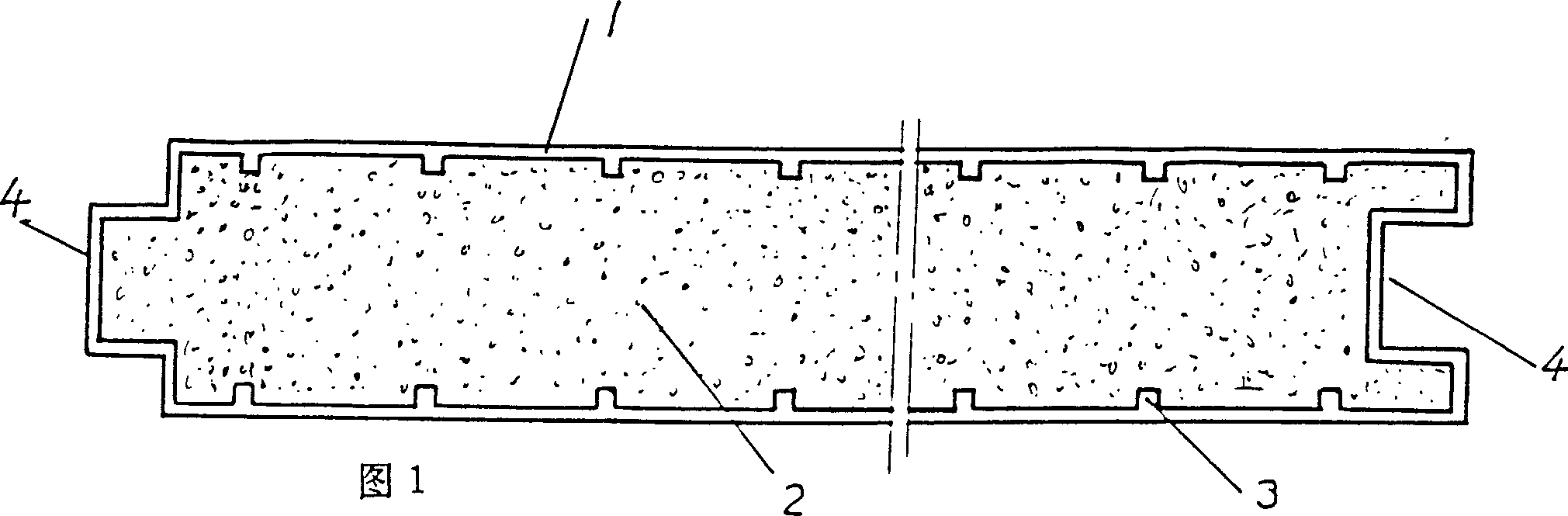

New type heat insulating plater, abnormal shape plate and its manufacturing method

A manufacturing method and a technology for profiled materials, which are applied in the field of building decoration materials, can solve the problems of poor corrosion resistance, cold resistance and flame retardancy, low density of structure, complicated installation process, etc., and achieve good corrosion resistance, cold resistance and flame retardancy. Low, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A. Raw material components and proportions of plastic hollow shapes: (by weight) calculus powder 60

[0020] PVC 30

[0021] Auxiliary 10

[0022] The additives are composed according to the following raw material components and proportions: (parts by weight) chlorinated paraffin 0.6, barium stearate 0.6, lead stearate 0.6, dioctyl phthalate 13, dibutyl phthalate 1.2, chlorinated polyethylene 0.4, tri-salt 2.4, di-salt 0.8, stearic acid 2.

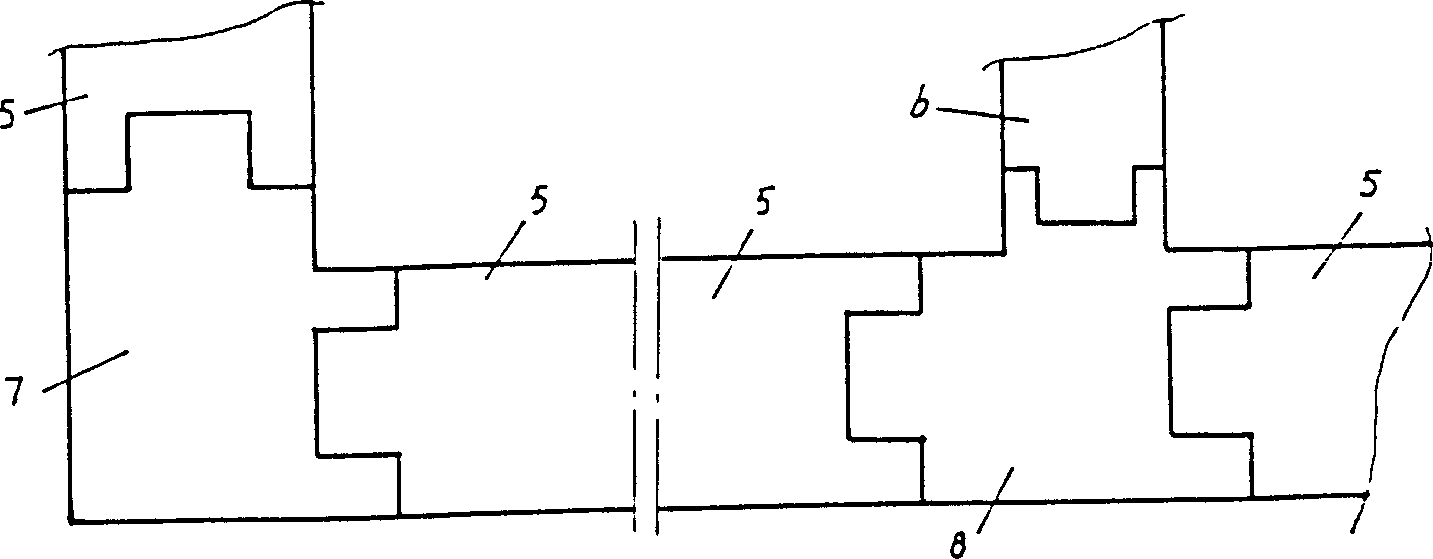

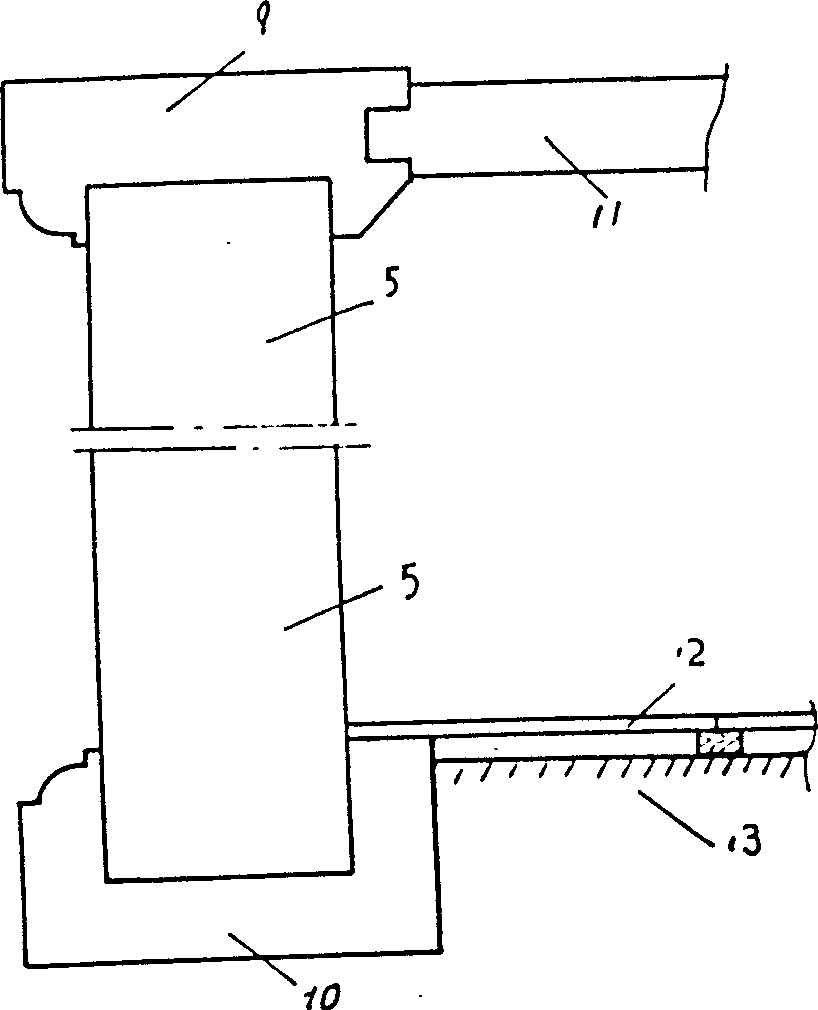

[0023] B. Manufacturing method: mix the raw materials of calculus powder, polyvinyl chloride, and additives according to the ratio and then knead them in a kneader. The kneading temperature is 110-120°C, and the kneading time is 30-35 minutes; The granulator extrudes pellets under high temperature at 170-180°C and high pressure; then put the pellets into the extruder at an extrusion temperature of 175-210°C, and extrude plastic holl...

Embodiment 2

[0025] A. Raw material components and proportions of plastic hollow shapes: (by weight) calculus powder 50

[0026] PVC 35

[0027] Auxiliary 12

[0028] The additives can be composed according to the following raw material components and proportions: (by weight) chlorinated paraffin 0.6, barium stearate 0.6, lead stearate 0.6, dioctyl phthalate 13, dibutyl phthalate Butter 1.2, chlorinated polyethylene 0.4, trisalt 2.4, disalt 0.8, stearic acid 2.

[0029] B, manufacturing method are the same as embodiment 1.

Embodiment 3

[0031] A. Raw material components and proportions of plastic hollow shapes: (by weight) calculus powder 40

[0032] PVC 40

[0033] Auxiliary 14

[0034] The additives can be composed according to the following raw material components and proportions: (by weight) chlorinated paraffin 0.6, barium stearate 0.6, lead stearate 0.6, dioctyl phthalate 13, dibutyl phthalate Butter 1.2, chlorinated polyethylene 0.4, trisalt 2.4, disalt 0.8, stearic acid 2.

[0035] B, manufacturing method are the same as embodiment 1.

[0036] According to chemical performance testing, the novel insulation board and profiled material of the present invention: heating dimensional change rate (%), ± 2.5; tensile strength (MPa) ≥ 13.0; drop hammer impact 0.5kg, r = 30mm, h = 0.5m Burst; impact strength (KJ / m 2 )≥14.0; Vicat softening point (℃)≥80.0. Tests and trials have proved that the product of the present invention has high hardne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com