Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Dental Restoration Repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The process of repairing broken or worn parts of a PERMANENT DENTAL RESTORATION.

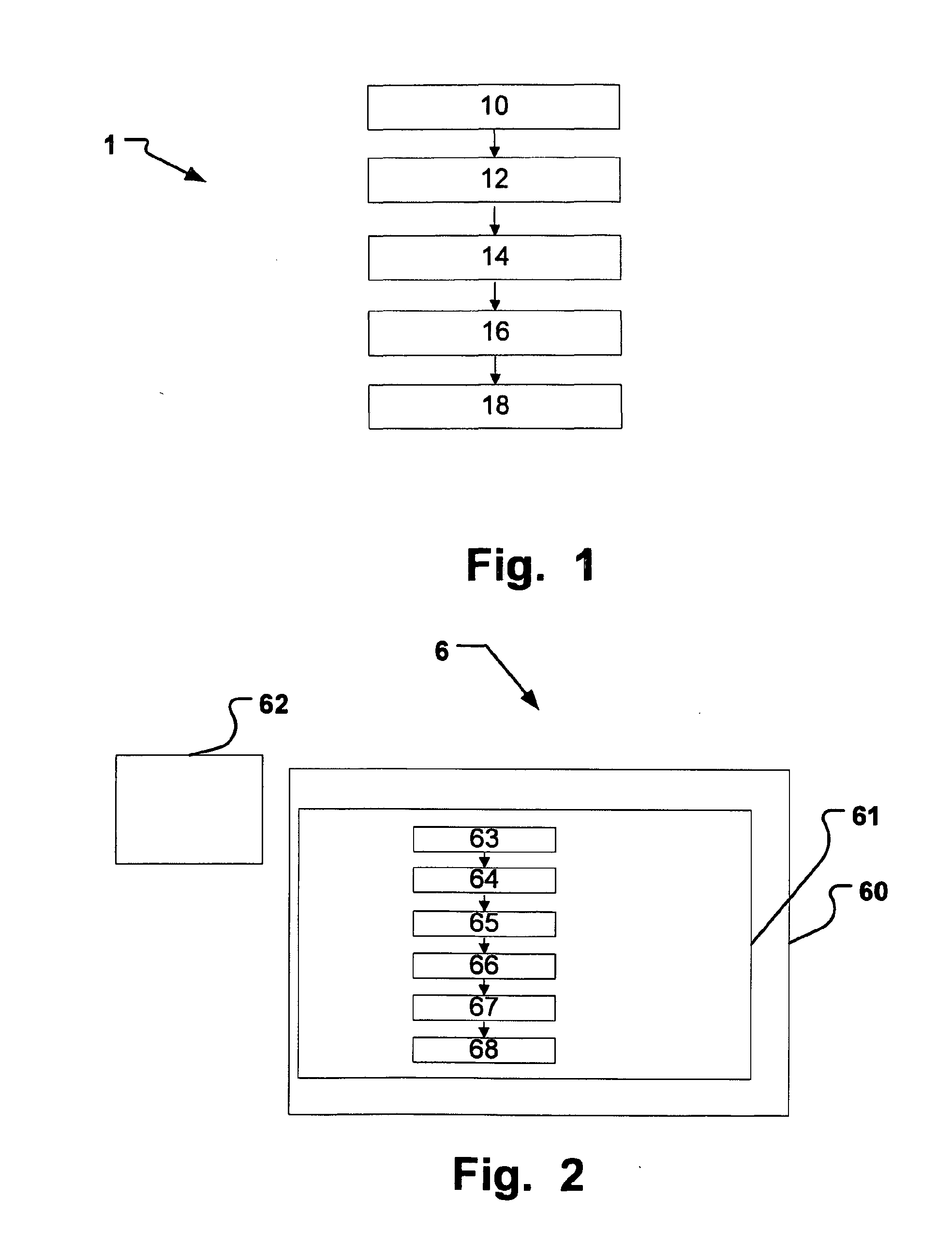

Methods for dental restoration

InactiveUS20040167646A1Additive manufacturing apparatusMechanical/radiation/invasive therapiesDentistryPreparation procedures

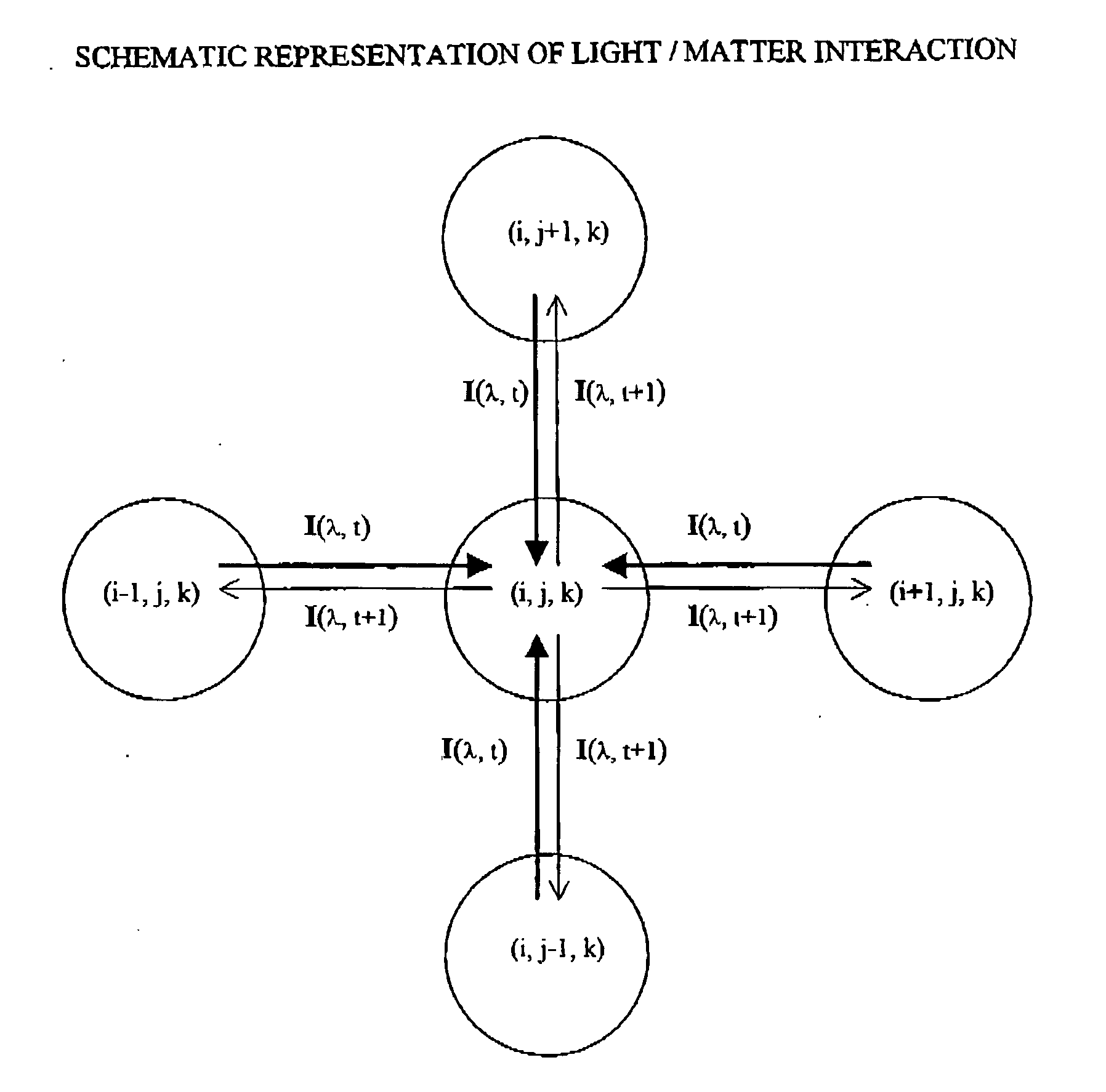

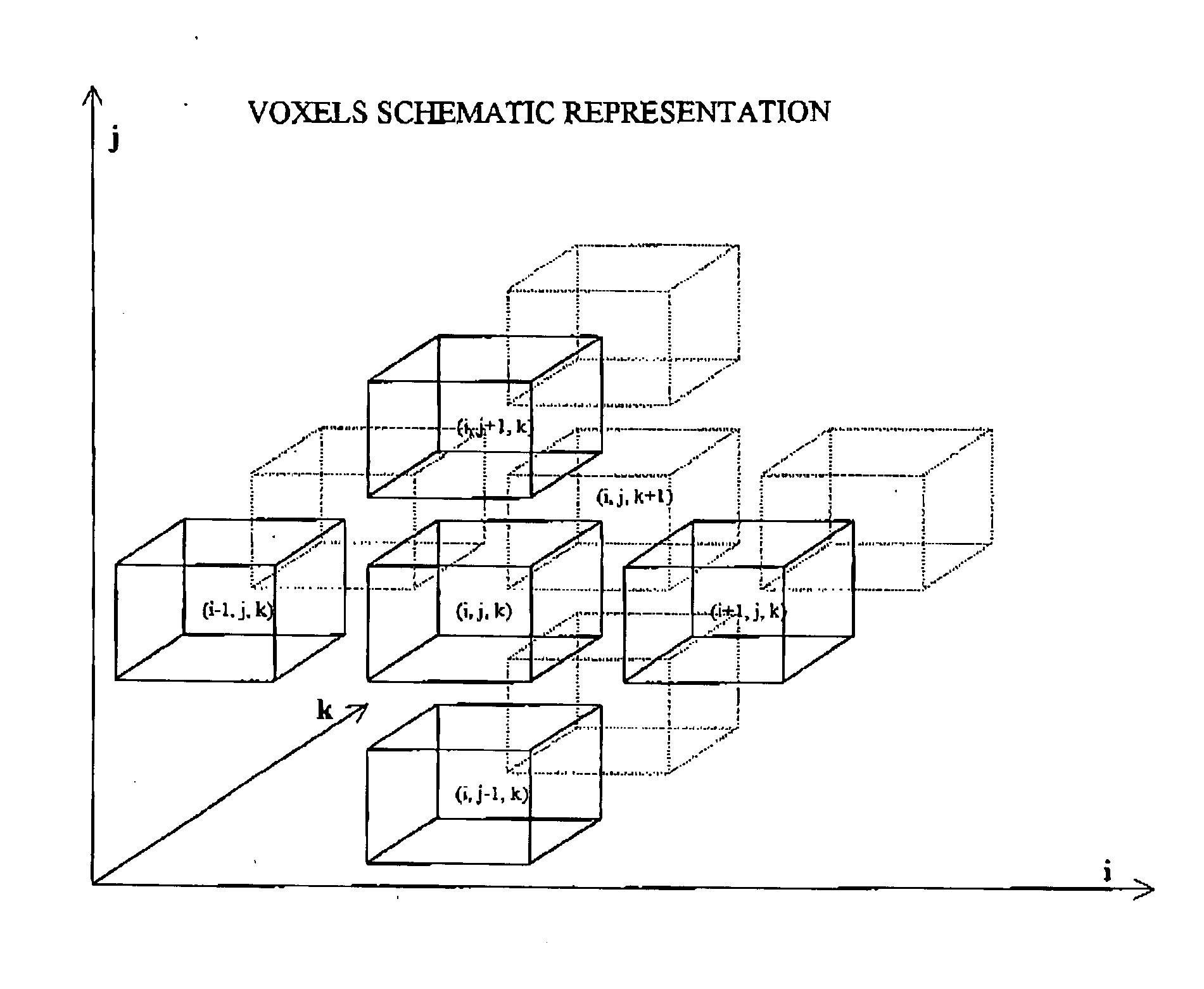

The present invention provides a method for preparing dental restorations, the method comprising the steps of (a) compiling a database of materials for use in preparing a dental restoration; (b) compiling a database of procedures for preparing the dental restoration; (c) determining the geometrical constraints of the dental restoration; (d) determining the aesthetic constraints of the dental restoration; and (e) inputting the geometrical constraints and the aesthetic constraints to a computer to mathematically select from the material database and the procedure database a recipe for producing the dental restoration.

Owner:CYNOVAD

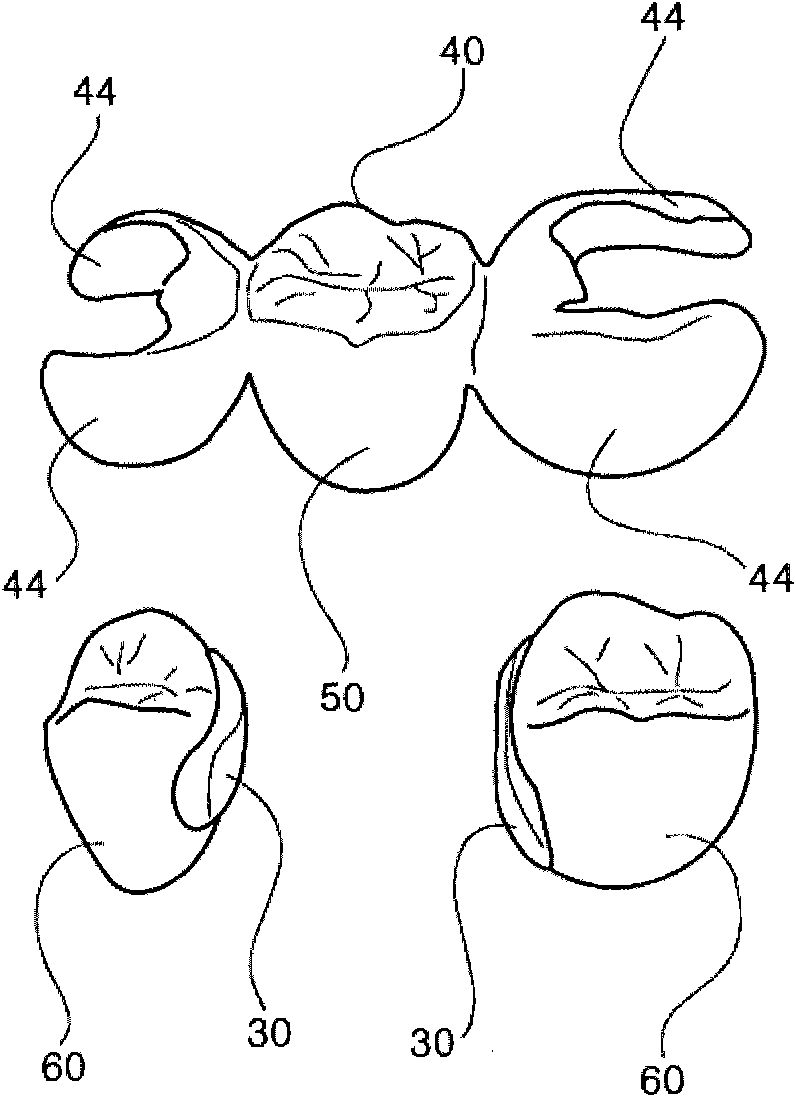

Method for dental restoration and related kit

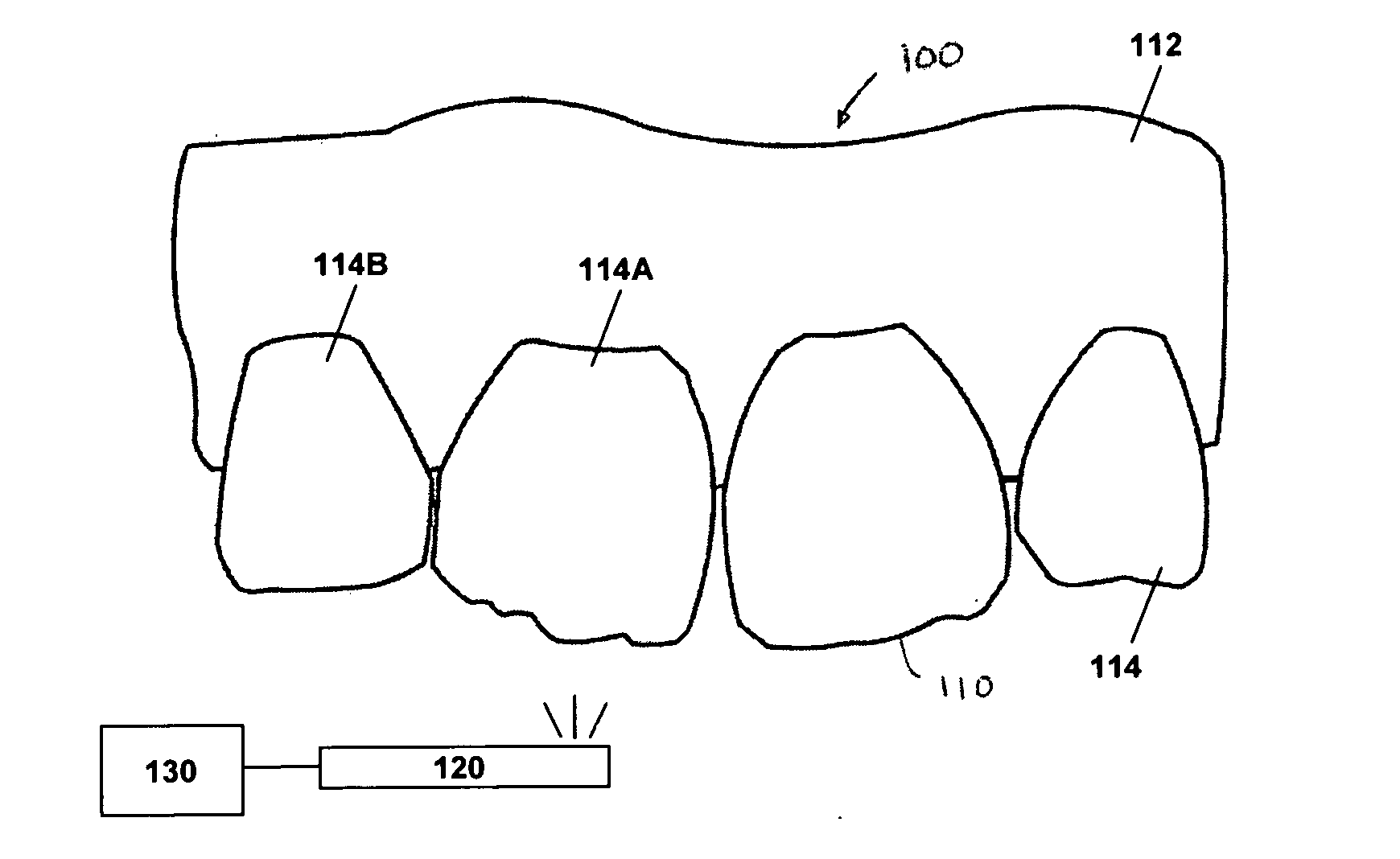

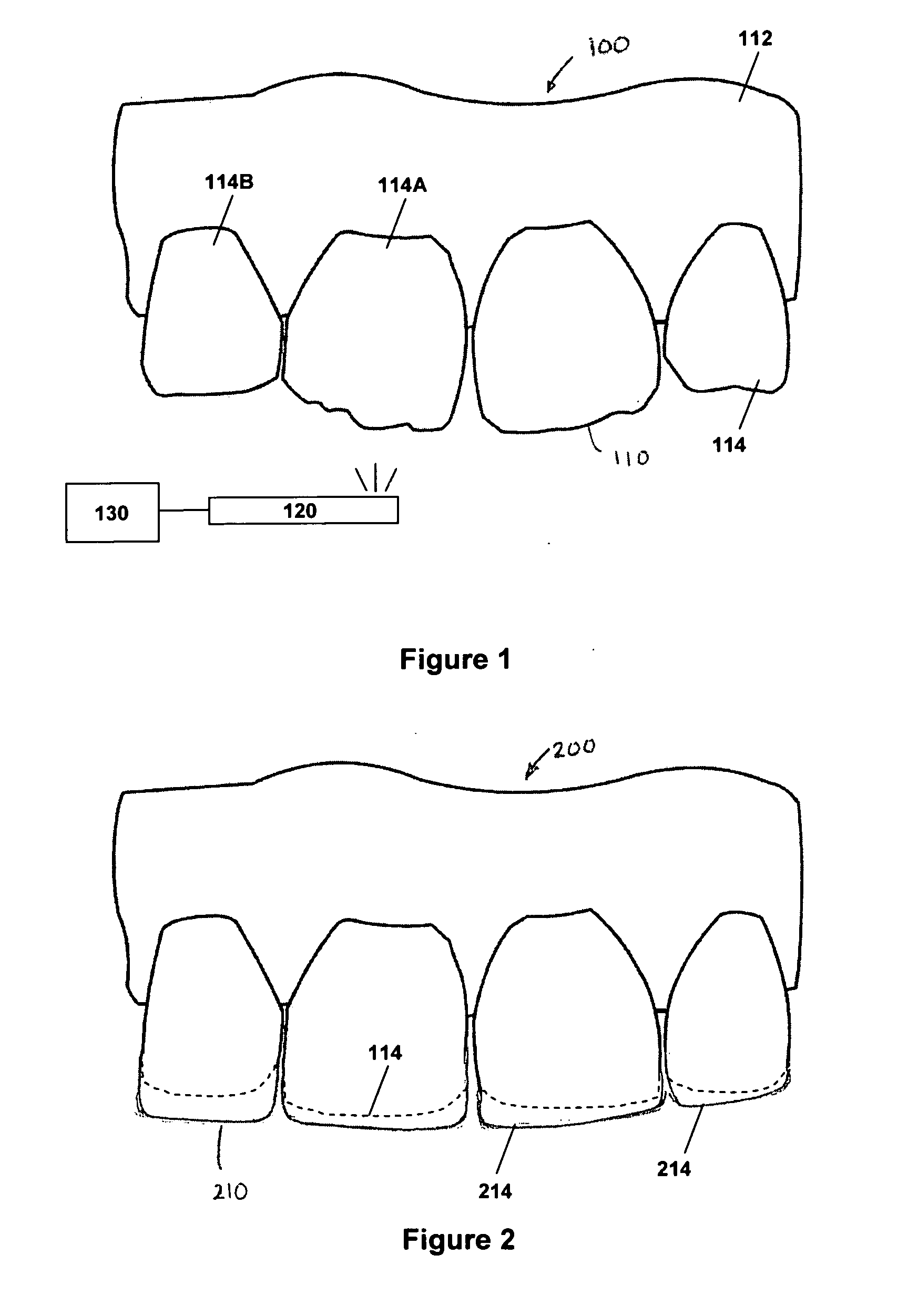

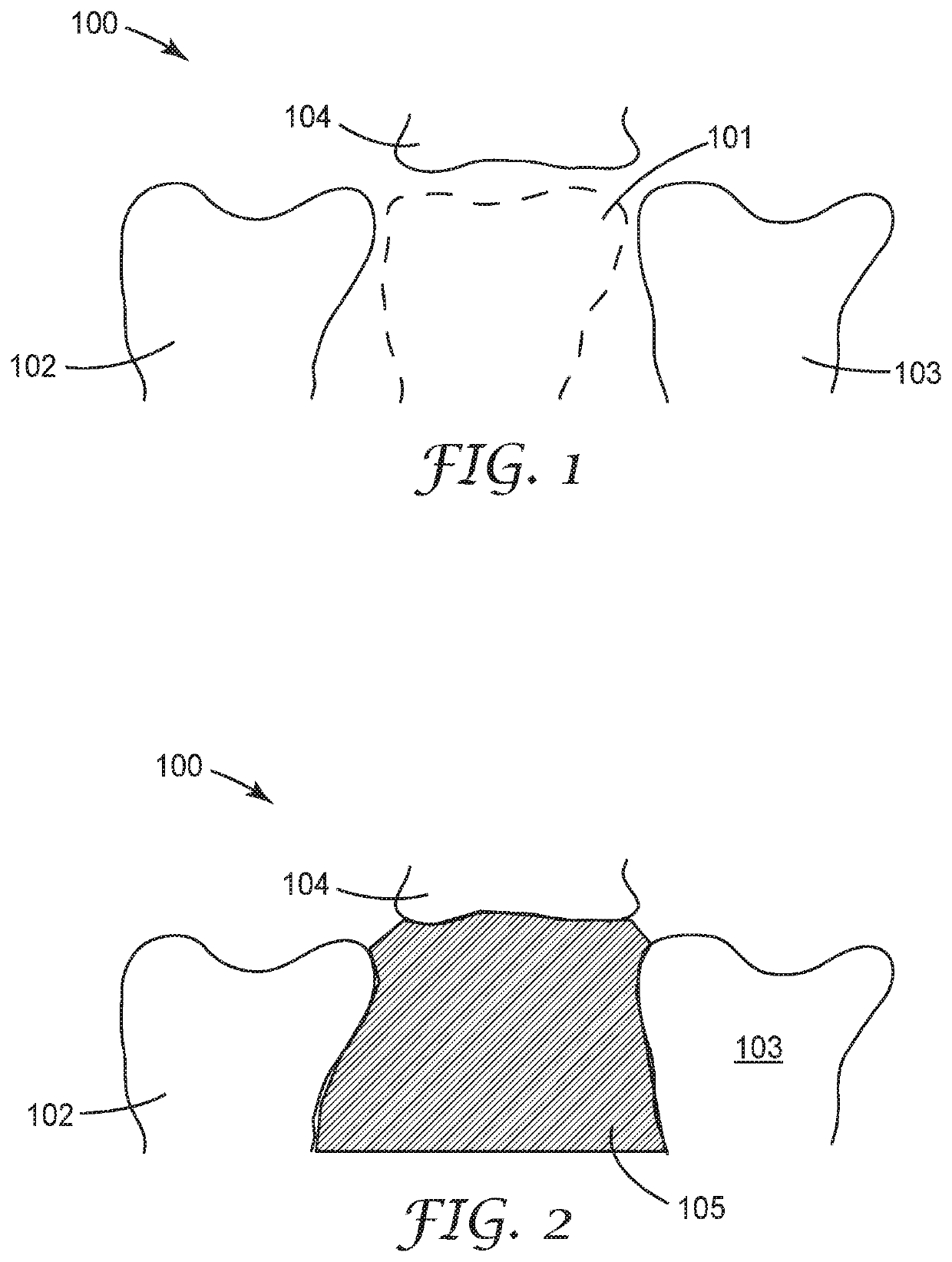

ActiveUS20110212420A1Resist slippagePrecise alignmentTeeth fillingDental articulatorsEngineeringOral cavity

The disclosure generally relates to a method for forming a dental mold. The method generally includes: (a) scanning an existing dental structure to generate a three-dimensional first digital model of the existing dental structure, (b) modifying the first digital model of the existing dental structure to generate a three-dimensional second digital model of a planned dental structure; (c) generating a three-dimensional third digital model corresponding to a negative of the second digital model; (d) digitally sectioning the third digital model into at least one buccal model portion and at least one lingual model portion of the third digital model; and (e) creating a dental mold comprising at least one buccal mold portion and at least one lingual mold portion based on the sectioned third digital model. The disclosure also relates to (a) methods of assembling the dental mold over a tooth and a gum of a patient having an existing dental structure in need of dental restoration, (b) methods of performing a dental restoration on the existing dental structure of the patient using the dental mold, and (c) kits including components for forming the dental mold and / or for performing the dental restoration using the dental mold.

Owner:VUILLEMOT WILLIAM C

Method of producing metal substructures for dental restorations

Methods are disclosed for forming a metal substructure that will subsequently be overcoated with ceramic layers to create a dental restoration. The methods involve the steps of providing a metal powder and applying the metal powder to a die and sintering the metal powder to form a solid structure that may be used as a coping. The application of the metal powder is done in a controlled fashion while minimizing the amount of necessary handwork. These application methods include: (a) alternatingly applying an adhesive and a metal powder to the selected portion of the die surface; and (b) forming the metal powder into a viscous slurry or slip and then dipping the die therein or spraying or pouring the slurry or slip onto the selected portion of the die surface.

Owner:THE EX ONE

Methods for dental restoration

InactiveUS7035702B2Additive manufacturing apparatusMechanical/radiation/invasive therapiesDental restorationRecipe

Owner:CYNOVAD

Dental repair material

InactiveUS20070009858A1Easy to operateEffective treatmentImpression capsDentistry preparationsRepair materialChloride

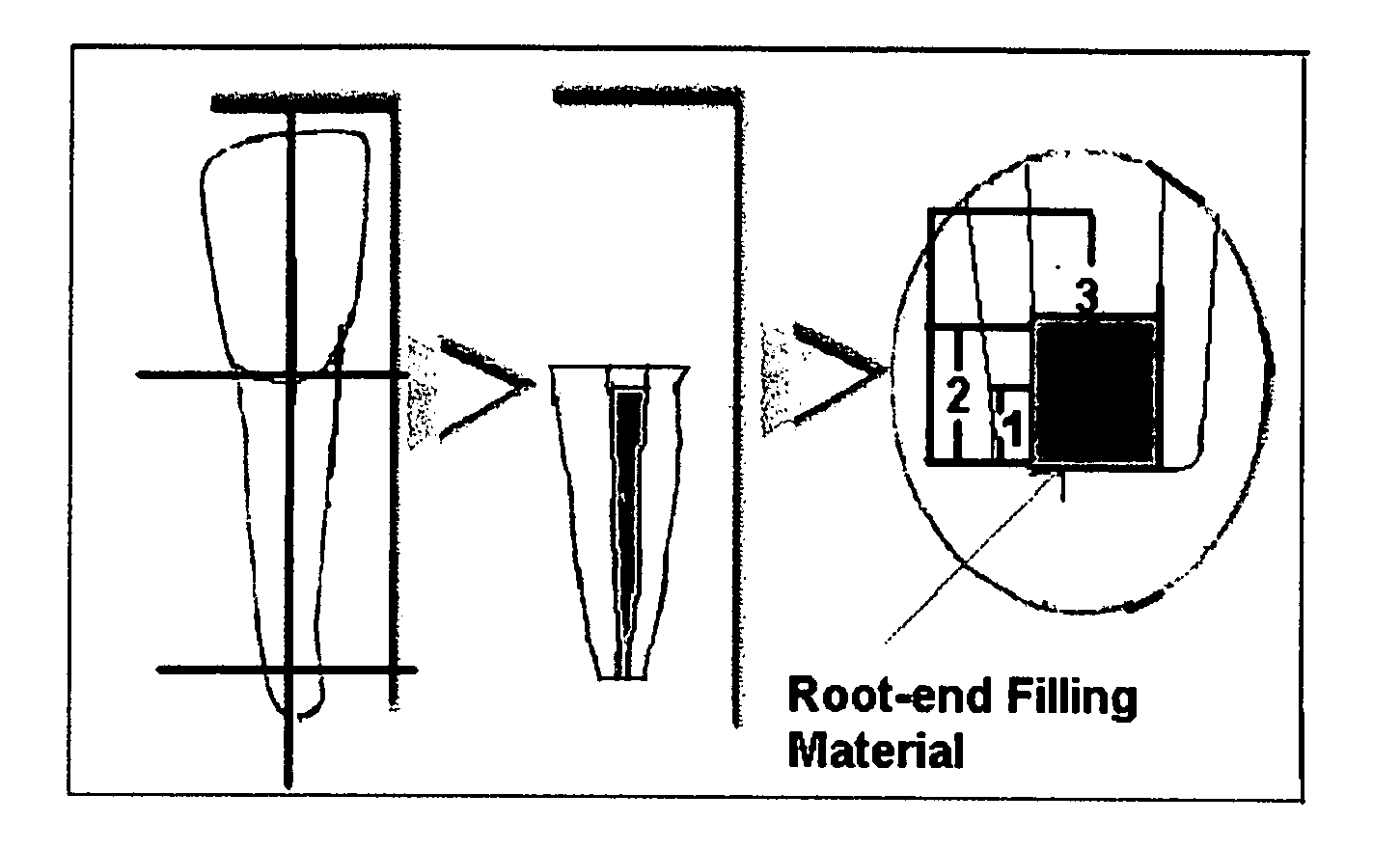

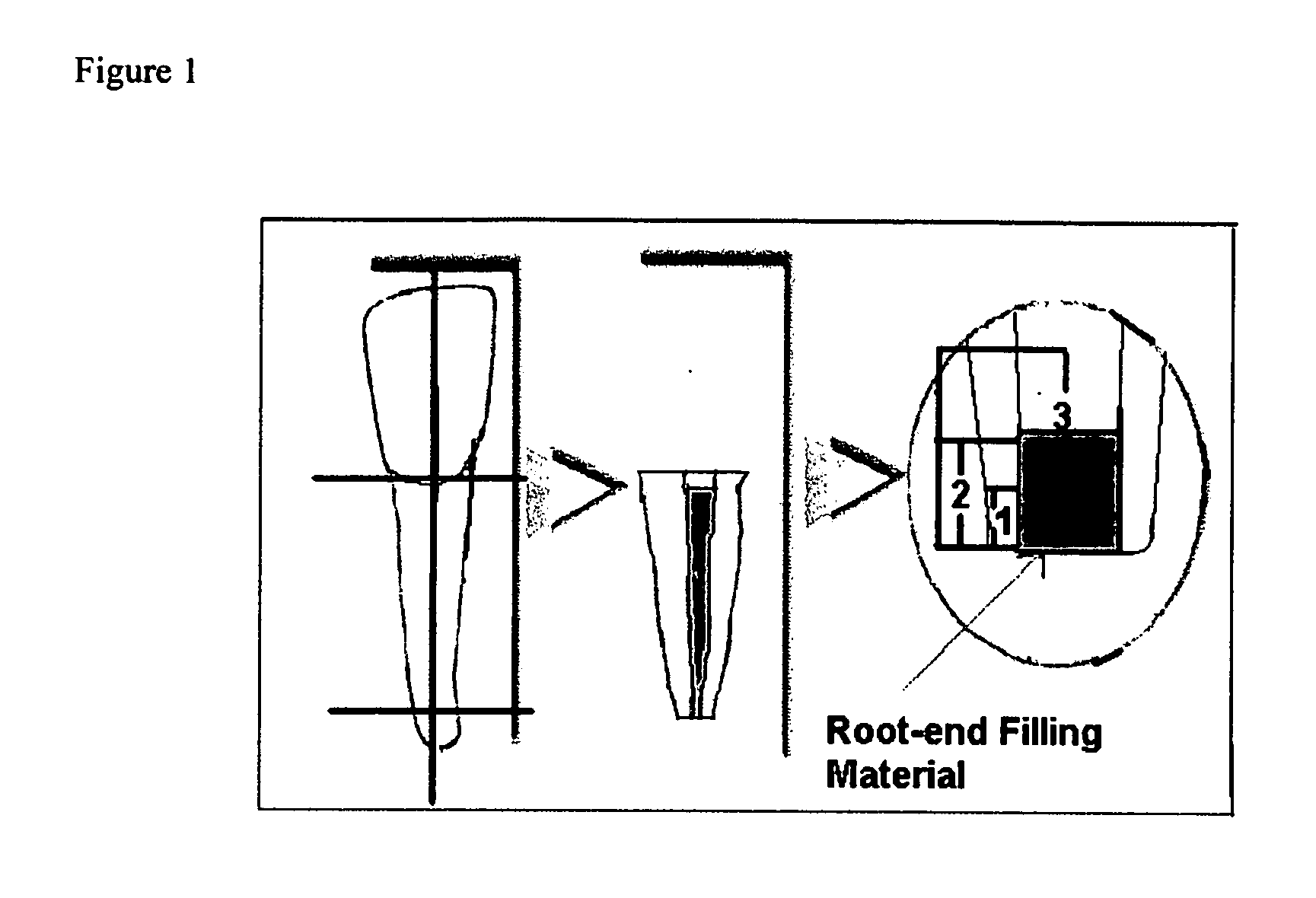

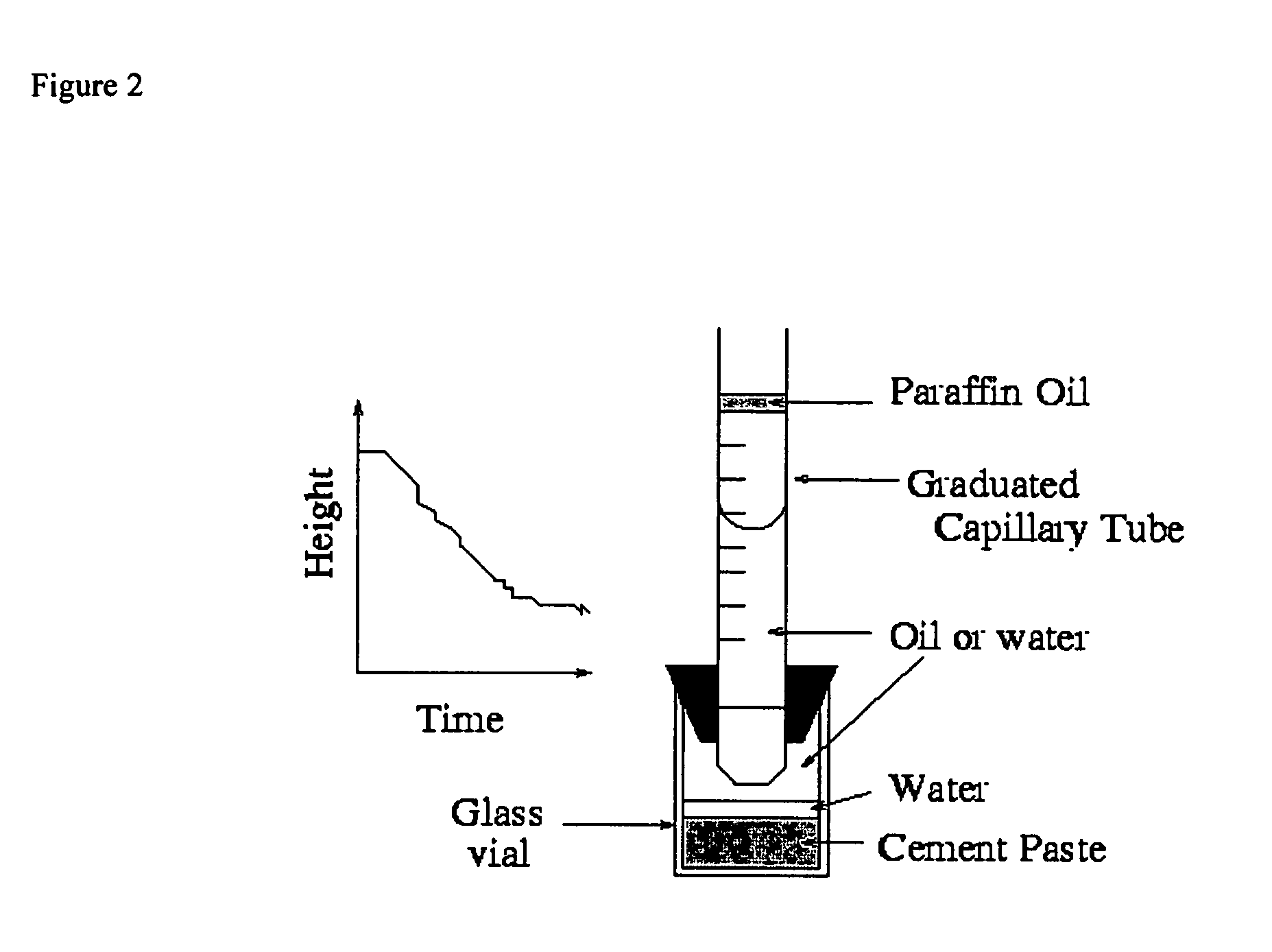

The invention is directed to an improved dental composition useful in the repair of cavities, apex repairs, root perforations and root canals. Disclosed is a dental composition and dental composition additive which have improved handling characteristics, for example improved viscosity and setting time. The addition of effective amounts of a modified cellulose and calcium chloride to available dental repair compounds, such as mineral trioxide compound, results in the improved dental composition without affecting the other characteristics of the dental repair compound.

Owner:SAINT LOUIS UNIVERSITY

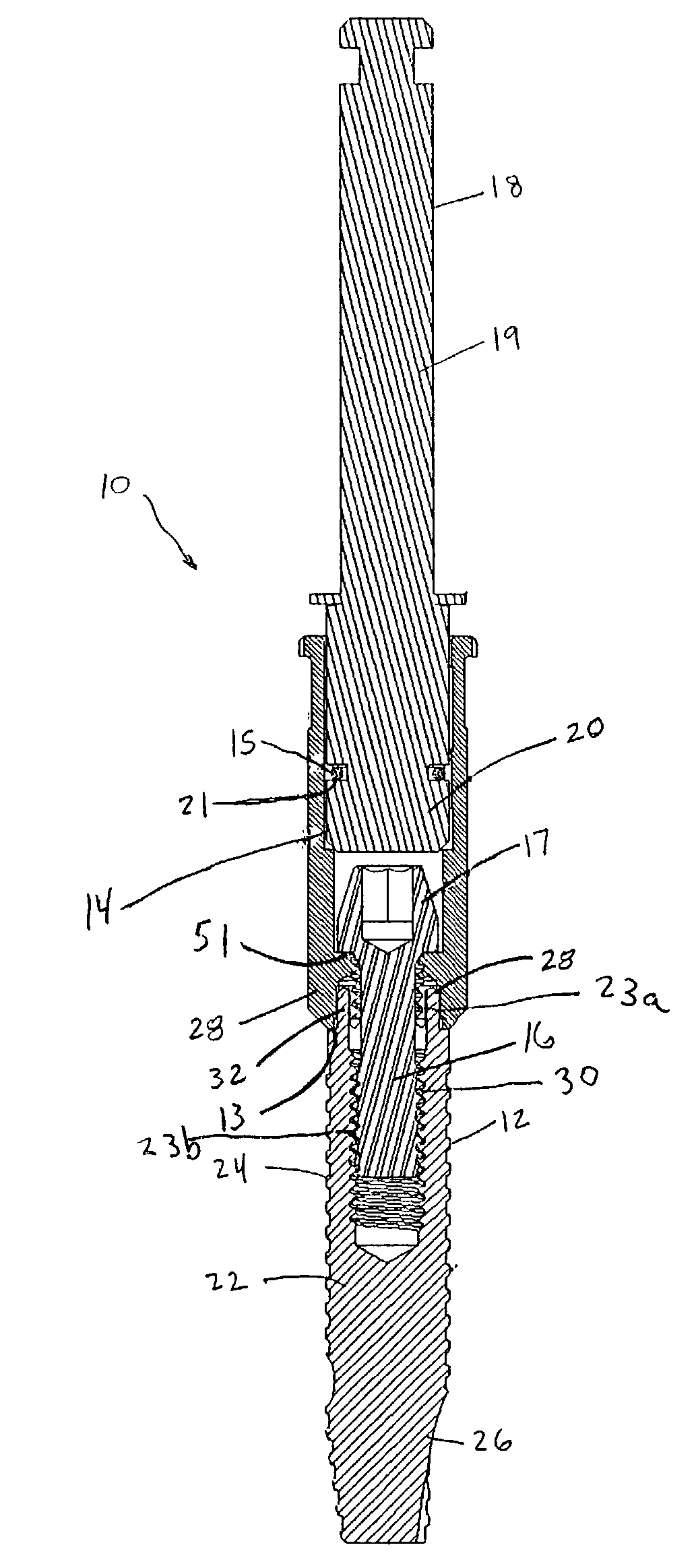

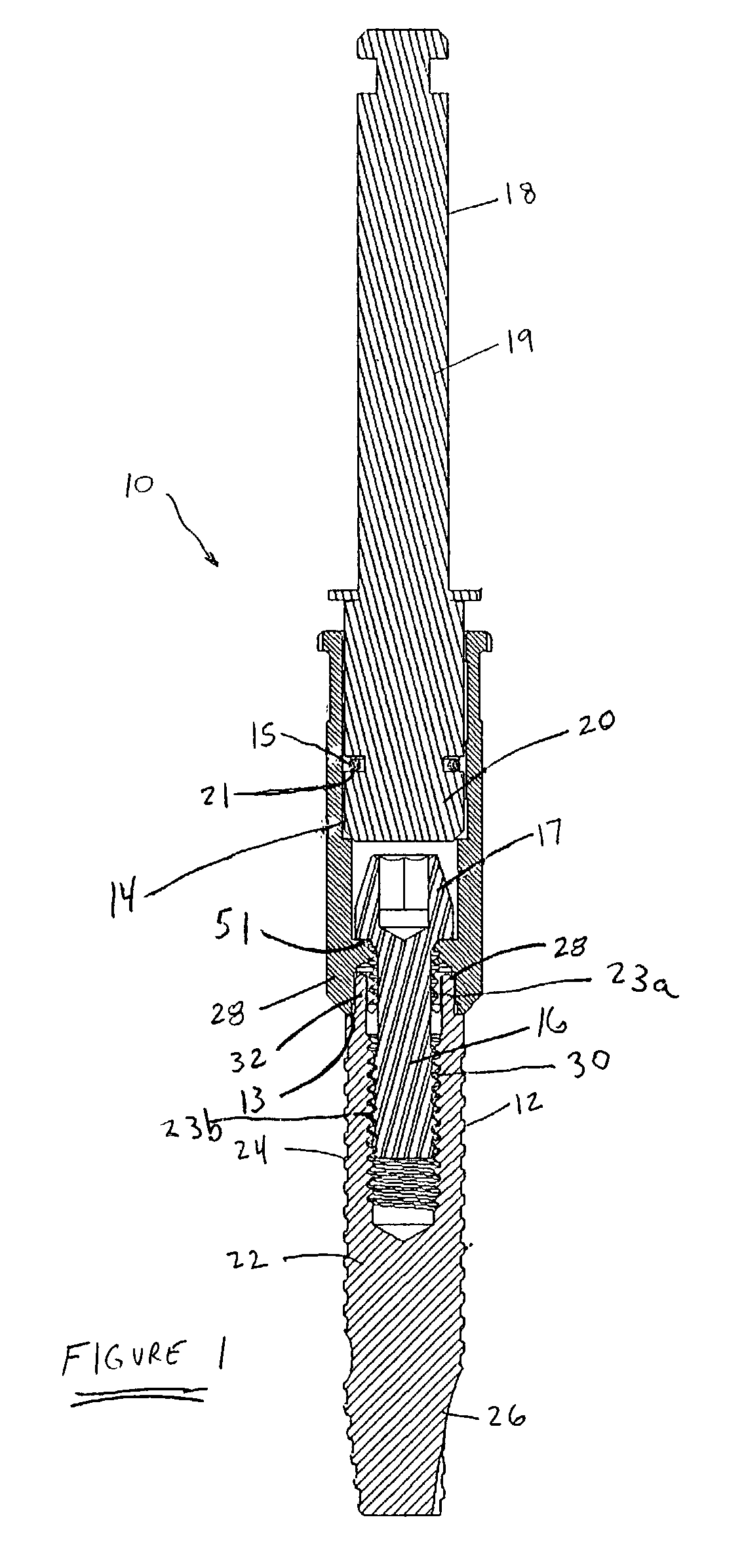

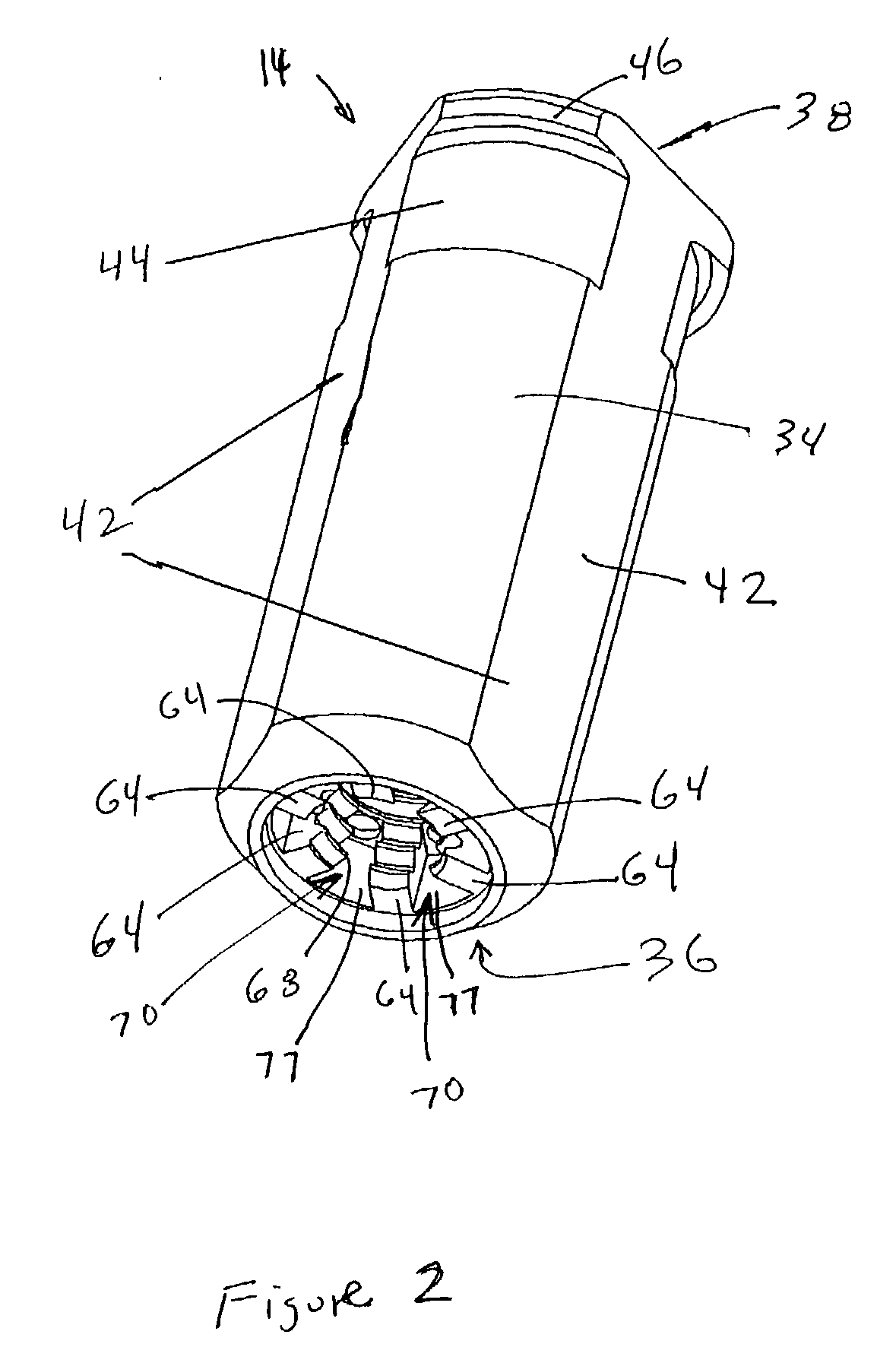

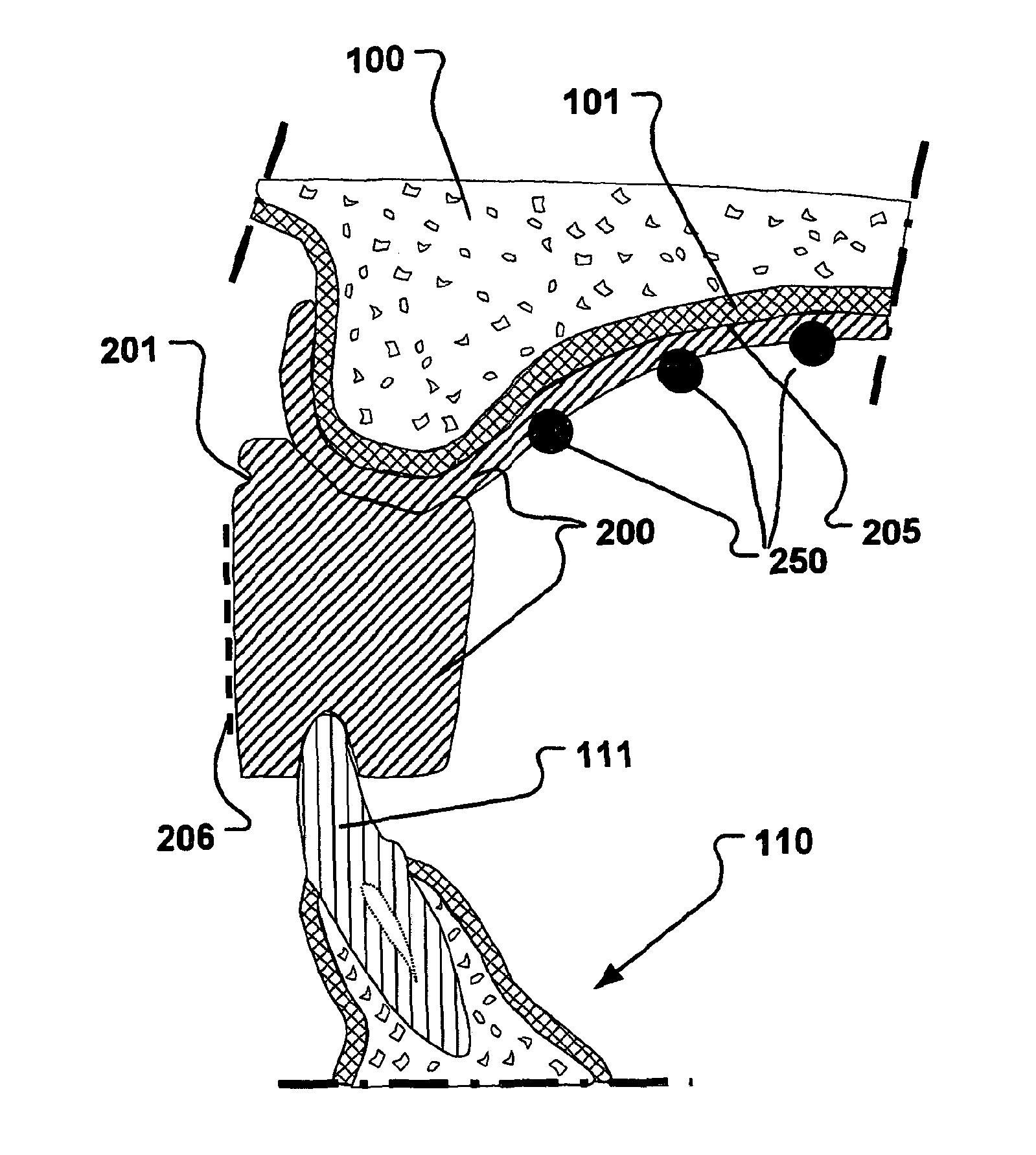

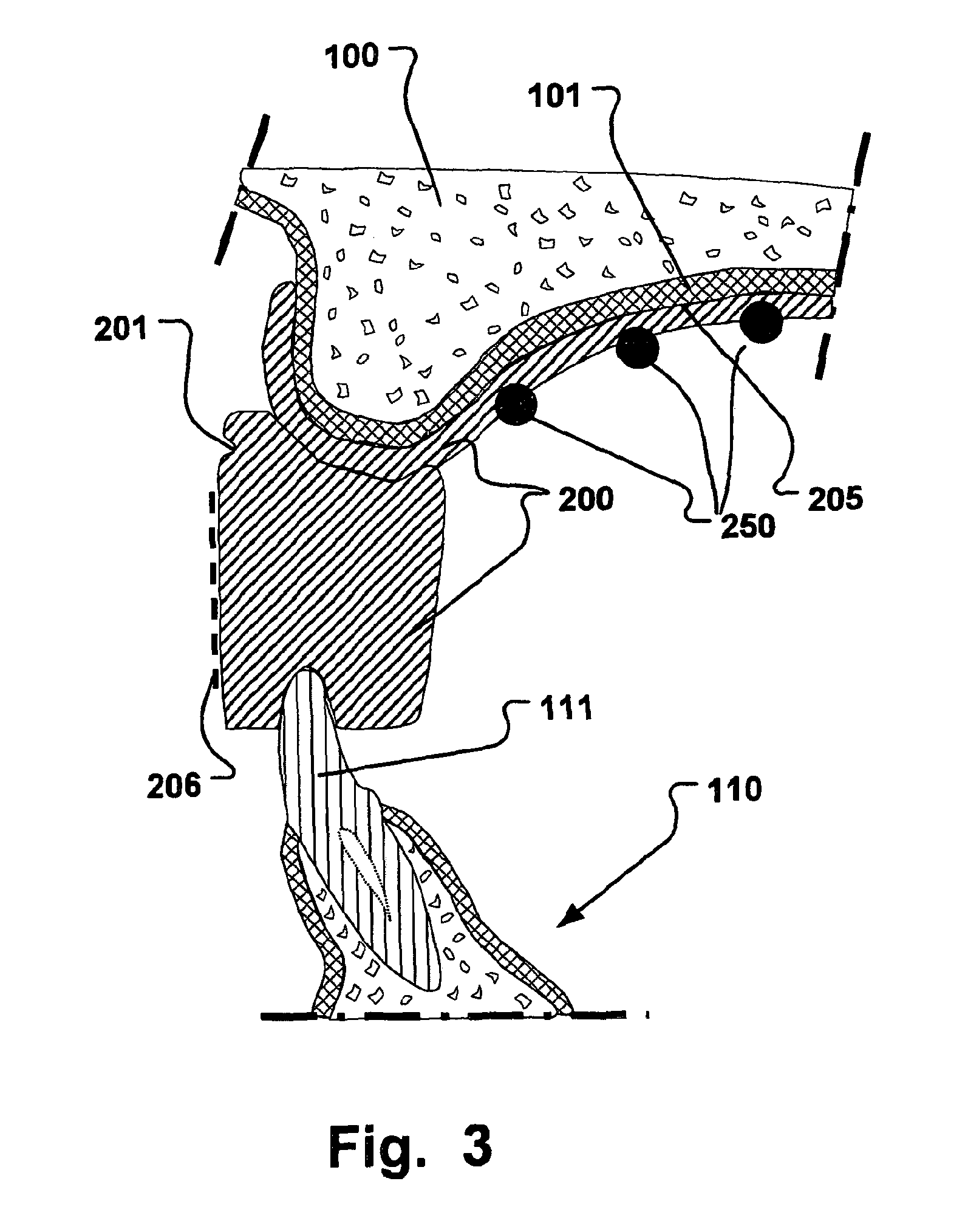

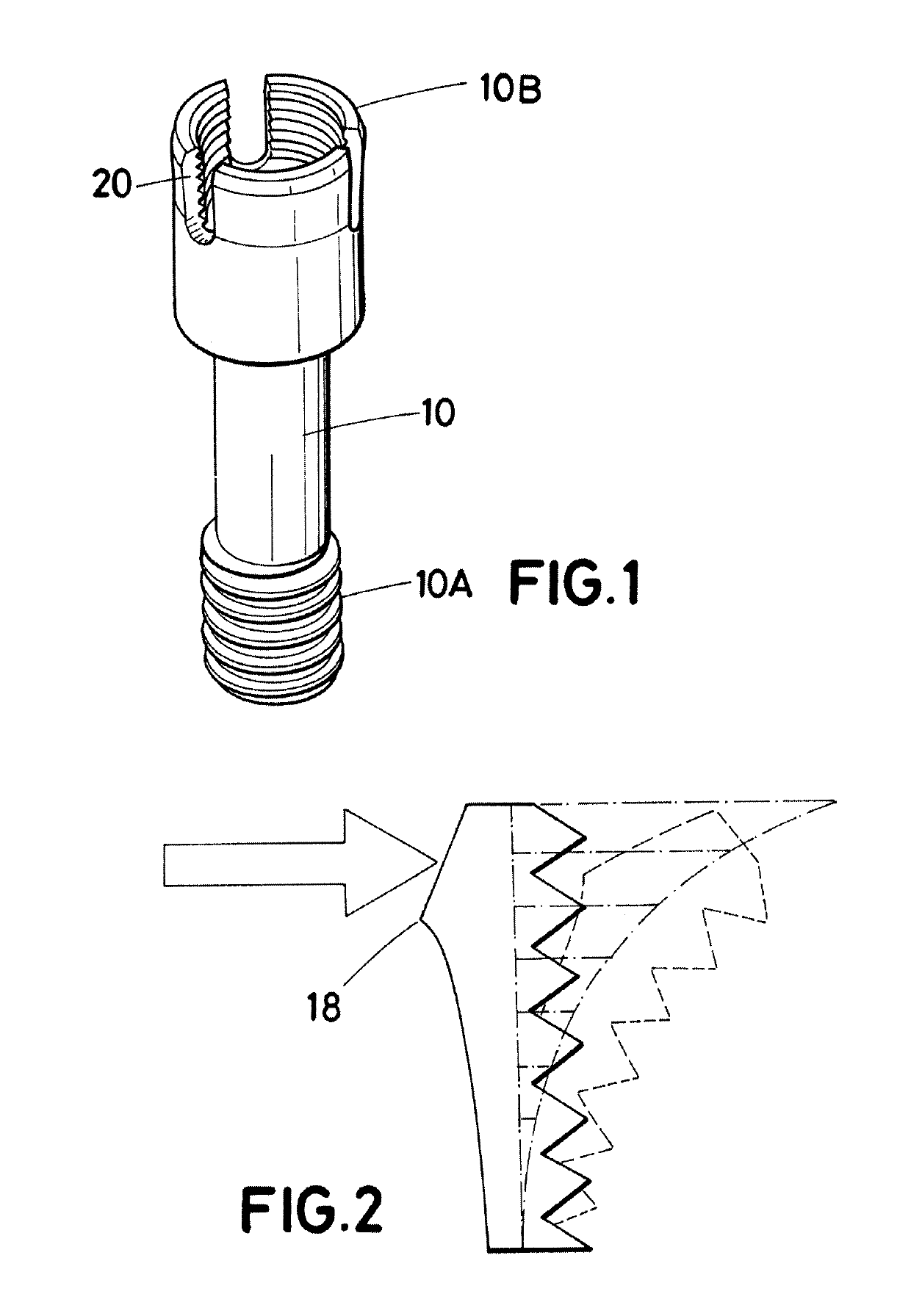

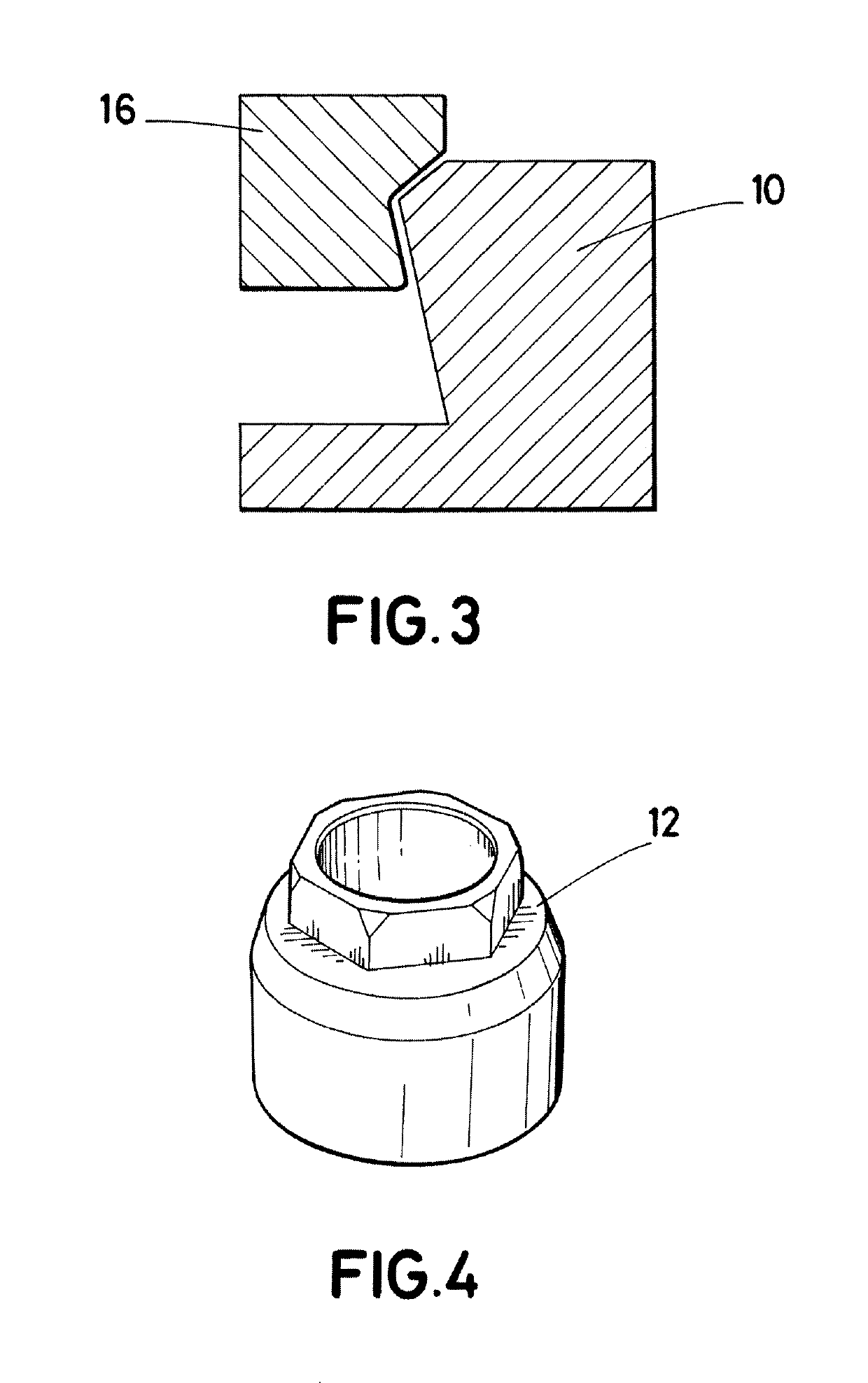

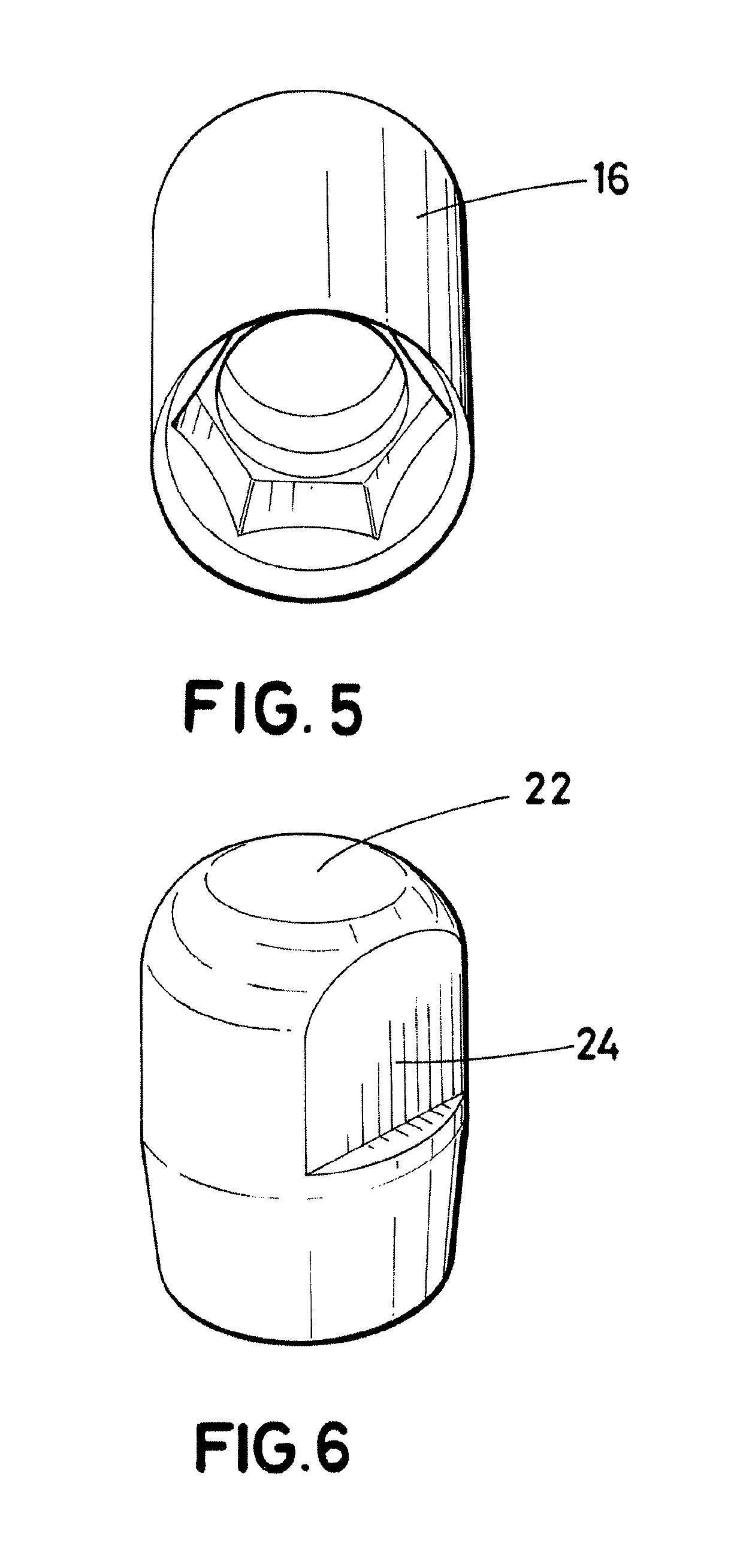

Impression post and temporary abutment and method of making dental restoration

InactiveUS20030054319A1Facilitating torque limitationEasy to shapeDental implantsFastening prosthesisEngineeringAbutment

The disclosed fixture mount limits torque that may be applied when installing a dental implant and also serves as an impression post and an abutment for a temporary prosthesis. In preferred embodiments, the fixture mount is formed of plastic and is subject to chair side modifications by the surgeon so as to be better suited as an abutment. Methods of shaping the fixture mount for use as an abutment and for making a dental restoration using the shaped abutment are disclosed.

Owner:ZIMMER DENTAL INC

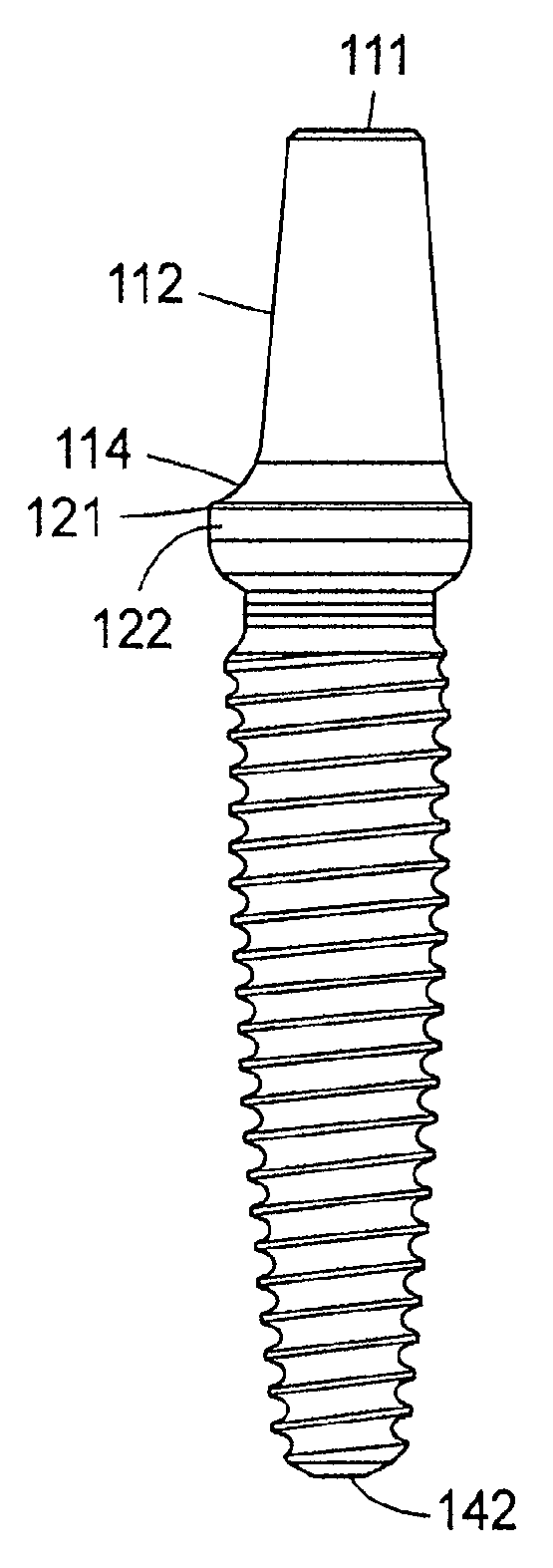

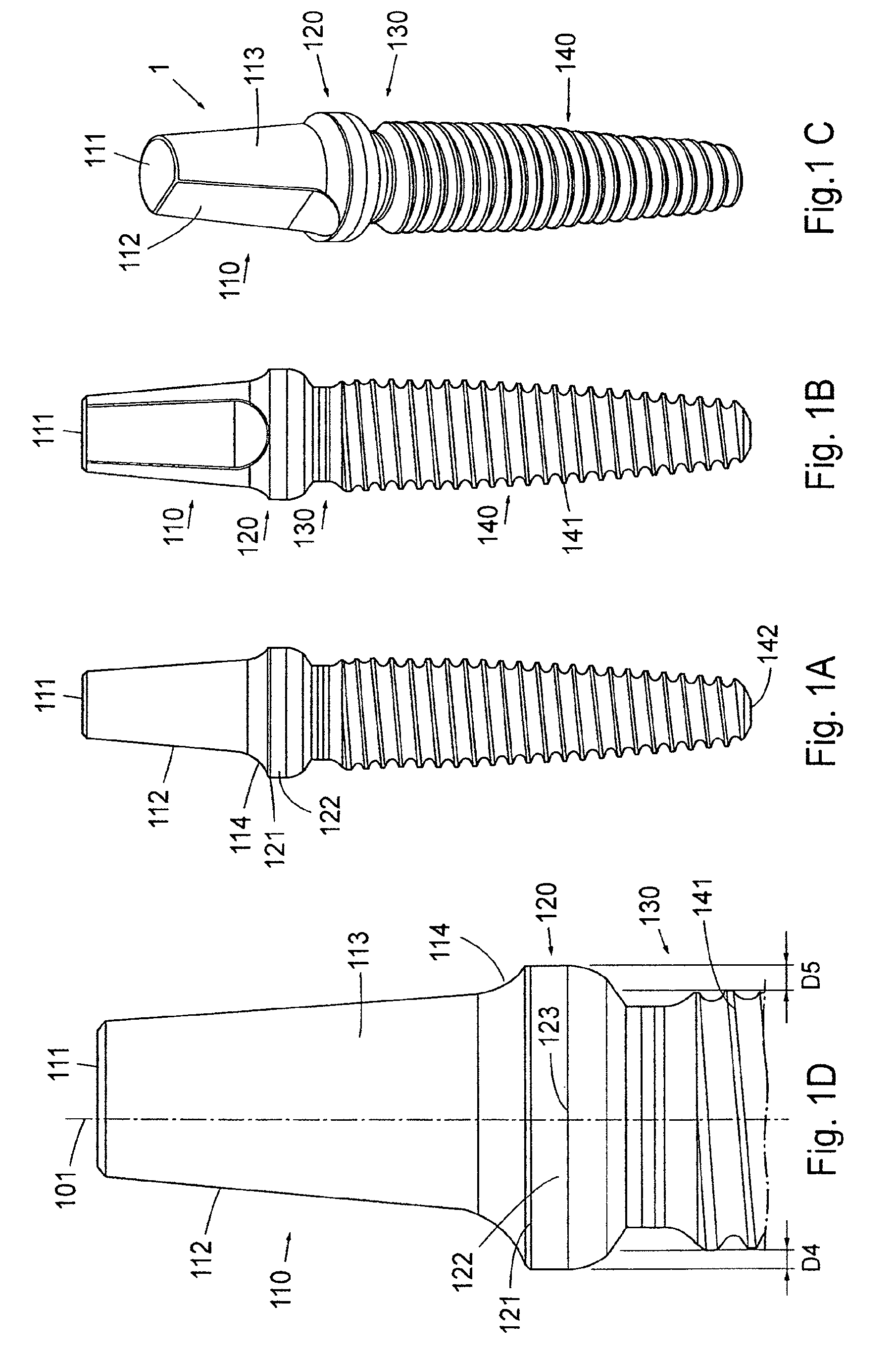

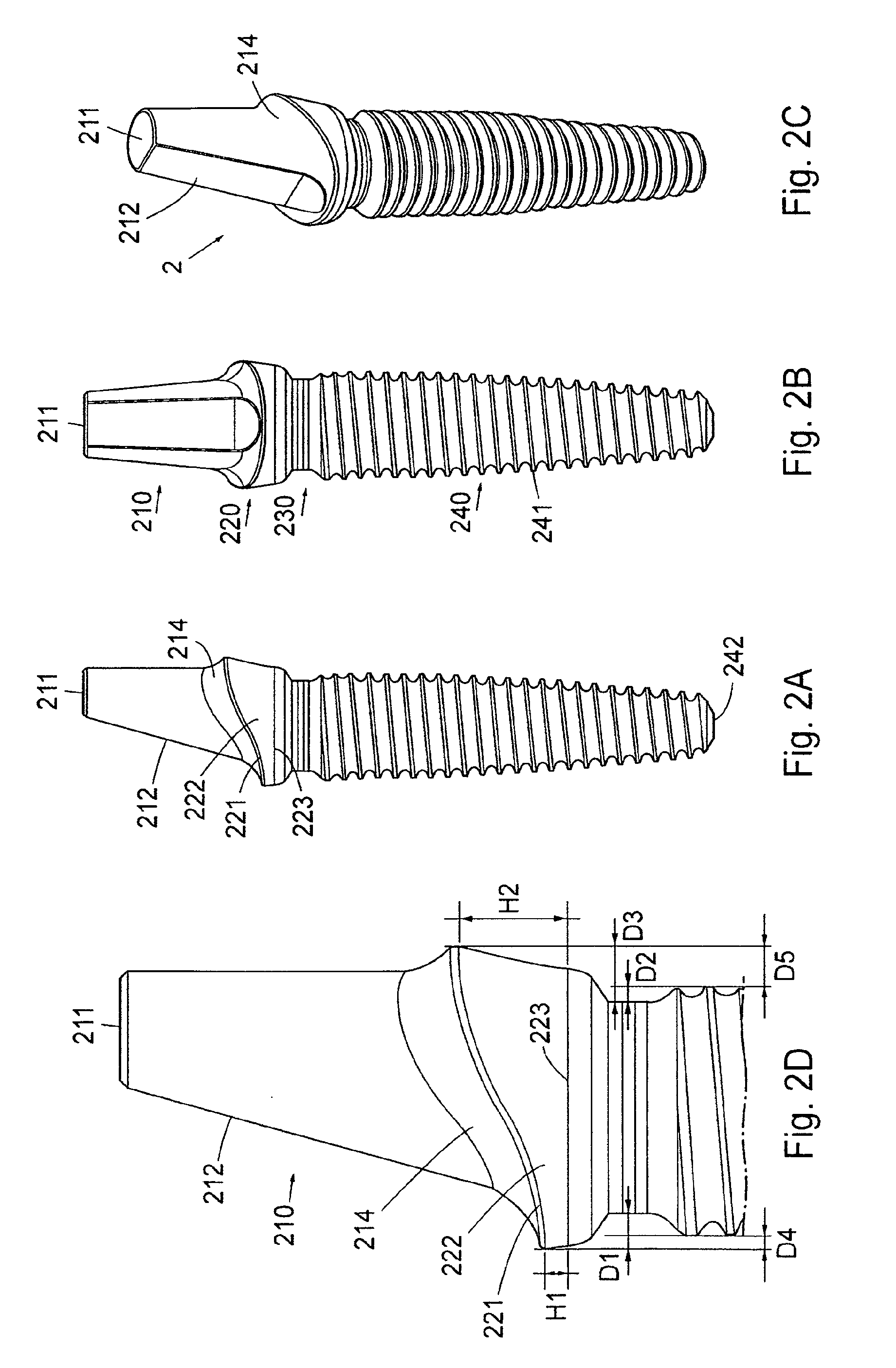

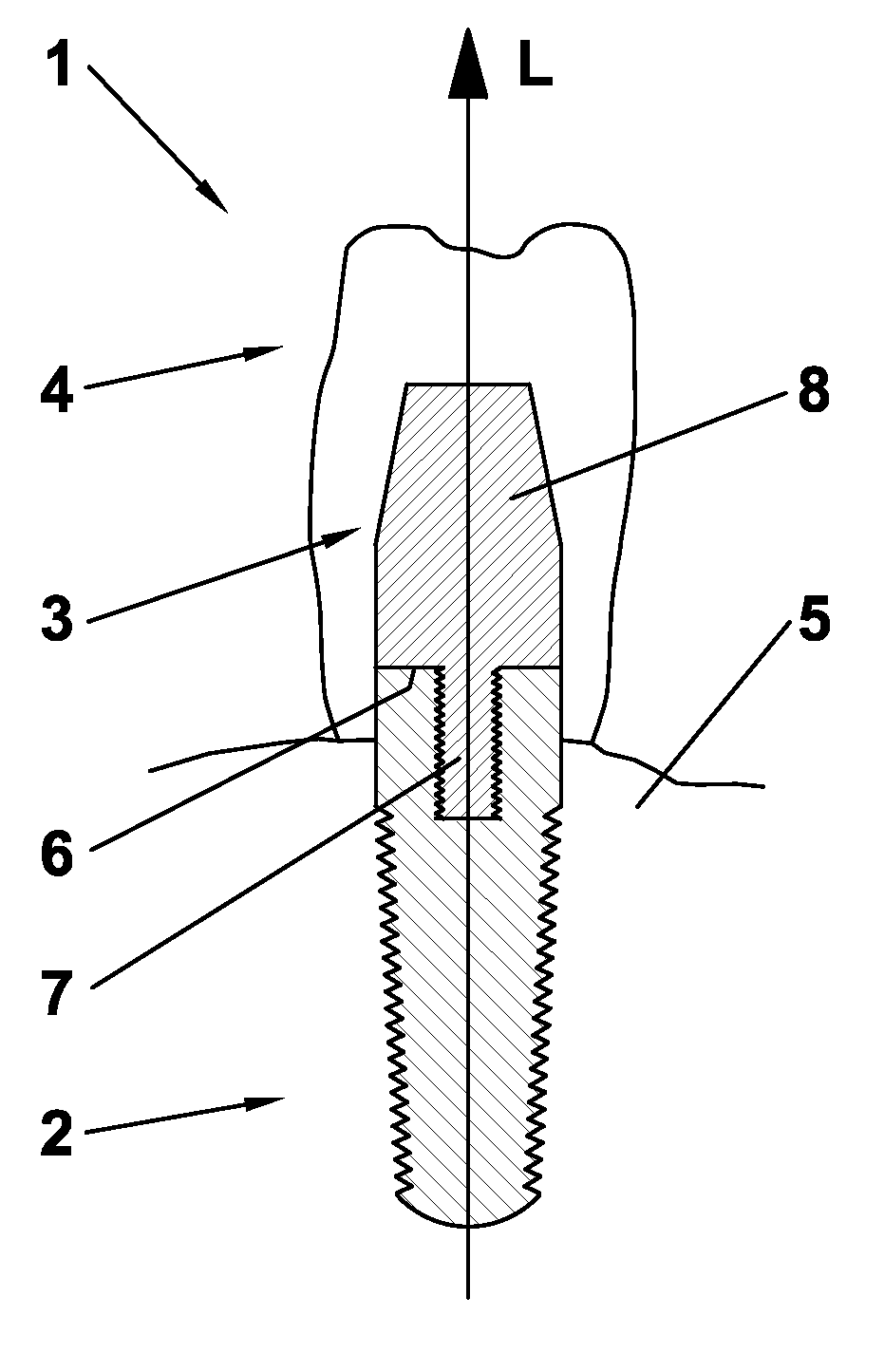

Ceramic one-piece dental implant

InactiveUS20110014586A1Easy to disassembleKeep widthDental implantsFastening prosthesisDental implantBiomedical engineering

A ceramic one-piece implant is provided that comprises a first portion and a second portion that are integrally formed with each other. The first portion can be arranged at a coronal end of the implant for fitting engagement with a dental restoration to the implant. The second portion can contiguously adjoin the first portion at a coronal edge. Further, the second portion can have a width and be arranged apically from the coronal end of the implant. The second portion can also be devised for arrangement in epithelial contact with soft tissue upon implantation of the dental implant. Furthermore, a curvature including the coronal edge can be adjustable by removal of material at least from the second portion while the width of the shoulder is substantially maintained.

Owner:NOBEL BIOCARE SERVICES AG

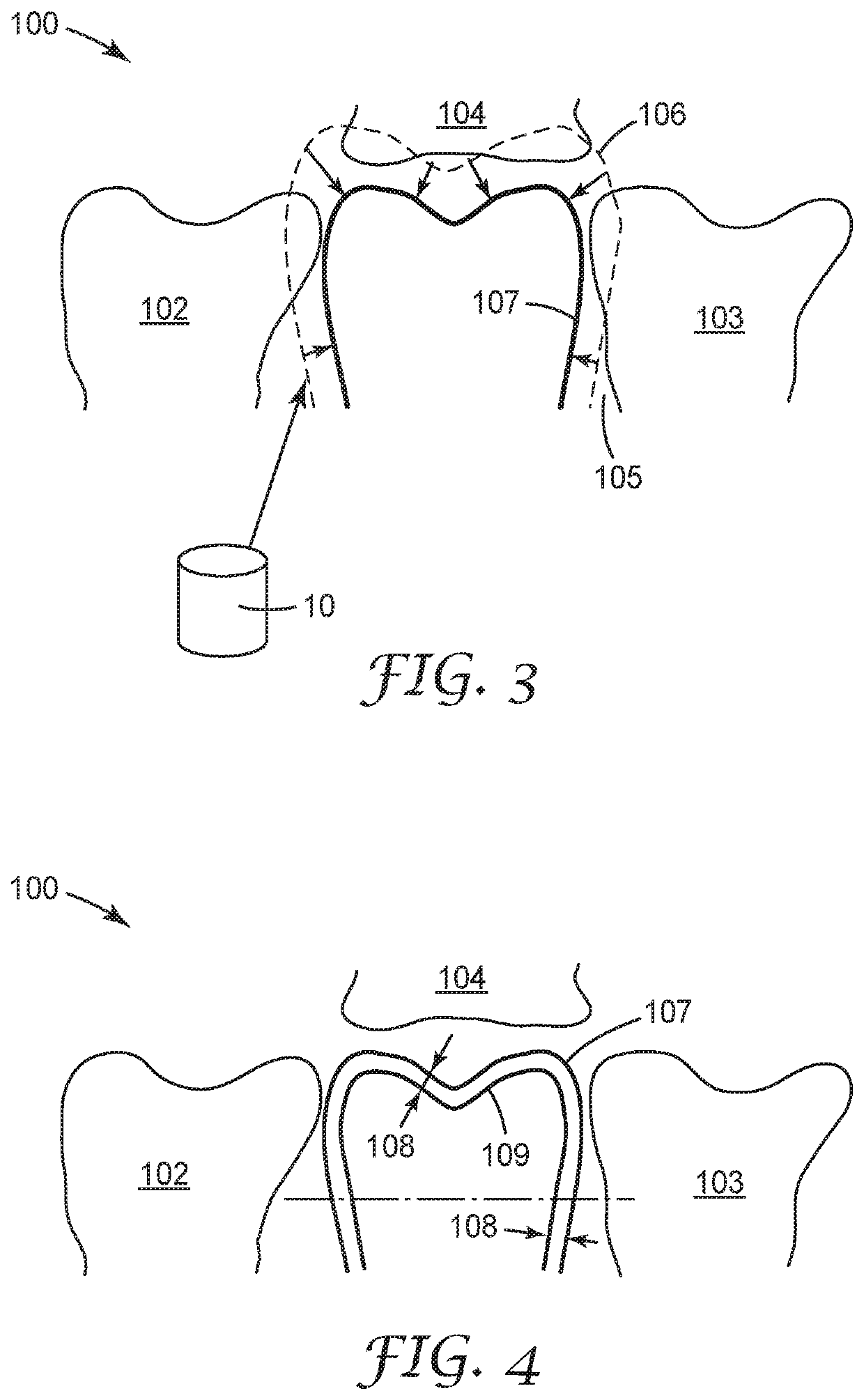

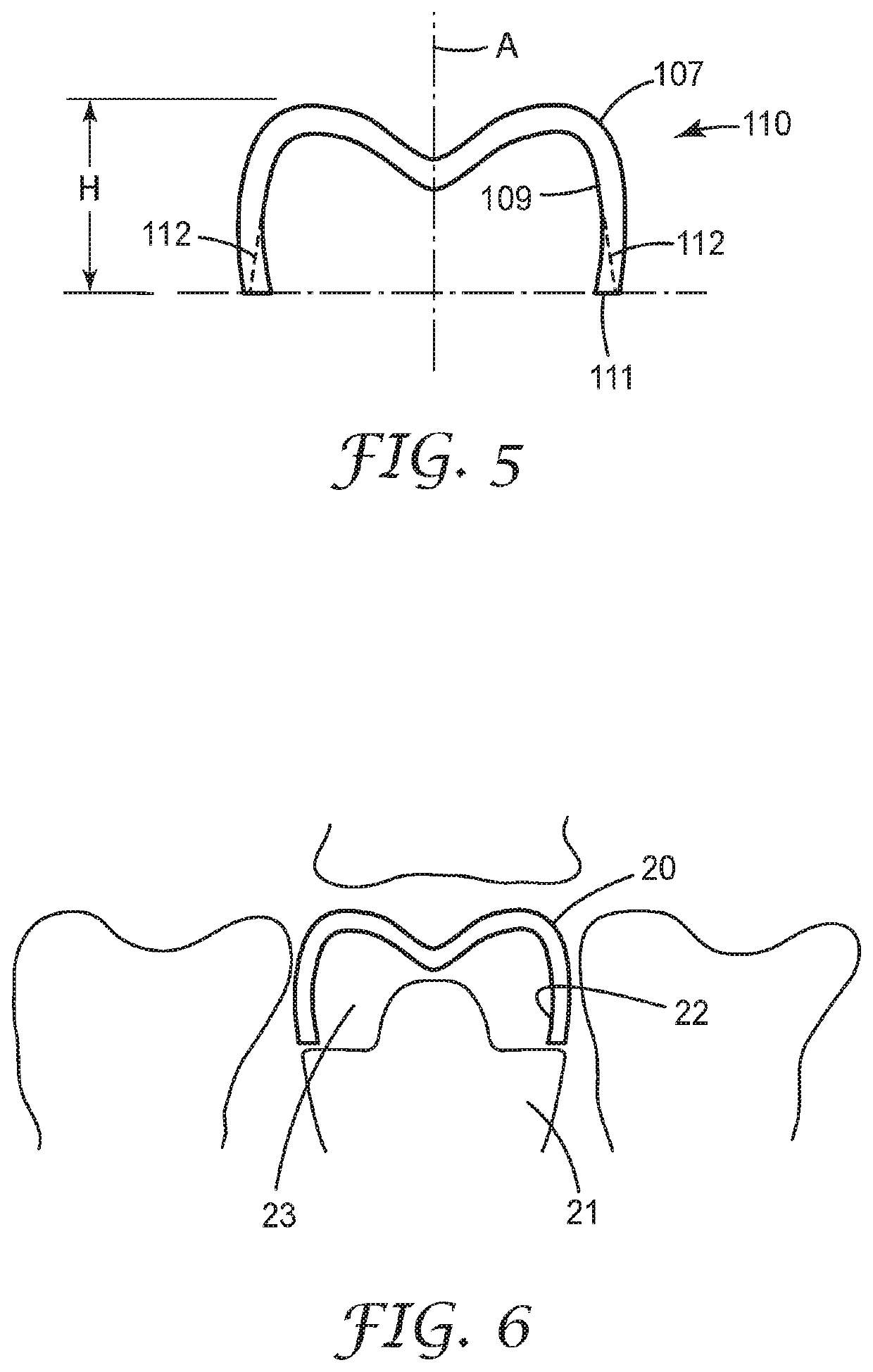

Method for dental restoration and related kit

The disclosure generally relates to a method for forming a dental mold. The method generally includes: (a) scanning an existing dental structure to generate a three-dimensional first digital model of the existing dental structure, (b) modifying the first digital model of the existing dental structure to generate a three-dimensional second digital model of a planned dental structure; (c) generating a three-dimensional third digital model corresponding to a negative of the second digital model; (d) digitally sectioning the third digital model into at least one buccal model portion and at least one lingual model portion of the third digital model; and (e) creating a dental mold comprising at least one buccal mold portion and at least one lingual mold portion based on the sectioned third digital model. The disclosure also relates to (a) methods of assembling the dental mold over a tooth and a gum of a patient having an existing dental structure in need of dental restoration, (b) methods of performing a dental restoration on the existing dental structure of the patient using the dental mold, and (c) kits including components for forming the dental mold and / or for performing the dental restoration using the dental mold.

Owner:VUILLEMOT WILLIAM C

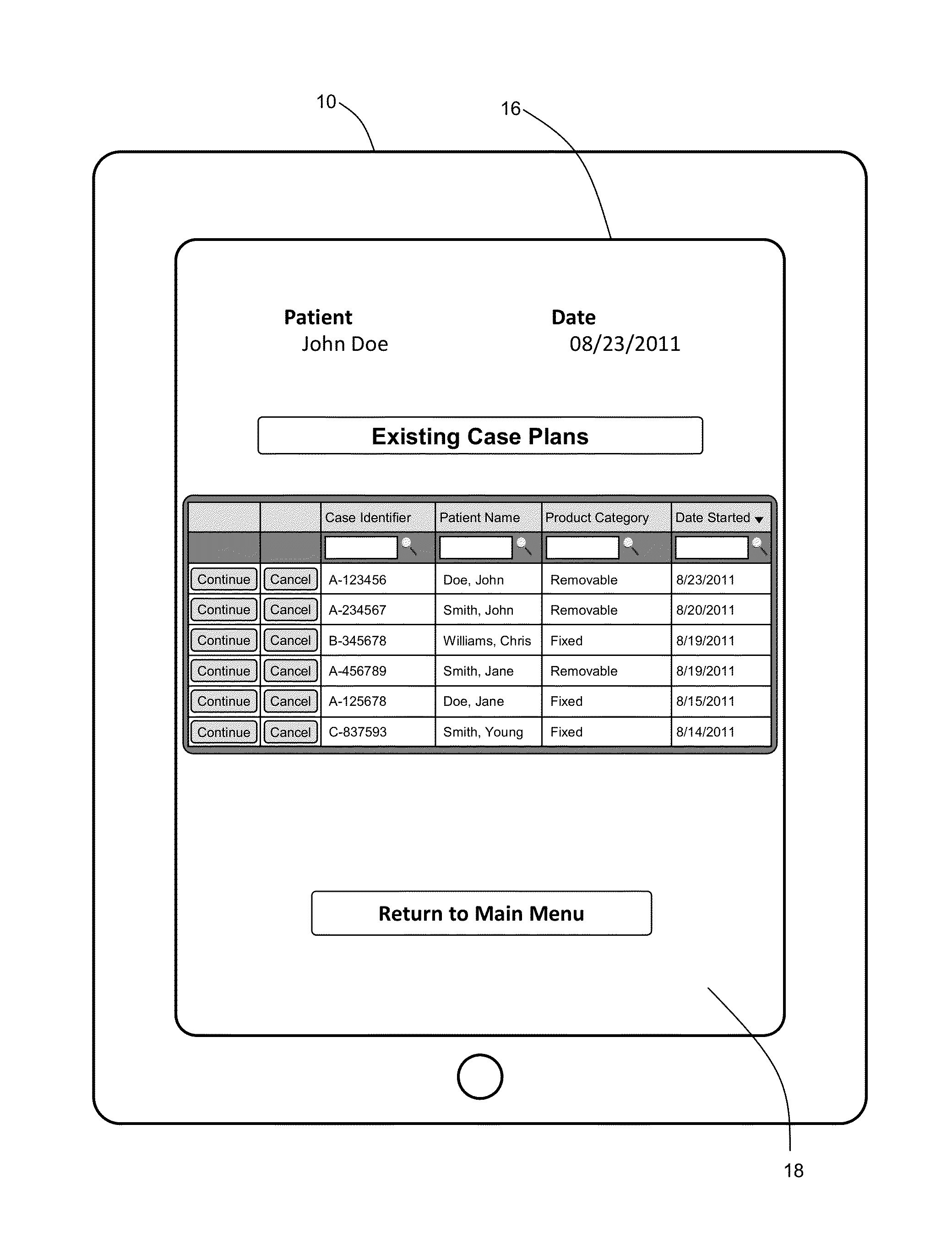

System and method for planning a first and second dental restoration

ActiveUS20120282567A1Improve time efficiencyMany timesSpecial data processing applicationsBoring toolsCode segmentMedical treatment

A computer-based method and system of virtually planning a dental restoration in a patient are disclosed, including steps, units or code segments for virtually planning a first dental restoration. First production data is based on the planned first dental restoration for production thereof or of a product related to a medical procedure for installing at least a portion of the first dental restoration in an oral cavity of the patient. Scan data is provided including factual position data and / or factual shape data based on the first dental restoration when at least partly installed in the oral cavity of the patient. The second dental restoration is virtually planned, including adjusting the planned first dental restoration in dependence of the scan data. Second production data is provided based on the planned second dental restoration useful for production of the second dental restoration.

Owner:NOBEL BIOCARE SERVICES AG

Machinable Porcelain Compositions and Mill Blanks Thereof

A porcelain blank comprising a porcelain composition for dental restorations comprising a leucite crystallite phase and a glass matrix phase, wherein the leucite crystallites possess diameters not exceeding about 10 micron. Preferably, the porcelain composition has a maturing temperature from about 750° C. to about 1050° C. and a coefficient of thermal expansion from about 9×10−6 / ° C. to about 17.5×10−6 / ° C., and comprises:SiO257-67 Al2O37-15K2O7-15Na2O6-15Li2O0.5-3.

Owner:ARDENT

Making method for bionic ceramic dental prosthesis

InactiveCN108618969AImprove wear performanceAchieve bionic color effectsImpression capsDentistry preparationsColor effectWear resistant

The invention relates to a making method for a bionic ceramic dental prosthesis. The method comprises the steps that conventional 3mol% yttrium-stabilized zirconium dioxide ceramic with high strengthand low transparency and ceramic with high transparency are selected as prefabricated powder; a blank block / disc is pressed in a layered mode; in a transition buffer layer from the lower surface of ablank to the upper surface, the proportion of the 3mol% yttrium-stabilized zirconium dioxide ceramic is gradually decreased from 100% to 0, and the proportion of the ceramic with low strength and hightransparency is gradually increased from 0 to 100%; an occlusal surface or an attractive area of a CAD digital model of the dental prosthesis is placed on a bionic performance / color layer, and an axial surface area is placed on a high-strength anti-fracture layer; and making is completed by utilizing dental prosthesis manufacturing equipment. The method has the advantages that the problems that ajaw tooth is excessively worn by a high-strength single-layer full zirconia prosthesis, no stress buffer exists in the all-ceramic prosthesis implanting process, and the prosthesis is prone to beingfractured in the long time when totally adopting a bionic abrasion-resistant ceramic material can be solved, and meanwhile, the bionic color effect of the prosthesis can be achieved.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Abutment for a dental implant

InactiveUS20120288825A1High retention rateIncrease mechanical retentionDental implantsFiberNatural tooth

The invention relates to an abutment for connecting a dental prosthesis to a dental implant, the abutment comprising a body portion for supporting the dental prosthesis and a contact surface apical to said body portion for contacting the dental implant.In order to allow an adjustment of the tooth restoration structure to properties of a natural tooth the abutment is composed of a resin that is reinforced with fibers substantially extending over the total length of said body portion towards said contact surface.

Owner:NORDIN PETER +1

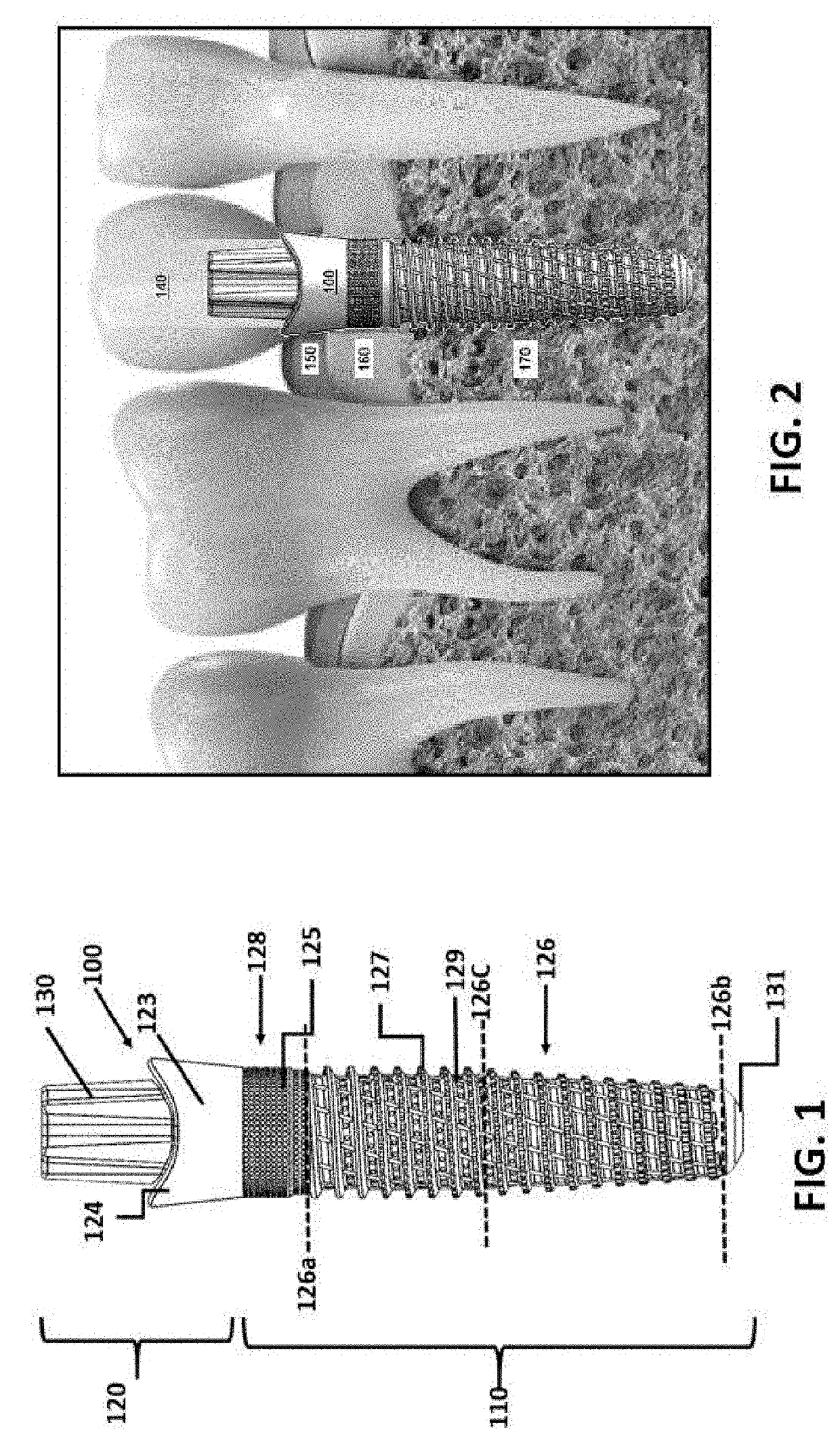

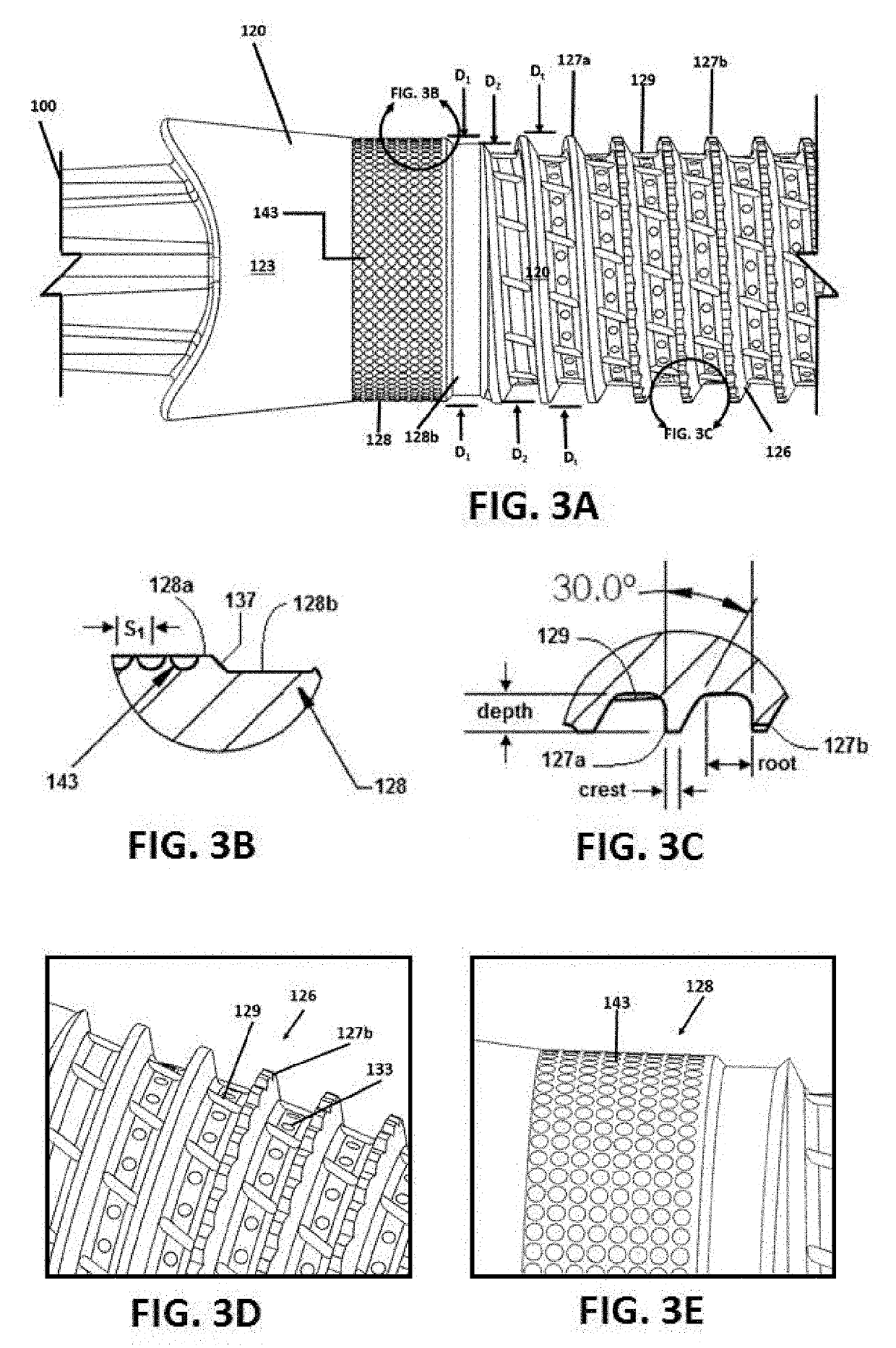

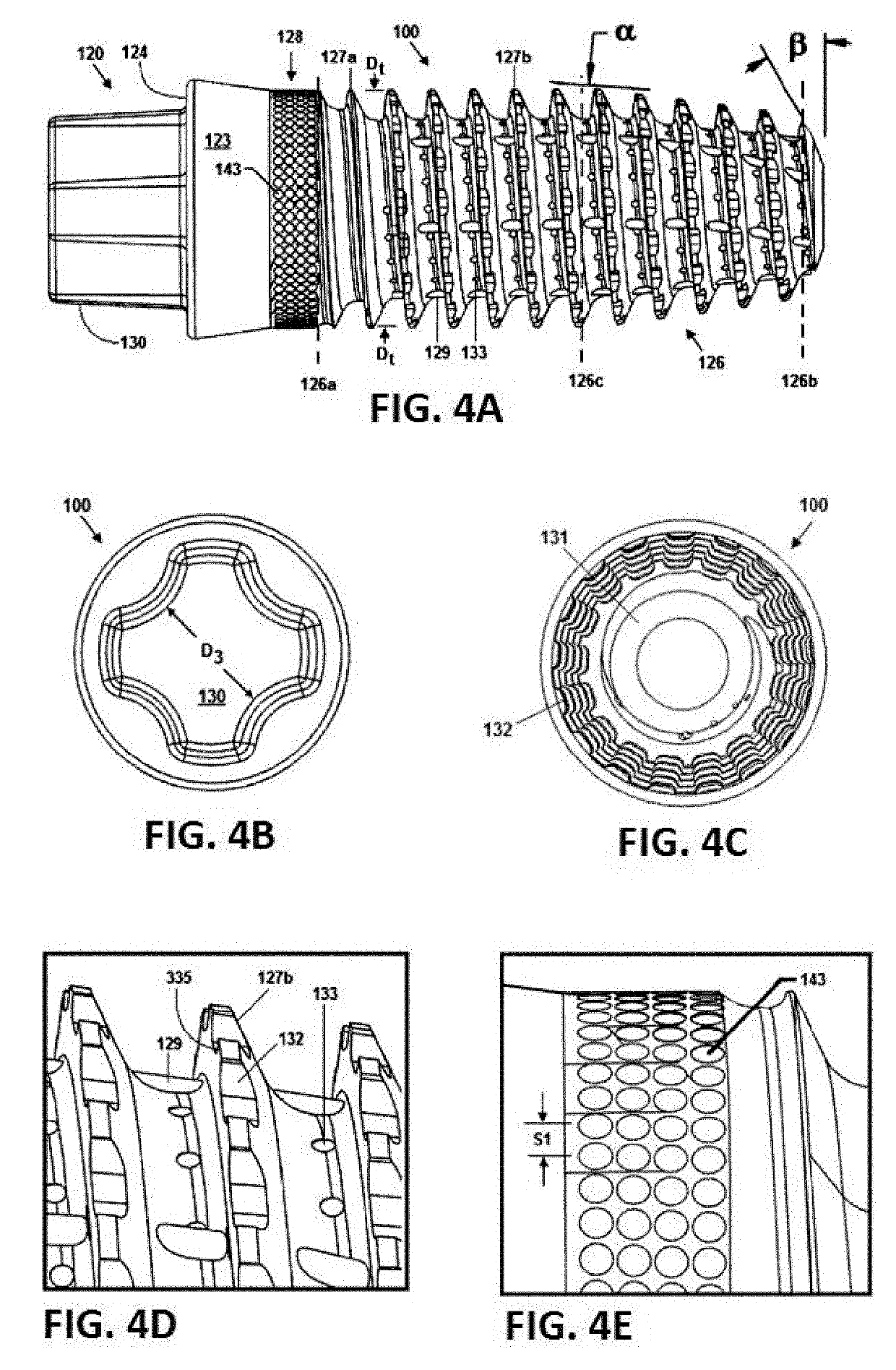

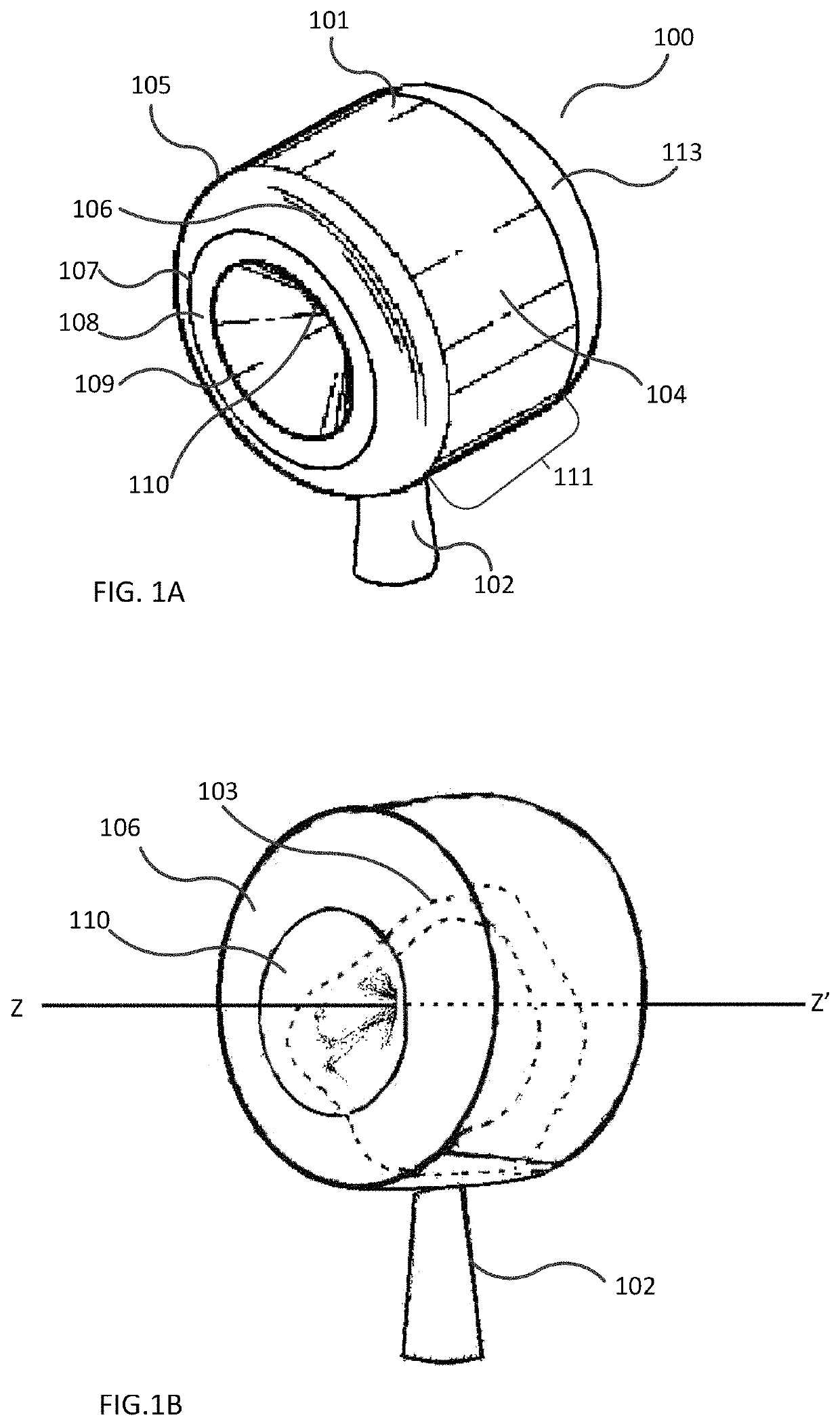

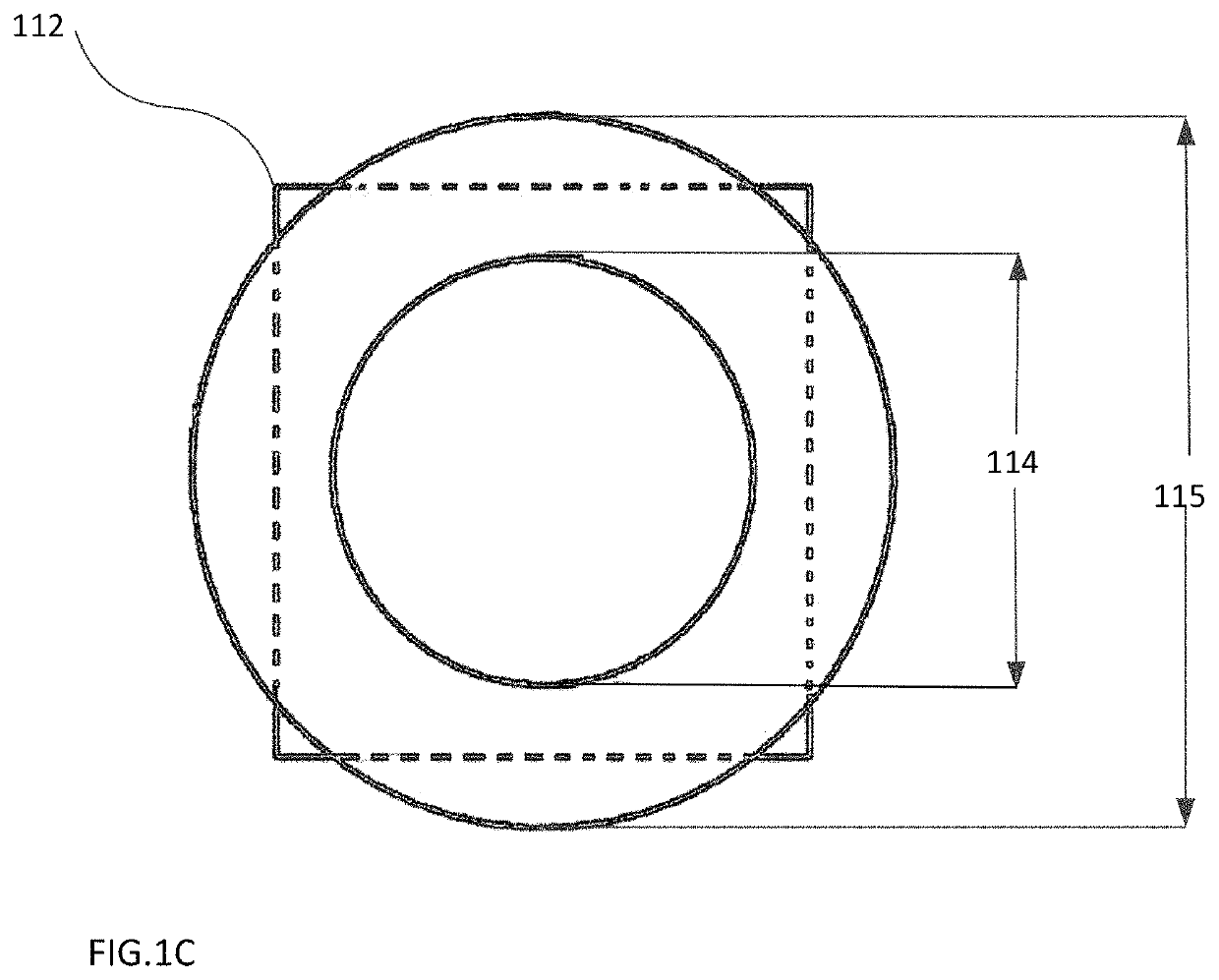

Osseointegrative surgical implant

ActiveUS20190269484A1Good light transmissionImprove stabilitySuture equipmentsDental implantsCeramic compositeTitanium oxide

Embodiments of the present invention provide an osseointegrative implant and related tools, components and fabrication techniques for surgical bone fixation and dental restoration purposes. In one embodiment an all-ceramic single-stage threaded or press-fit implant is provided having finely detailed surface features formed by ceramic injection molding and / or spark plasma sintering of a powder compact or green body comprising finely powdered zirconia. In another embodiment a two-stage threaded implant is provided having an exterior shell or body formed substantially entirely of ceramic and / or CNT-reinforced ceramic composite material. The implant may include one or more frictionally anisotropic bone-engaging surfaces. In another embodiment a densely sintered ceramic implant is provided wherein, prior to sintering, the porous debound green body is exposed to ions and / or particles of silver, gold, titanium, zirconia, YSZ, α-tricalcium phosphate, hydroxyapatite, carbon, carbon nanotubes, and / or other particles which remain lodged in the implant surface after sintering. Optionally, at least the supragingival portions of an all-ceramic implant are configured to have high translucence in the visible light range. Optionally, at least the bone-engaging portions of an all-ceramic implant are coated with a fused layer of titanium oxide.

Owner:OSSEODYNE SURGICAL SOLUTIONS LLC

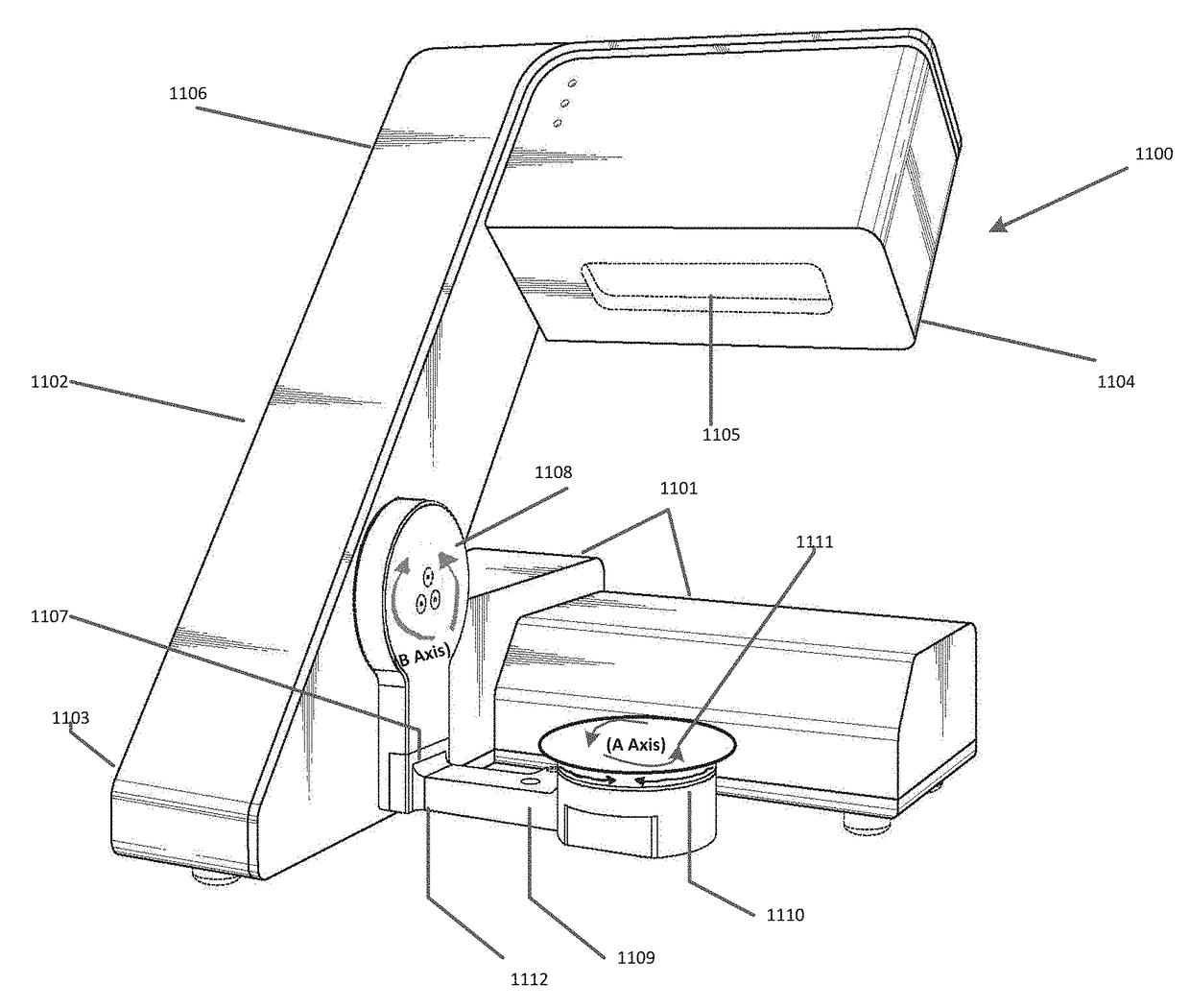

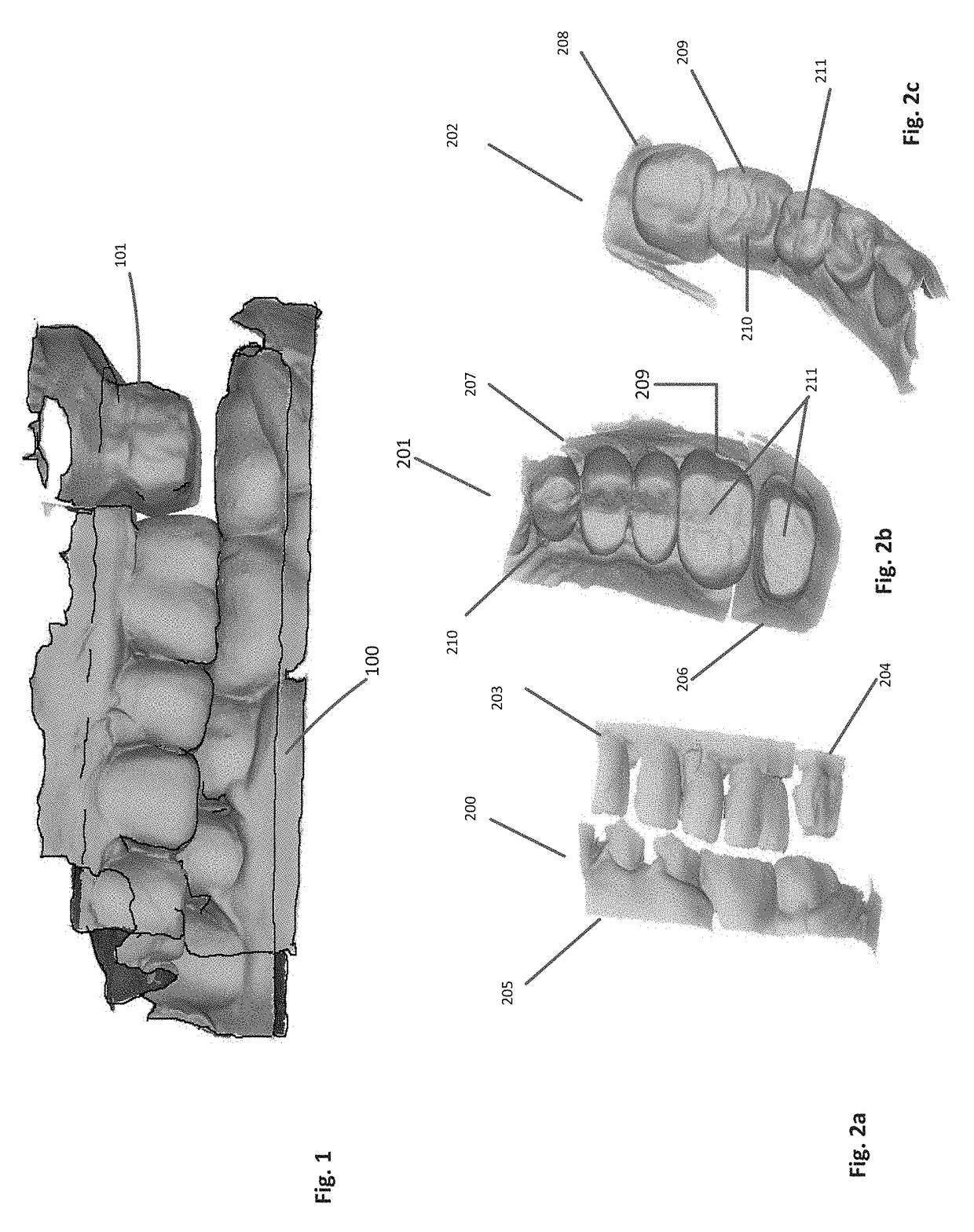

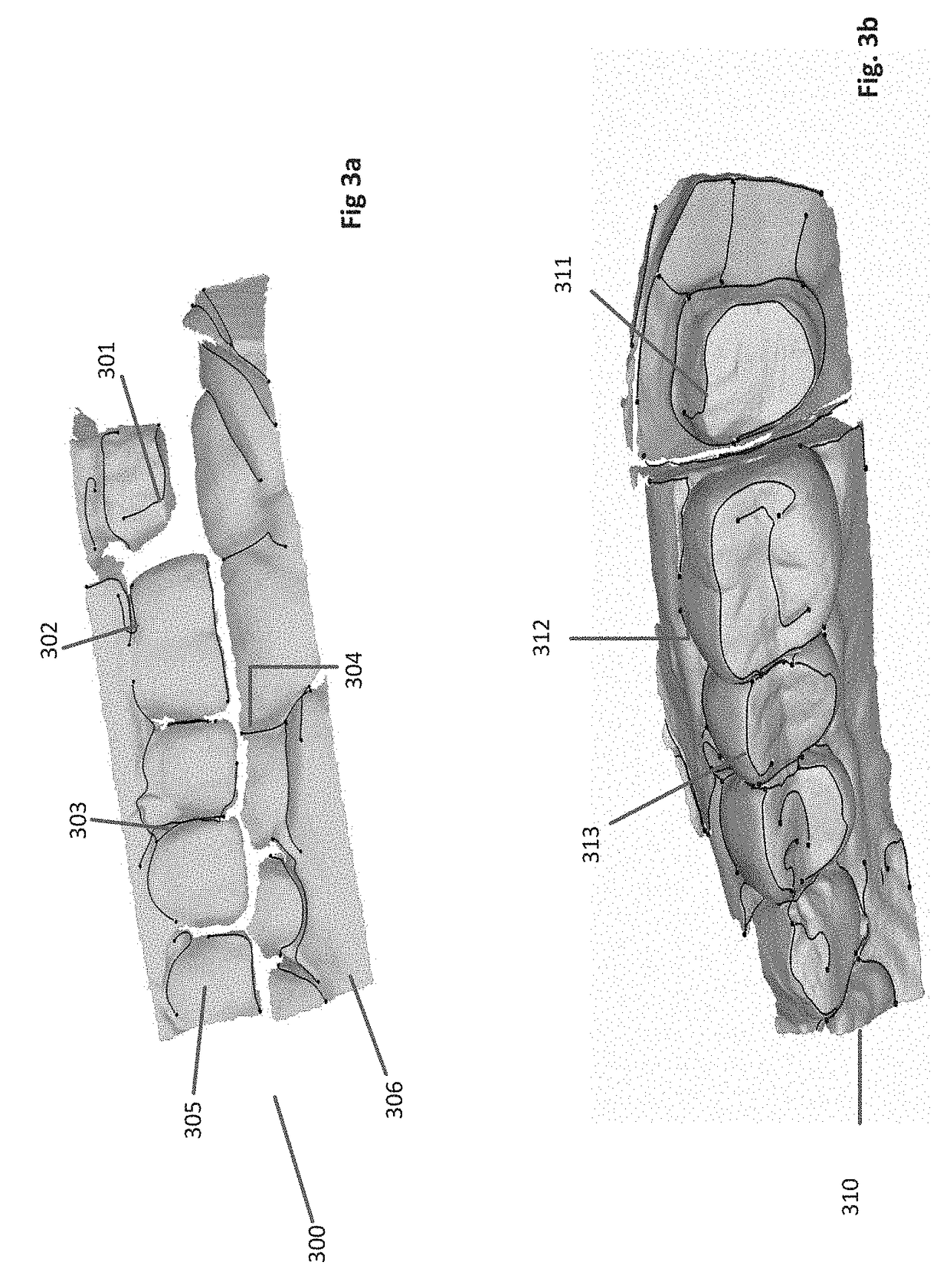

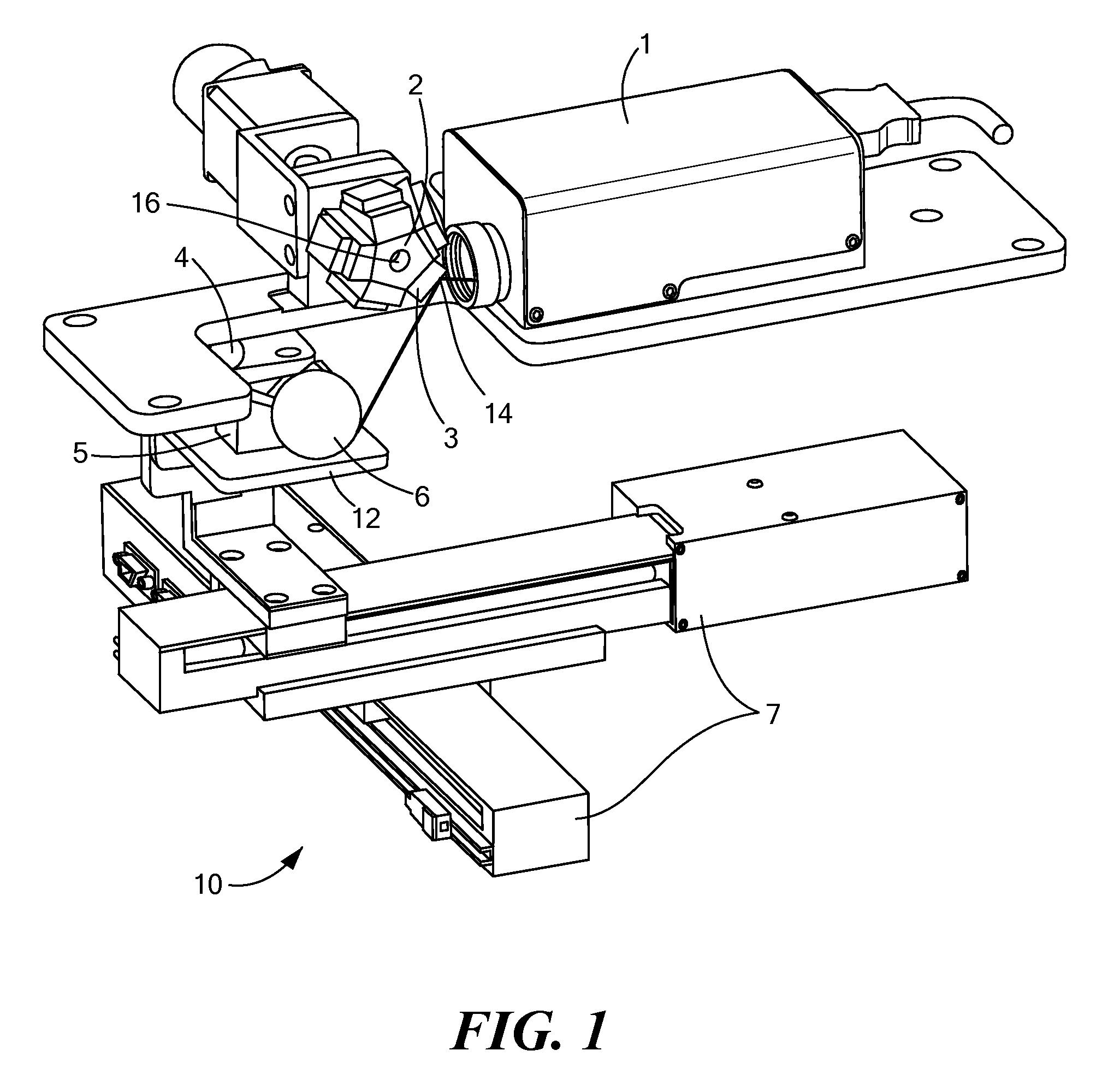

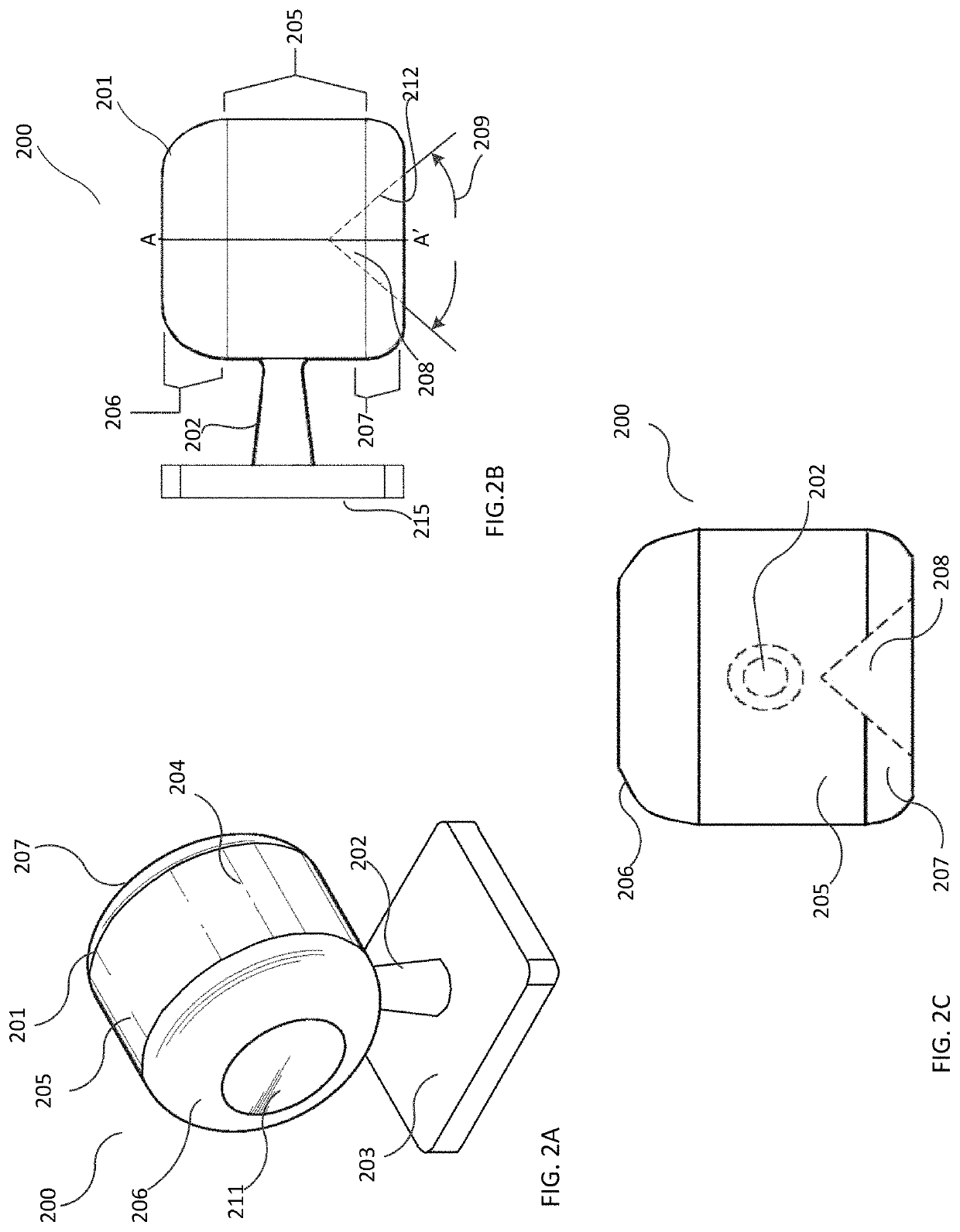

Method and Apparatus for Generation of 3D Models with Applications in Dental Restoration Design

ActiveUS20170181817A1Provide efficiencyEfficient executionImage enhancementImpression capsPhysical modelWork flow

Methods and apparatus are provided for generating computer 3D models of an object, by registering two or more scans of physical models of an object. The scans may be 3D scans registered by a curve-based registration process. A method is provided for generating a 3D model of a portion of a patient's oral anatomy for use in dental restoration design. Also provided are scanning workflows for scanning physical models of an object to obtain a 3D model.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

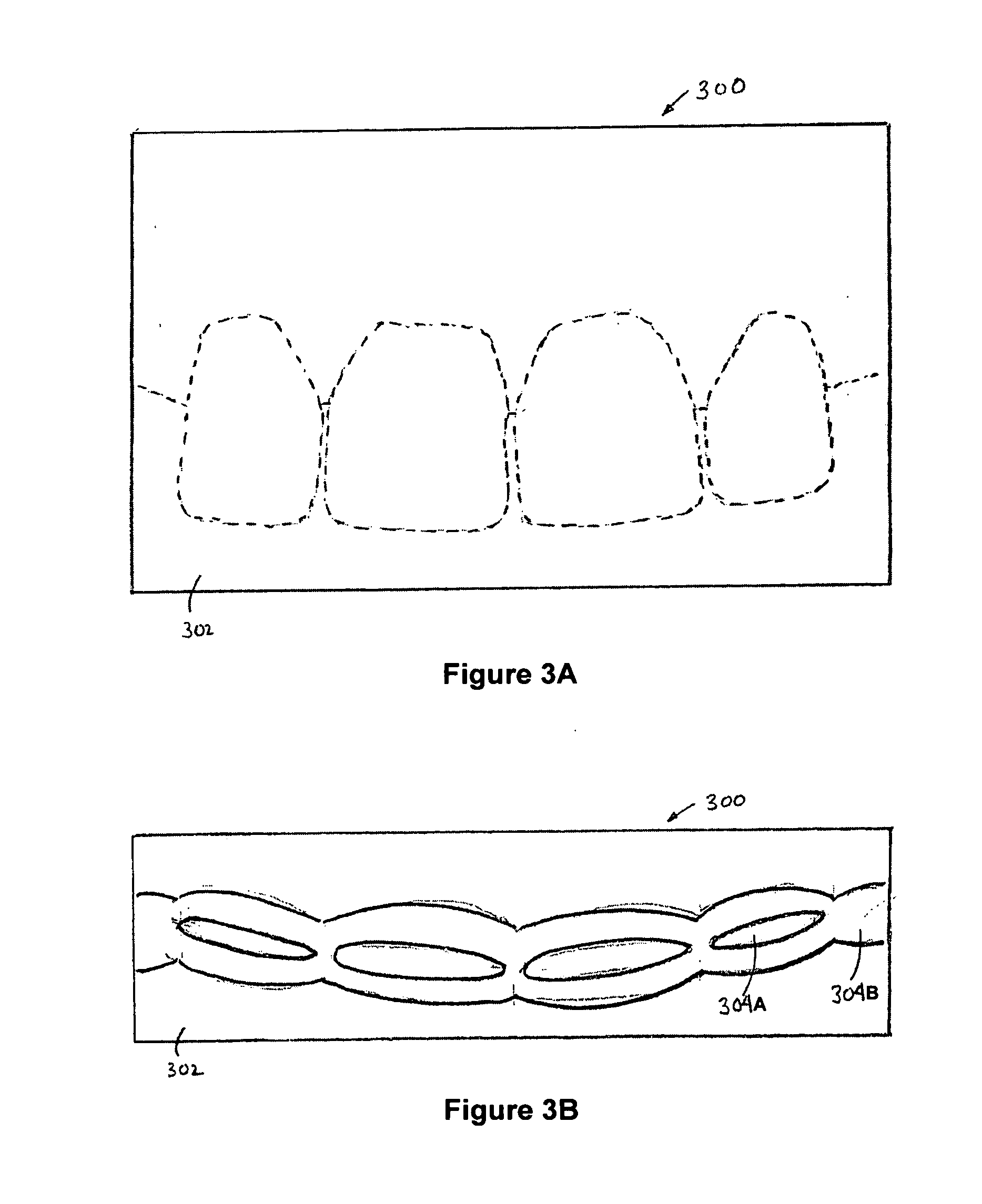

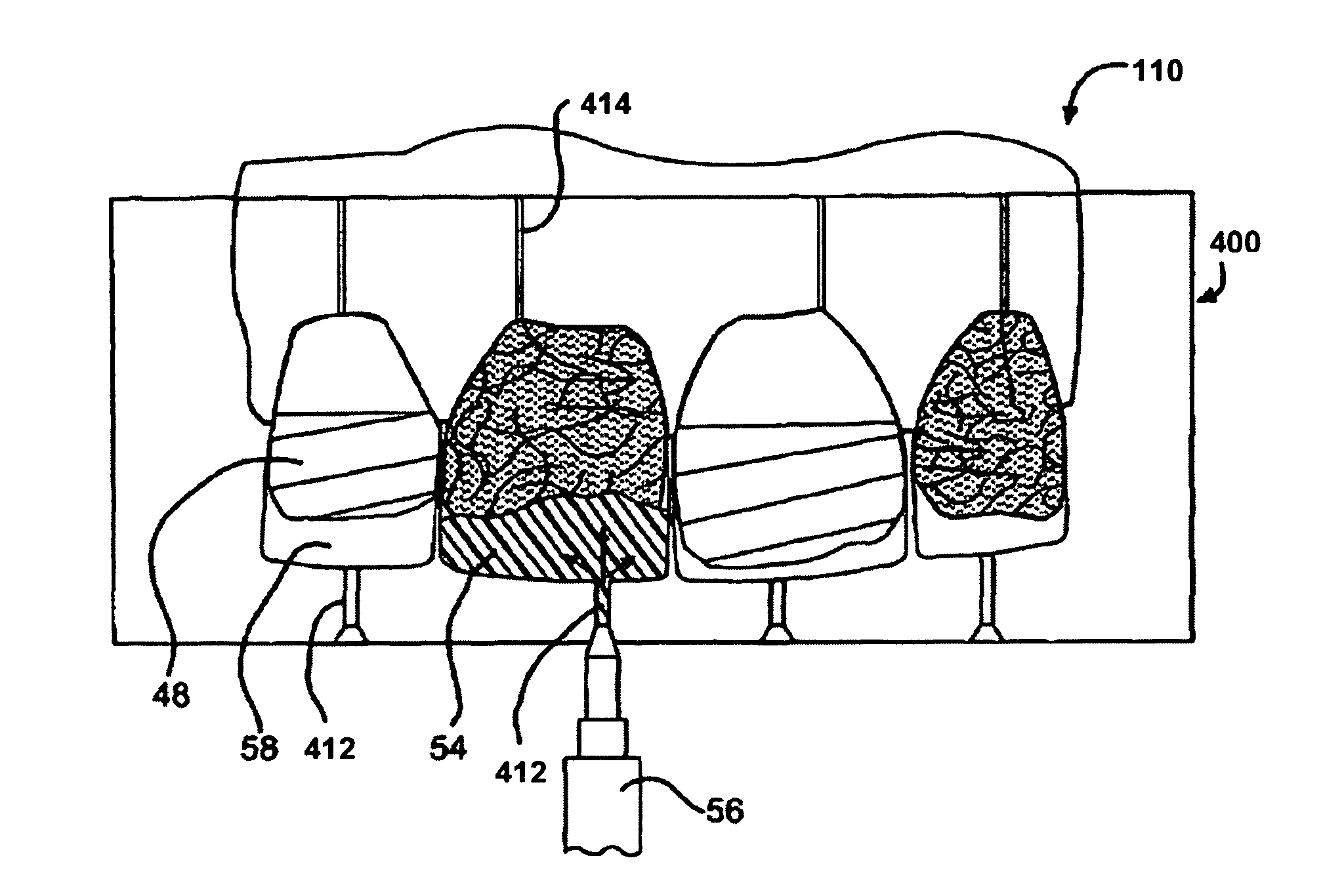

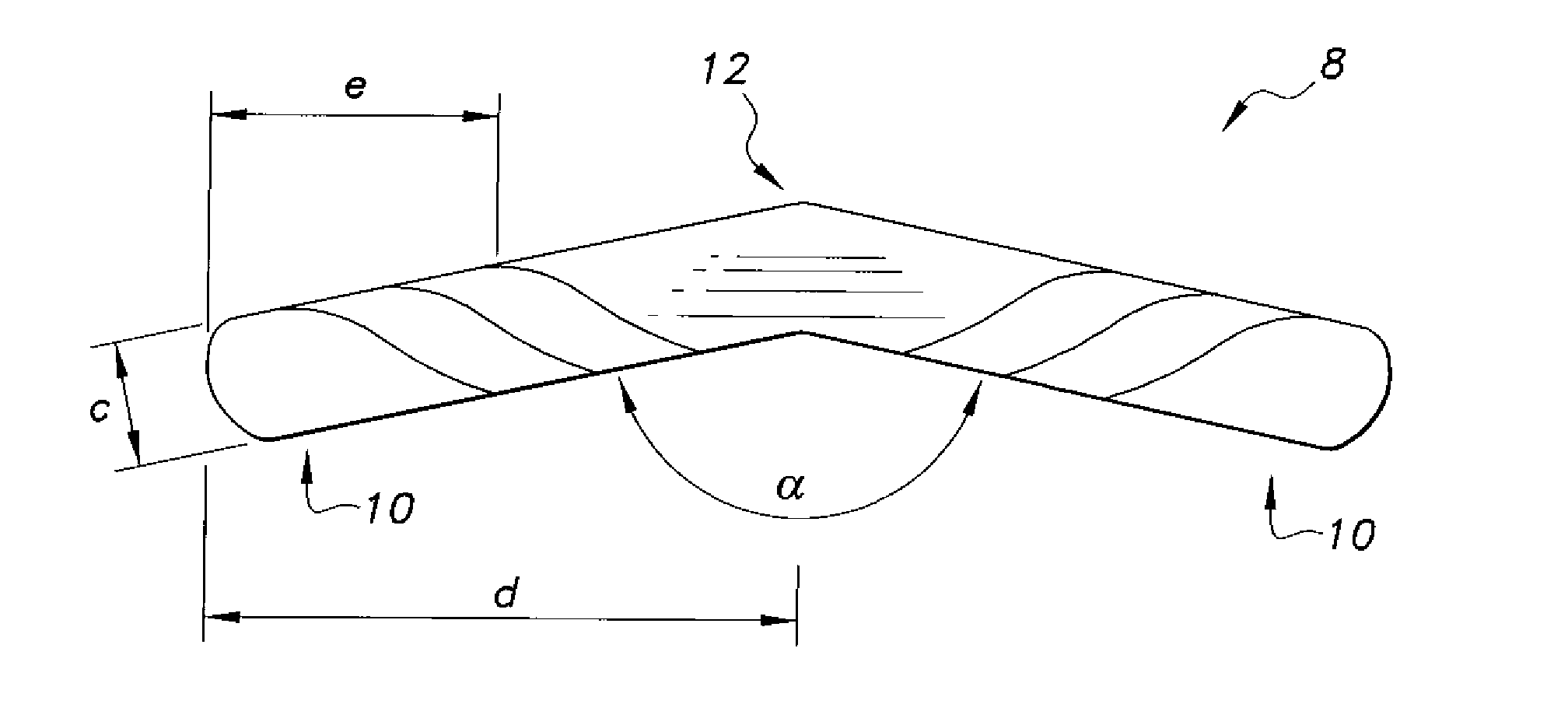

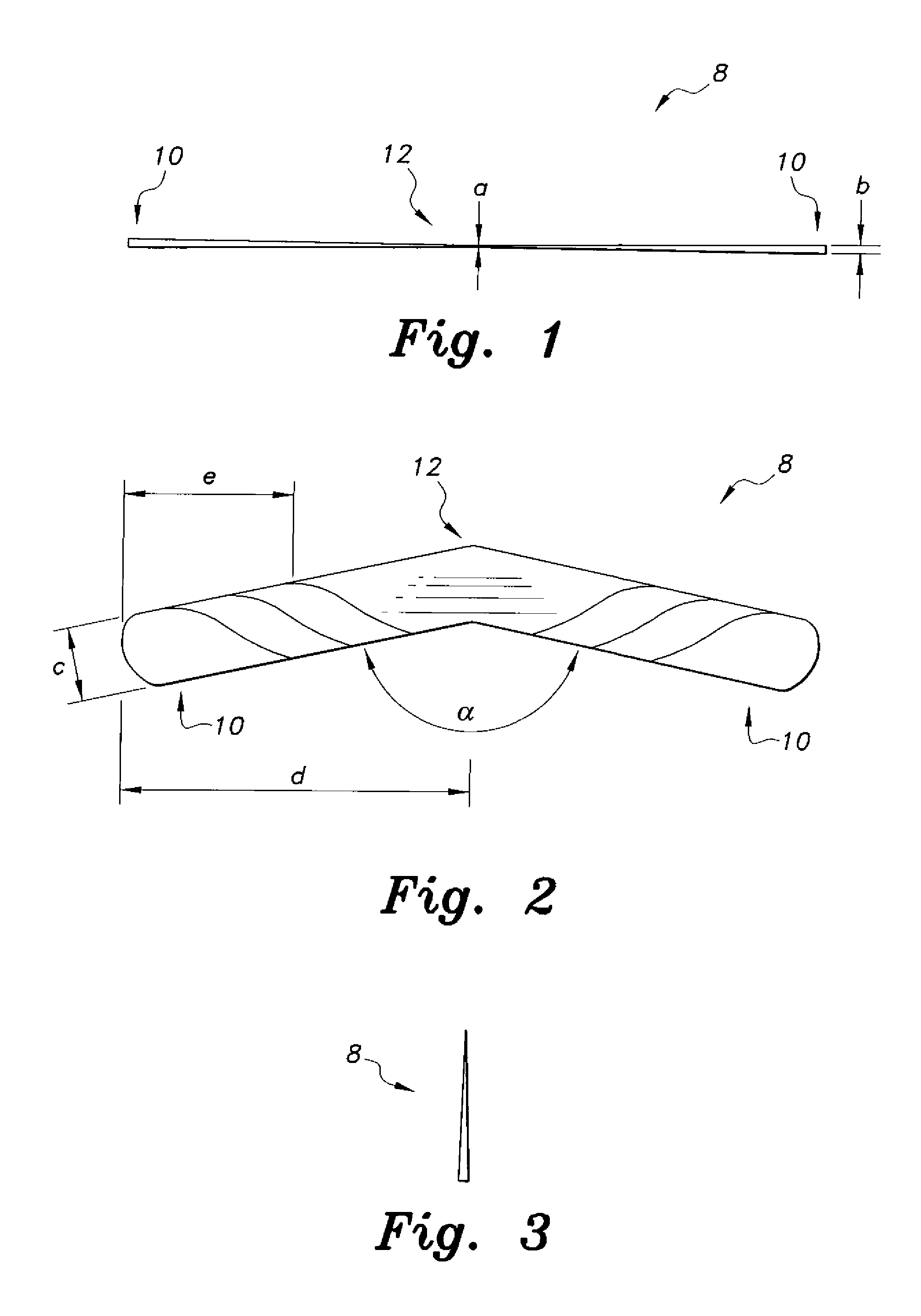

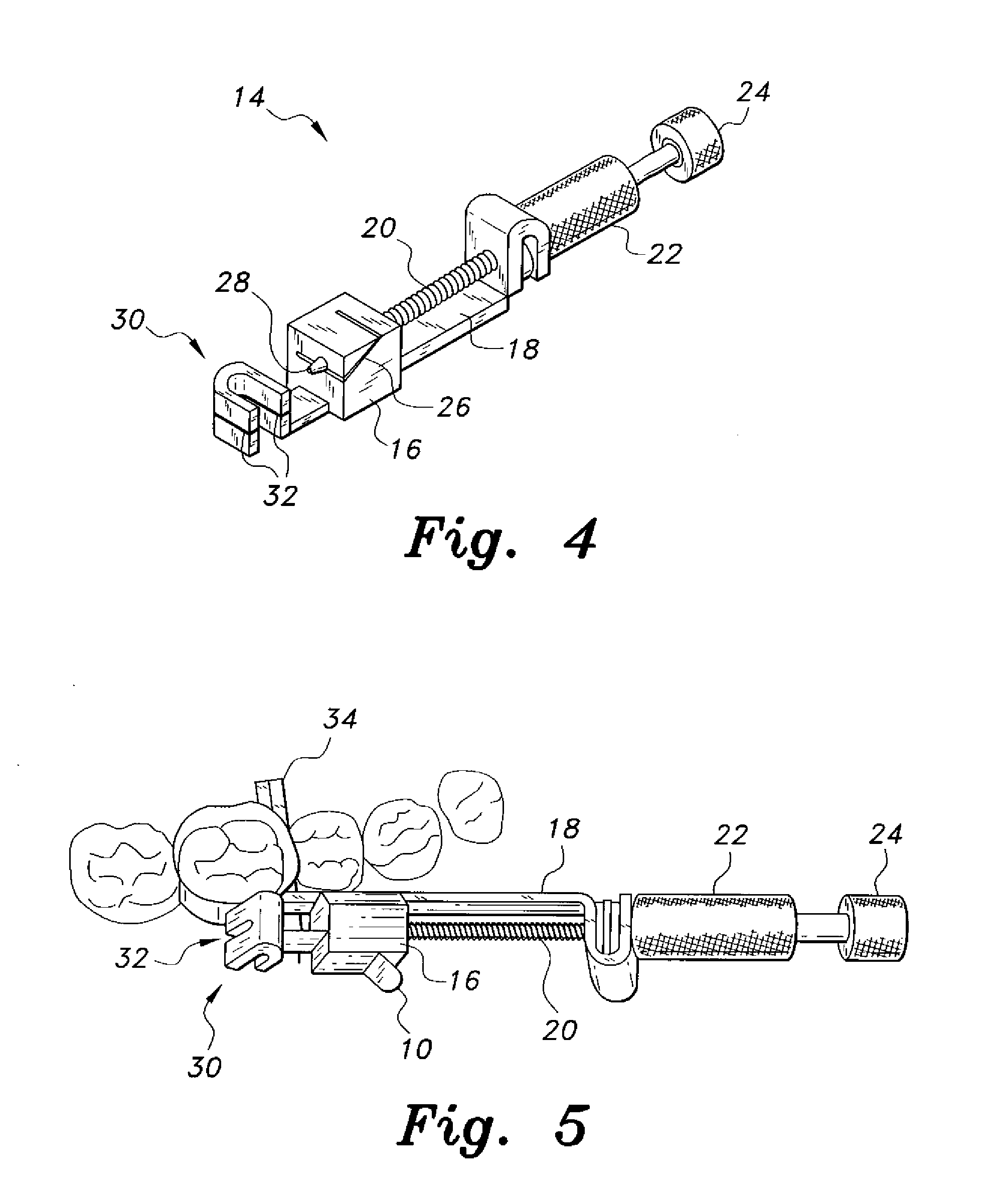

Plastic clear band for dental restorations

The plastic clear band for dental restoration is a dental matrix band having an elongate body with first and second ends and at least one light transmissive portion midway between the first and second ends. The first and second ends have a thickness greater than the light transmissive portion, the band tapering in thickness from a thin central portion to the thick first and second ends. The thick first and second ends are adapted to provide a bearing surface for the clamping screws of a matrix band retainer, while the thin central portion provides a snug fit and tight contact with the tooth. The band is made from biocompatible plastic, and has an inverted V-shape or chevron configuration when viewed from the front.

Owner:KING SAUD UNIVERSITY

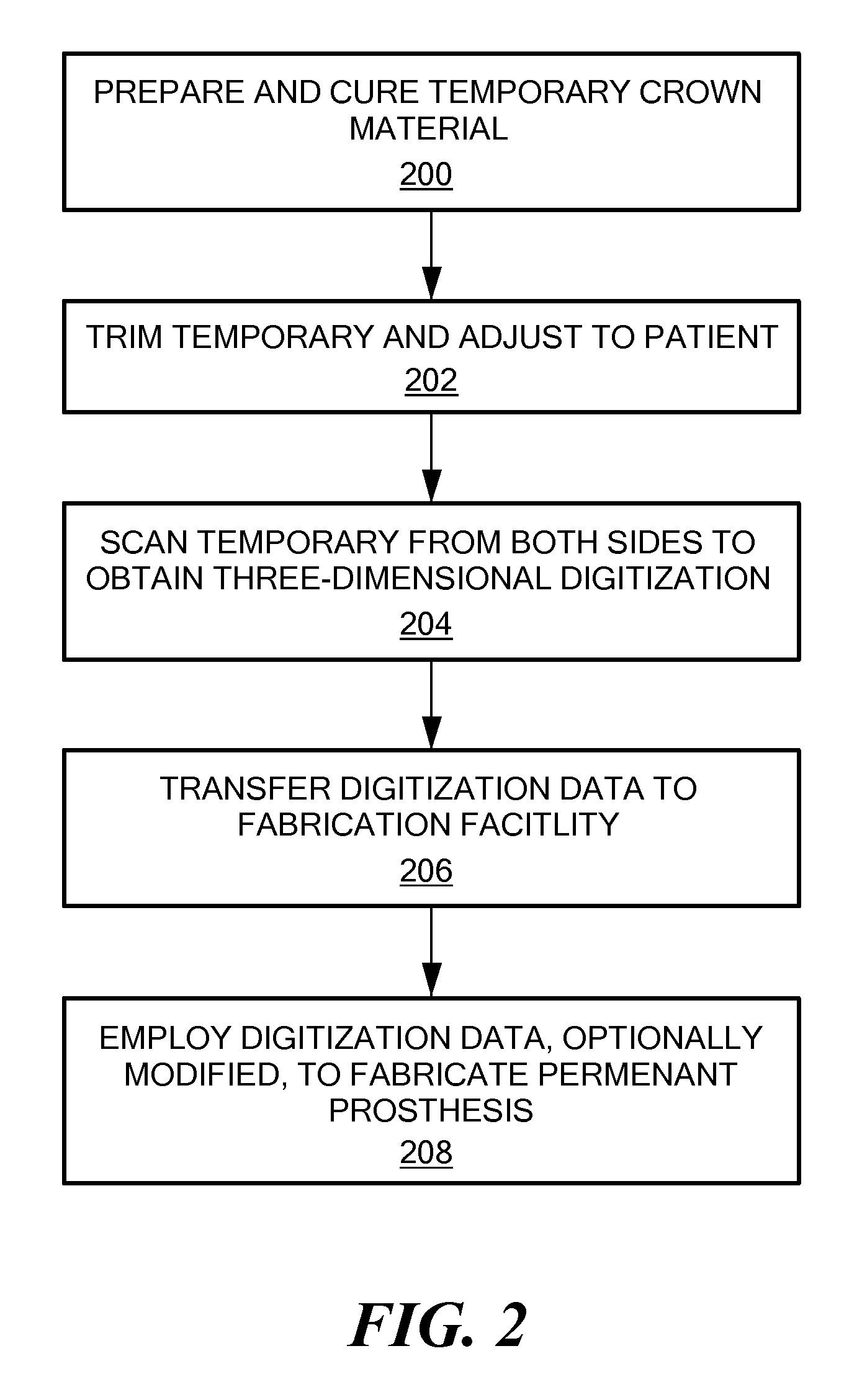

Dental Prosthesis Fabrication Based on Local Digitization of a Temporary

InactiveUS20090254299A1Mechanical/radiation/invasive therapiesDigital computer detailsDigital dataCo ordinate

A system and methods for obtaining and processing data requisite for fabrication of a dental restorative prosthesis. A dental temporary is fashioned at a site of patient treatment, and fitted in the patient's mouth. The temporary is then characterized by three-dimensional digital data based on distances measured by means of three-dimensional co-ordinate measuring equipment. The three-dimensional data are transmitted to a fabrication site, where a prosthesis may be fabricated. Additionally, information based upon the three-dimensional digital data characterizing the temporary may also be provided to a dentist at the site of patient treatment. The prosthesis design may be edited prior to fabrication.

Owner:OPTIMET OPTICAL METROLOGY

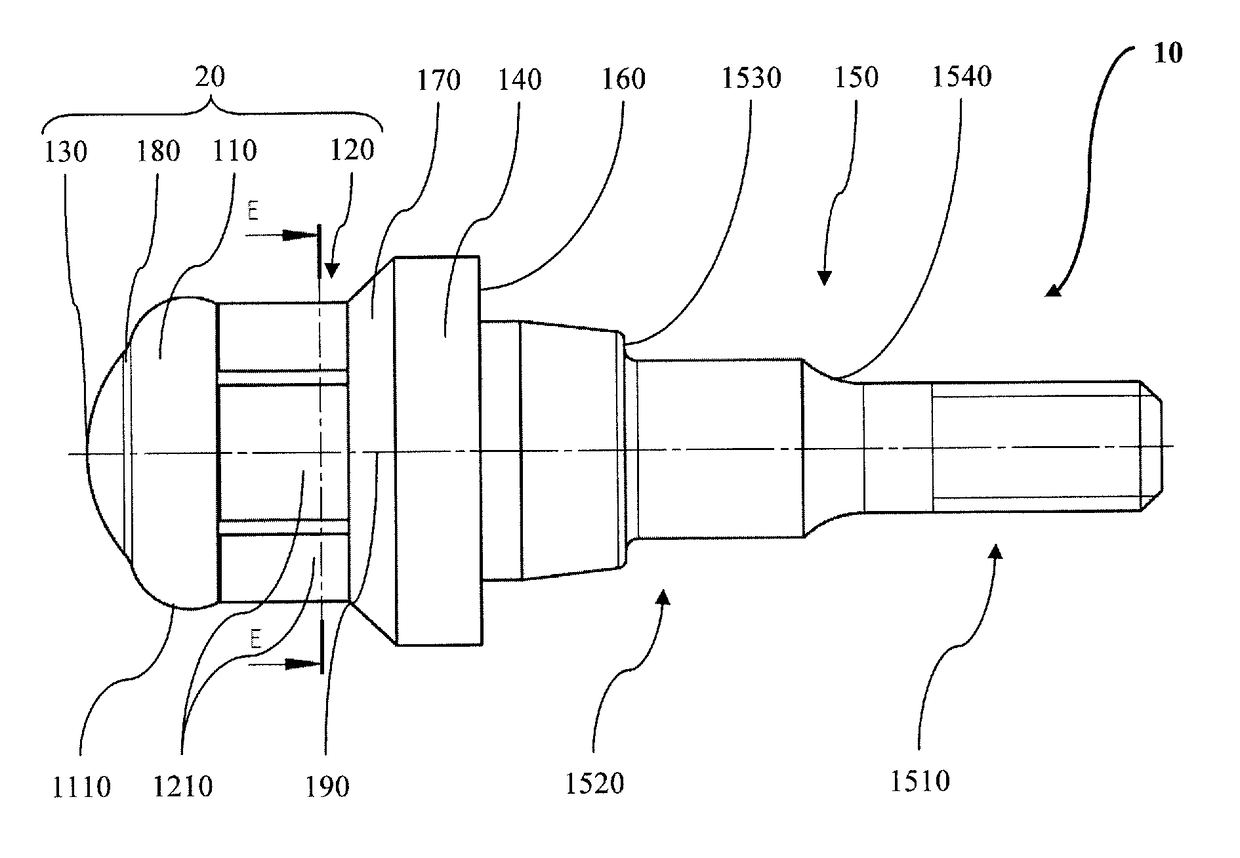

Dental restoration preform and method of making the same

ActiveUS11045291B2High strengthShorten the timeCeramic shaping apparatusTooth crownsDentistryUltimate tensile strength

A machinable preform for shaping into dental restorations is described that comprises material having suitable strength for use in dental applications without requiring further processing after shaping to strengthen the material (such as sintering). In one embodiment, a preform is comprised of a machinable dental material having a Vickers hardness value in the range of 4HV GPa to 20HV GPa, and comprises a body and a stem that extends from the outer surface of the body that supports the body during shaping. A method for making the machinable preform, and a kit comprising a machinable preform and a grinding tool, are also described.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

Device for repairing teeth and accessories thereof

Owner:乐园口腔株式会社

Method and system for tooth restoration

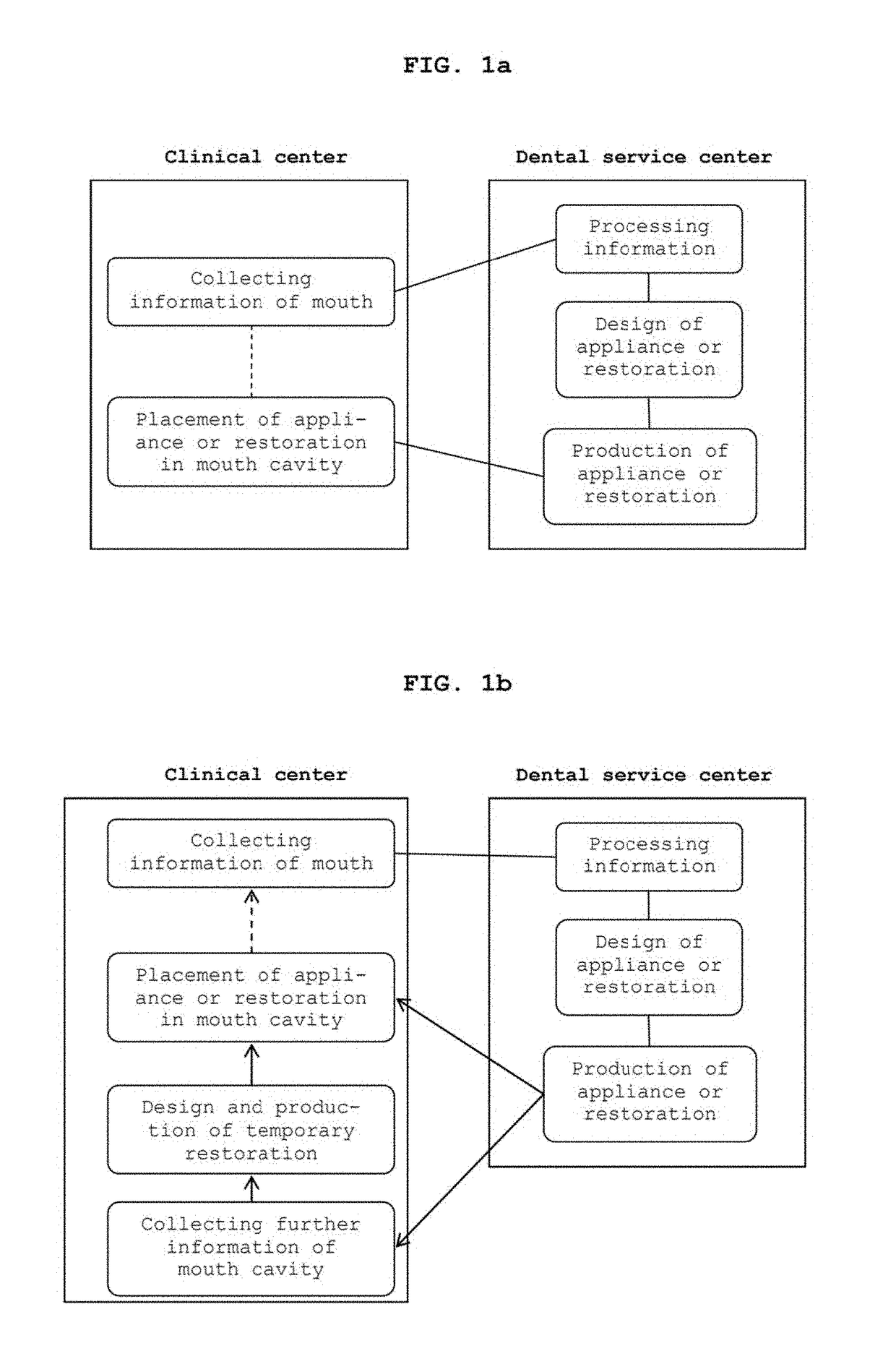

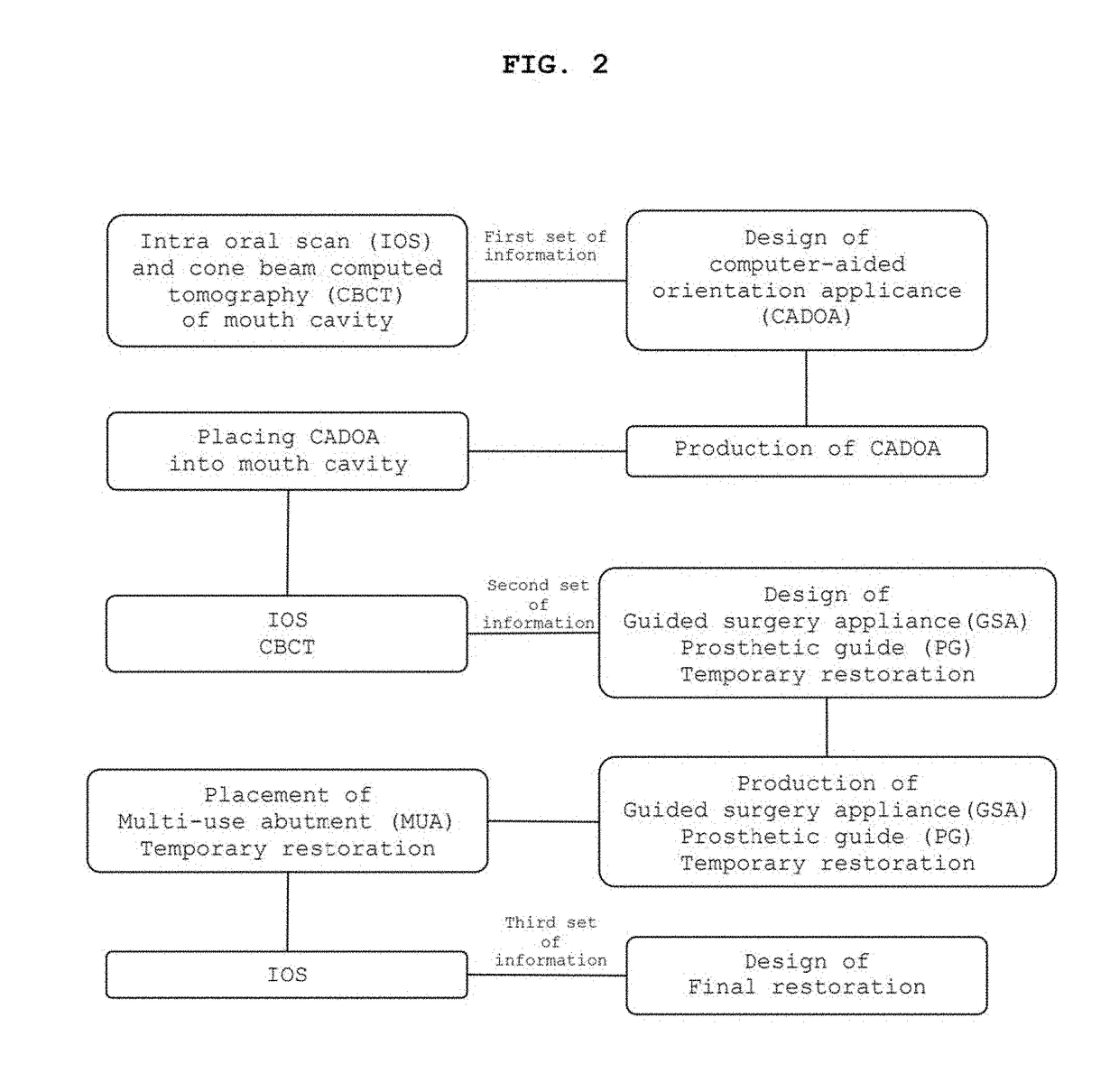

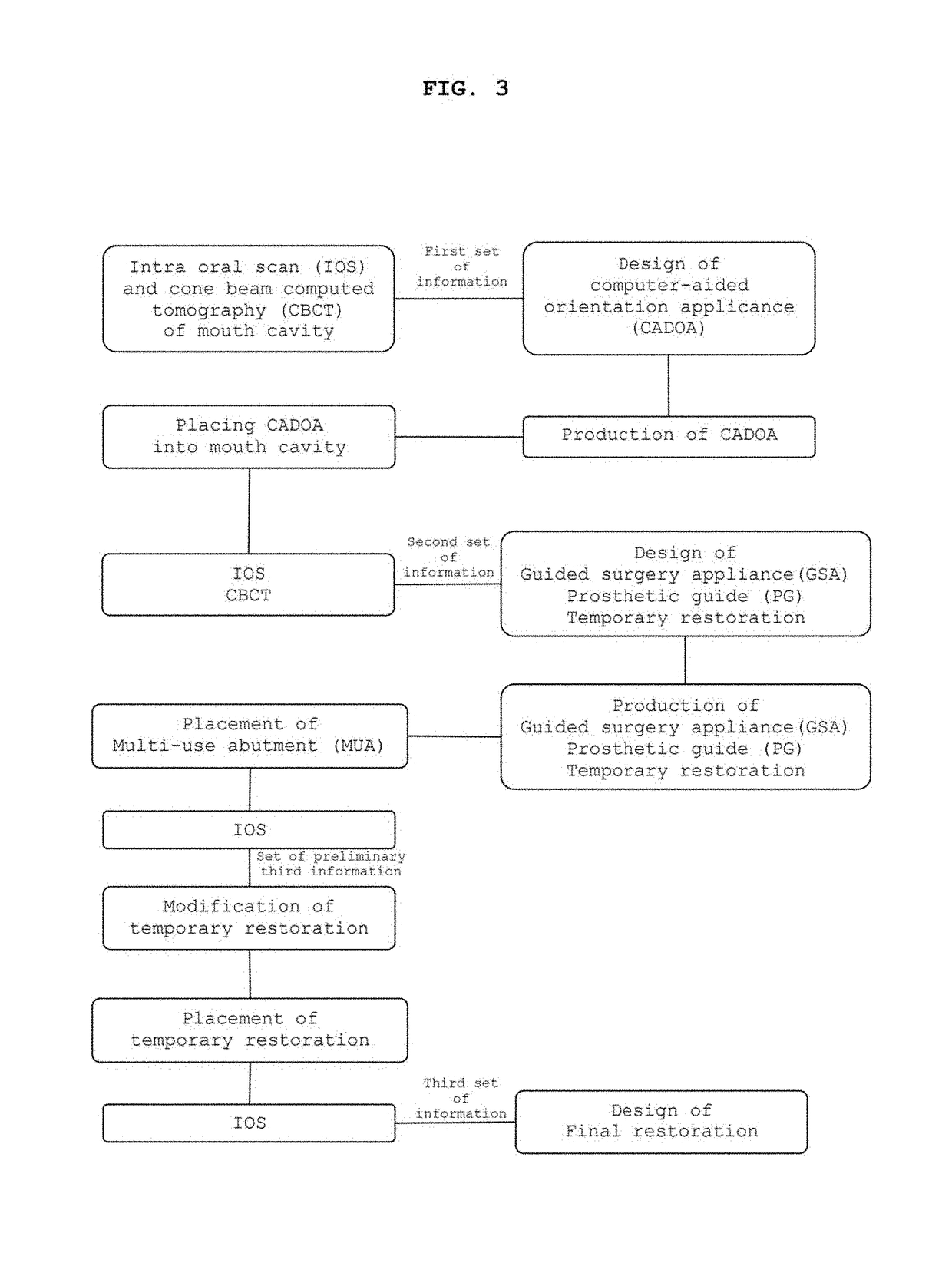

A method for denture restoration includes steps of generating sets of digital information of a mouth cavity of a person for providing firstly either an orientation appliance or a temporary restoration and subsequently a final restoration. The digital information is generated firstly from the mouth cavity alone and subsequently with the orientation appliance or the temporary restoration within the mouth cavity. The invention also relates to a system for performing this method, and to an orientation appliance and a prosthetic guide to be used in performing the method.

Owner:JUZBASIC AMIR +1

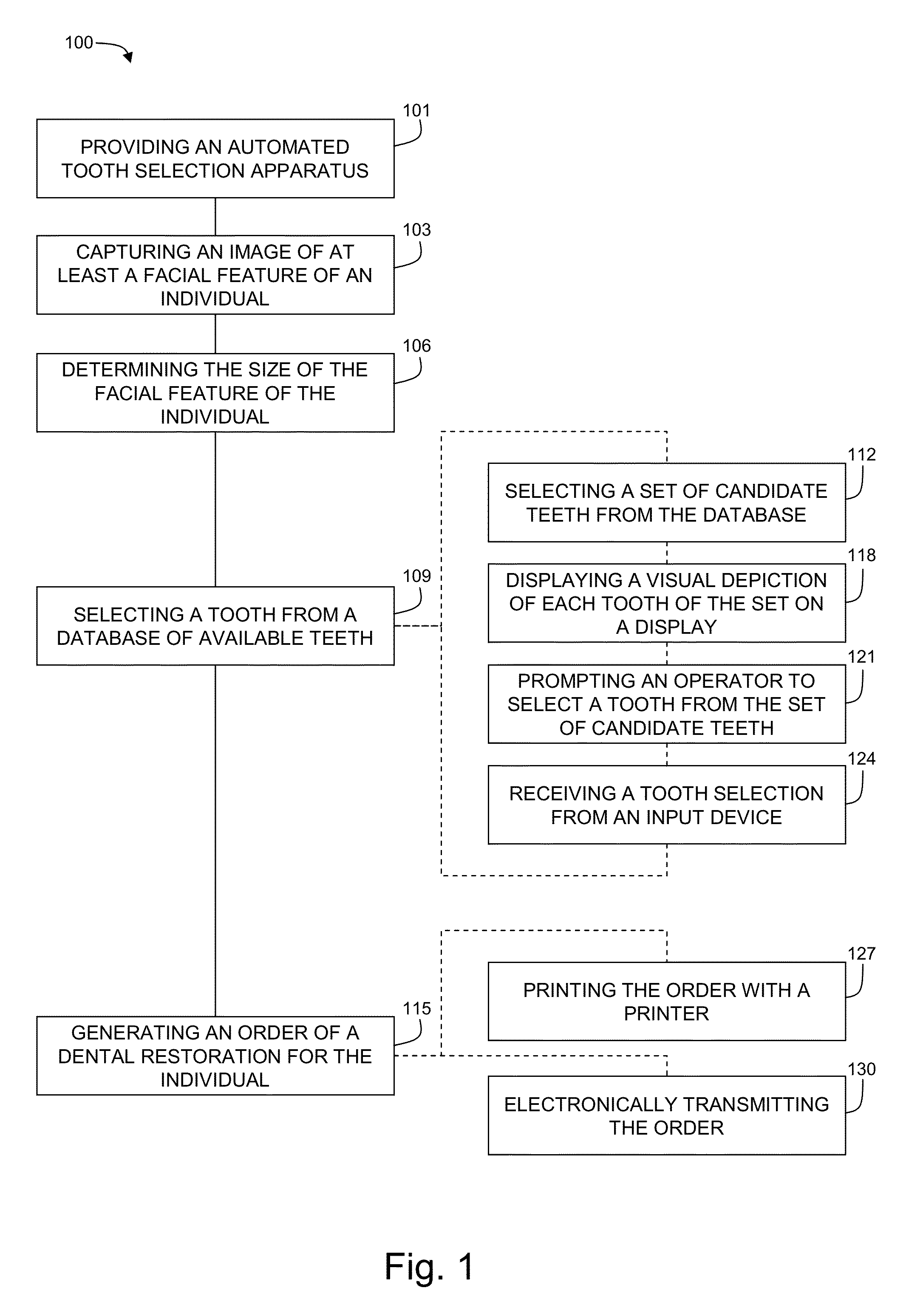

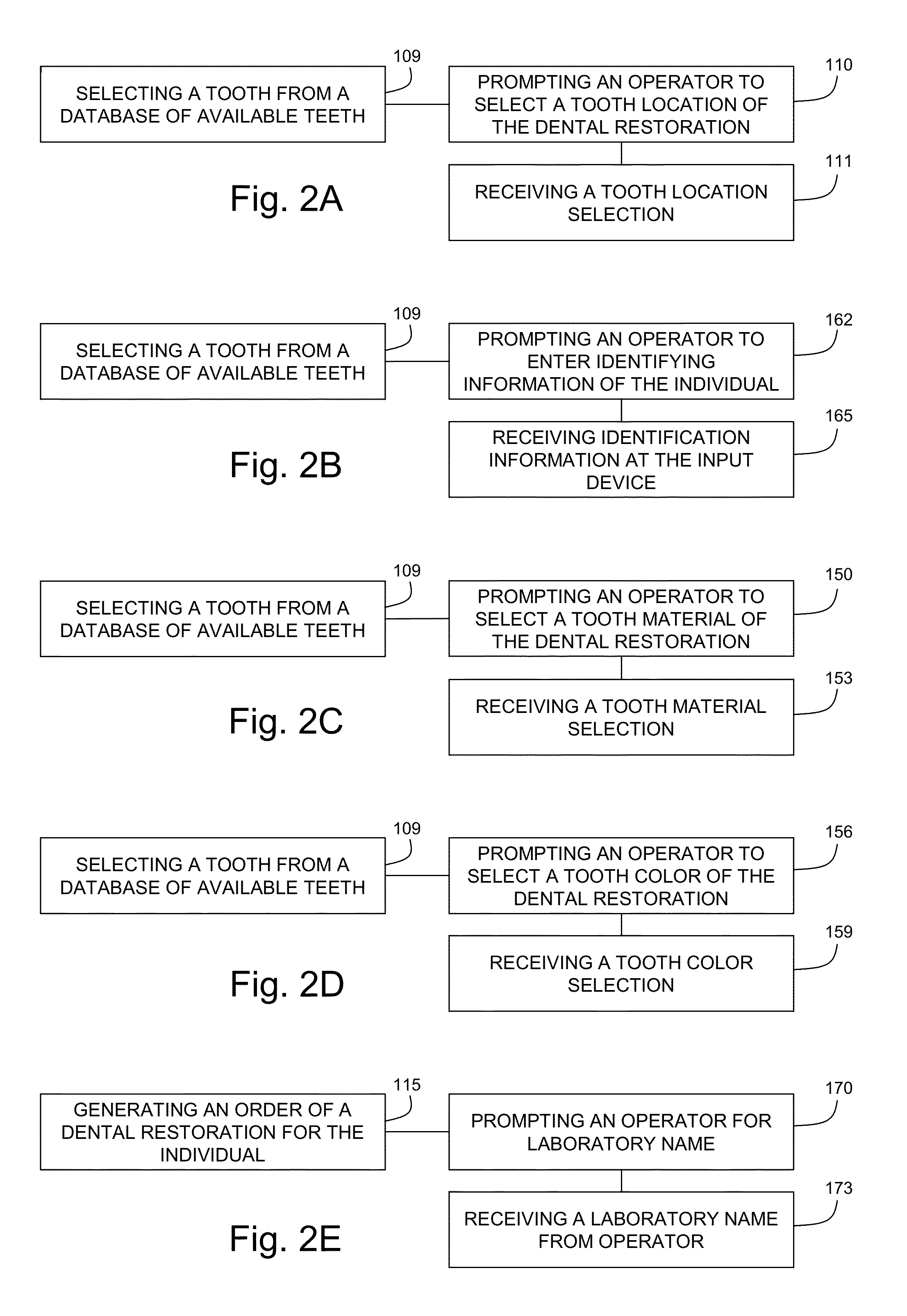

System and method for tooth selection and order generation

InactiveUS20130166312A1Data processing applicationsMechanical/radiation/invasive therapiesComputer scienceImage capture

The present invention may be embodied as a method or a system for generating an order for a dental restoration of an individual. An automated tooth selection apparatus is disclosed, comprising an image capture device and a processor. The automated tooth selection apparatus is configured to capture range data for each captured image, wherein the range data corresponds to the distance between the image capture device and the individual. An image is captured of a facial feature of the individual using the image capture device. The processor is used to determine the size of the facial feature of the individual. A tooth for the dental restoration of the individual is selected from a database of available teeth based on the determined size of the facial feature. An order for a dental restoration is generated including the selected tooth.

Owner:IVOCLAR VIVADENT AG

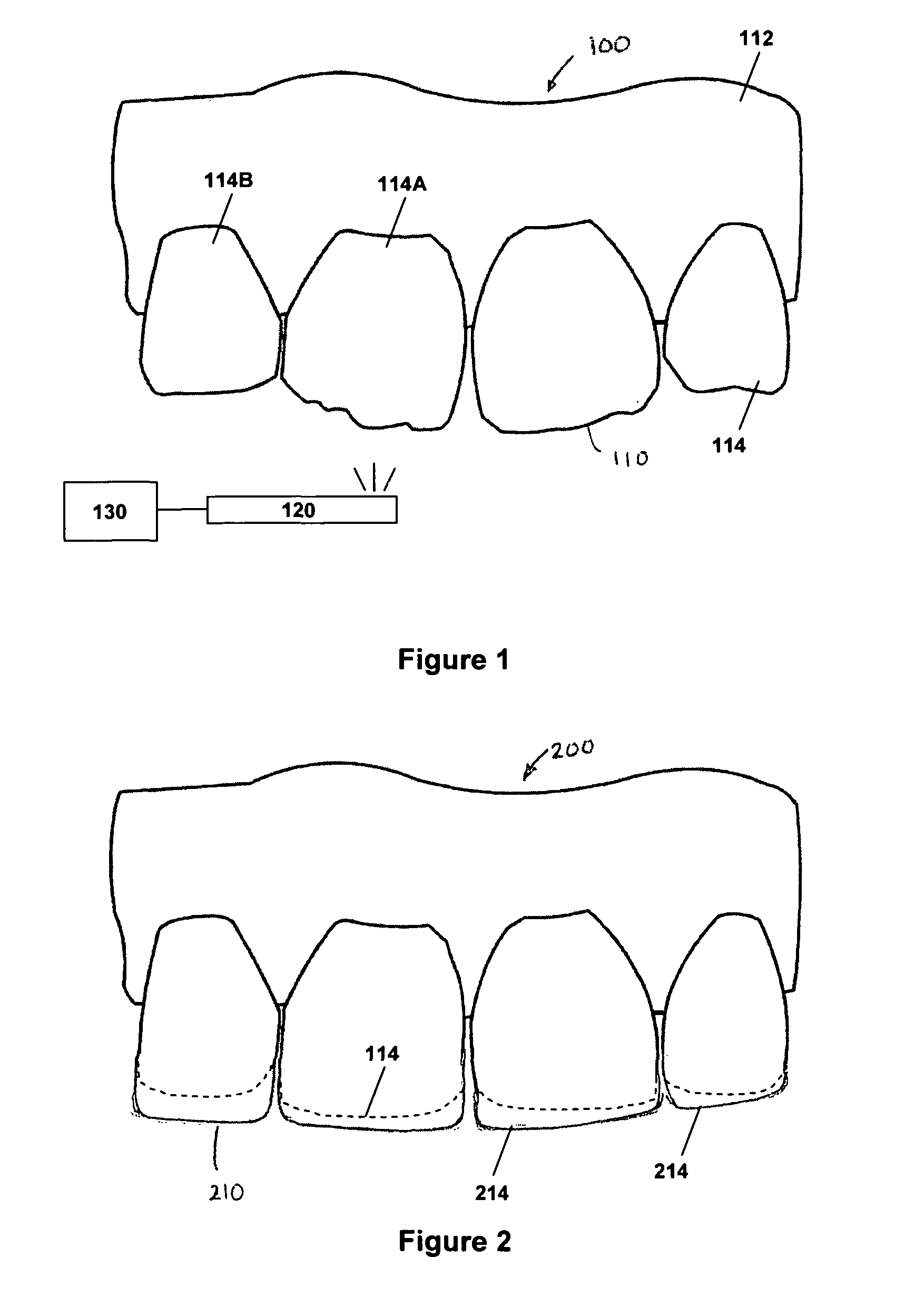

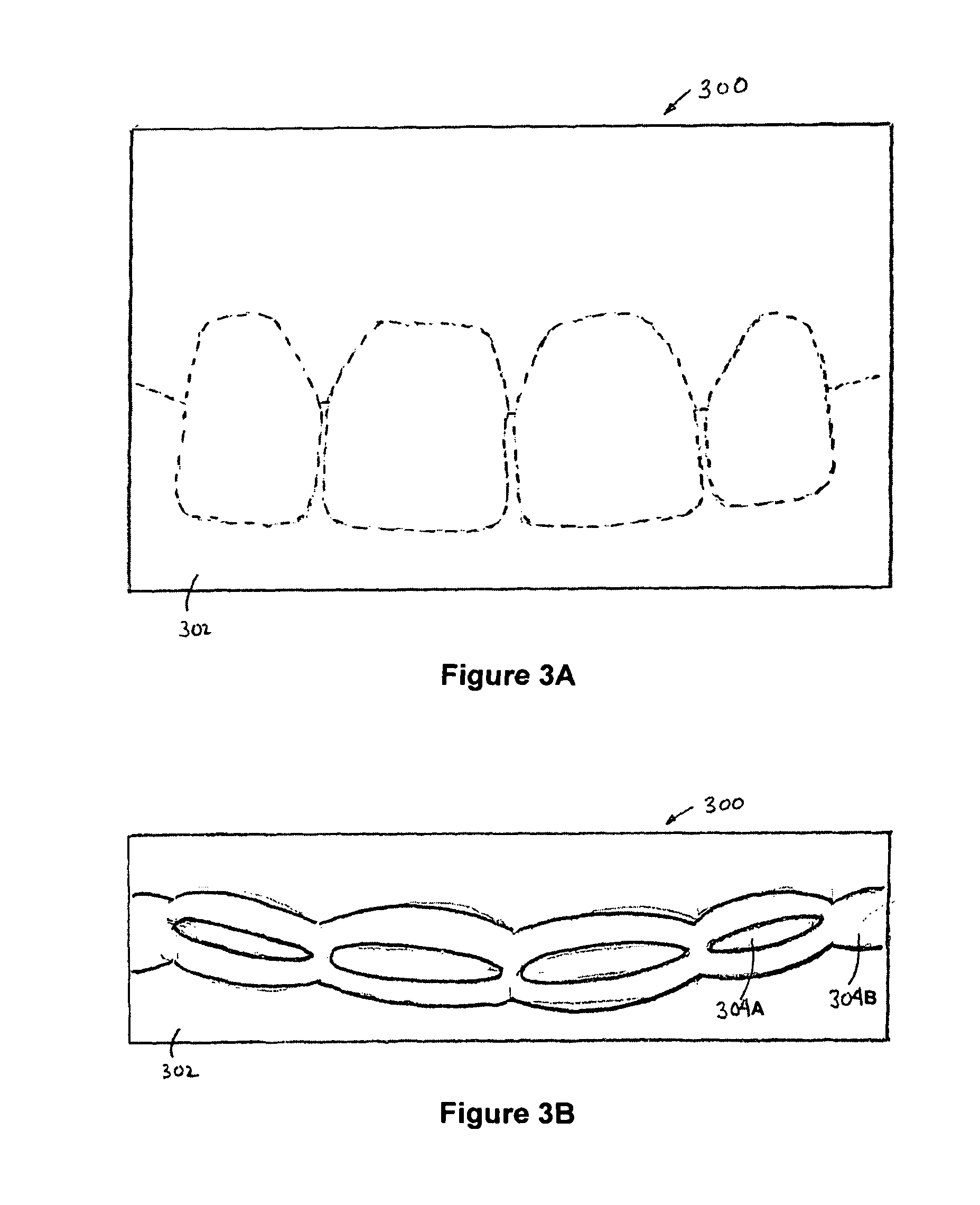

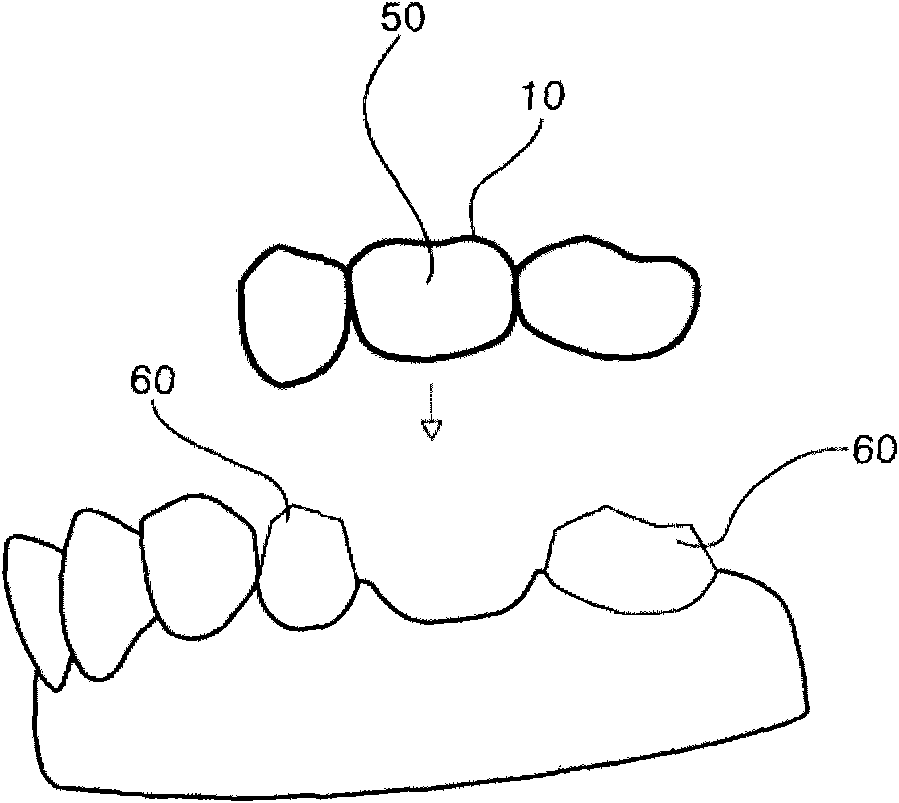

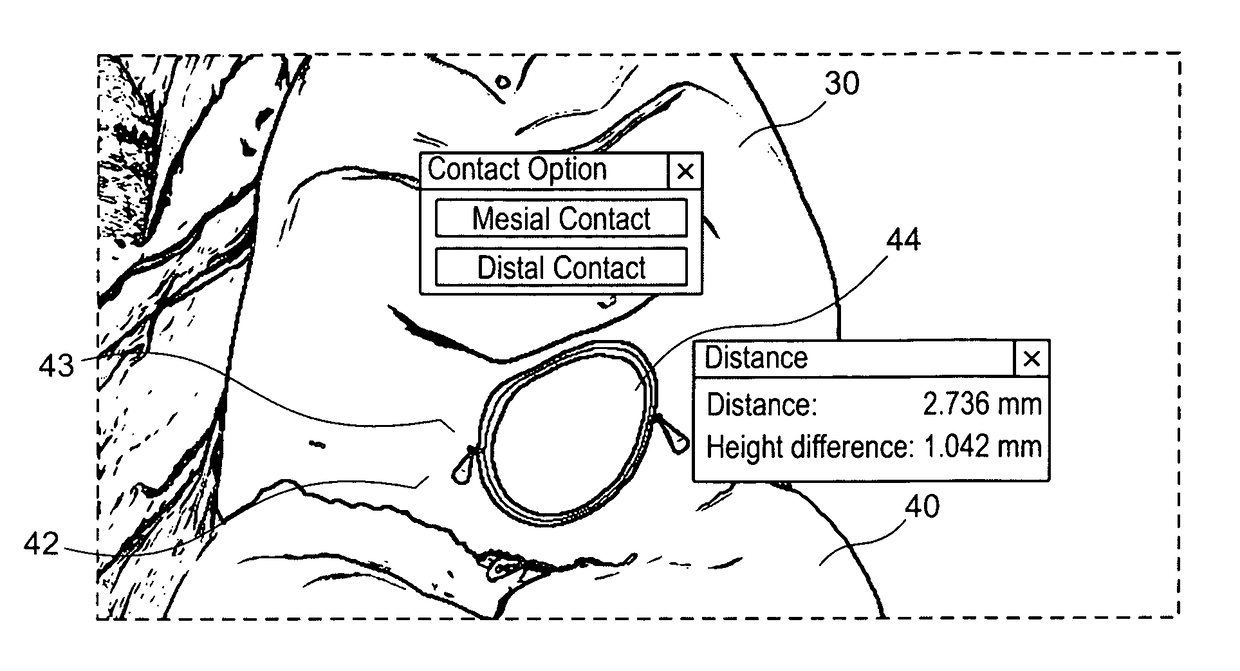

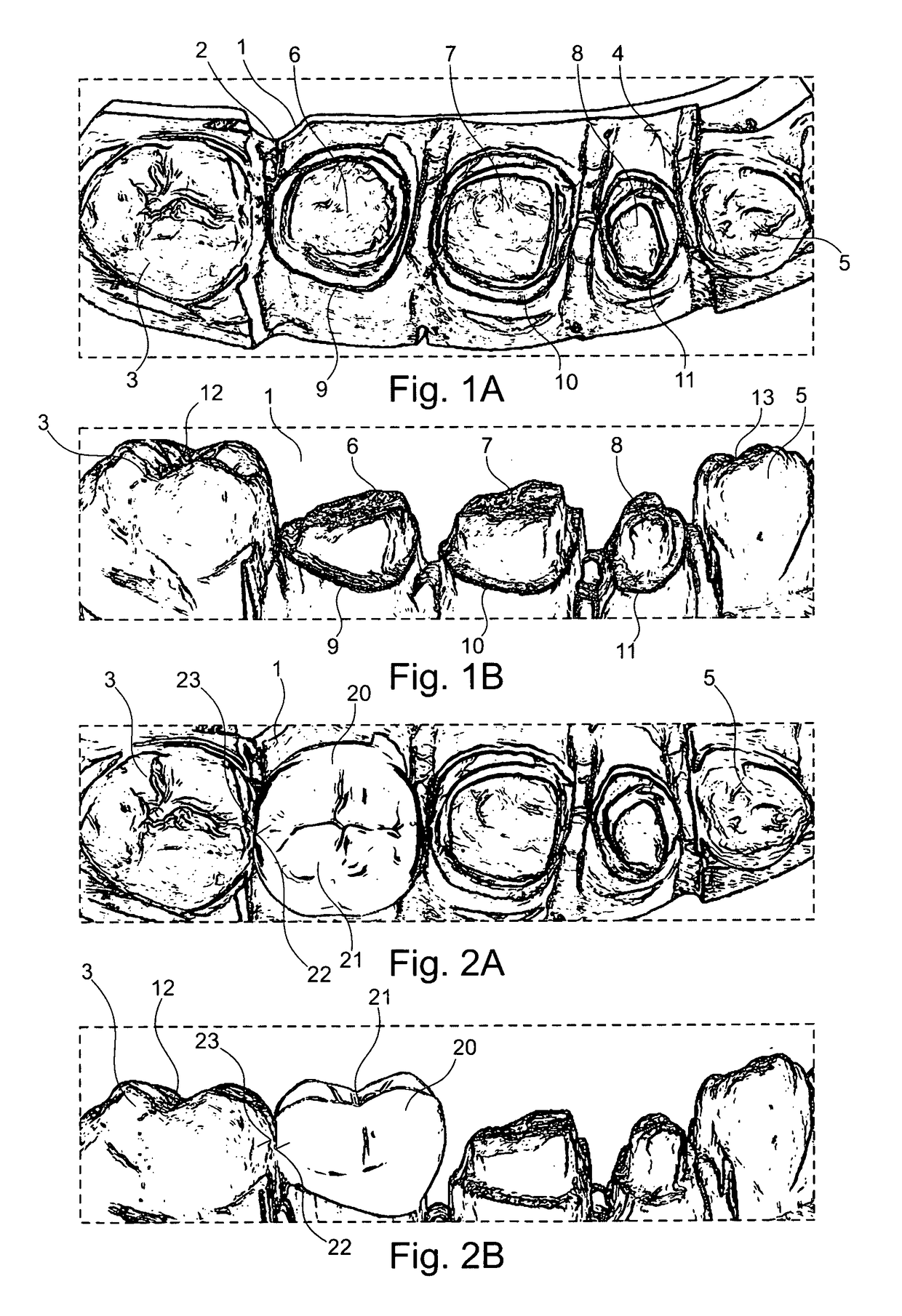

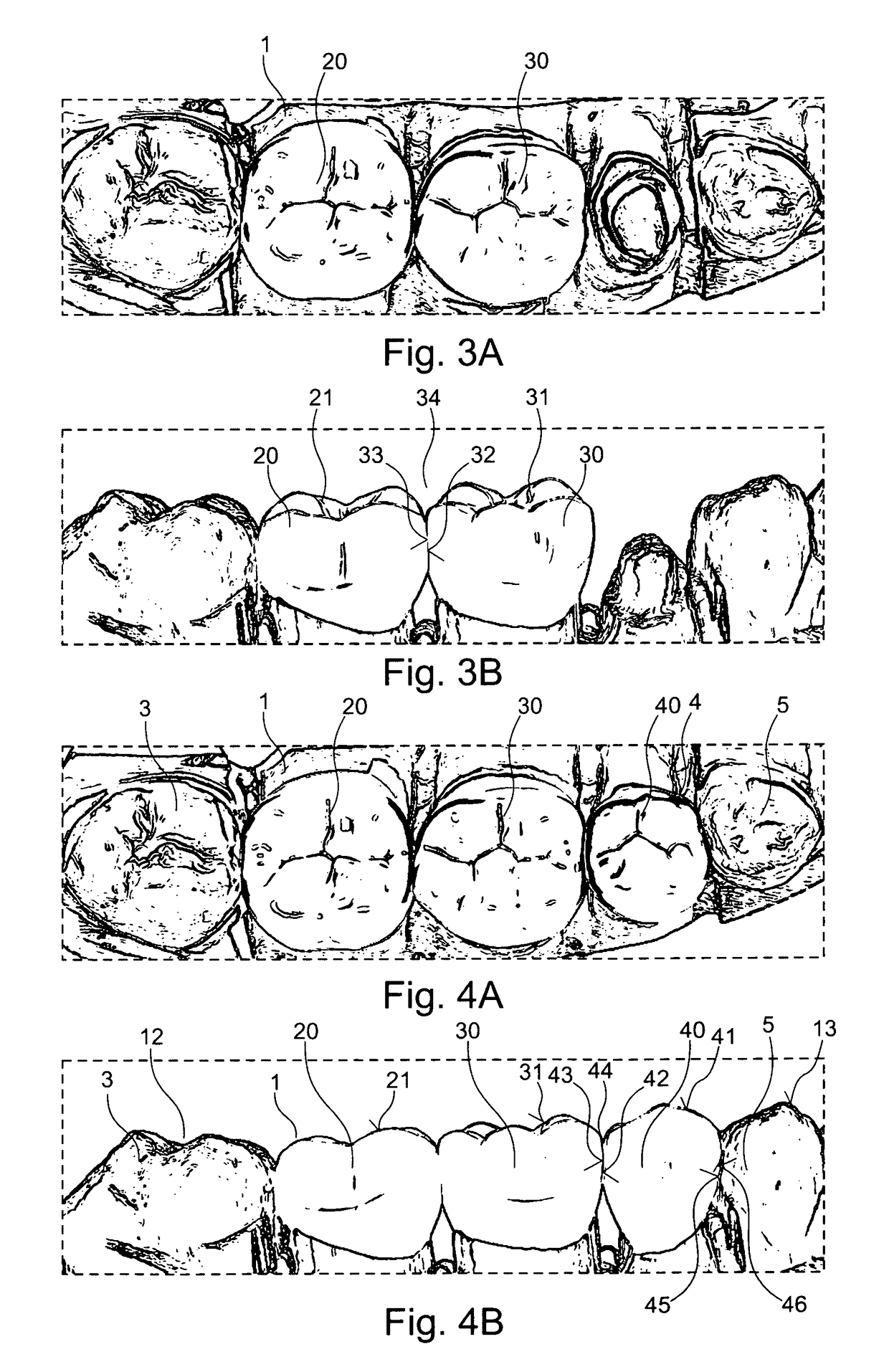

Method for designing a plurality of adjacent tooth restorations using CAD/CAM technology

ActiveUS9675431B2Increase productionTeeth fillingFastening prosthesisDentistryBiomedical engineering

The invention relates to a method for designing a plurality of adjacent tooth restorations using CAD / CAM technology. In a first step, the virtual model of a first tooth restoration at the first border of the restoration site is designed. In a second step, the virtual model of the second tooth restoration adjacent to the first tooth restoration is designed, the second tooth restoration being adjusted to match the first tooth restoration. The virtual model of the first tooth restoration is adjusted in relation to the second tooth restoration in a third step, if required. This procedure is then repeated for all of the other tooth restorations in the restoration site.

Owner:SIRONA DENTAL SYSTEMS

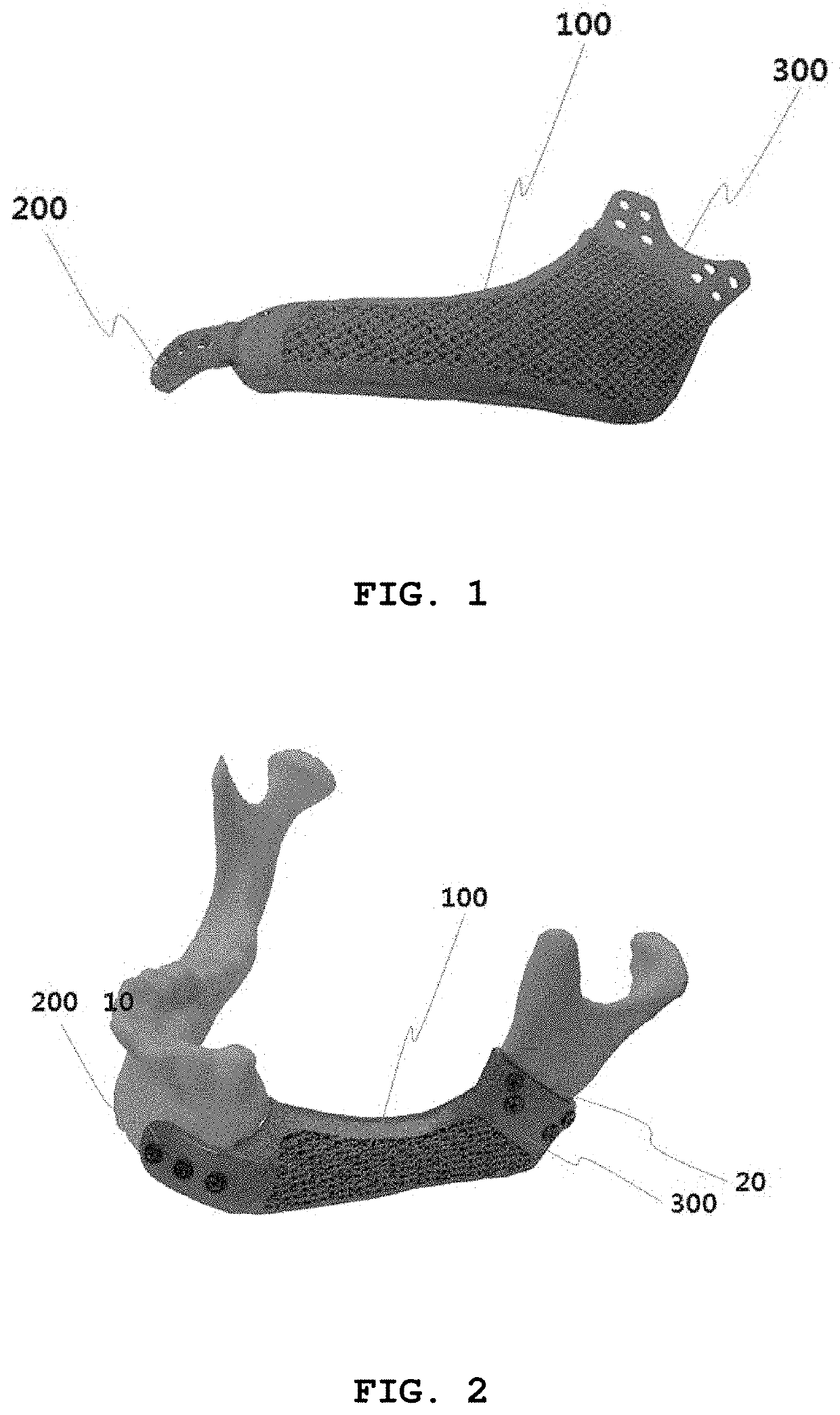

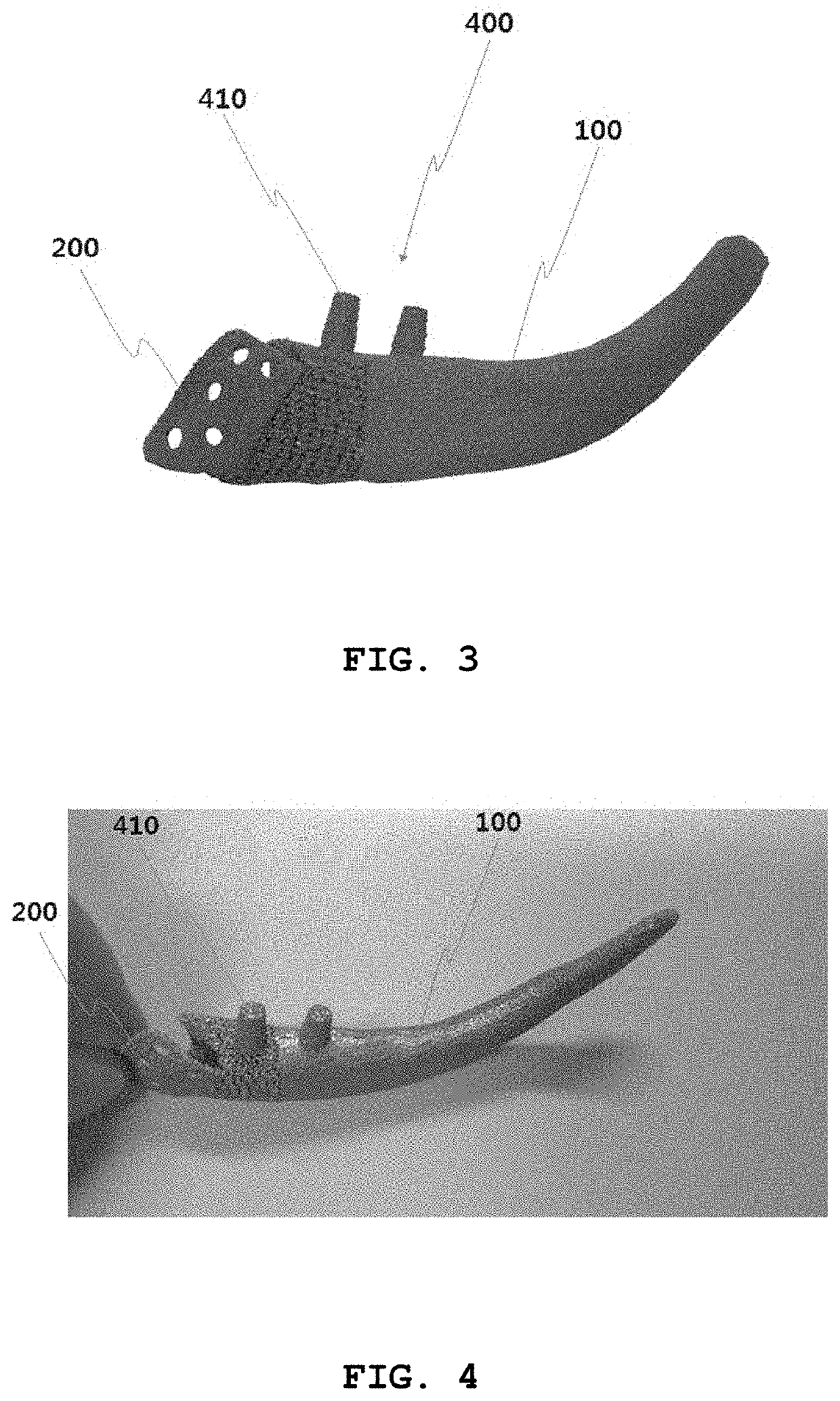

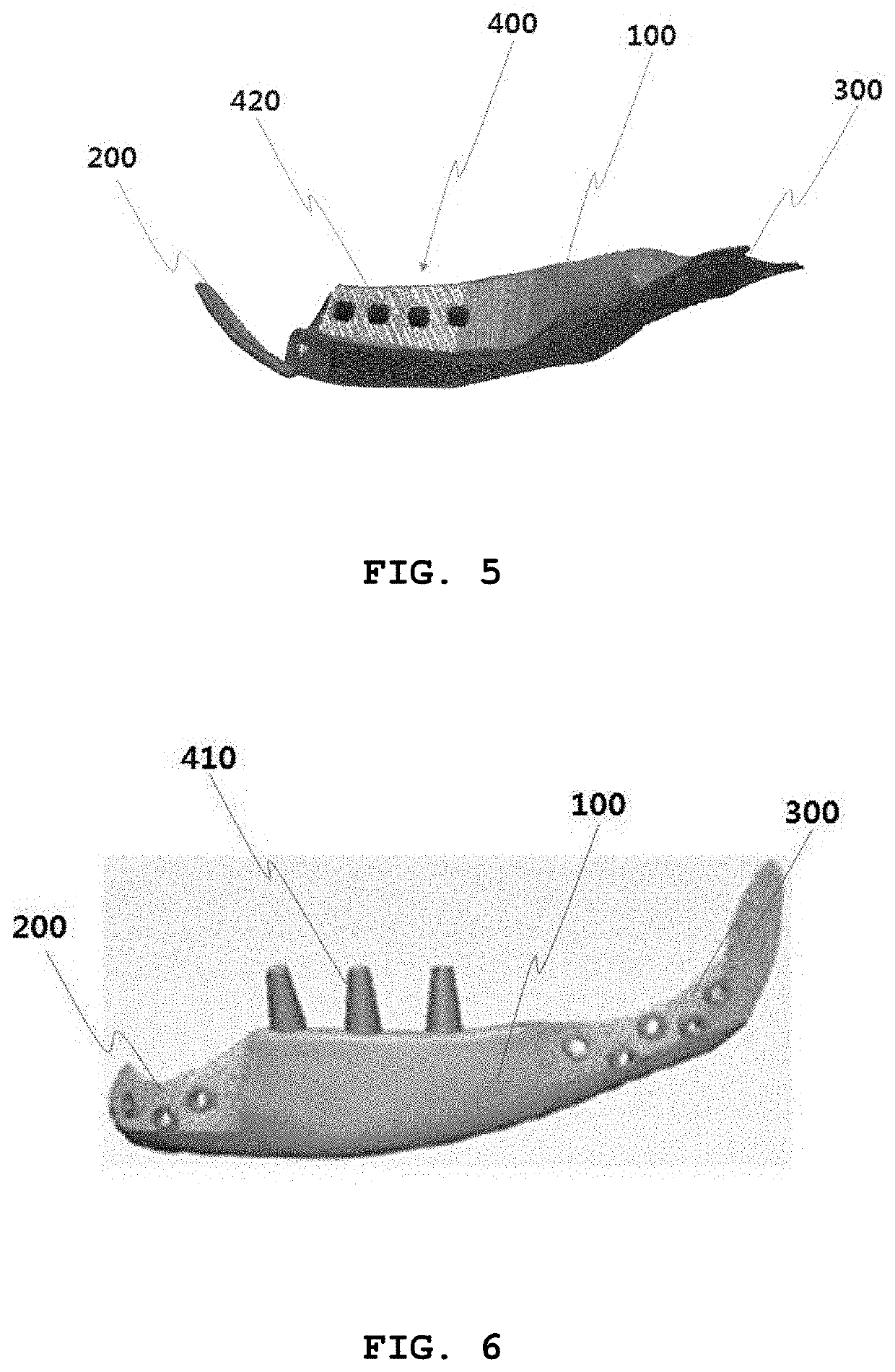

Patient-specific mandibular implant inserted into mandibular defect region and method of manufacturing the same

ActiveUS20200205984A1Avoid damageAdditive manufacturing apparatusBone implantDentistry3 dimensional printing

Disclosed is a patient-specific mandibular implant inserted into a mandibular defect region and a method of manufacturing the same, and more particularly, to a patient-specific mandibular implant inserted into a mandibular defect region, which can be easily and rapidly manufactured using personalized three-dimensional (3D) printing technology for a defect region, can provide an effect of preparing a later step for restoring a tooth in advance, and can be easily manufactured tooth restoration data based on the Korean standard database (DB), and a method of manufacturing the same.

Owner:MEDYSSEY

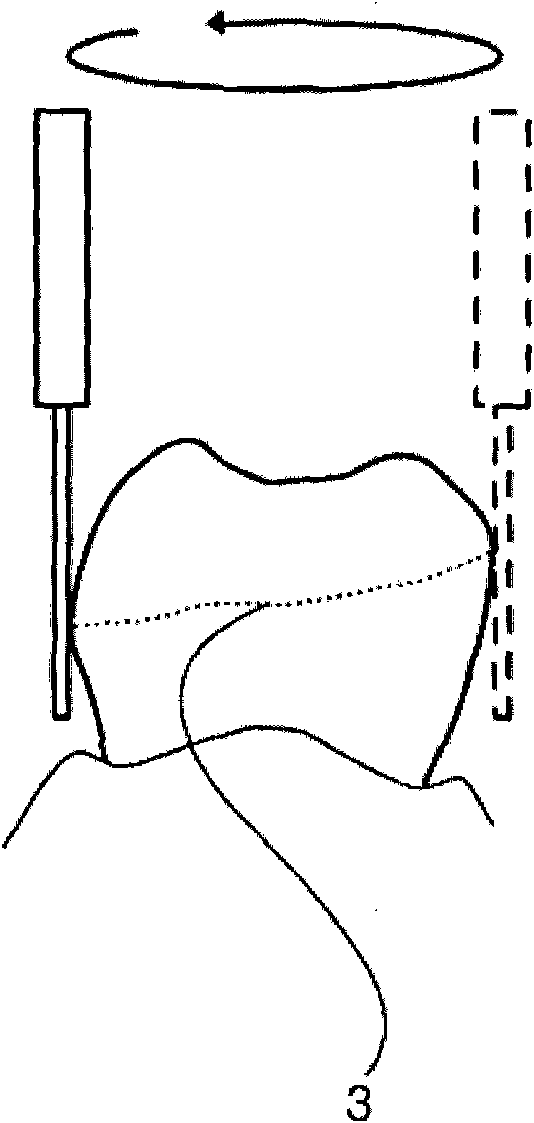

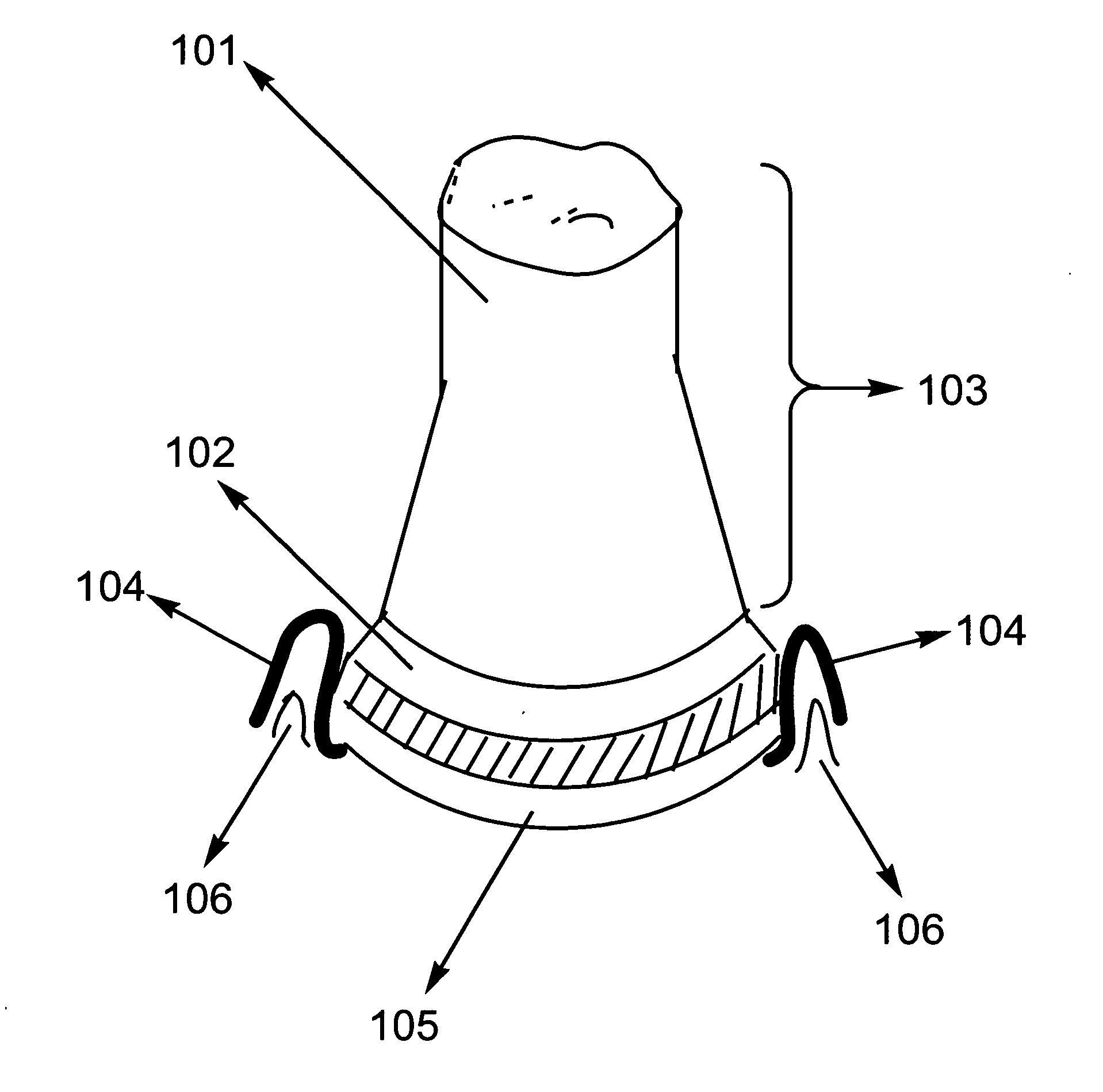

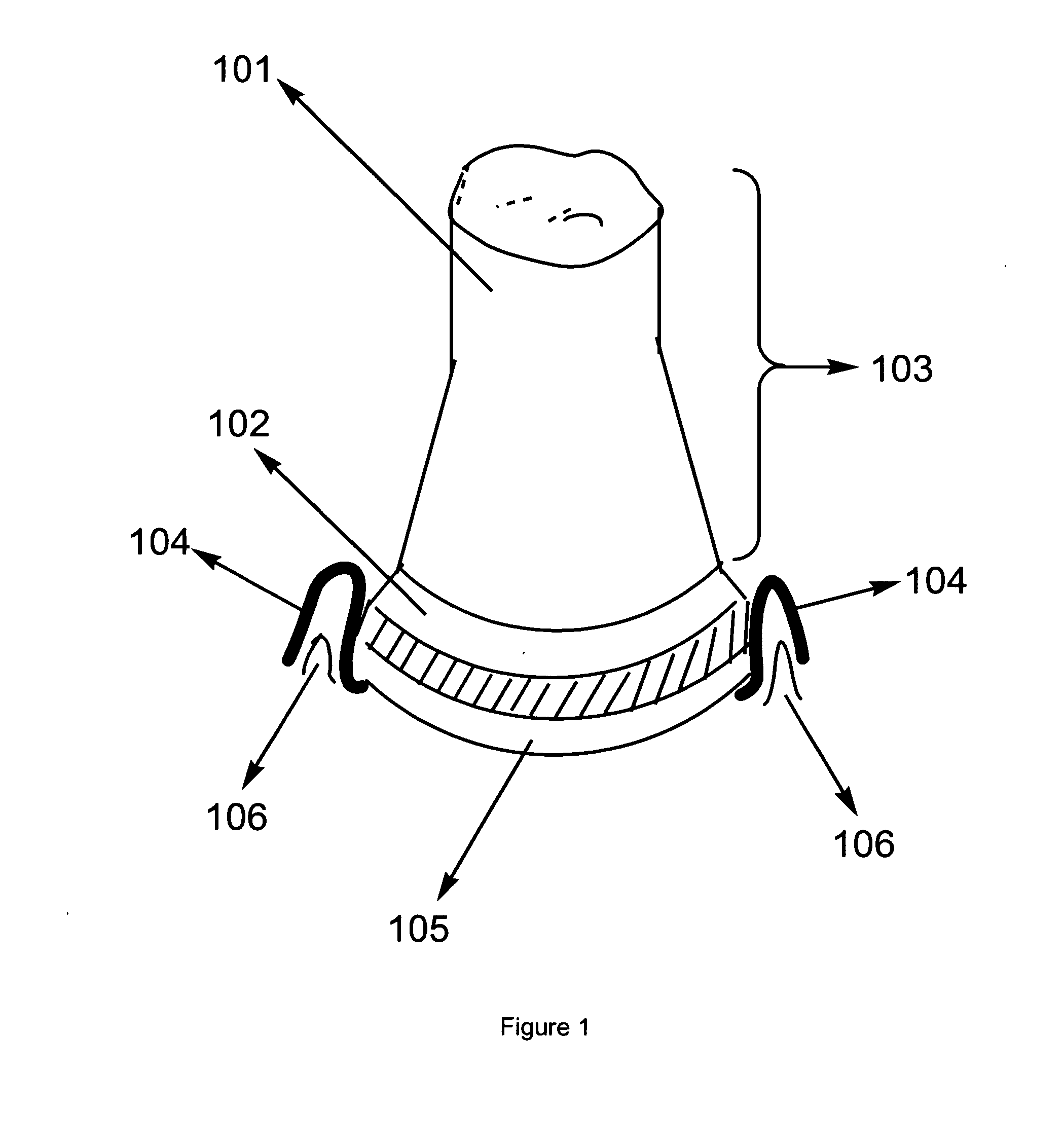

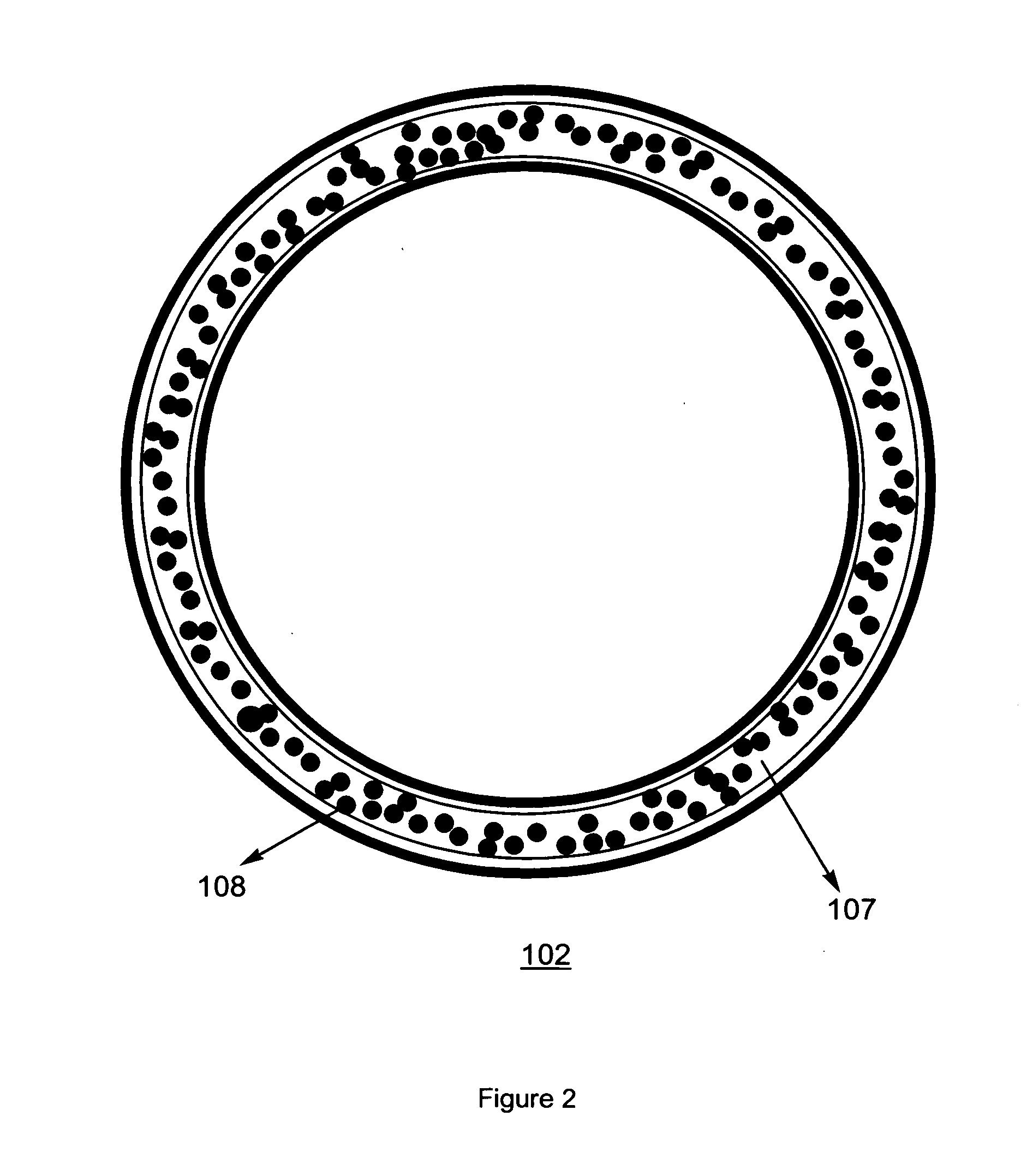

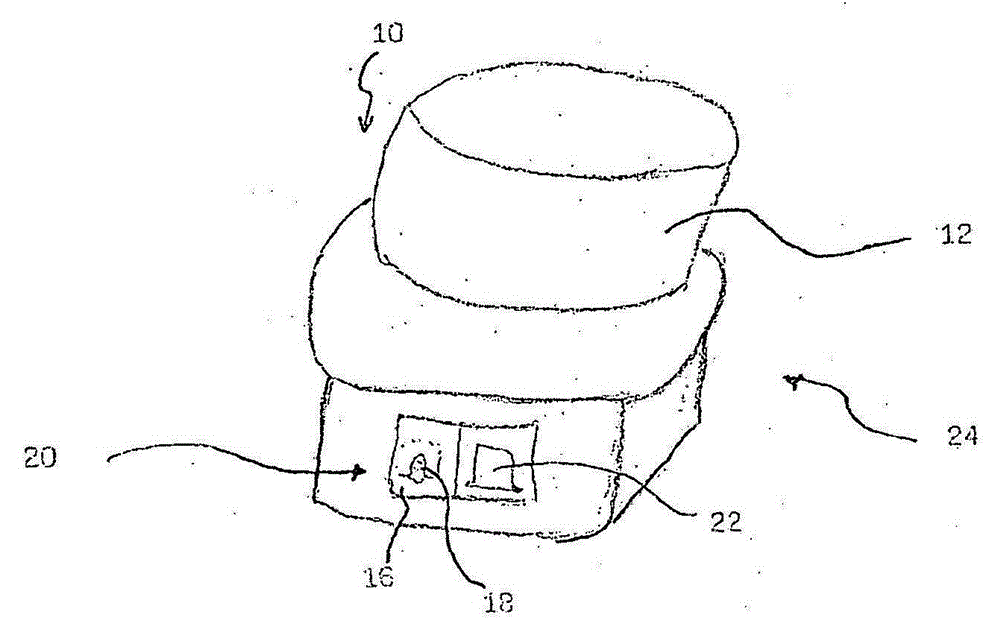

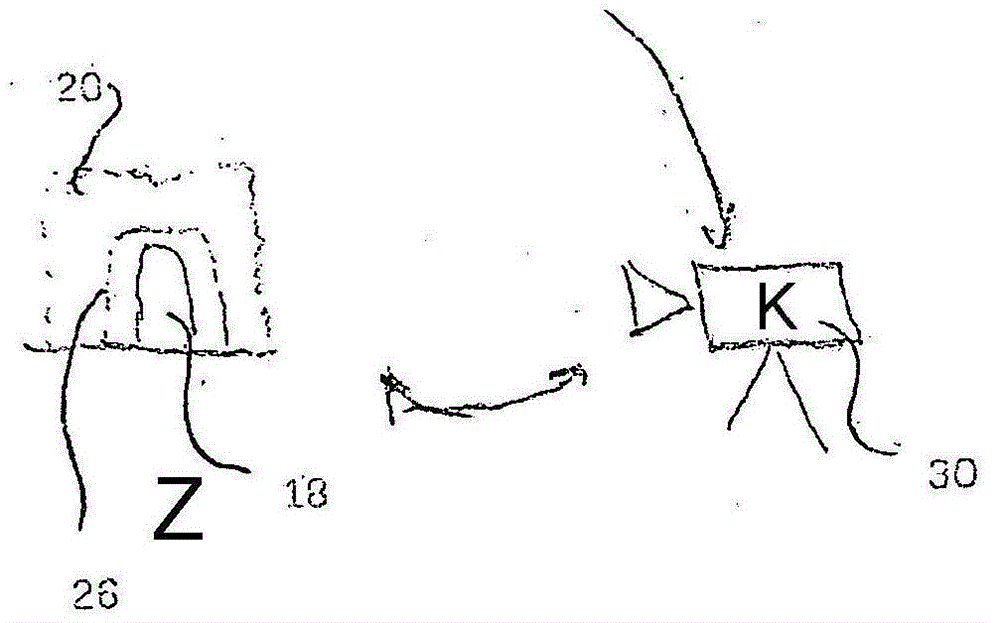

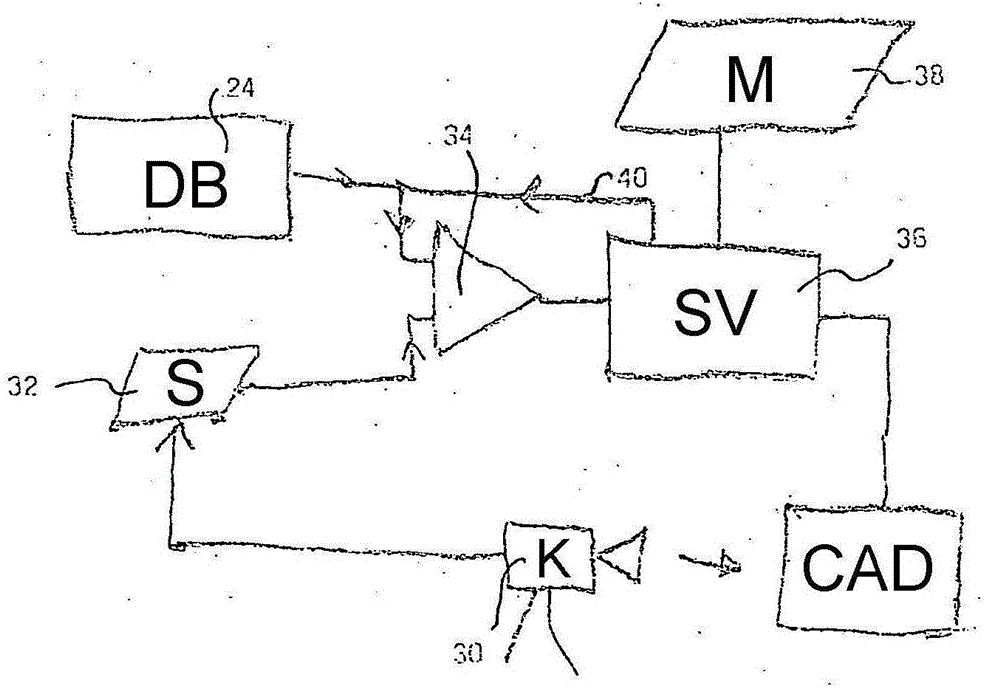

Dental restoration system and method thereof

The invention provides a dental restoration system comprising a crown base such as a dentin or an abutment and a shape determiner that surrounds and measures the shape of an apical part in the crown base. The invention also provides a method of dental restoration, which comprises measuring the shape of the crown base that is not surrounded by the shape determiner; determining the shape of the entire crown base; and preparing a crown to be secured on the crown base. The invention exhibits merits such as a much simpler procedure, less gum injury and bone recession, cost-effectiveness, and excellent compatibility with CAD / CAM system, among others.

Owner:ZUGA MEDICAL

Method of making a dental restoration

ActiveUS20200100863A1Designing can be facilitatedMinimizes stepImpression capsAdditive manufacturing apparatusVirtual spaceSubject tooth

A method of making a dental restoration has the steps of: determining a virtual space available for accommodation of a dental restoration for a tooth to be restored; retrieving a predefined virtual master dental restoration surface from a database; fitting the virtual master dental restoration surface in the space to provide a virtual outer dental restoration surface; creating a virtual inner dental restoration surface independent of a shape of the tooth to be restored; providing a virtual model of a dental restoration based on a combination of the virtual outer dental restoration surface and the virtual inner dental restoration surface; and fabricating the dental restoration based on the dental restoration model.

Owner:3M INNOVATIVE PROPERTIES CO

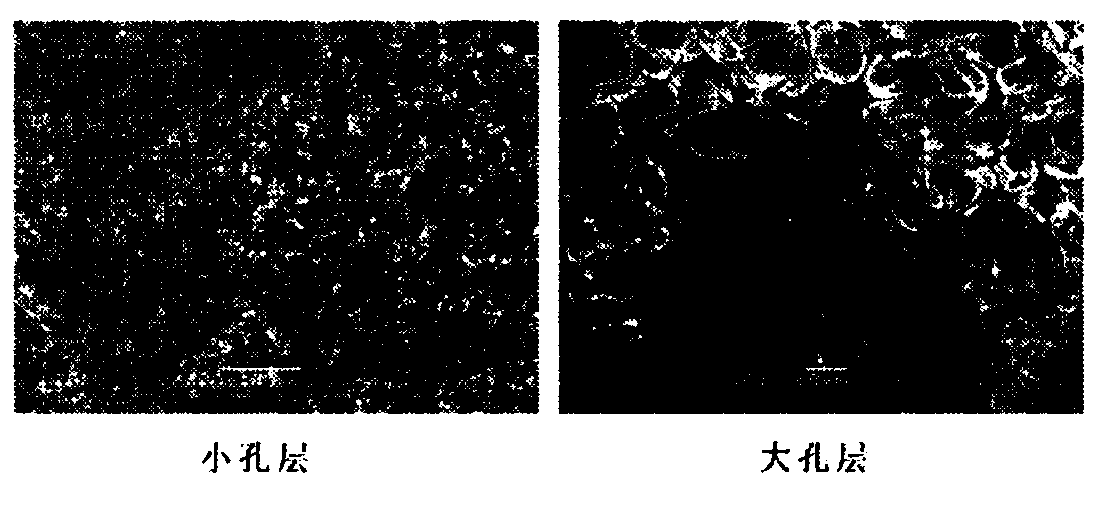

Preparation method of guided tissue regeneration membrane for tooth restoration

ActiveCN110559479AImprove mechanical propertiesGood biocompatibilityTissue regenerationProsthesisFreeze-dryingBiocompatibility Testing

The invention discloses a preparation method of a guided tissue regeneration membrane for tooth restoration, wherein the preparation method comprises the following steps: (1) dissolving a synthetic polymer material in an organic solvent, uniformly dispersing, pouring the solution into a culture dish, and freezing; and obtaining a first layer structure; (2) dissolving a natural polymer material inan organic solvent, adding inorganic bioactive particles, uniformly dispersing, casting the mixed solution onto the first layer structure, and then freezing; and obtaining a composite layer structure;and (3) carrying out freeze drying on the composite layer structure obtained in the step (2). The synthetic polymer and natural polymer composite material is adopted, so that the biocompatibility ofthe composite membrane is improved while the mechanical property of the composite membrane is improved; a gradient temperature freezing mode is adopted in a matched mode, distribution of pore structures on the longitudinal structure of the composite membrane is regulated and controlled, the pore structure with the gradient structure is formed, adhesion and growth of cells are better facilitated, and a remarkable effect is achieved.

Owner:苏州高哲斯环境新材料有限公司

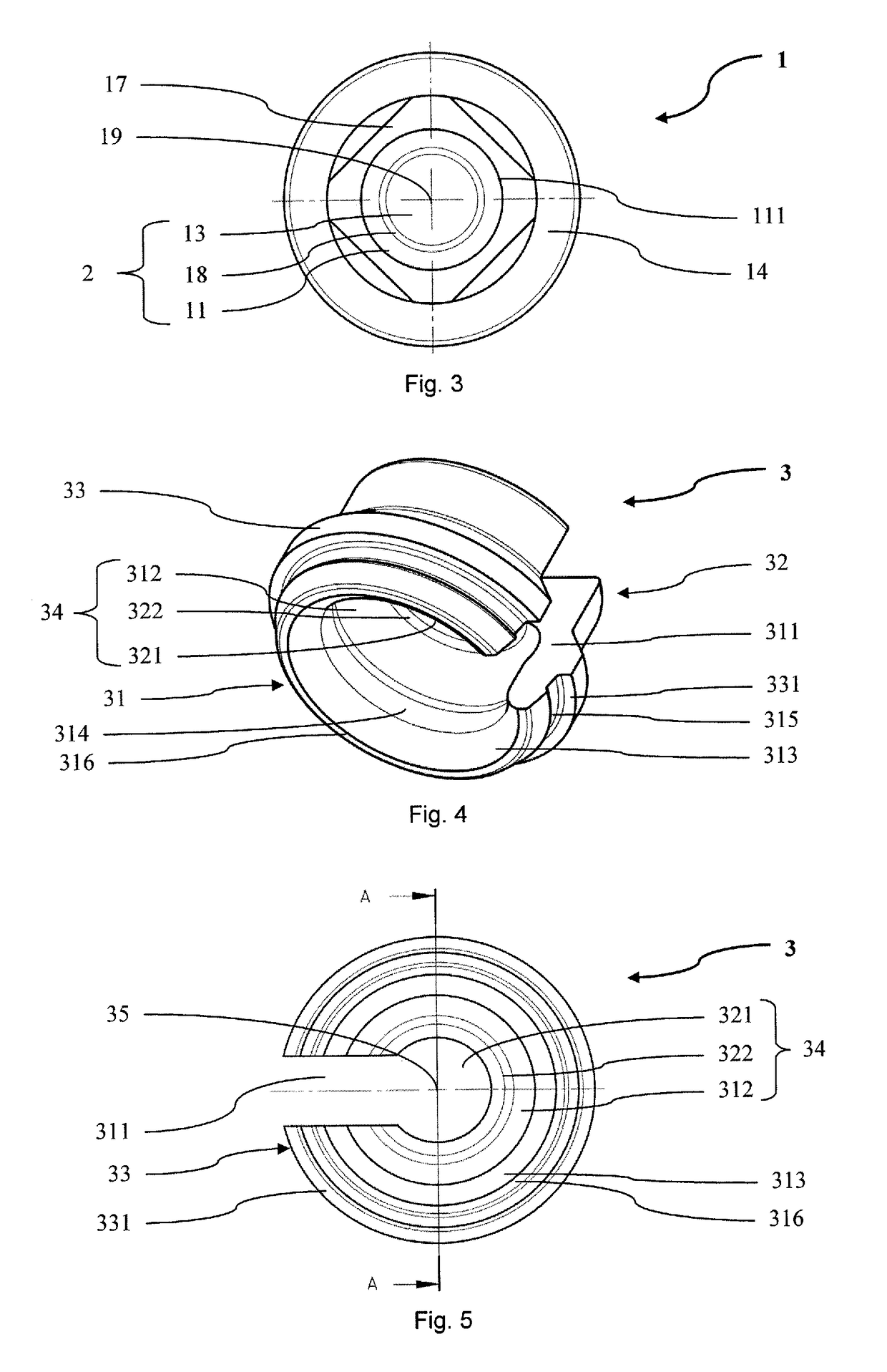

Dental prosthesis system

A flexible dental prosthesis system including: a longitudinally elongated flexible screw having a first end suitable for being fitted by means of threading in a dental implant and a second open end that can be inwardly deformed having a threaded hole on its inside and a projecting flange on its outside; a transmucosal post with a through hole suitable for inserting the flexible screw; and an upper connection element having a hole at one of its ends suitable for being coupled on the second end of the flexible screw by means of an inner recess in said hole corresponding with the projecting flange on the outside of the second end of the flexible screw.

Owner:CLINICA DENTAL COSTA CODINA SL

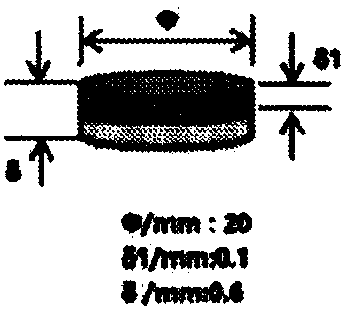

Method for producing a dental restoration part, and dental furnace

InactiveCN104883996ASimple structureMechanical/radiation/invasive therapiesFurnace typesImage recordingLayer thickness

The method involves determining image data i.e. three-dimensional data, of external contour of a dental restoration part (20) and applied layers of the part. The part is arranged in an image recording area of an image recording device i.e. three-dimensional camera. Layer thickness and / or color of the layers are determined before the manufacturing of the part. The layer thickness is compared with the image data, and an error signal is produced when the layer thickness and / or the color and / or other parameter do not correspond to predetermined layer based on the image data. An independent claim is also included for a dental oven.

Owner:IVOCLAR VIVADENT AG

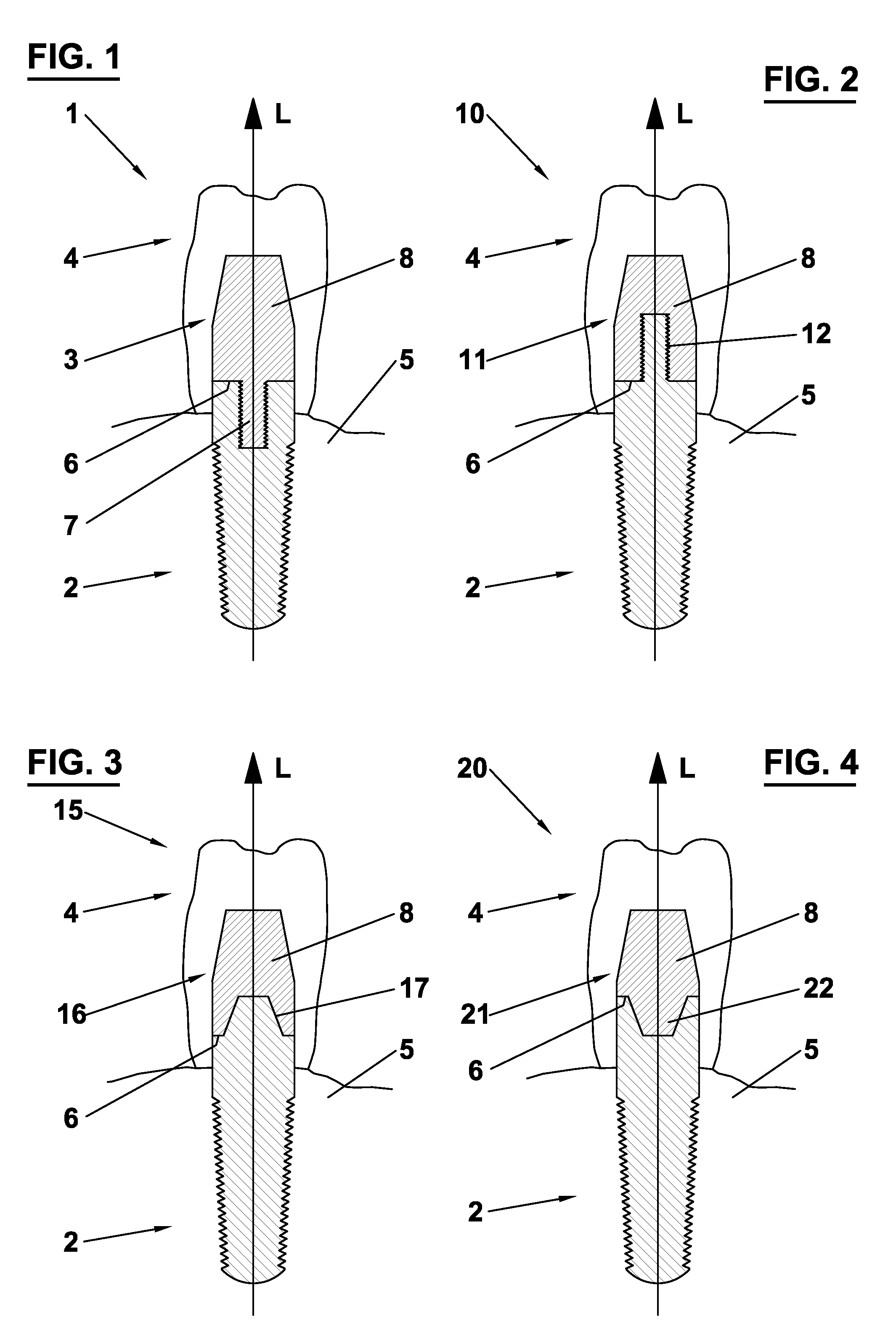

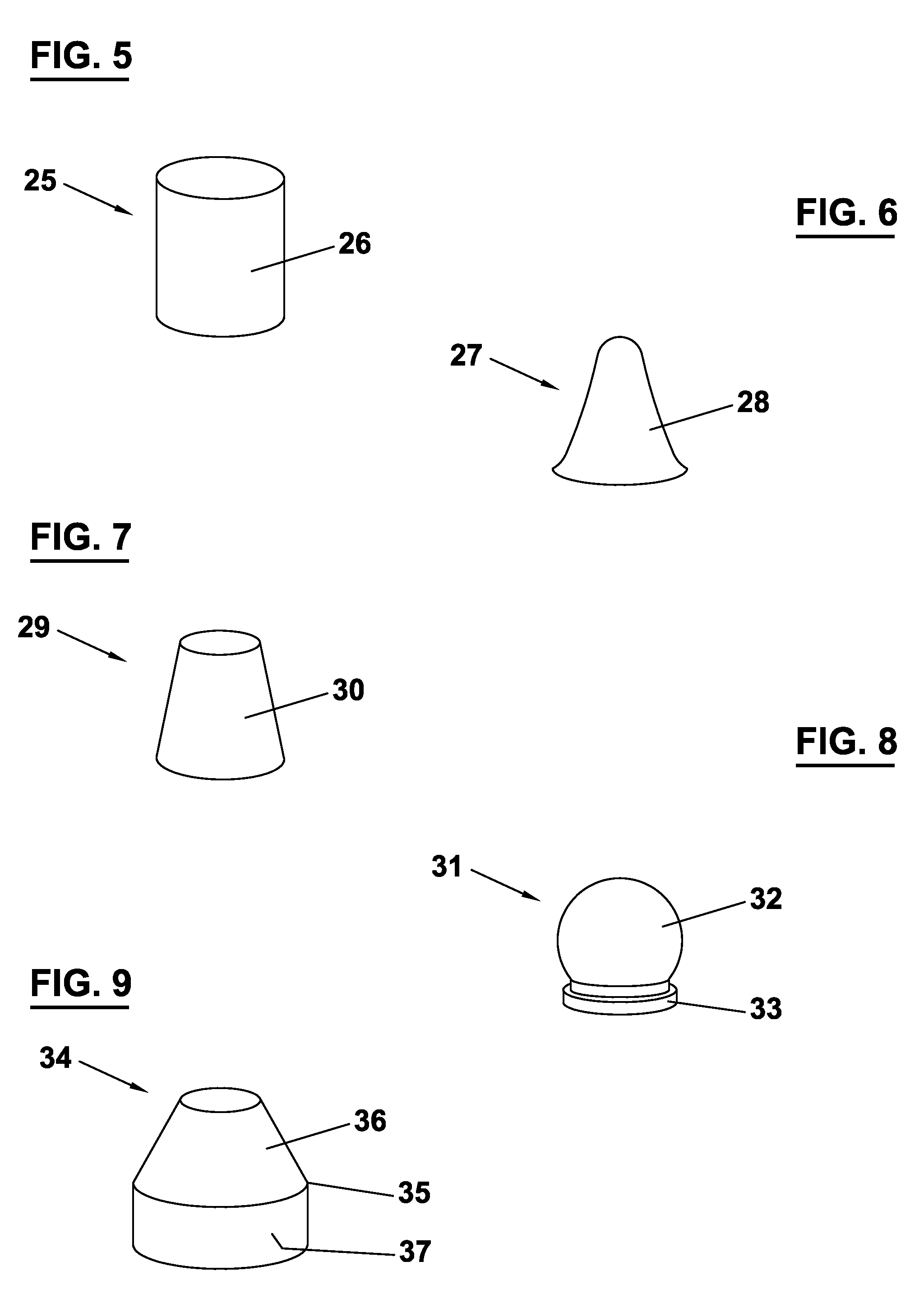

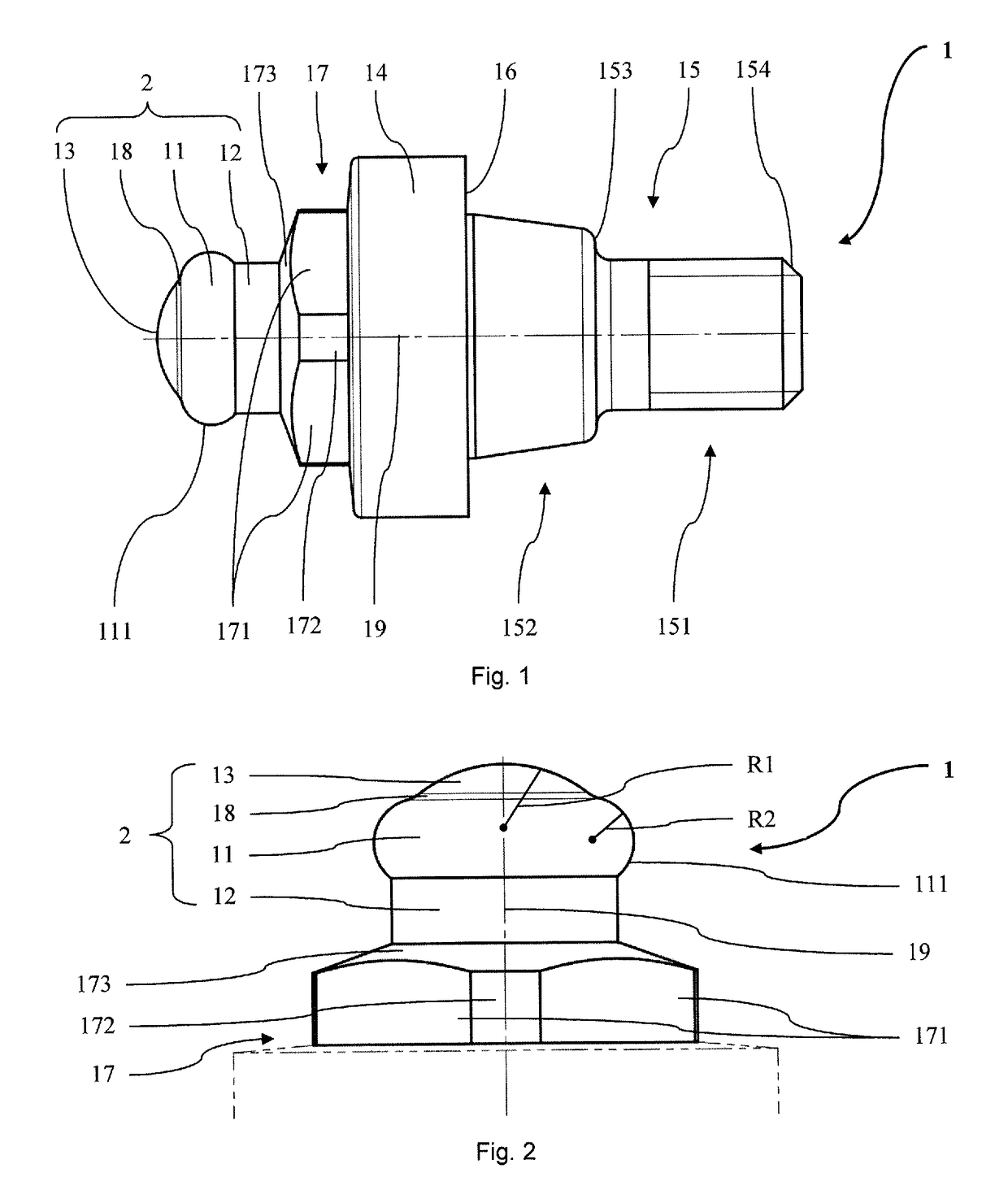

Devices for connecting a dental prosthetic construction to a jawbone

A male piece for reversible and detachable connection of a dental prosthetic construction to a jawbone, said male piece being designed with a fastening structure, by means of which the male piece can be fastened onto the jawbone, onto an implant that has been implanted in the jawbone, onto a tooth stump or onto a neighboring tooth, comprising a body section having an exterior surface corresponding to a lateral surface of a cylinder, such that the central axis of the cylinder defines a longitudinal axis of the male piece; a snap-on section, which is offset axially with respect to the longitudinal axis of the male piece relative to the body section, said snap-on section, comprising an exterior surface with a convex curvature along the longitudinal axis, which protrudes outward from the longitudinal axis of the male piece beyond the exterior surface of the body section; and a head end, which terminates the male piece axially with respect to its longitudinal axis, wherein the snap-on section is arranged closer to the head end than is the body section, and a concave intermediate section is arranged between and the head end and the convexly curved exterior surface of the snap-on section.

Owner:INSTITUT STRAUMANN AG

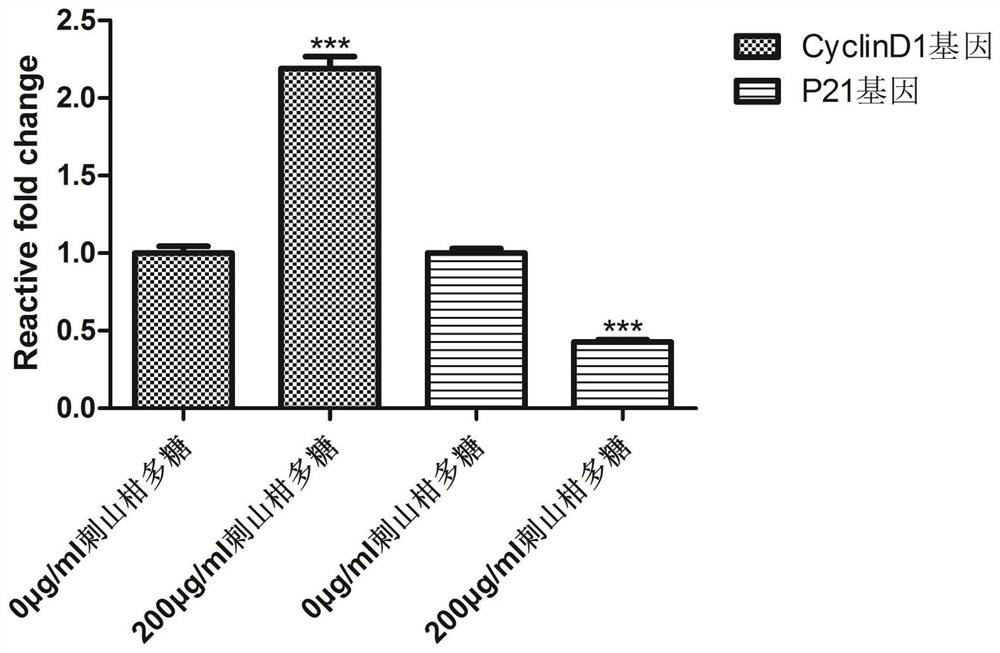

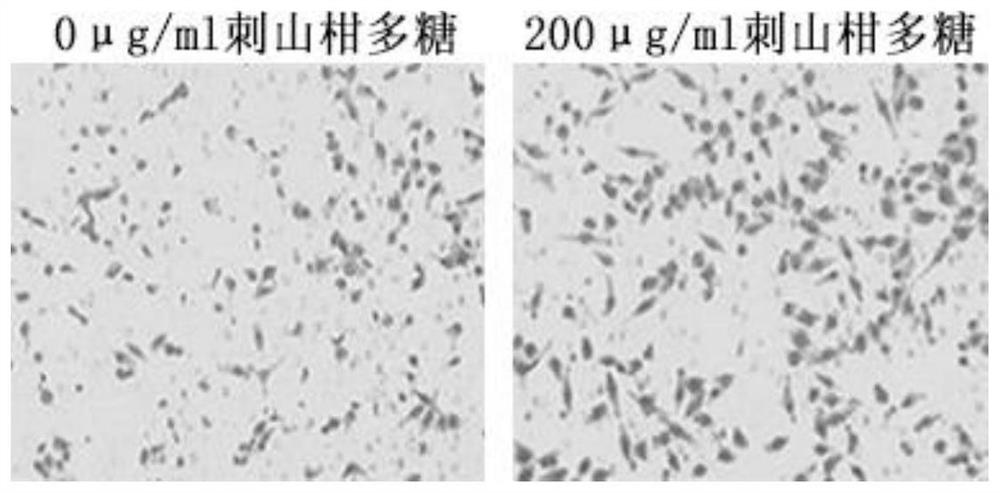

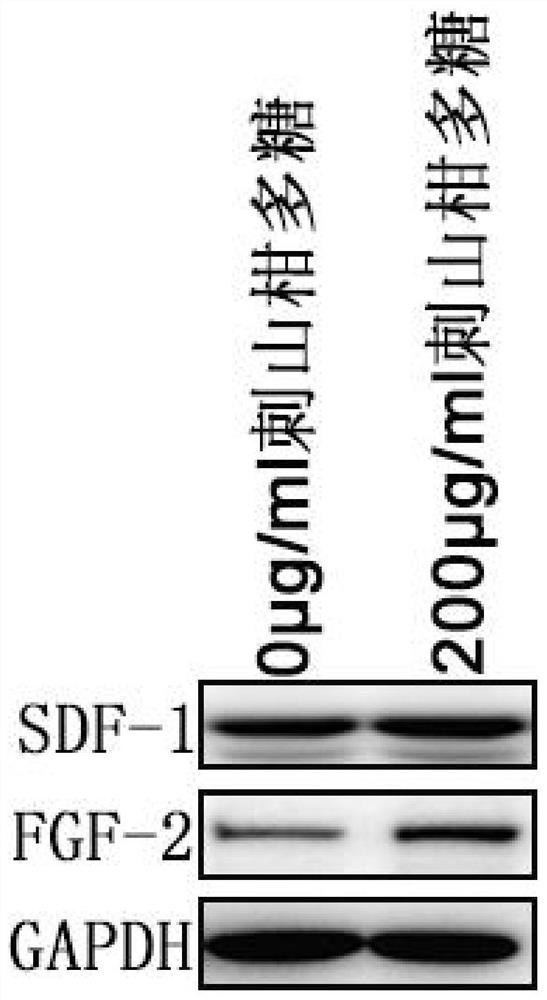

Biological agent for promoting proliferation and migration of dental pulp stem cells

ActiveCN111690603APromote proliferationPromote migrationSkeletal/connective tissue cellsCell culture active agentsWestern blotDentistry

The invention provides a biological agent for promoting proliferation and migration of dental pulp stem cells, and belongs to the technical field of stem cells. CCK-8, fluorescent quantitative PCR, Transwell experiments and Western Blot experiments prove that the capparis spinosa polysaccharide can effectively promote proliferation and cell migration of dental pulp stem cells, and possibility is provided for further developing application of the dental pulp stem cells in the aspect of dental restoration.

Owner:青岛赛尔斯干细胞库有限公司 +1

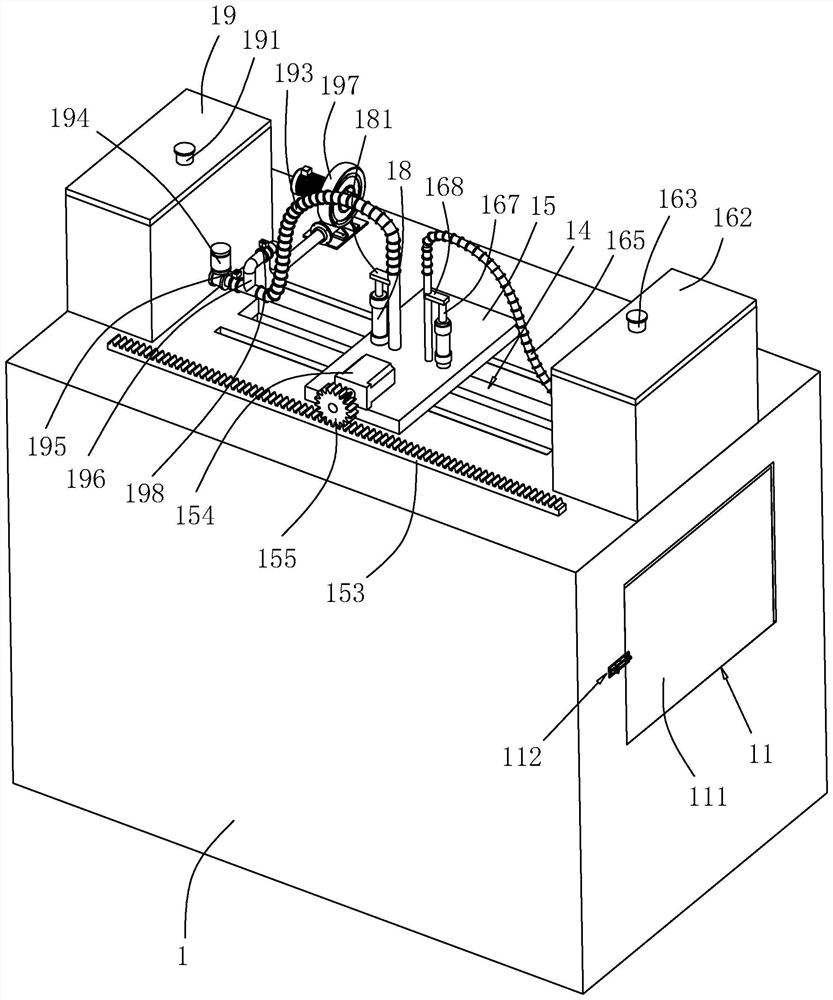

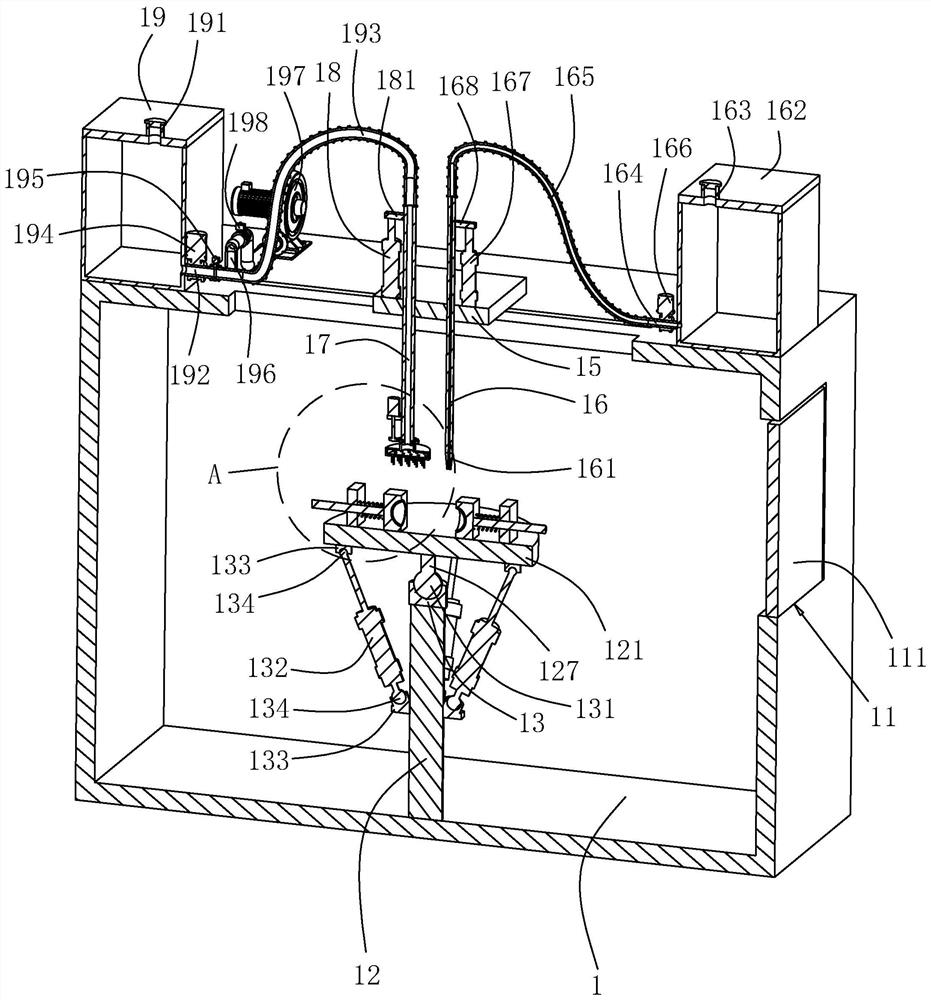

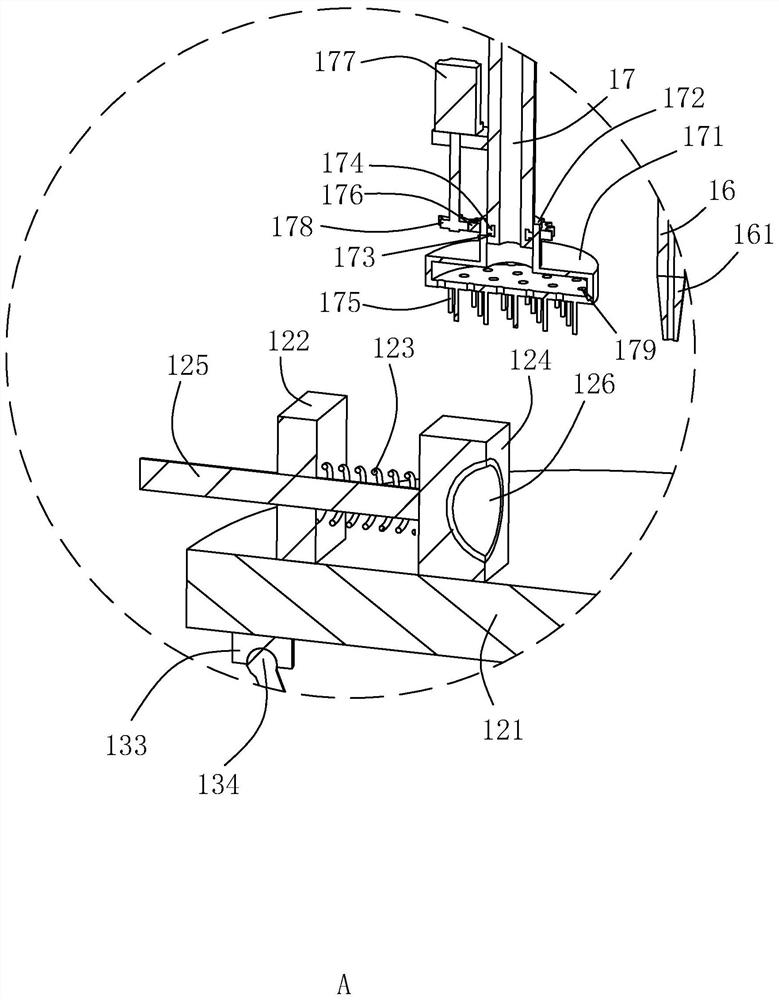

Tooth restoration device

ActiveCN112842593ASave human effortAchieve dryingTeeth fillingTooth rinsingAcid etchingRestoration device

The invention relates to a tooth restoration device which comprises a box body, an opening is formed in the side wall of the box body, and a door body used for closing the opening is hinged to the box body; a supporting rod is arranged in the box body and located on the bottom wall of the box body, a supporting plate is arranged at the end, away from the bottom wall of the box body, of the supporting rod, and a fixing device used for fixing teeth is arranged on the supporting plate; a strip-shaped opening is formed in the top wall of the box body, a movable plate is slidably arranged on the top wall of the box body in the length direction of the strip-shaped opening, and an acid etching device and a cleaning device are arranged on the movable plate and located on the two sides of the movable plate; and the movable plate is provided with a driving device used for driving the movable plate to move in the length direction of the strip-shaped opening. The method has the advantage of saving manpower for artificial acid etching and tooth restoration cleaning.

Owner:深圳新致美精密齿研有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com