Early strength type polycarboxylate water reducer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of building materials, can solve the problems of insufficient early strength of concrete, and achieve the effect of accelerating the cement hydration acceleration period, adding less amount, and improving the early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

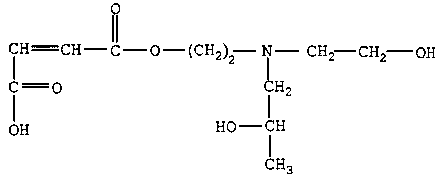

[0041]In the reaction equipment equipped with stirring, temperature control and condensing reflux devices, put 16.3g of DEIPA (diethanol monoisopropanolamine) in a four-necked flask, add 7.4g of propionic acid for neutralization, and control the temperature below 55 ℃, then add 9.8g of maleic anhydride, 0.47g of catalyst p-toluenesulfonic acid and 0.0094g of polymerization inhibitor hydroquinone, control the reaction temperature at about 105°C, and stop the reaction until the acid value no longer decreases. Pressure distillation removes propionic acid, promptly obtains the unsaturated ester A containing alcoholamine group, and its structural formula is as follows:

[0042]

Embodiment 2

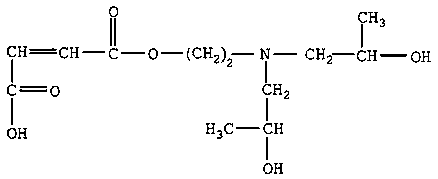

[0044] In the reaction equipment equipped with stirring, temperature control and condensing reflux devices, put 17.7g of EDIPA (monoethanol diisopropanolamine) in a four-necked bottle, add 7.4g of propionic acid for neutralization, and control the temperature below 58 ℃, then add 9.8g of maleic anhydride, 0.50g of catalyst p-toluenesulfonic acid and 0.01g of inhibitor hydroquinone, control the reaction temperature at about 110℃, and stop the reaction until the acid value no longer decreases. Pressure distillation removes propionic acid, promptly obtains the unsaturated ester B containing alcoholamine group, and its structural formula is as follows:

[0045]

Embodiment 3

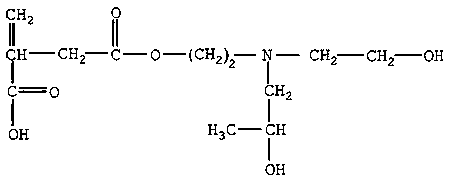

[0047] In the reaction equipment equipped with stirring, temperature control and condensing reflux devices, 16.3g of DEIPA (diethanol monoisopropanolamine) was placed in a four-necked flask, 7.4g of propionic acid was added for neutralization, and the temperature was controlled at 60 ℃, then add 13.1g itaconic anhydride, 0.52g catalyst phosphorus pentoxide and 0.01g polymerization inhibitor p-hydroxyanisole, control the reaction temperature at about 105 ℃, and stop the reaction until the acid value is no longer reduced. Pressure distillation removes propionic acid, promptly obtains the unsaturated ester C containing alcoholamine group, and its structural formula is as follows:

[0048]

[0049] Preparation of early-strength polycarboxylate superplasticizer

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com