External wall heat preservation formwork and production method thereof

An external wall insulation and production method technology, applied in the field of building insulation, can solve problems such as hidden dangers, increased hidden dangers, and different shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

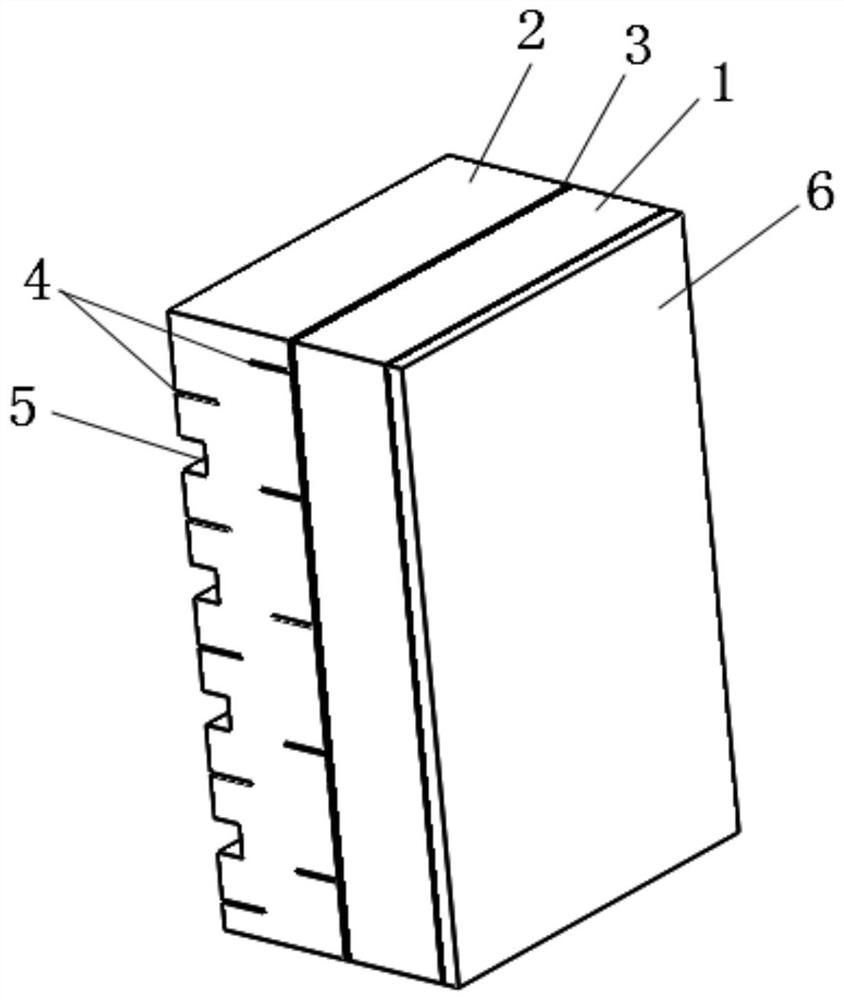

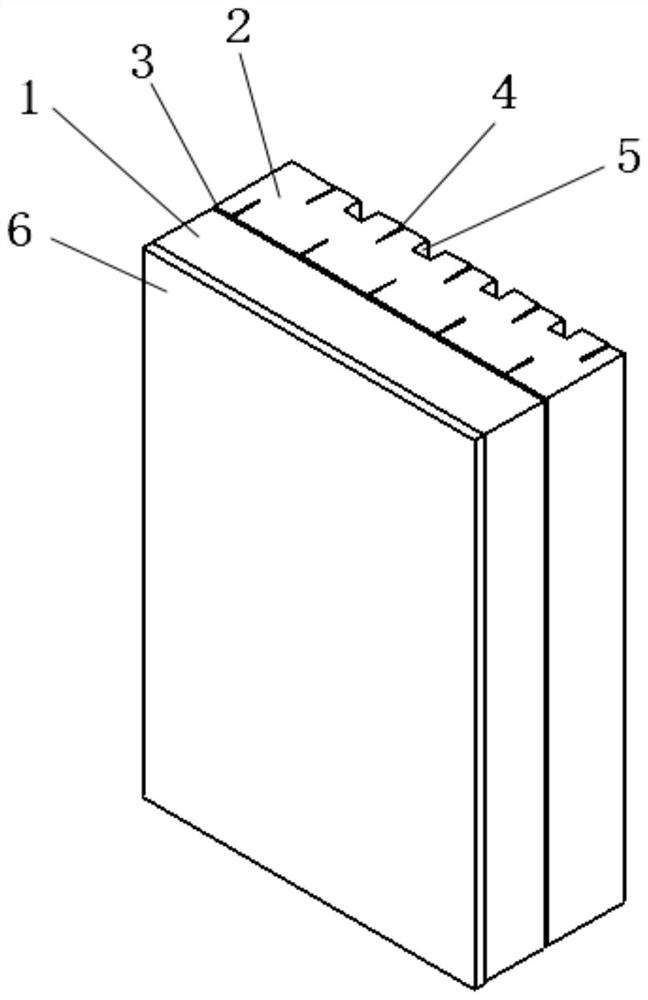

[0035] Such as Figure 1 to Figure 4 As shown, this specific embodiment provides a thermal insulation formwork for external walls, including an inorganic-wrapped organic particle layer 1 and an organic thermal insulation layer 2, the organic thermal insulation layer 2 is located on one side of the inorganic-wrapped organic particle layer 1, and the inorganic-wrapped organic particle layer 1 A grid cloth 3 is arranged between the organic insulation layer 2, and the inorganic-wrapped organic particle layer 1, the grid cloth 3, and the organic thermal-insulation layer 2 are of an integrated structure, and the thickness of the inorganic-wrapped organic particle layer 1 is preferably 3-5 cm. The thickness of the organic insulation layer 2 is designed according to the actual situation. By compounding mesh cloth between the inorganic-wrapped organic particle layer and the organic insulation layer, a reinforcement layer is formed between the inorganic-wrapped organic particle layer an...

specific Embodiment approach 2

[0042] This specific embodiment provides a production method of the external wall thermal insulation template described in specific embodiment 1, which mainly includes the following steps: firstly produce the whole large inorganic-wrapped organic particle layer 1 by means of compression molding, and then cut it into small pieces A block of inorganic-wrapped organic particle layer 1 is combined with a small piece of inorganic-wrapped organic particle layer 1 with mesh cloth 3 and an organic insulation layer 2; specifically, a layer of adhesive is applied on the surface of the inorganic-wrapped organic particle layer 1 materials, and then spread the mesh cloth 3, and then compound the organic insulation layer 2 on the surface to bond the two together; The grid cloth 3, and compound the inorganic-wrapped organic particle layer 1 on this surface, so that the two are bonded into one; in this solution, the bonding material is preferably bonding mortar. Production of large inorganic-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com