Storage tank barrel section integrated forming method and integrated storage tank barrel section

A barrel section and storage tank technology, which is applied in the field of spacecraft, can solve problems such as unsuitable aluminum alloys, and achieve the effects of improving reliability, high product dimensional accuracy, and high product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for integrally forming the barrel section of the storage tank according to the present invention comprises the following steps:

[0044] The first is the billet making process, using the casting ring rolling process to process the original billet; or using the coil welding process to roll the flat plate into a billet, and carry out non-destructive testing on the weld.

[0045] Specifically, the billet making process is divided into two technological solutions:

[0046] Option One:

[0047] 1) The hollow aluminum alloy ingot is used as the original billet, and the ingot is heated;

[0048] 2) Using a numerically controlled ring rolling mill, the heated hollow aluminum alloy ingot is rolled and deformed, so that the diameter of the billet is increased to the target size φ, the length is increased to H, and the material state is an annealed state.

[0049] Option II:

[0050]1) Using the numerical control roll bending process, the plate (material state is annea...

Embodiment 2

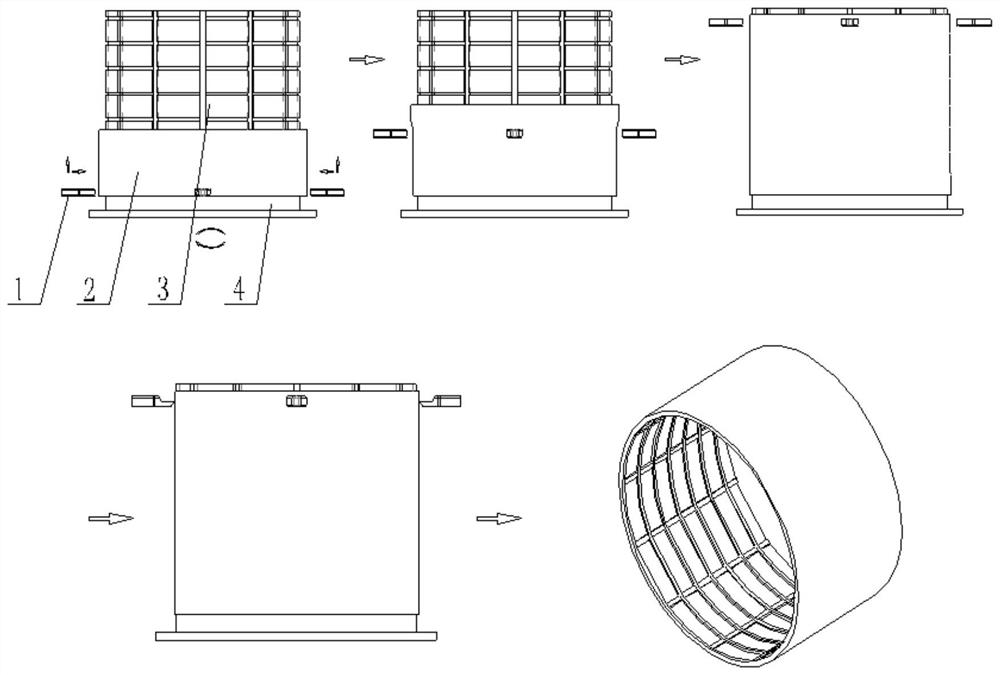

[0065] Such as figure 1 A schematic diagram of a method for integrally forming a storage tank section is shown, including the following steps:

[0066] 1) Obtain the original shell 2 by processing the billet making process described above;

[0067] 2) Install the spinning mold 3 with split structure, insert the original tube blank 2 into the spinning mold 3, and install it on the spinning base 4, start the spinning forming equipment, and put the four spinning wheels 1 into to the billet;

[0068] 3) Through the axial and normal movement of the four spinning wheels 1, the tube blank is fed in the axial direction to increase its length; the tube blank material is pressed into the groove of the spinning die 3 by feeding in the normal direction;

[0069] 4) When the material thinning rate of the original tube blank 2 increases to 5%, the spinning die 3 is removed, and the original tube blank 2 is subjected to stress relief annealing treatment;

[0070] 5) Continue to install th...

Embodiment 3

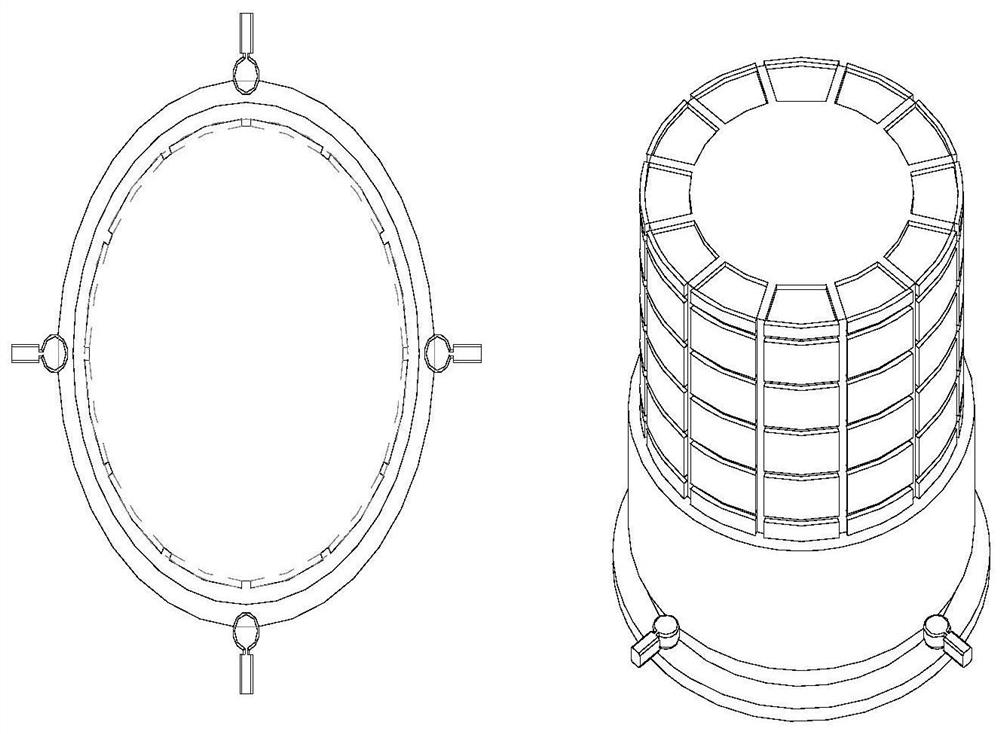

[0077] The invention also discloses an integrated storage tank barrel segment, which is prepared by adopting the above-mentioned integrated forming method of the storage tank barrel segment.

[0078] The integrated storage tank barrel section described in embodiment 3 utilizes the integrated forming method of the storage tank barrel section described in embodiment 1 or embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com