Self-centering sealing piece for achieving floating through gas pressure difference action and mounting method of self-centering sealing piece

A seal and pressure difference technology, applied in the field of self-concentric seals, can solve problems such as unfavorable sealing performance, applicable line speed and temperature restrictions, and achieve the effect of improving safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

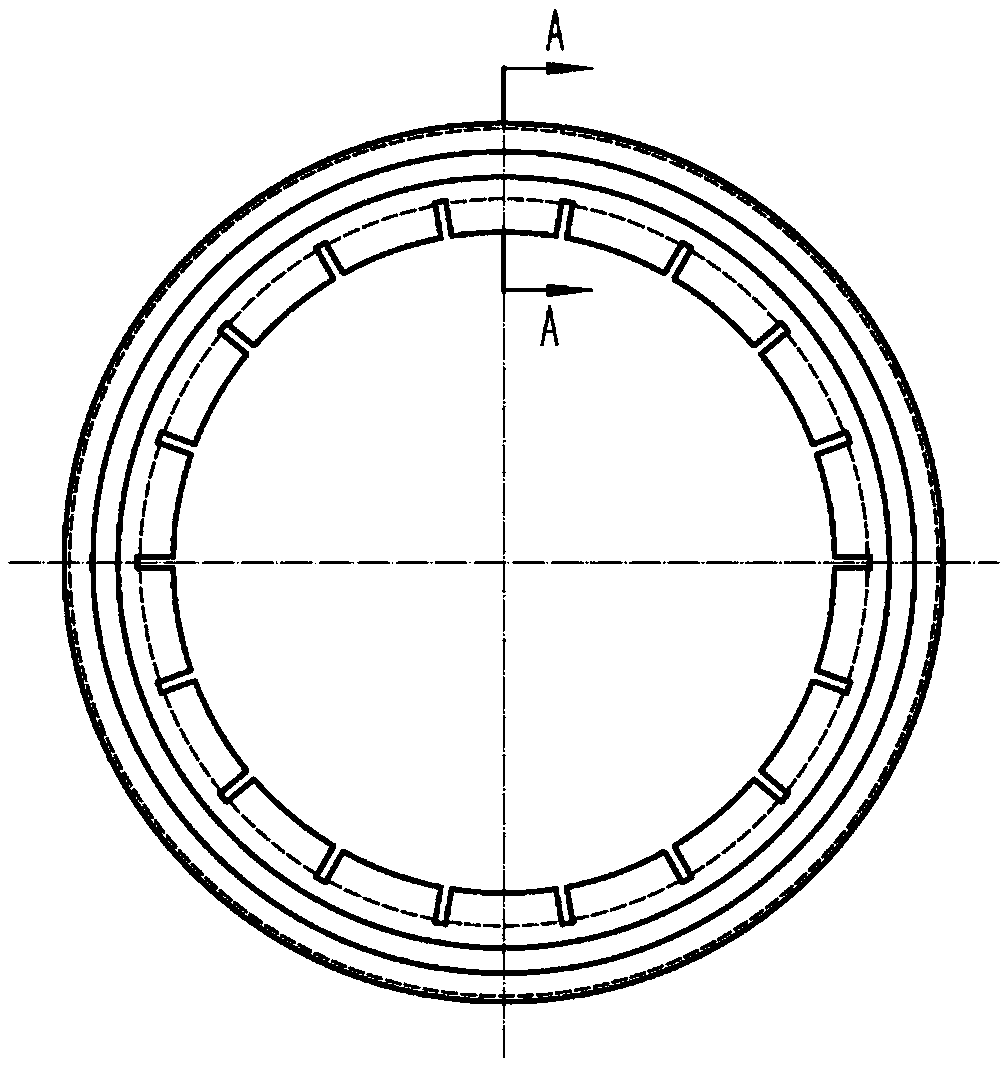

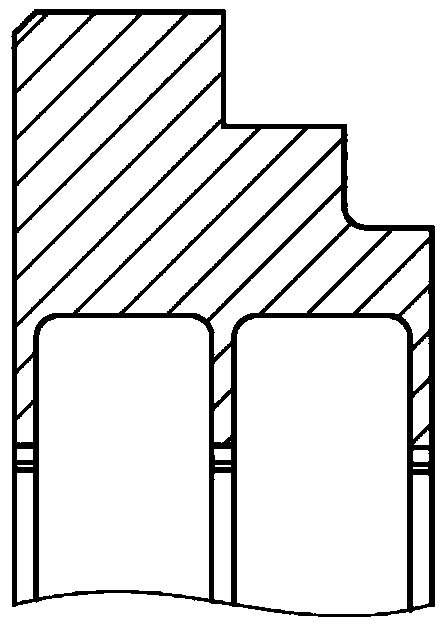

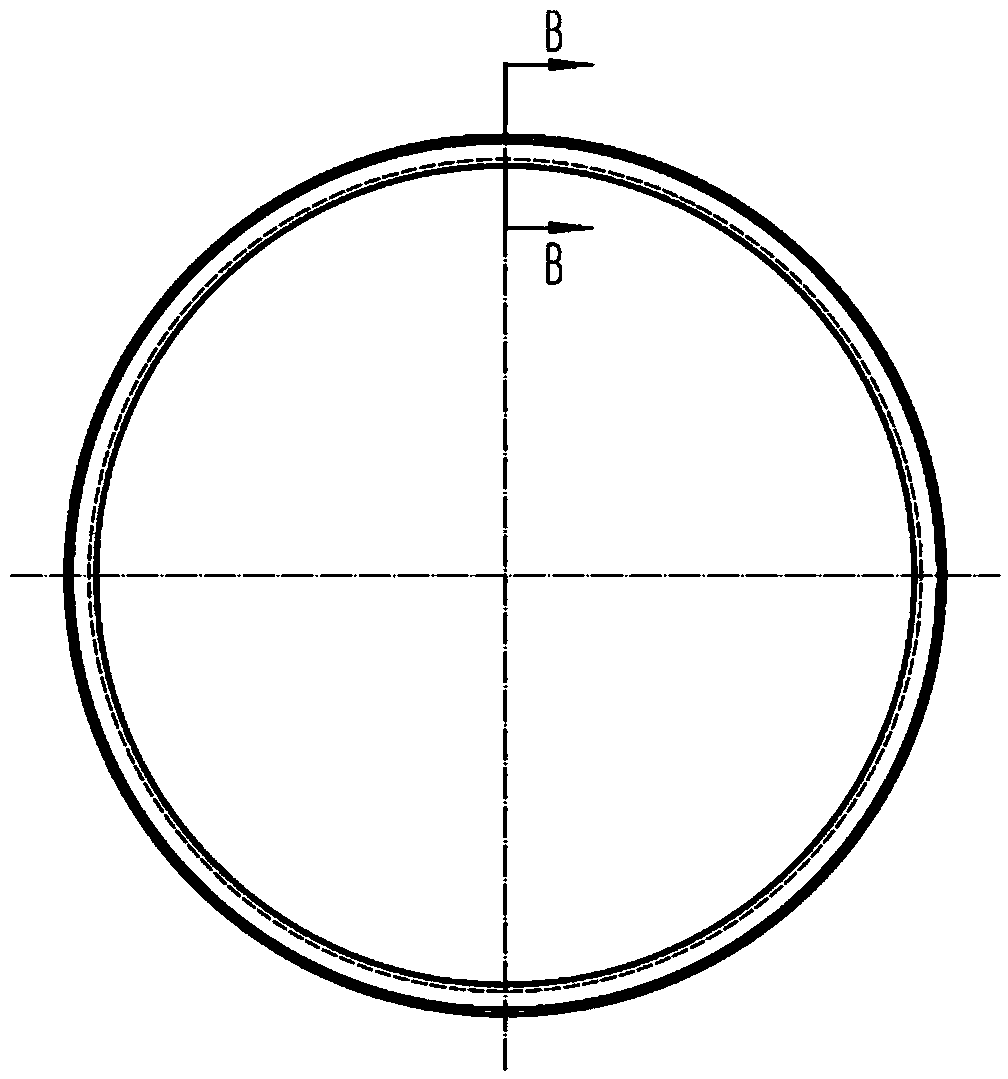

[0034] like Figure 1-7 As shown, a self-concentric seal that utilizes the effect of gas pressure difference to realize floating is applied to the shaft end of a certain type of aero-engine. Composed of the ball retaining ring 4, the main seal ring 1 is a three-tooth labyrinth structure, and the three seal teeth are concentric, and the inner diameters of the first seal tooth 31 and the second seal tooth 32 on the high-pressure side are both φ120.6mm, and the last on the low-pressure side The inner diameter of a sealing tooth 33 is φ120.4mm, and the outer diameter of the rotor 13 matched therewith is φ120mm. 18 circumferential spacers 2 are inlaid and welded on the main sealing ring 1. The circumferential spacers 2 are rectangular and have a thickness of 1.95 mm. φ120.3mm. The ball retaining ring 4 is closely matched with the main sealing ring 1, and forms a circular track on the low-pressure side 22 to accommodate the anti-friction ball 3. The diameter of the anti-friction b...

Embodiment 2

[0040] The seal of this embodiment is applied to the shaft end of the main helium fan of a nuclear power unit. Since the main helium fan adopts a magnetic suspension bearing, there is often a large amount of transient rotor jump, and the traditional labyrinth seal is difficult to adapt to long-term continuous operation. . The seal applied to the shaft end of the main helium blower and the installation method are similar to those in Embodiment 1, and the only difference is the specific size, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com