Stable bucket tooth, tooth seat and assembly for excavator

A technology of excavator and shovel tooth holder, which is applied in the field of excavation and loading of working machinery parts, can solve the problems of small curvature radius, uneven force, and easy cracking at the joint, so as to reduce production cost, reduce scrap rate, Not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

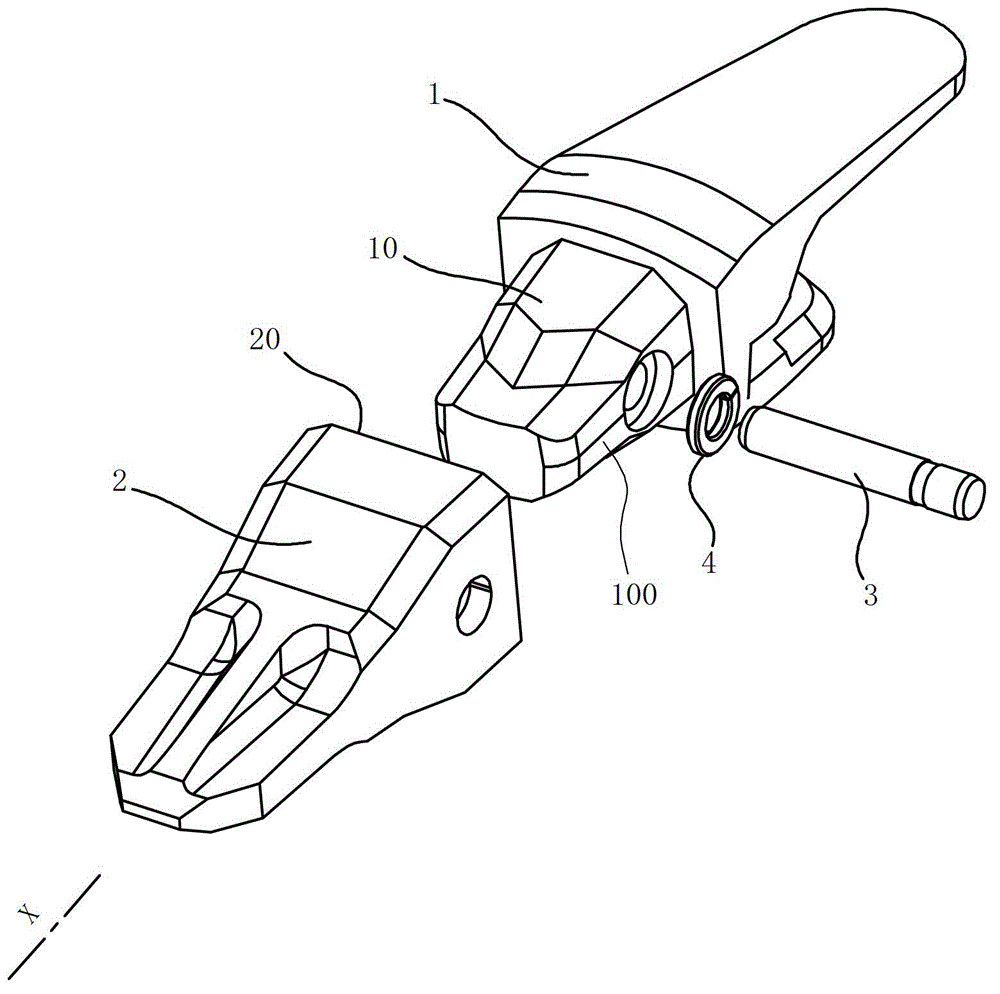

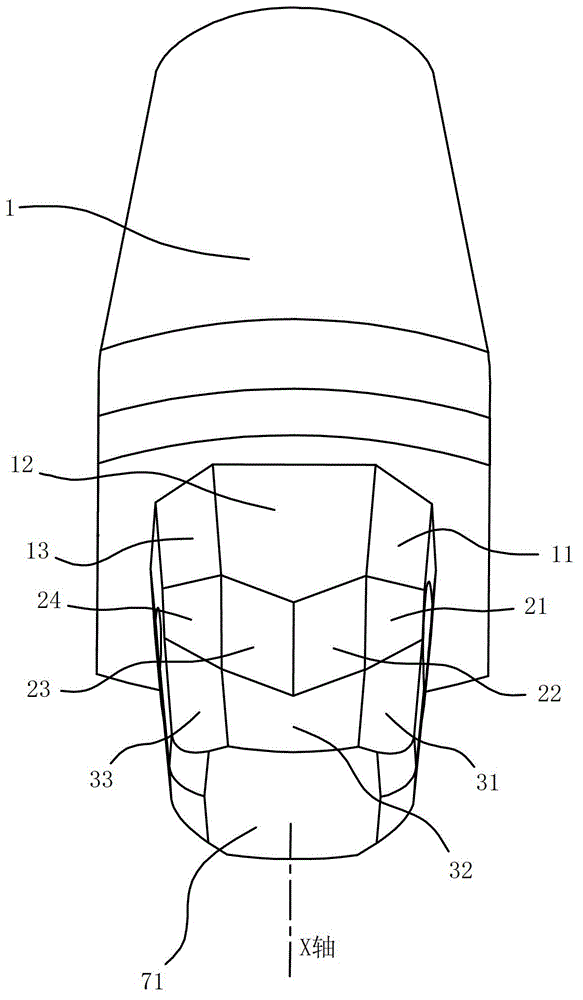

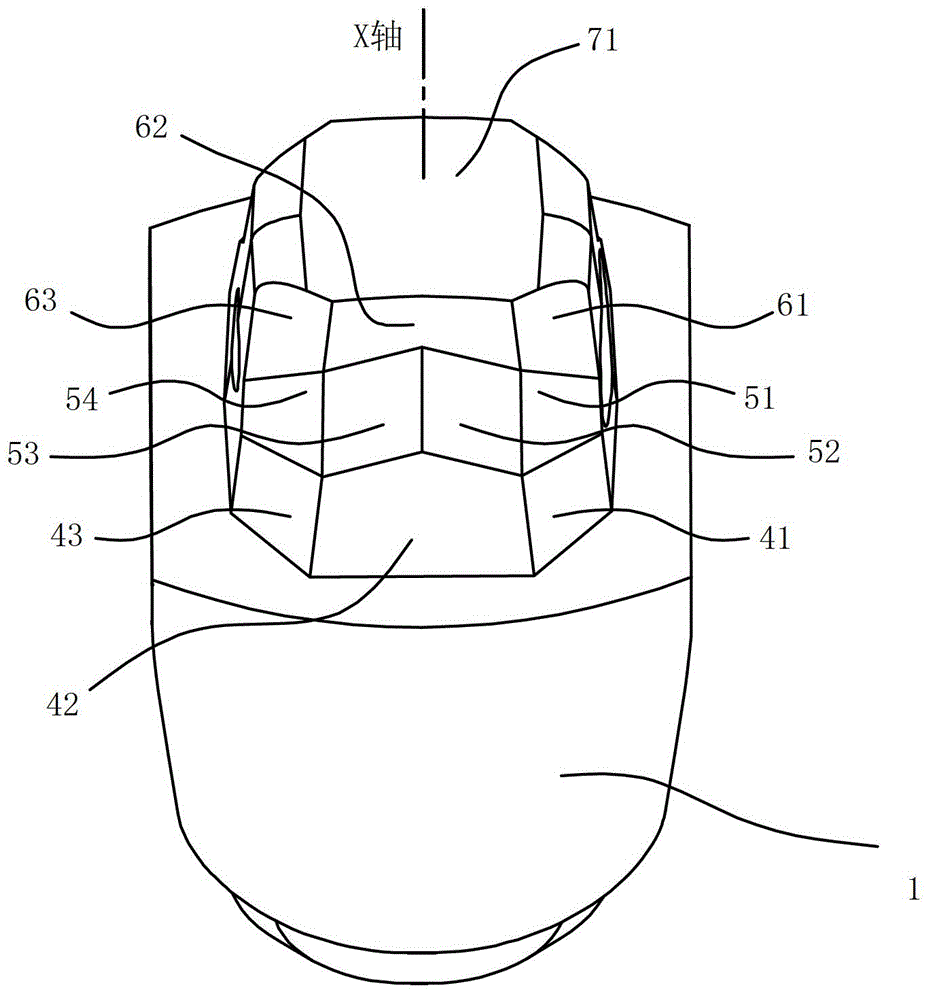

[0035] like figure 1 As shown, an embodiment of an excavator bucket tooth assembly includes an adapter 1 , a tooth 2 , and a locking pin. The lock pin includes a pin 3 and a snap ring 4 . There is a bucket tooth chamber 20 with an open rear end at the rear of the bucket tooth 2, and a tooth holder head 10 at the front of the tooth holder 1. Both the bucket tooth chamber 20 and the tooth holder head 10 are provided with lock pin holes, such as Figure 7 The shown tooth seat head 10 is accommodated in the bucket tooth cavity 20 and is fixedly connected by a locking pin. Both the bucket tooth cavity 20 and the tooth seat head 10 have a larger rear end and a smaller front end, and the inner surface of the bucket tooth cavity 20 is complementary to the outer surface of the tooth seat head 10 .

[0036] like figure 1 , figure 2 , image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com