Special waterproof anti-slip coating for outer wall as well as preparation method and application of special waterproof anti-slip coating

A coating and anti-slip technology, applied in the direction of coating, etc., can solve the problem of low comprehensive performance of exterior wall coatings, and achieve the effect of good anti-sag performance, good compatibility, and strong anti-slip ability of the facade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

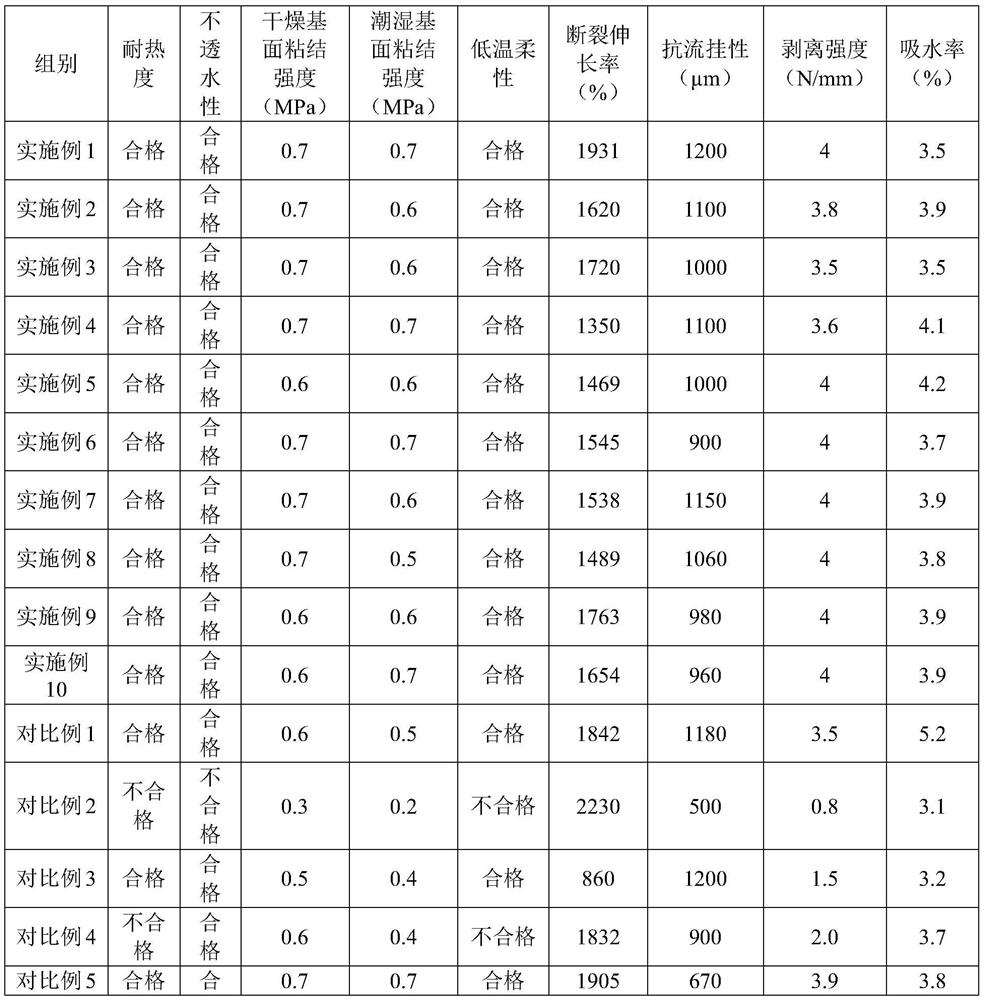

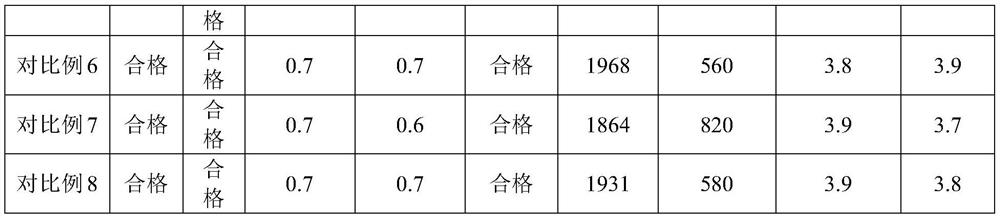

Examples

Embodiment 1

[0044] A special waterproof coating for exterior walls, which consists of the following components in parts by weight:

[0045] Modified asphalt: 24.5 parts; anionic slow-cracking emulsifier (sodium lauryl sulfate): 1.5 parts; polymer emulsion (silicone-modified acrylic emulsion): 50 parts; thixotropic agent (organic bentonite): 0.4 parts; Rheological agent (non-ionic associative polyurethane): 0.4 parts; defoamer (organic silicon): 0.2 parts; silane coupling agent (KH560): 0.5 parts; water (deionized water): 22.5 parts.

[0046] The preparation method of this waterproof paint comprises the following steps:

[0047] (1) 23 parts by weight of 90 # The asphalt is heated to about 148°C, and 1.5 parts by weight of SBS (styrene-butadiene-styrene block copolymer) is added to completely swell the asphalt to obtain modified asphalt;

[0048] (2) Evenly disperse 1.5 parts by weight of anionic slow-cracking emulsifier in 22.5 parts of deionized water, raise the temperature to about 57...

Embodiment 2

[0052] A special waterproof coating for exterior walls, which consists of the following components in parts by weight:

[0053]Modified asphalt: 27 parts; anionic slow-cracking emulsifier (sodium lauryl sulfate): 1.5 parts; polymer emulsion (silicone-modified acrylic emulsion): 45 parts; thixotropic agent (organic bentonite): 0.5 parts; Rheological agent (non-ionic associative polyurethane): 0.45 parts; defoamer (organic silicon): 0.15 parts; silane coupling agent (KH560): 0.4 parts; water (deionized water): 25 parts.

[0054] The preparation method of the waterproof coating is the same as that of Example 1, the only difference being that the amount of each component added is the amount of each component mentioned above in Example 2.

Embodiment 3

[0056] A special waterproof coating for exterior walls, which consists of the following components in parts by weight:

[0057] Modified asphalt: 26 parts; anionic slow-cracking emulsifier (sodium lauryl sulfate): 2 parts; polymer emulsion (silicone-modified acrylic emulsion): 50 parts; thixotropic agent (organic bentonite): 0.3 parts; Rheological agent (non-ionic associative polyurethane): 0.3 parts; defoamer (organic silicon): 0.2 parts; silane coupling agent (KH560): 0.2 parts; water (deionized water): 21 parts.

[0058] The preparation method of the waterproof coating is the same as that of Example 1, the only difference being that the amount of each component added is the amount of each component mentioned above in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com