Closed extruding fine blanking die based on floating female die structure

A die and fine blanking technology is applied to the floating die structure of closed extrusion fine blanking and the field of obtaining closing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

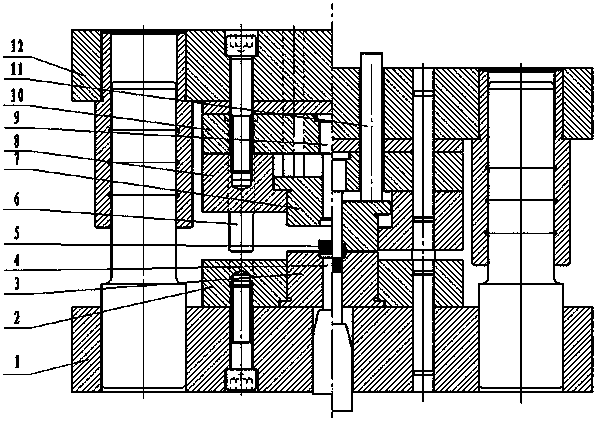

[0017] Closed extrusion fine blanking die structure of the present invention is as figure 1 as shown, figure 1 The left side of is to reflect the position before the start of forming, and the right is to reflect the situation at the end of forming. On the upper side of the axial joint surface of the mould, an auxiliary die 7, a stop ring 8 and a punch 9 are arranged, and an annular material pit is arranged on the edge of the die mouth of the auxiliary die. The auxiliary die 7 can move up and down, and it is a sliding fit with the stop ring 8 and the punch 9. A dowel 11 is arranged on the upper surface of the auxiliary die 7, and the dowel 11 passes through the punch fixed plate 10, the backing plate and the upper die holder 12, and transmits the power of the fine blanking cylinder of the equipment. On the lower side of the mold axial joint surface, a main die 3 is provided, and an annular material pit is arranged on the edge of the die opening of the main die. The storage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com