Pressure resistance large overloading accelerometer and preducing method thereof

An accelerometer and large overload technology, applied in the field of microelectronics, can solve the problems of incompatibility of integrated circuit technology, poor sensitivity of large overload accelerometers, etc., and achieve the effect of easy anti-high overload structure, simple structure and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

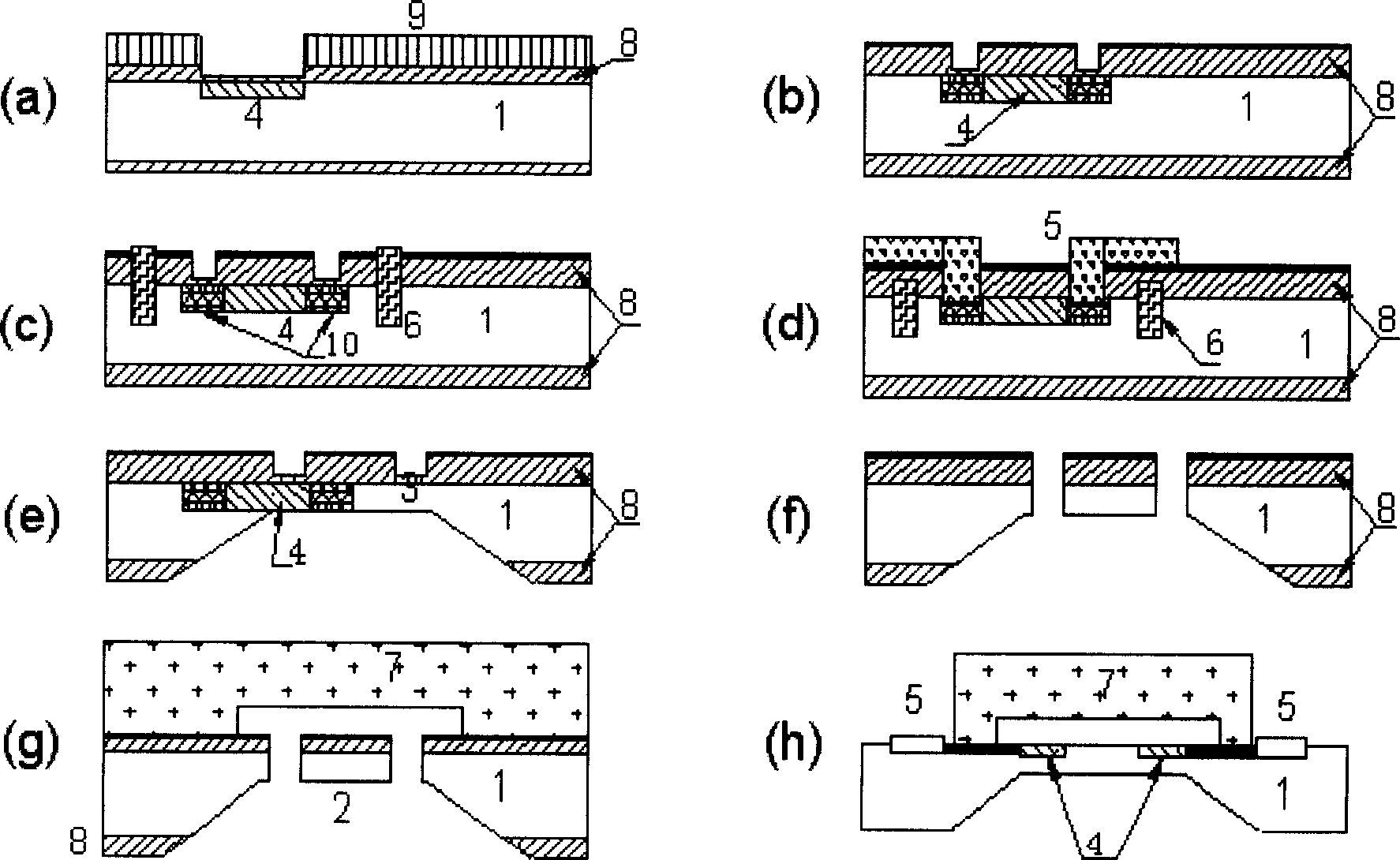

[0026] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings of the present invention.

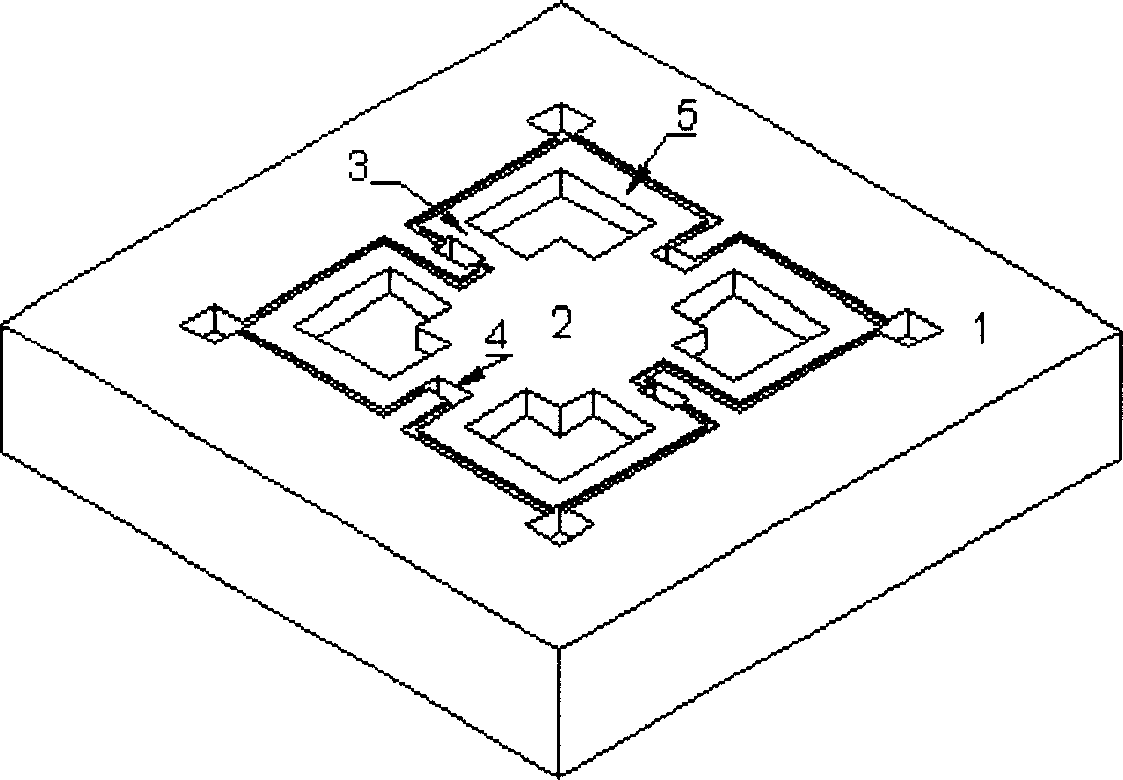

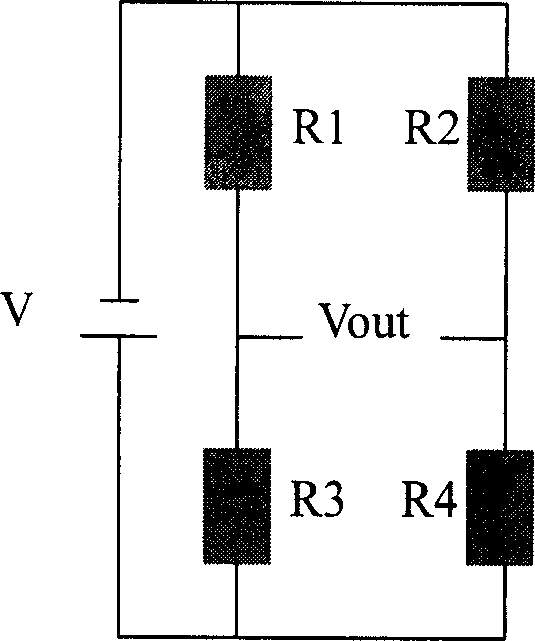

[0027] figure 1 Shown is a structural schematic diagram of the accelerometer of the present invention, the whole structure includes a sensitive mass, four beams, piezoresistors on the beams, metal wiring and welding points, and a silicon substrate.

[0028] The functions and connections of each part are as follows:

[0029] 1) Sensitive mass 2, when the accelerometer is subjected to an impact in a sensitive direction, the inertia of the mass 2 will cause displacement and deformation of the mass 2 relative to the silicon substrate 1 .

[0030] 2) Four crossbeams 3, the crossbeams 3 are used as the supporting arms of the mass block 2, and at the same time as the preparation area of the piezoresistor. When the impact occurs, the mass block 2 pulls the beam 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com