Method for preparing metal-ceramic composite material

A technology for ceramic composite materials and ceramic slurry is applied in the preparation of metal-ceramic composite materials and the field of composite material preparation, and achieves the effects of good chemical stability, good application prospects and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

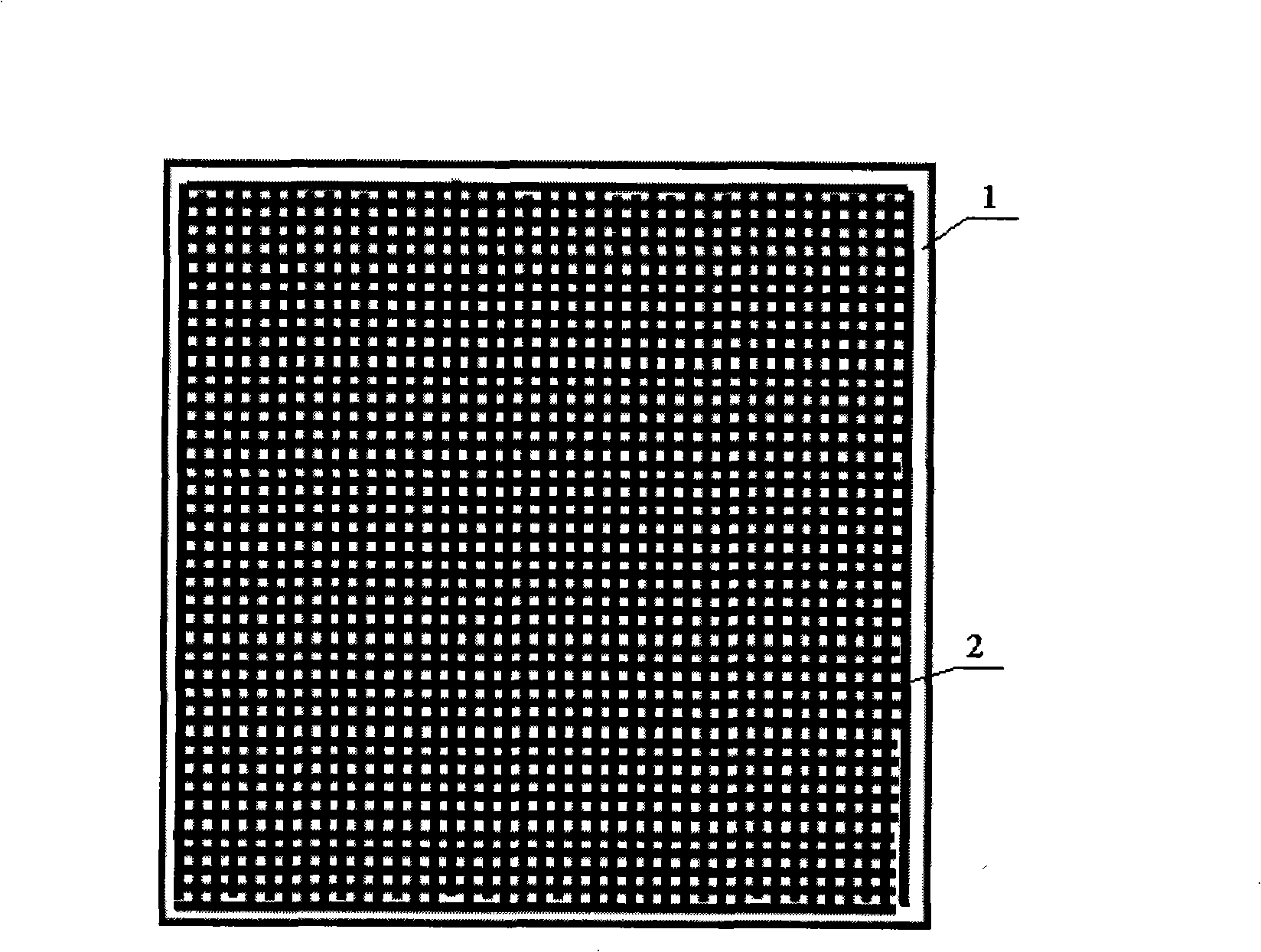

[0041] According to volume percentage, take Al with a particle size of 0.1 μm to 50 μm 2 o 3 Powder 30%, binder polyvinyl butyral solution 40%, solvent ethanol 30%, mix evenly, vacuum degass and sieve, and make ceramic slurry; according to volume percentage, the particle size is 0.1μm~ 70% of 50 μm Ni powder, 30% of a mixture of rosin turpentine, castor oil and terpineol, mixed evenly, and after vacuum degassing and sieving, prepared Ni screen printing slurry; the ceramic slurry was prepared by tape casting method The material is cast into a green body with a thickness of 50 μm, and the Ni screen printing slurry is printed on the ceramic green body with a screen printing machine, and a metal Ni mesh is formed on the surface of the ceramic green body, and the mesh of the Ni mesh is 10. ×10μm, interval 200μm, thickness 100μm, made of Ni mesh Al 2 o 3 Composite green bodies, which are stacked in sequence to obtain a laminate, which is heat-sealed under the conditions of a temp...

Embodiment 2

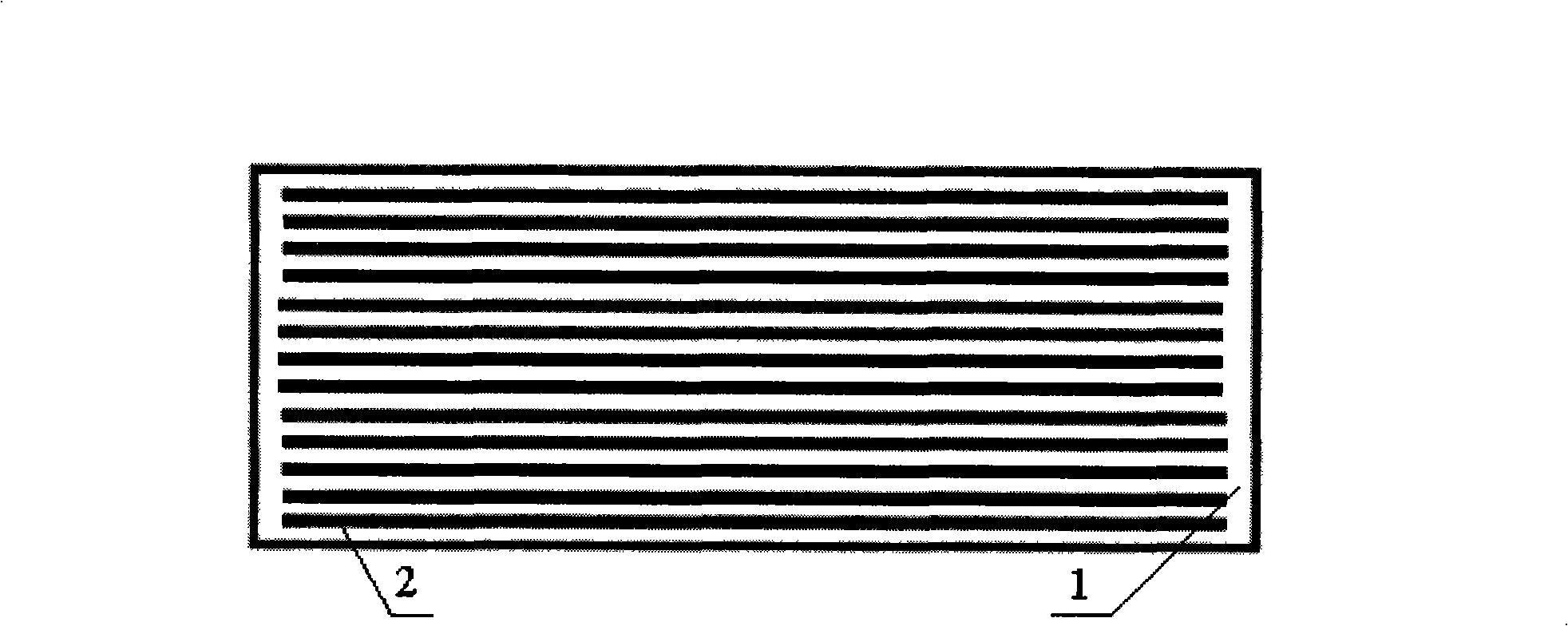

[0046] According to volume percentage, take TiO with a particle size of 0.1 μm to 50 μm 2 Powder 70%, binder polyvinyl alcohol solution 10%, solvent deionized water 20%, mix evenly, vacuum degass and sieve, and make ceramic slurry; according to volume percentage, the particle size is 0.1μm~ Mix 30% of 50 μm Cu powder, 70% mixture of terpineol and ethyl cellulose to prepare Cu screen printing slurry; cast the ceramic slurry into a green body with a thickness of 100 μm by tape casting method, and use a screen The printing machine prints the Cu screen printing paste on the ceramic green body, and forms Cu stripes on the surface of the ceramic green body. The stripe width is 100 μm, the interval is 300 μm, and the thickness is 50 μm. 2 Composite green body, the composite green body is laminated in order to obtain a layered object, and the layered object is heat-sealed under the conditions of a temperature of 400 ° C and a pressure of 50 MPa, so that the TiO 2 The layers are conne...

Embodiment 3

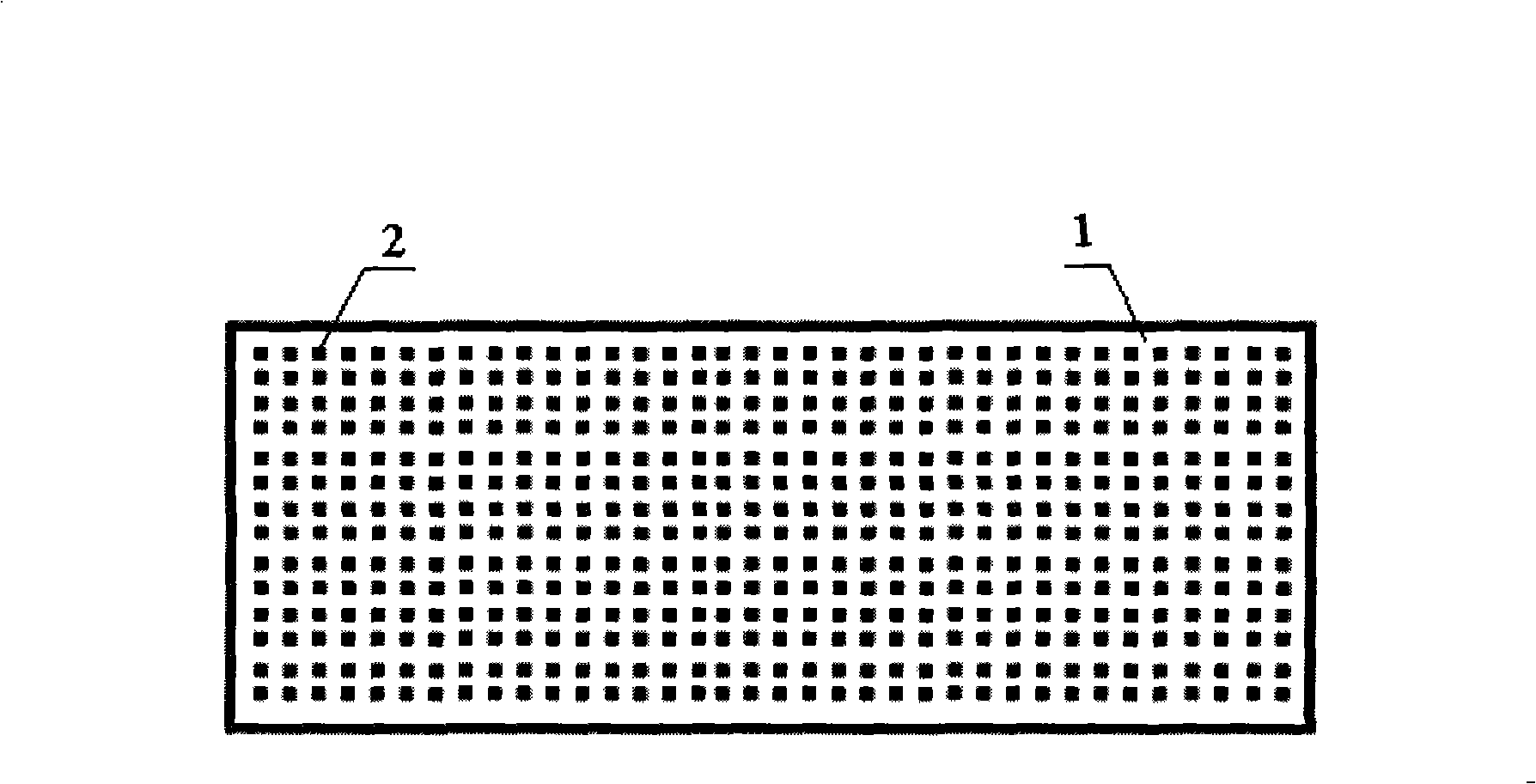

[0051] According to volume percentage, ZrO with a particle size of 0.1 μm to 50 μm is taken 2 Powder 30%, binder methyl cellulose solution 10%, solvent ethanol 60%, mix to make ceramic slurry; according to volume percentage, take 50% of SUS316L stainless steel powder with a particle size of 0.1 μm to 50 μm, rosin turpentine, castor Mix 50% of the mixture of sesame oil and terpineol to prepare stainless steel screen printing slurry; the ceramic slurry is cast into a green body with a thickness of 200 μm by tape casting method, and the stainless steel screen printing slurry is coated with a screen printing machine. The material is printed on the ceramic green body, and S-shaped stainless steel stripes are formed on the surface of the ceramic green body. The stripe width is 300 μm, the interval is 400 μm, and the thickness is 100 μm. It is made of stainless steel / ZrO 2 Composite green body, the composite green body is stacked in order to obtain a layered object, and the layered o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com