Touch electrode structure, touch screen and display device

A technology of touch electrodes and display devices, which is applied in the fields of electrical digital data processing, instruments, calculations, etc., and can solve the problems of difficult design of touch electrodes in display area/touch area, incomplete coverage of touch electrodes, poor linearity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

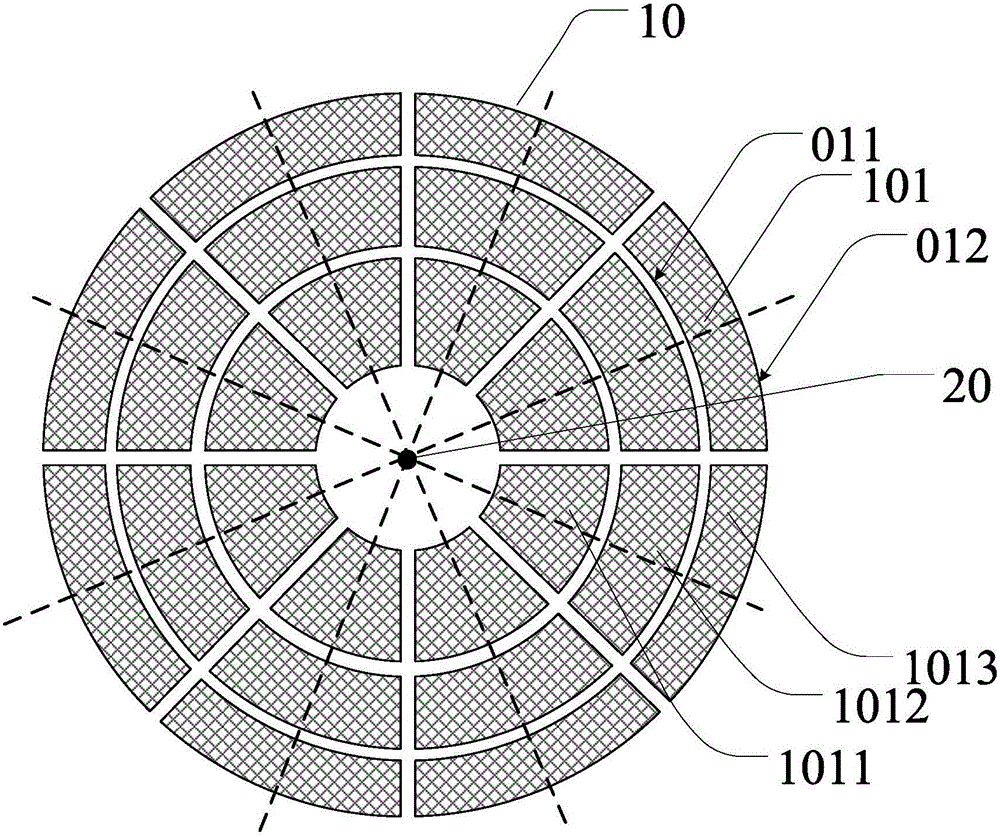

[0054] This embodiment provides a touch electrode structure, such as figure 2 As shown, a plurality of touch electrode groups 10 are included, and the plurality of touch electrode groups 10 are arranged around a center 20 . Each touch electrode group 10 includes a plurality of touch electrodes 101 . A plurality of touch electrodes 101 in each touch electrode group 10 are respectively arranged from a place close to the center 20 to a direction away from the center 20, and the size of the end 012 away from the center of each touch electrode 101 along the circumferential direction is larger than that of the touch electrode 101. The dimension of the end 011 near the center along the circumferential direction.

[0055] figure 2 8 touch electrode groups 10 are shown in , and each touch electrode group 10 includes 3 touch electrodes 101 . It should be noted, figure 2 It is only a schematic illustration, and the touch electrode groups and the number of touch electrodes included...

Embodiment 2

[0078] In Embodiment 1 and the examples described therein, each touch electrode structure may further include a central touch electrode 102 , and the central touch electrode 102 may be located at the center 20 .

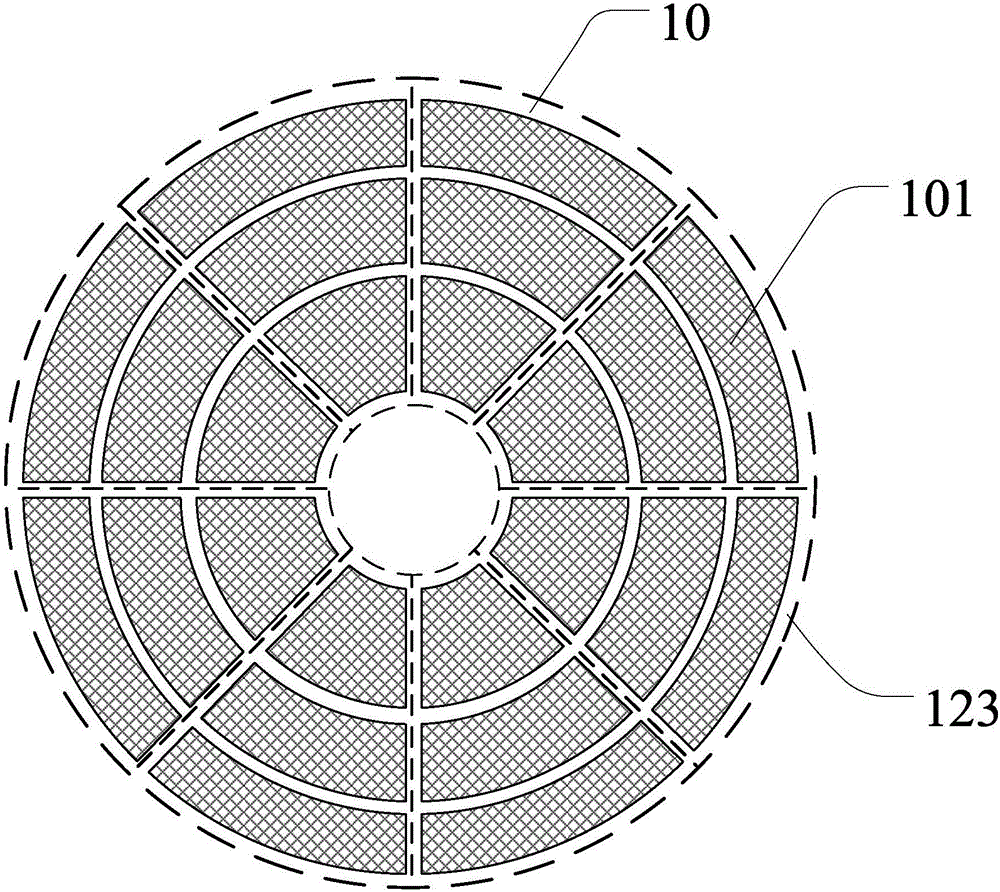

[0079] Such as Figure 5a As shown, the central touch electrode 102 and each touch electrode 101 in the plurality of touch electrode groups 10 cover a circular area.

[0080] Such as Figure 5b As shown, the central touch electrode 102 and each touch electrode 101 in the plurality of touch electrode groups 10 cover a fan-shaped area.

[0081] For example, the central touch electrode 102 and each touch electrode 101 in the plurality of touch electrode groups 10 may also cover a polygonal area.

[0082] It should be noted that the area covered by the central touch electrode 102 and the touch electrodes 101 in the plurality of touch electrode groups 10 is not limited to the above examples, and can be determined according to the number of touch electrode groups 10 and ...

Embodiment 3

[0087] In the touch electrode structure described in any of the above-mentioned embodiments and examples, for example, as Figure 6a , 6b , 6e, may also include a plurality of wires 111 (such as Figure 6e shown), each touch electrode 101 can be connected to each wire 111 through the transfer hole 151, wherein each touch electrode 101 in each touch electrode group 10 is electrically connected to each wire 111 for input / output signal . Figure 6a , 6b is a plan view of the touch electrode structure, Figure 6e for Figure 6a A-A' section view in . It should be noted that each touch electrode 101 can also be arranged on the same layer as each wire 111 and be directly connected to each other. There is no limit to this.

[0088] For example, if Figure 6a with Figure 6e As shown, a plurality of wires 111 are disposed on the base substrate 100 , an insulating layer 114 is disposed on the layer where the plurality of wires 111 are located, and a plurality of via holes 151 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com