Preparation process of high-strength aluminum alloy plate and aluminum alloy plate

An aluminum alloy plate and a preparation process technology, applied in the field of aluminum alloy plate, can solve the problems of inability to satisfy the manufacturing and forming process of automobile structural parts, poor stamping performance, etc., and achieve the advantages of promoting dynamic recrystallization, reducing stress, and improving stamping performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

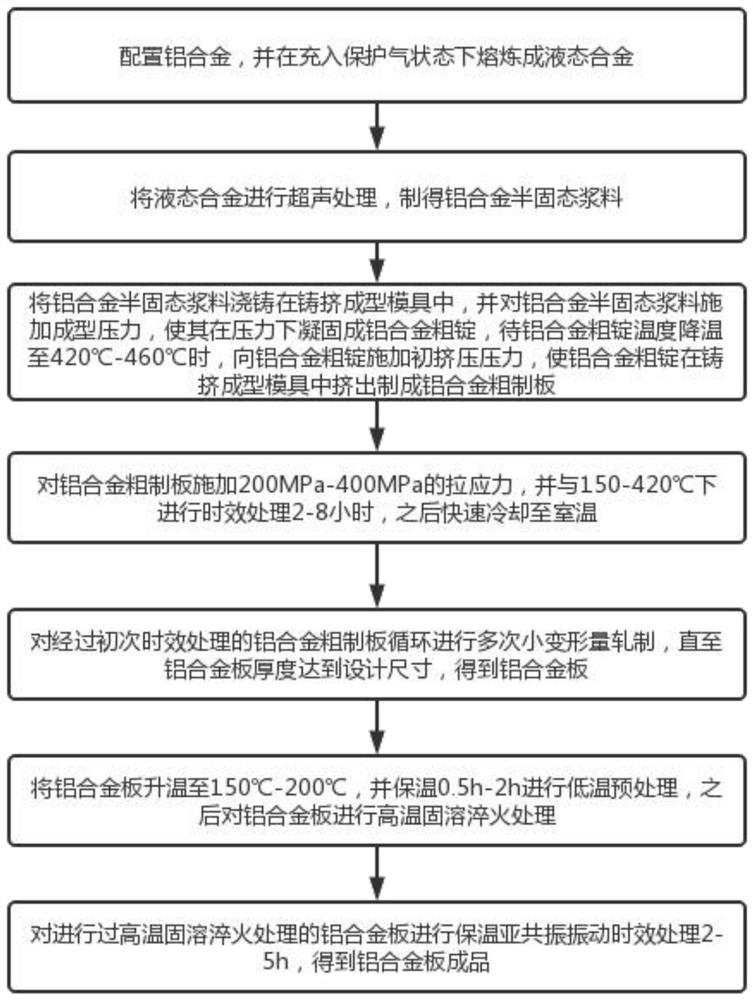

Method used

Image

Examples

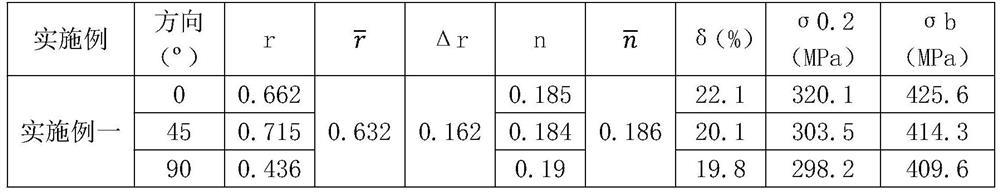

Embodiment 1

[0038] In this embodiment: the composition ratio of the aluminum alloy is: Zn: 4.5%, Mg: 2.0%, Cu: 1.0%, Ni: 0.06%, Ti: 0.05%, Y: 0.02%, Zr: 0.02%, and the balance is Al

[0039] Heating: raise the temperature of the furnace to 500°C and keep it for a period of time. After the furnace temperature is stable, raise the furnace temperature to 780°C-800°C;

[0040] Metal ingot melting: Weigh the metal ingot according to the alloy ratio, put the metal ingot in the drying furnace for preheating and drying, then first add pure aluminum into the furnace, and simultaneously feed SF into the furnace 6 and N 2 Mix the protective gas, after the pure aluminum is completely melted, add the remaining metal ingots to the furnace, and stir the liquid alloy for 30s-45s to fully mix the alloy components;

[0041] Static removal of impurities: put the molten alloy in a liquid state for 30min-45min, and remove the oxide film on the surface of the liquid alloy;

[0042] Ultrasonic treatment: tra...

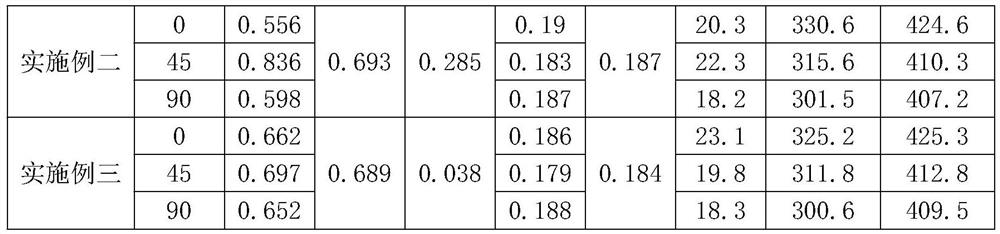

Embodiment 2

[0050] In this embodiment: the composition ratio of the aluminum alloy is: Zn: 5.2%, Mg: 1.2%, Cu: 1.8%, Ni: 0.02%, Ti: 0.15%, Y: 0.01%, Zr: 0.05%, and the balance is Al

[0051] Heating: raise the temperature of the furnace to 500°C and keep it for a period of time. After the furnace temperature is stable, raise the furnace temperature to 780°C-800°C;

[0052] Metal ingot melting: Weigh the metal ingot according to the alloy ratio, put the metal ingot in the drying furnace for preheating and drying, then first add pure aluminum into the furnace, and simultaneously feed SF into the furnace 6 and N 2 Mix the protective gas, after the pure aluminum is completely melted, add the remaining metal ingots to the furnace, and stir the liquid alloy for 30s-45s to fully mix the alloy components;

[0053] Static removal of impurities: put the molten alloy in a liquid state for 30min-45min, and remove the oxide film on the surface of the liquid alloy;

[0054] Ultrasonic treatment: tra...

Embodiment 3

[0062] Embodiment two:

[0063] In this embodiment: the composition ratio of the aluminum alloy is: Zn: 4.8%, Mg: 1.6%, Cu: 1.5%, Ni: 0.06%, Ti: 0.08%, Y: 0.02%, Zr: 0.05%, and the balance is Al

[0064] Heating: raise the temperature of the furnace to 500°C and keep it for a period of time. After the furnace temperature is stable, raise the furnace temperature to 780°C-800°C;

[0065] Metal ingot melting: Weigh the metal ingot according to the alloy ratio, put the metal ingot in the drying furnace for preheating and drying, then first add pure aluminum into the furnace, and simultaneously feed SF into the furnace 6 and N 2 Mix the protective gas, after the pure aluminum is completely melted, add the remaining metal ingots to the furnace, and stir the liquid alloy for 30s-45s to fully mix the alloy components;

[0066] Static removal of impurities: put the molten alloy in a liquid state for 30min-45min, and remove the oxide film on the surface of the liquid alloy;

[0067]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com