Abnormal shape box column and processing craft thereof

A processing technology and special-shaped box technology, which is applied in the field of steel structure manufacturing, can solve the problems that can not really meet the needs of builders and customers, affect the installation of external connectors, and have a long construction period, and achieve good protection. Support and stability, good anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

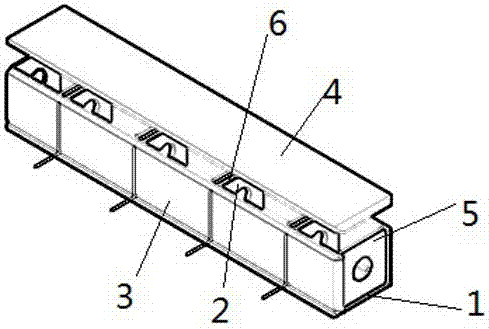

[0043] A special-shaped box-shaped column as shown in the figure, including: a panel 1, a partition 2, a web 3 and an upper flange 4;

[0044] The relationship between the above components is as follows:

[0045] The partition 2 is arranged on the panel 1, the web 3 is arranged on both sides of the partition 2, and is fixedly connected with the panel 1, the upper flange 4 is arranged above the two webs 3, and the panel Both ends of 1 are provided with process partitions 5, and the partitions 2 cooperate with the web 3 and the upper flange 4.

[0046] In this embodiment, the inner side of the web 3 is provided with a groove, and the groove is matched with the partition plate 2 .

[0047] In this embodiment, a sheath is provided in the groove, and a texture is provided on the sheath.

[0048] In this embodiment, lining boards 6 are provided on both sides of the partition board 2 , and the lining boards 6 are higher than the partition board 2 .

Embodiment 2

[0050] A special-shaped box-shaped column as shown in the figure, including: a panel 1, a partition 2, a web 3 and an upper flange 4;

[0051] The relationship between the above components is as follows:

[0052] The partition 2 is arranged on the panel 1, the web 3 is arranged on both sides of the partition 2, and is fixedly connected with the panel 1, the upper flange 4 is arranged above the two webs 3, and the panel Both ends of 1 are provided with process partitions 5, and the partitions 2 cooperate with the web 3 and the upper flange 4.

[0053] In this embodiment, the inner side of the web 3 is provided with a groove, and the groove is matched with the partition plate 2 .

[0054] In this embodiment, a sheath is provided in the groove, and a texture is provided on the sheath.

[0055] In this embodiment, lining boards 6 are provided on both sides of the partition board 2 , and the lining boards 6 are higher than the partition board 2 .

[0056] The processing technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com