Steel tube-I beam combination steel tube concrete special-shaped columns and manufacture method thereof

A technology of combining steel pipes and I-beams, applied in the directions of columns, piers, pillars, etc., can solve the problems of reducing the bearing capacity of components, poor shear and torsional bearing capacity, and easy premature buckling, so as to improve the bearing capacity and Seismic capacity, improved bearing capacity and ductility, effect of preventing premature buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

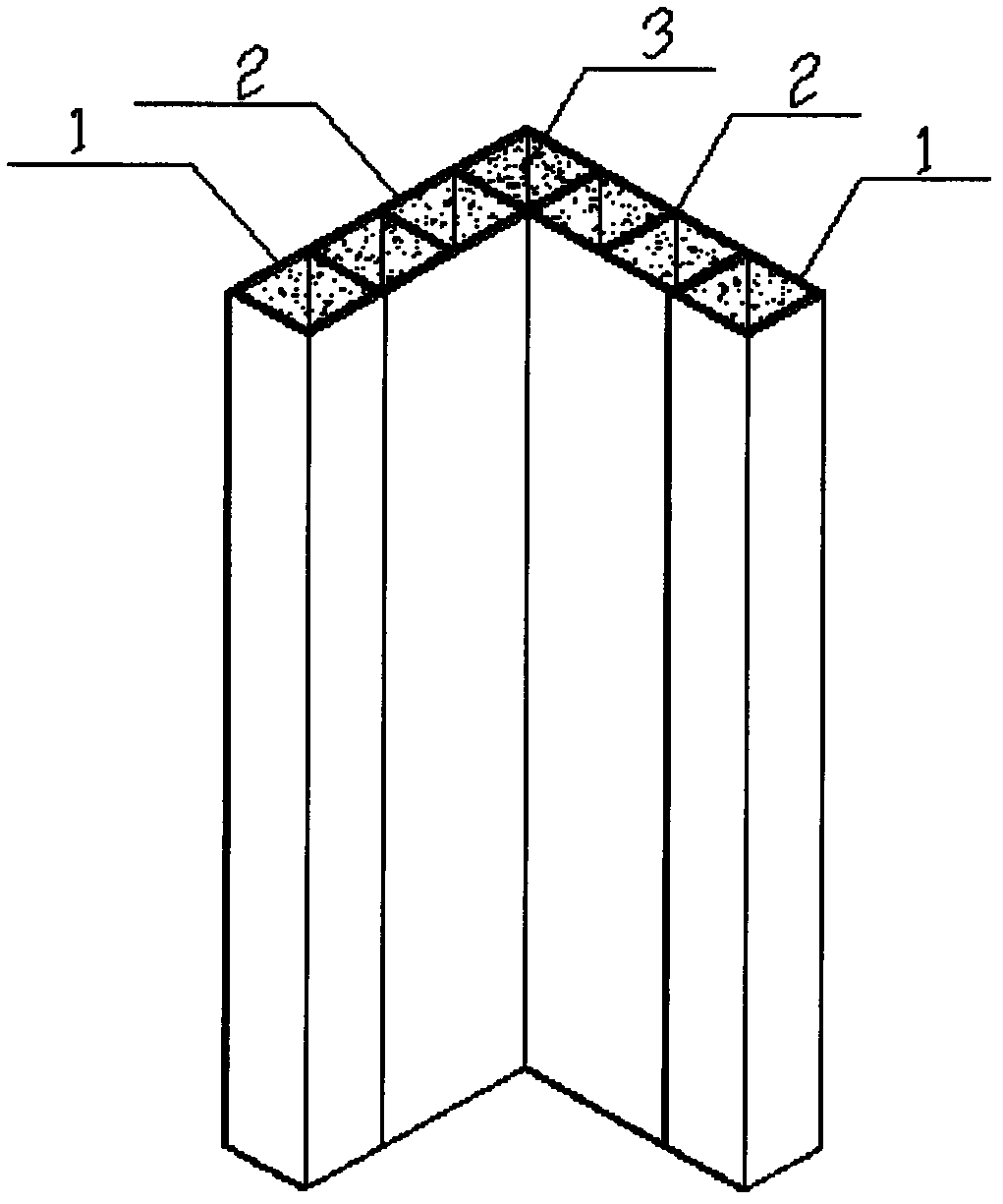

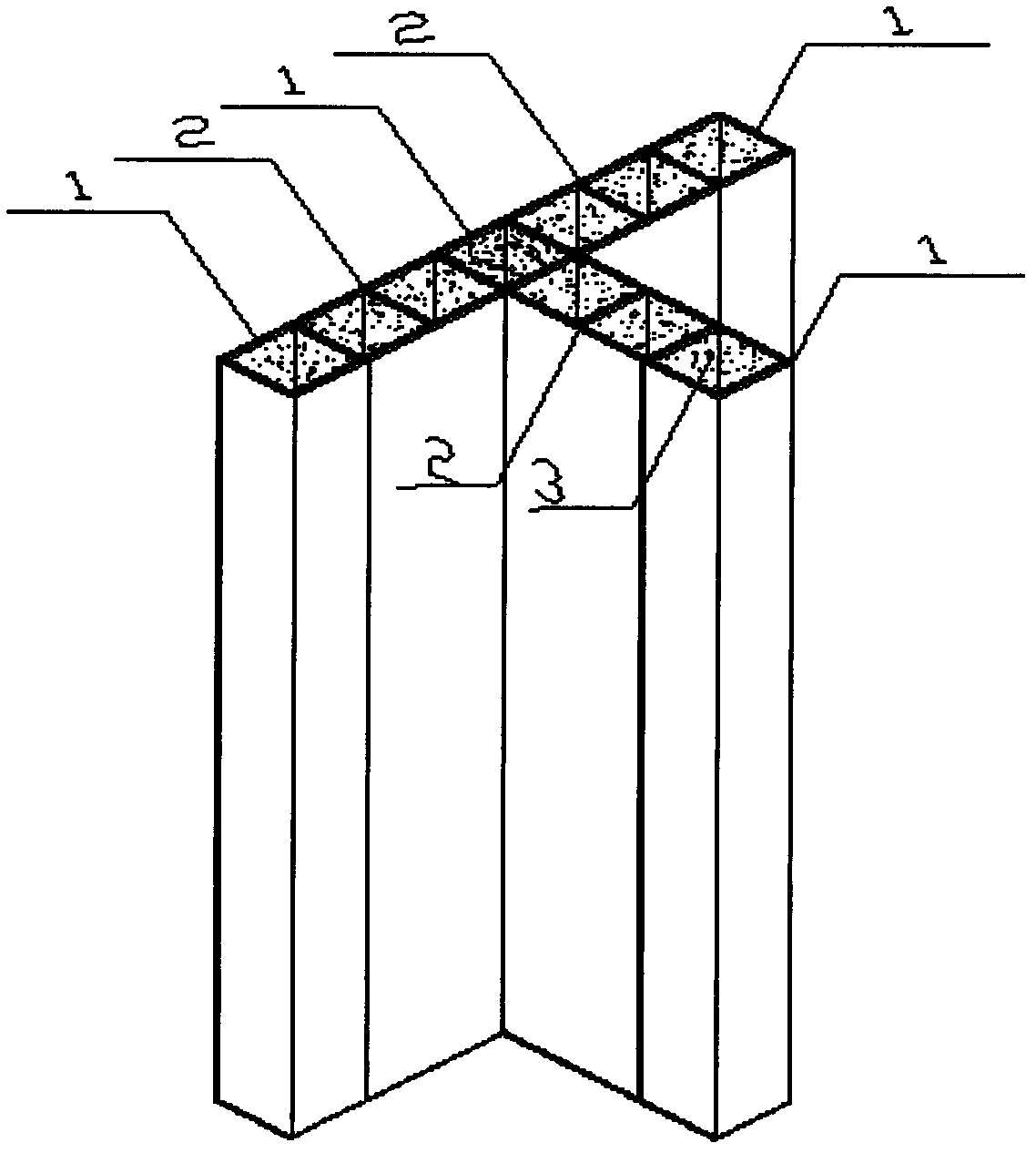

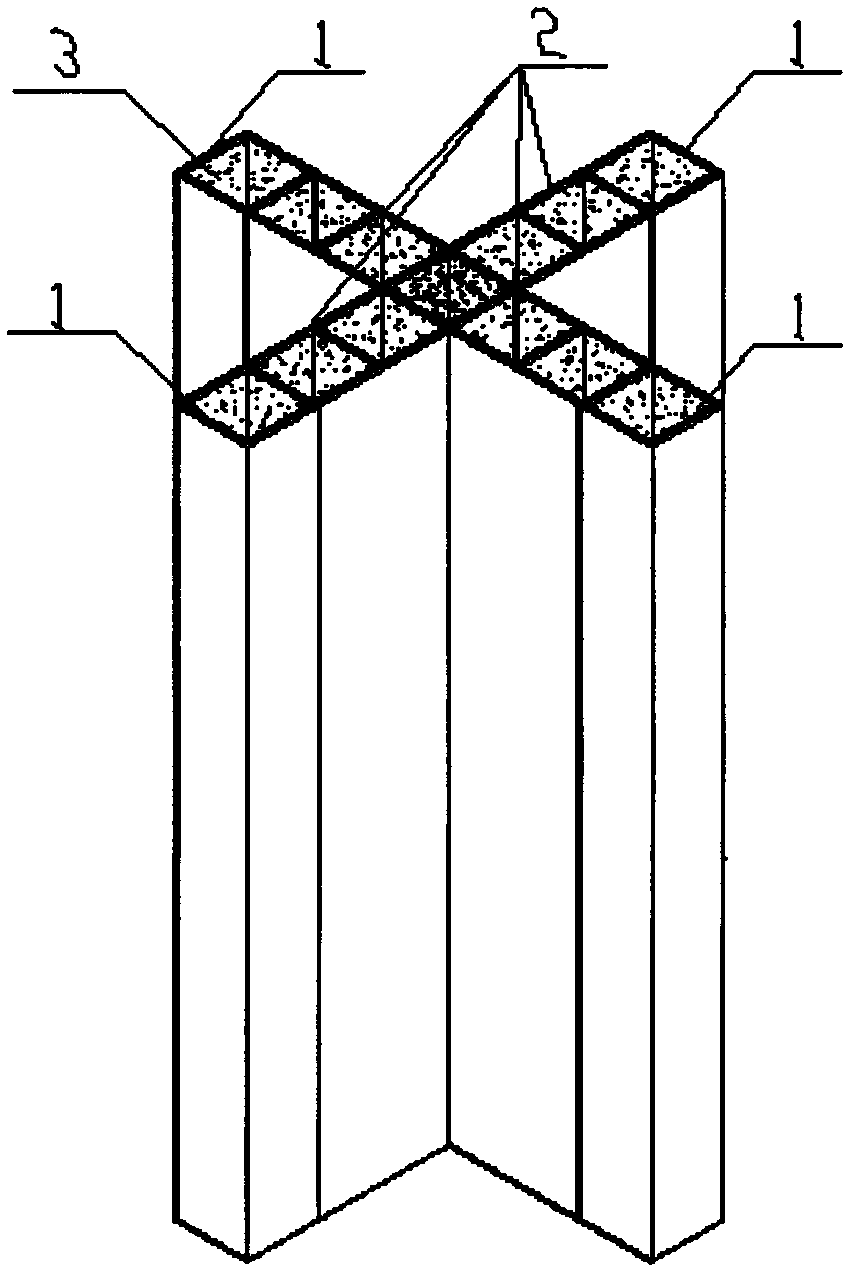

[0033] Such as Figure 1-10 As shown, the present invention provides a steel pipe-I-steel combined steel pipe concrete special-shaped column, which consists of a steel pipe 1, an I-steel 2, and concrete 3 poured therein. The column is to weld the I-beam on the adjacent side of the steel pipe, and then weld the steel pipe 1 to the other end of the I-beam 2, and connect multiple steel pipes 1 and I-beam 2 to form a cross-sectional shape of L-shape, T-shape or ten. Shaped steel pipe-I-steel composite steel pipe concrete special-shaped column, and then fill the space separated by steel pipe and I-steel with concrete. Steel pipe 1 is welded or rolled; working steel 2 is welded or rolled, such as figure 1 and figure 2 shown.

[0034] The steel pipe-I-steel composite steel pipe concrete special-shaped column refers to that the components are transported to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com