High-temperature retarders suitable for polycarboxylate concrete dehydragent and method for making same

A technology of concrete water reducing agent and polycarboxylate, which is applied in the field of concrete admixtures, can solve the problems of poor retarding effect and delayed concrete setting time, and achieve the effects of delaying setting time and improving fluidity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

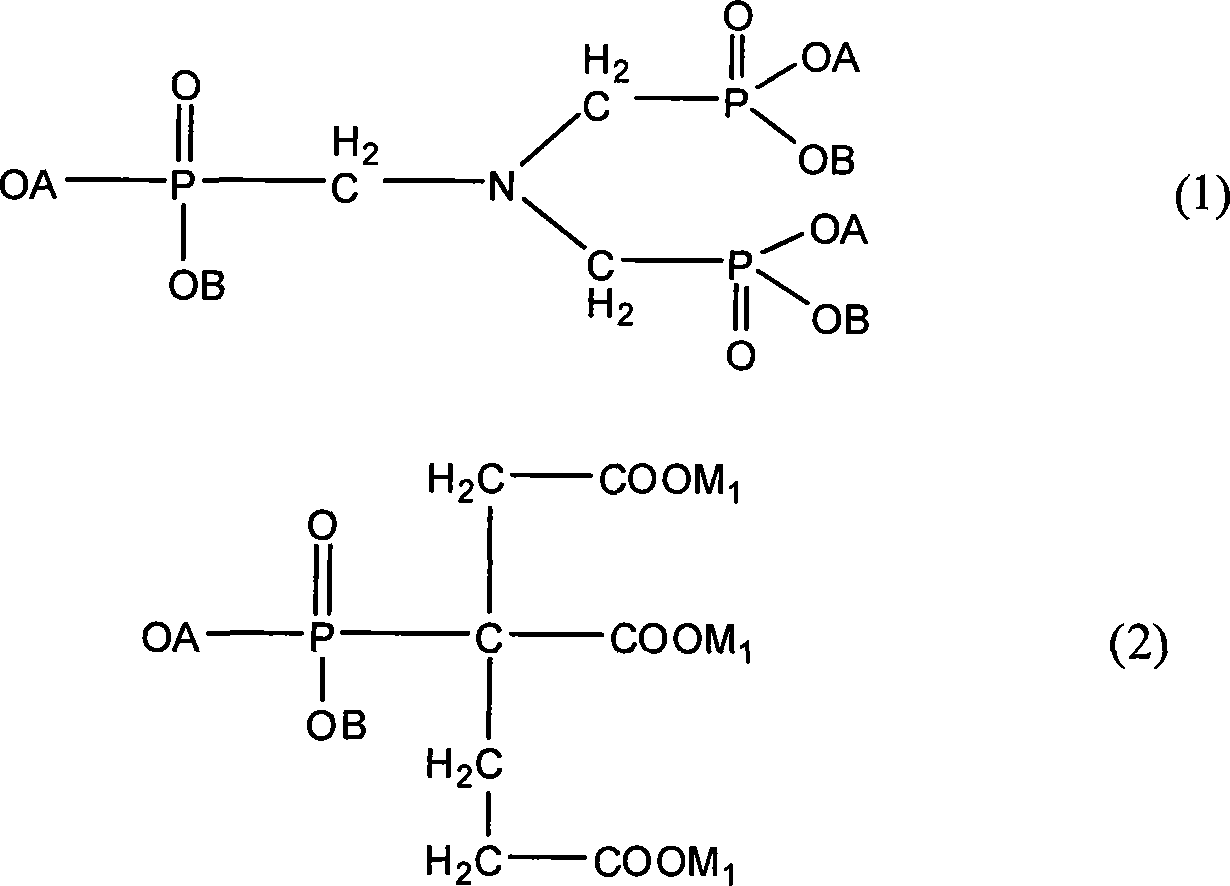

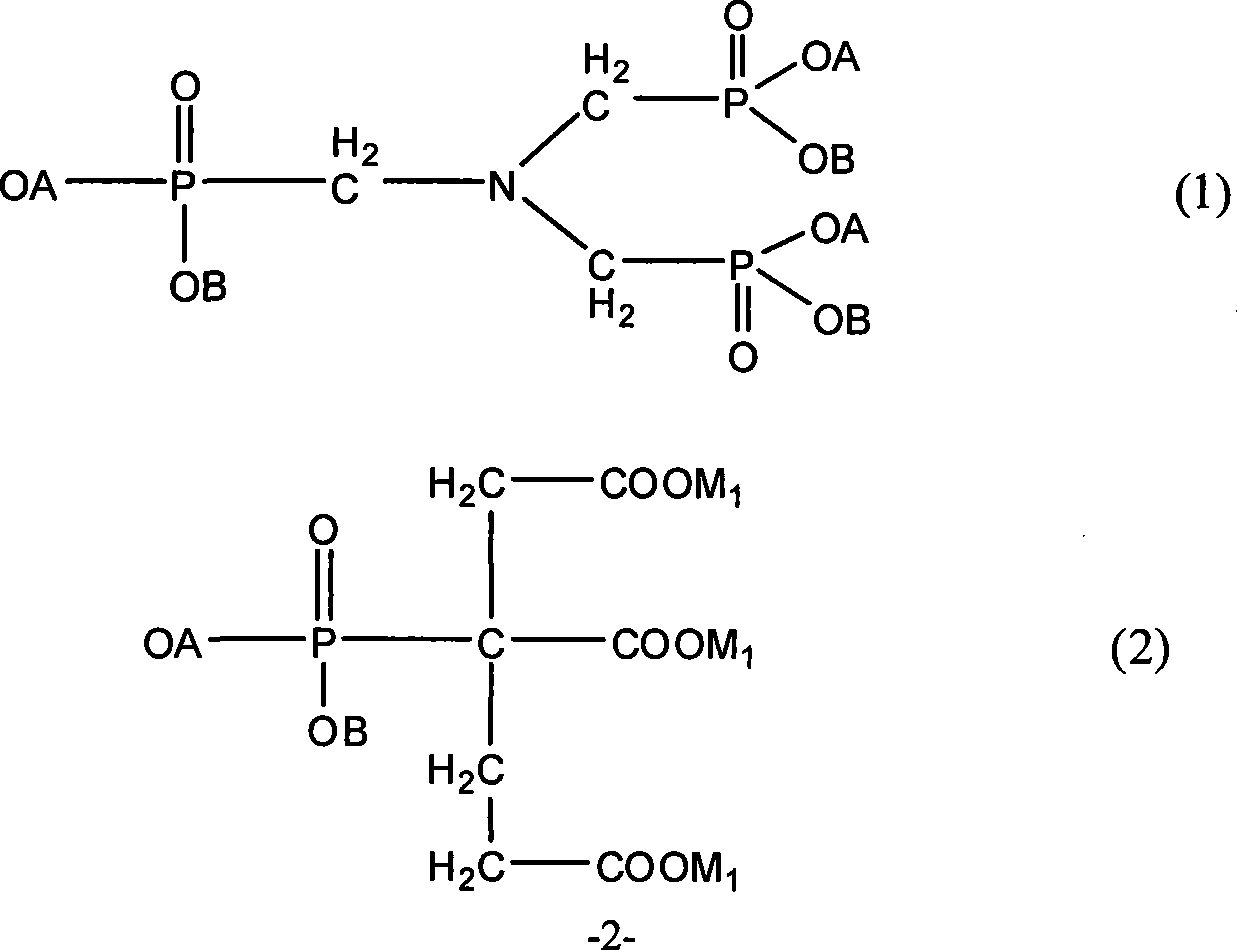

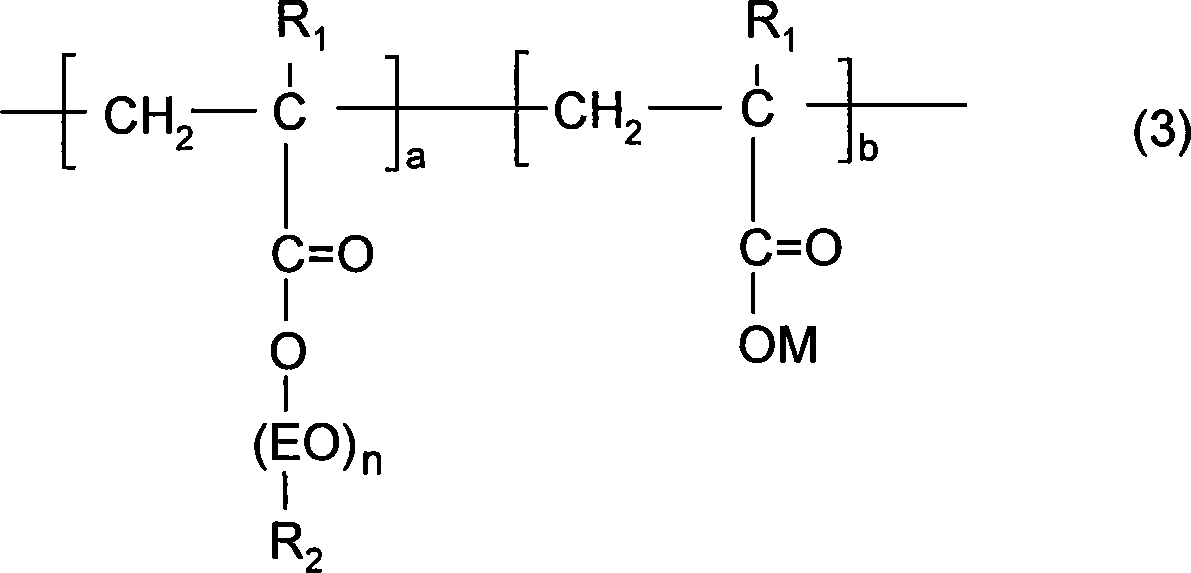

Method used

Image

Examples

Embodiment 1

[0049] Add 250kg of tap water in the 1000L reactor, drop into aminotrimethylene phosphonic acid (A-1) 150kg successively, 2-phosphonic acid butane-1,2,4-tricarboxylic acid pentasodium salt (A-5) 100kg, stir Evenly, at the same time open the reactor jacket to circulate the cooling water, add dropwise 300kg of 30% sodium hydroxide solution within 30min, the pH value of the solution is 6.2, then add 120kg of sucrose (B-1) and 75kg of sorbitol (C-1) in turn , C 8-10 Alkyl glucoside (APG-2) 15kg, stirred until it dissolves into a uniform solution with a solid content of 48.5% and a pH value of 6.3.

Embodiment 2

[0051] Add tap water 460kg in 1000L reactor, drop into aminotrimethylene phosphonic acid hexasodium salt (A-3) 285kg successively, stir well, then add glucose (B-2) 140kg successively, sorbitol (C-1) 95kg, C 12-14 Alkyl glucoside (APG-1) 20kg, stirred until it dissolves into a uniform solution with a solid content of 54.0% and a pH value of 6.7.

Embodiment 3-4

[0053] The types and proportions of raw materials used in Examples 3-4 are shown in Table 3. The preparation process is the same as in Example 1, except that the amount of alkali used to adjust the pH value of the solution is different, and the final pH value is 6-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com