Technology and tool for reducing deformation of annular casting thin-walled part after machining and casting

A thin-walled parts processing and thin-walled parts technology, which is applied in the field of thin-walled ring parts processing, can solve the problems of high assembly and sealing requirements, seal failure, and easy ellipse, and achieve the elimination of deformation stress, good sealing performance, and reduced deformation of ellipse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A process method for reducing post-processing deformation of annular cast thin-walled parts, specifically as follows:

[0050] Increase the fixed position of the pressure plate

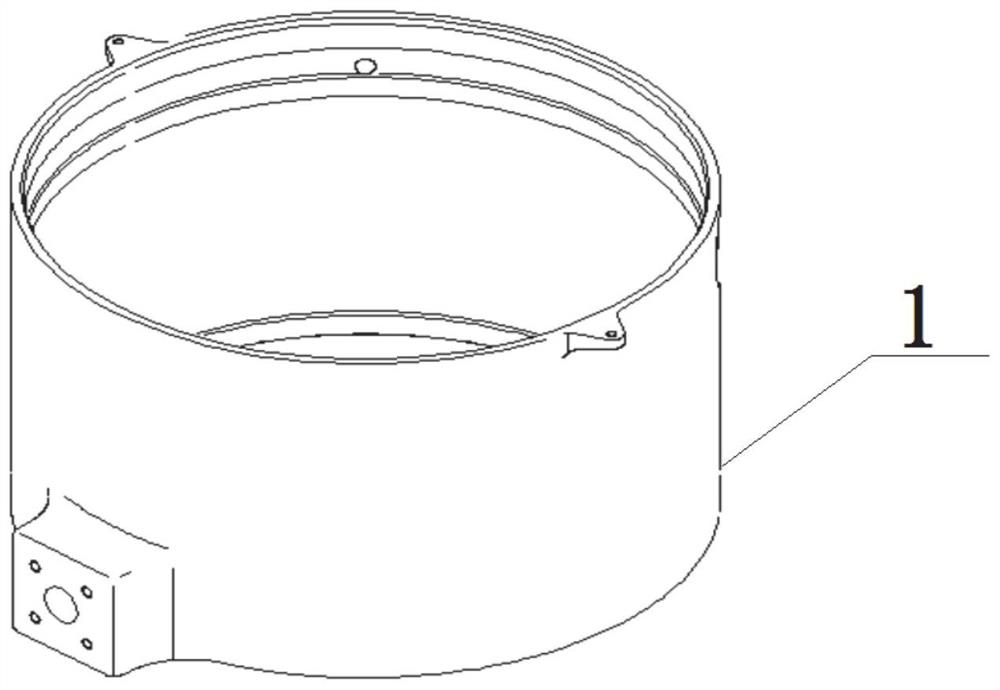

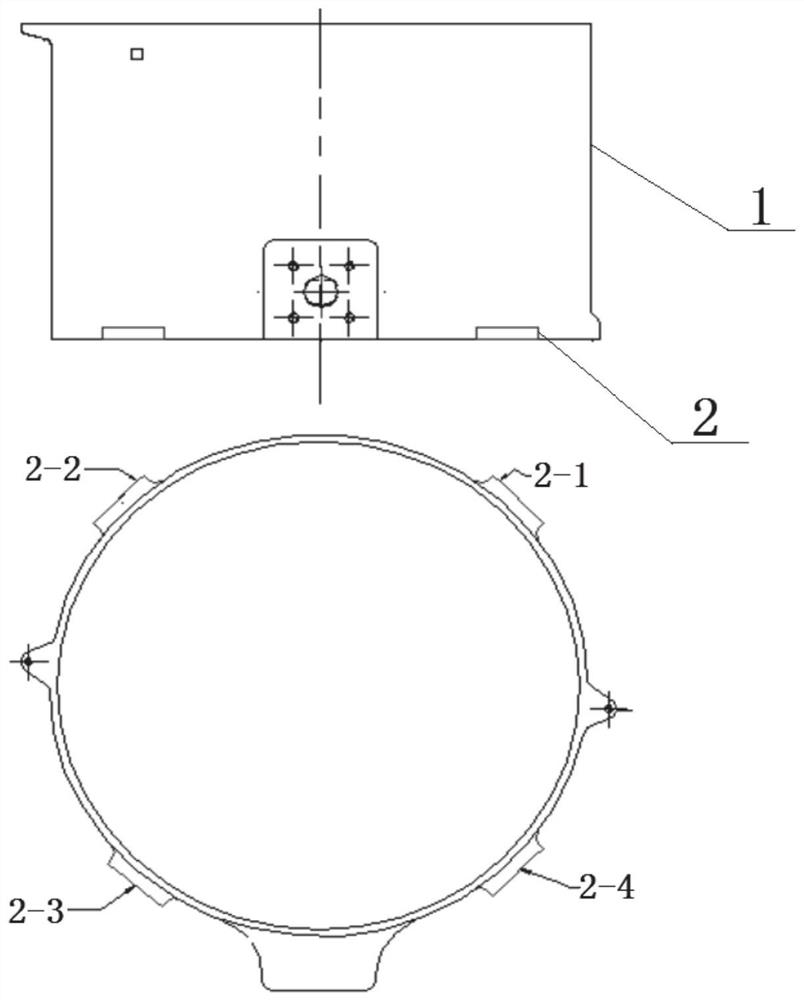

[0051] as follows figure 1 As shown for the ring structure without clamping position, as follows figure 2 The red parts 1-4 shown in the figure change the product structure by casting. Add a briquetting structure near the lower part of the product body and increase the clamping position. The briquetting position must be evenly distributed along the circumferential direction.

[0052] Elimination of casting internal stress method: The surface of the cast thin-walled parts is cleaned by falling sand. And further through the surface sand blasting treatment, after sand blasting, let it stand for at least 7 days of natural aging to eliminate the internal stress of casting.

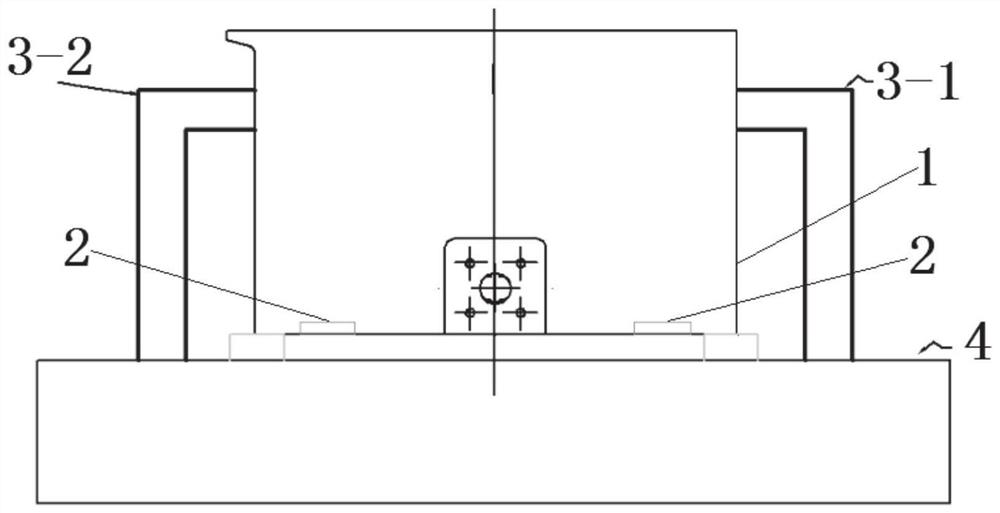

[0053] Attached below image 3 Four lateral supports are added symmetrically in the middle, and the support position in t...

Embodiment 2

[0059] A tool for reducing the deformation of ring-shaped cast thin-walled parts after processing, including: a pressure block 2, a lateral support 3, there are multiple pressure blocks 2, and a plurality of lateral supports 3, and the position of the pressure block 2 is cast along the ring The thin-walled parts 1 are evenly distributed in the circumferential direction; the lateral supports 3 are symmetrically arranged around the ring-shaped cast thin-walled part 1 and are in an inverted L shape.

[0060] Compared with the direct top pressing method, the method of adding lateral support 3 and casting body pressing block 2 can minimize the problem of deformed ellipse caused by pressing.

Embodiment 3

[0062] A tool for reducing the deformation of ring-shaped cast thin-walled parts after processing, including: a pressure block 2, a lateral support 3, there are multiple pressure blocks 2, and a plurality of lateral supports 3, and the position of the pressure block 2 is cast along the ring The thin-walled parts 1 are evenly distributed in the circumferential direction; the lateral supports 3 are symmetrically arranged around the ring-shaped cast thin-walled part 1 and are in an inverted L shape.

[0063] The support position in the installation height direction of the lateral support 3 is close to the processing position of the inner diameter of the annular cast thin-walled part 1 . In order to better eliminate the influence of inner diameter processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com