Differential type horizontal micro-force measuring device and measuring method thereof

A measuring device, differential technology, applied in the field of measurement, can solve problems such as gravity and temperature structure design, micro force value not established, micro force calibration or measurement influence, etc., to achieve easy processing and manufacturing, and eliminate lever deformation , precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

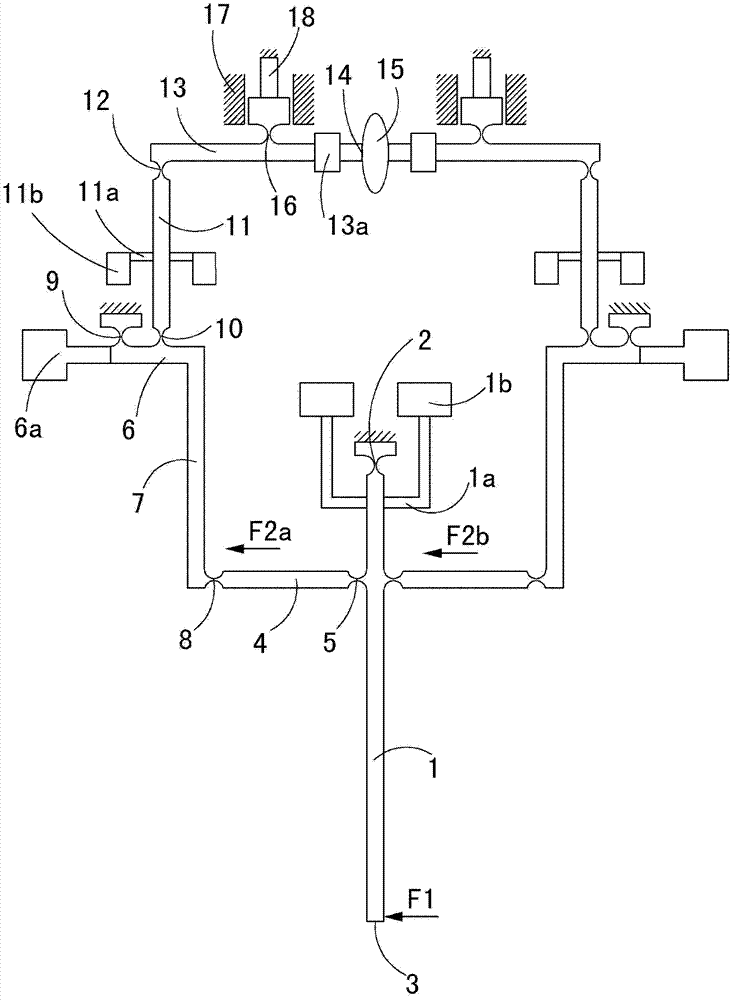

[0025] see figure 1 , figure 2 In this embodiment, the differential horizontal micro-force measuring device is based on the vertically arranged primary lever 1 as the central rod, and in the same vertical plane, a pair of secondary levers are symmetrically located on both sides of the primary lever 1, and Connect with the secondary lever 1 through the primary transition rod 4 on one side respectively, and a pair of secondary levers are connected with the tertiary lever 13 on the respective side through the secondary transition rod 11 respectively;

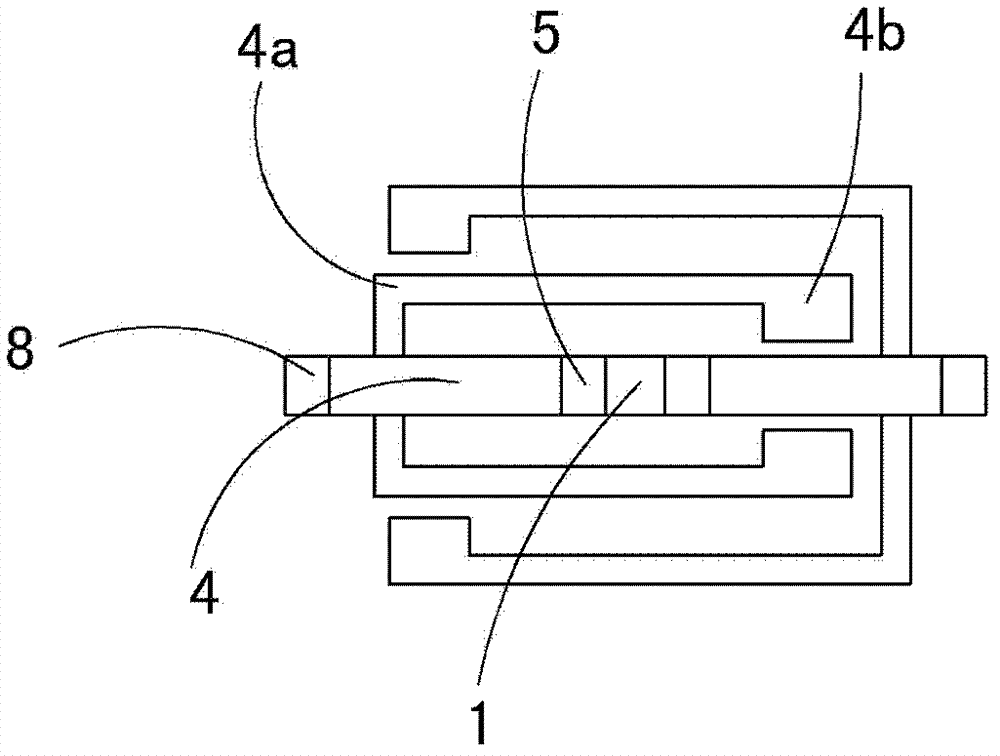

[0026] The first level lever 1 is a straight rod, the top of the straight rod is the first level fulcrum 2, the bottom end of the straight rod is the free end 3 as the input end, the measured micro force F1 is loaded on the free end 3 of the straight rod; the middle of the first level lever 1 Connect with the inner end of the primary transition rod 4 symmetrically located on both sides through the primary flexible hinge 5;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com