Manufacturing process for thin-wall metal hollow rotor cup

A technology of hollow rotor and manufacturing process, which is applied in the field of manufacturing process of metal hollow rotor cup, which can solve the problems affecting product qualification rate, poor cup roundness, uneven wall thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] The preparation method of the present invention is as follows:

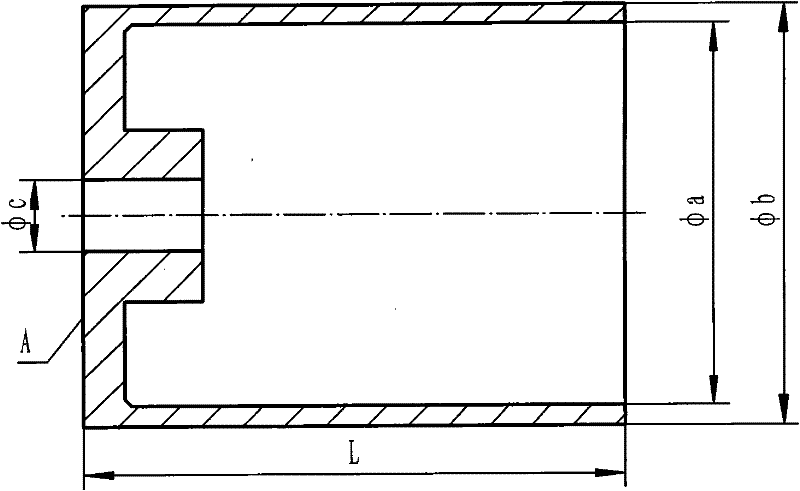

[0016] 1) First, the annealed bar is roughly turned to obtain a hollow rotor cup with an outer diameter of φb, an inner diameter of φa and an inner hole of φc (see figure 1 ), and then low-temperature annealing treatment to eliminate stress;

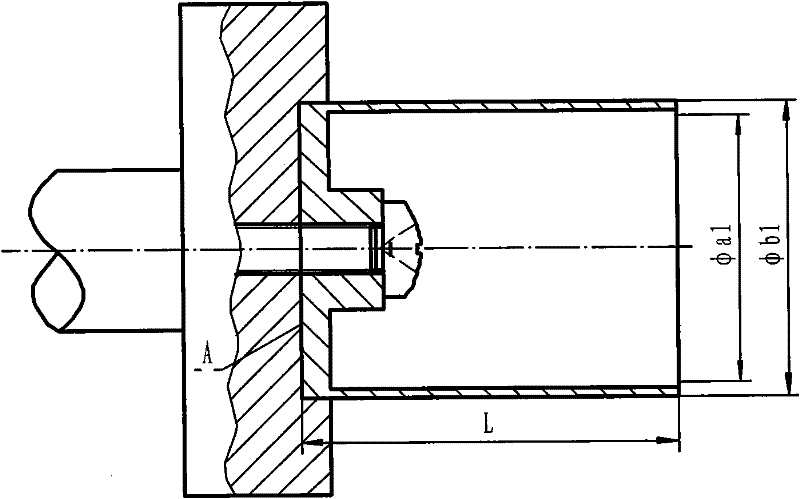

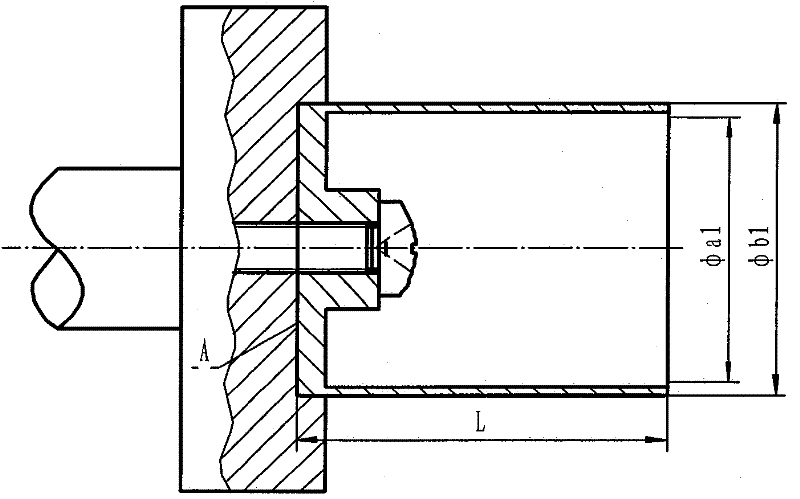

[0017] 2) Clamp the outer circle φb of the rotor cup with a spring chuck, and process the end face A of the rotor cup so that the total length L of the rotor cup has a machining allowance of 0.8mm to 1mm;

[0018] 3) Position the end face A and the outer circle φb, and tighten the screws. According to the actual processing size requirements, the inner circle φa of the rotor cup is finely turned in place with a diamond tool so that the inner diameter is φa1, and then the inner circle is tested with a pneumatic plug gauge. The actual measurement tole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com