Epoxy resin emulsion modified cement-based patching material and preparation material thereof

A technology of epoxy resin emulsion and repair materials, which is applied in the field of epoxy resin emulsion modified cement-based repair materials and its preparation, and can solve the problems of rapid repair of unsuitable underwater concrete cracks, low bonding strength of the base layer, poor dispersion resistance, etc. problems, to achieve the effect of excellent mechanical properties, fast curing speed and strong chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 100 parts of sulphoaluminate cement, 10 parts of silica fume and 50 parts of quartz powder into the stirring pot, stir at a speed of 60r / min for 20-30s; then add 28 parts of water, 10 parts of epoxy resin emulsion, 5 1 part of water-based tackifying rosin resin emulsion and 0.5 part of water reducer, stirring at a speed of 60r / min for 60-80s; finally add 6 parts of water-based curing agent and 0.5 part of lithium carbonate, stirring at a speed of 60r / min for 20-30s , you can get epoxy resin emulsion modified cement-based repair material.

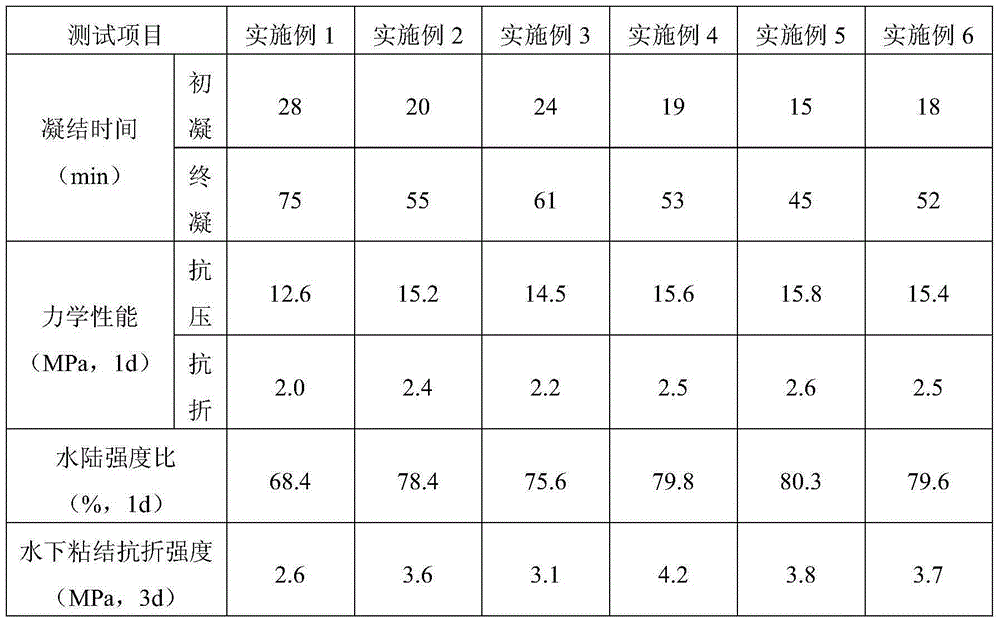

[0032] The initial setting and final setting time, 1d compressive strength and flexural strength, water-land strength ratio and underwater bonding flexural strength of the epoxy resin emulsion modified cement-based repair material were tested respectively. The initial setting and final setting time, 1d compressive strength and flexural strength test were carried out according to "Test Regulations for Polymer Modified Cement Mort...

Embodiment 2

[0037] An epoxy resin emulsion modified cement-based repair material, the distribution ratio of each component is calculated in parts by weight: 100 parts of sulfoaluminate cement, 25 parts of epoxy resin emulsion, 14 parts of water-based curing agent, 0.5 parts of lithium carbonate, 6 parts of water-based thickening rosin resin emulsion, 0.6 part of water reducer, 9 parts of silica fume, 45 parts of quartz powder and 23 parts of water, choose sulphoaluminate cement, epoxy resin emulsion, water-based curing agent, quick-setting agent (using lithium carbonate), water-based tackifying rosin resin emulsion, water reducing agent, silica fume, quartz powder and water;

[0038] The preparation method is the same as in Example 1. The performance test results are shown in Table 1.

Embodiment 3

[0040] An epoxy resin emulsion modified cement-based repair material, the distribution ratio of each component is calculated in parts by weight: 100 parts of sulfoaluminate cement, 35 parts of epoxy resin emulsion, 18 parts of water-based curing agent, 0.6 parts of lithium carbonate, 5 parts of water-based thickening rosin resin emulsion, 0.4 part of water reducer, 12 parts of silica fume, 55 parts of quartz powder and 14 parts of water, choose sulphoaluminate cement, epoxy resin emulsion, water-based curing agent, quick-setting agent (carbonic acid Lithium), water-based tackifying rosin resin emulsion, water reducing agent, silica fume, quartz powder and water;

[0041] The preparation method is the same as in Example 1. The performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com