainly described.

[0045] (Structure of Magnetic Sensor Device)

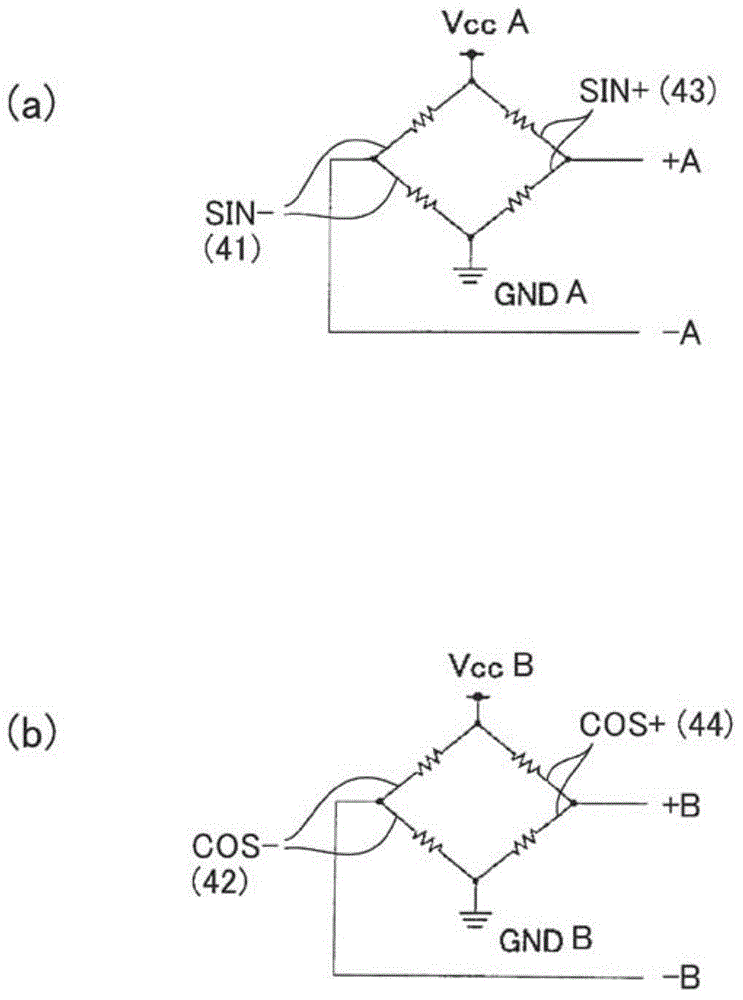

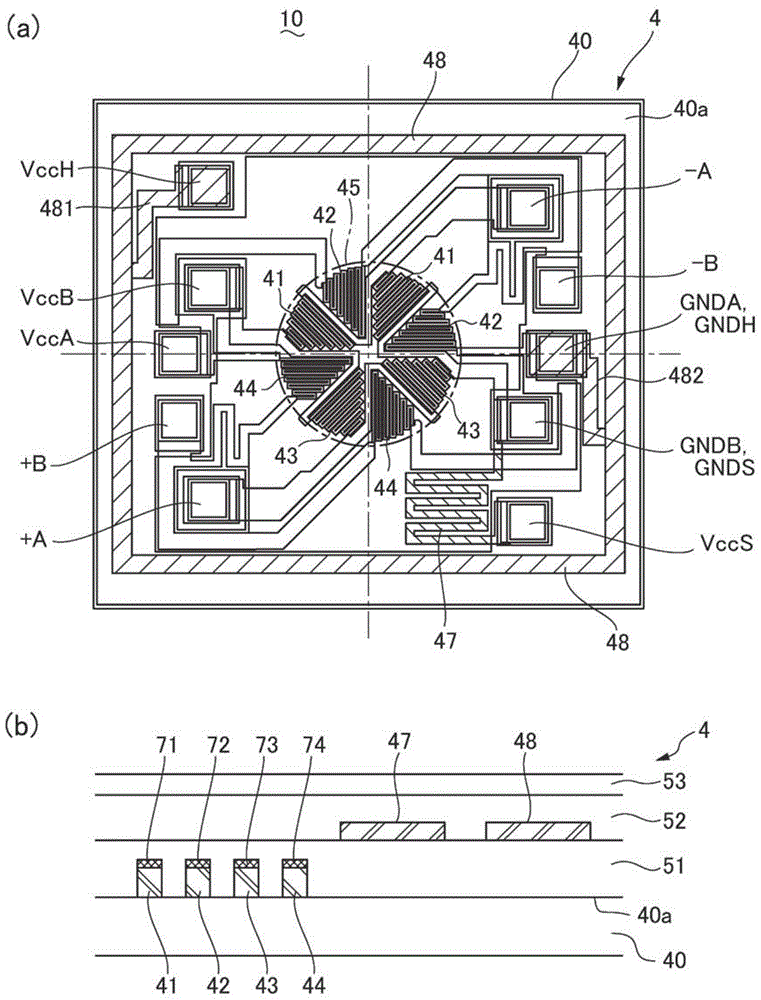

[0046] figure 1 It is an explanatory diagram showing the principle of the magnetic sensor device 10 having the magnetoresistive element 4 to which the present invention is applied, and the rotary encoder 1, figure 1 (a) is an explanatory d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com