Self-cleaning type stone-like paint and preparation method thereof

A stone-like coating and self-cleaning technology, applied in the field of coatings, can solve the problems of stone-like coatings and self-cleaning coatings that are easy to fall off, affect the durability of the coating, and have unsatisfactory waterproof effects, and achieve excellent hydrophobicity and stain resistance. , prolong the service life, and improve the artificial weather aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

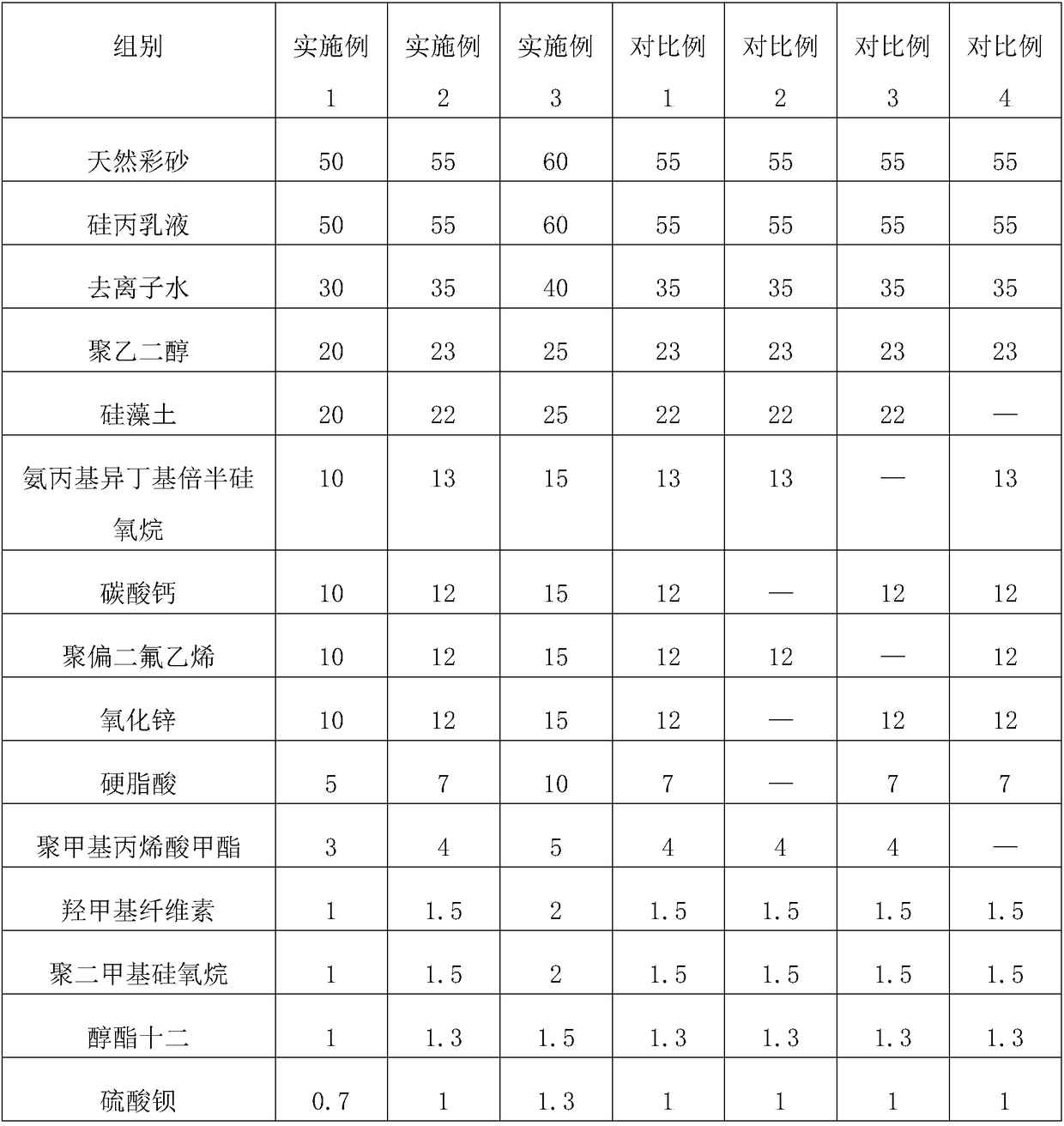

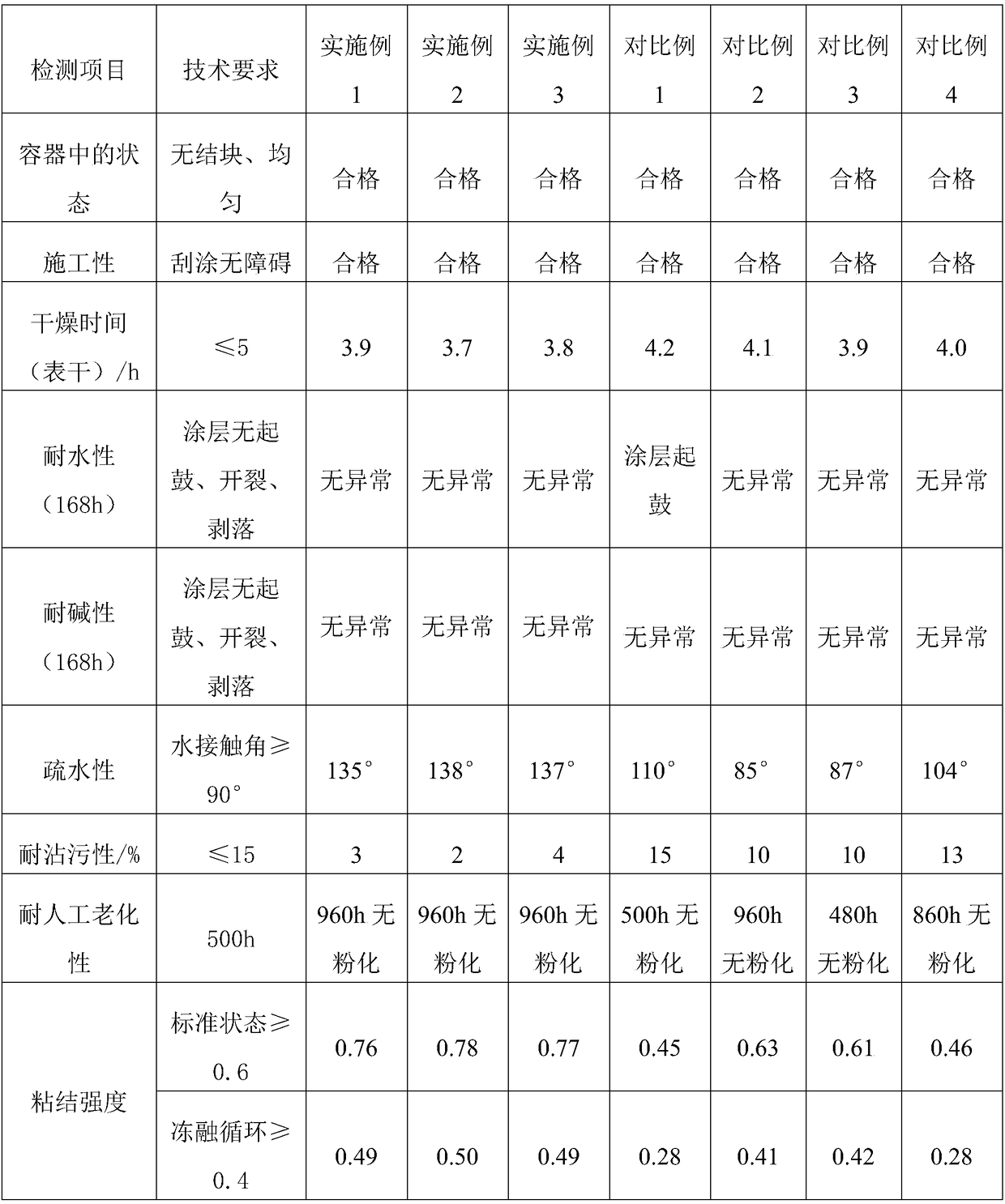

Embodiment 1

[0030] A kind of self-cleaning type imitation stone coating, its preparation method comprises the following steps:

[0031] S1. According to the following formula of self-cleaning stone imitation paint, weigh each component for later use;

[0032] 50 parts of natural colored sand, 50 parts of silicone acrylic emulsion, 30 parts of deionized water, 20 parts of polyethylene glycol, 20 parts of diatomaceous earth, 10 parts of aminopropyl isobutyl silsesquioxane, 10 parts of calcium carbonate, 10 parts of polyvinylidene fluoride, 10 parts of zinc oxide, 5 parts of stearic acid, 3 parts of polymethyl methacrylate, 1 part of hydroxymethyl cellulose, 1 part of polydimethylsiloxane, alcohol ester dodeca 1 part, 0.7 part of barium sulfate.

[0033] Among them, the average molecular weight of polyethylene glycol is 400, the diatomite is 200 mesh diatomite, and the natural colored sand is 80-120 mesh natural colored sand.

[0034] S2. Add 30% of the formula water, silicon acrylic emuls...

Embodiment 2

[0040] A kind of self-cleaning type imitation stone coating, its preparation method comprises the following steps:

[0041] S1. According to the following formula of self-cleaning stone imitation paint, weigh each component for later use;

[0042] 55 parts of natural colored sand, 55 parts of silicone acrylic emulsion, 35 parts of deionized water, 23 parts of polyethylene glycol, 22 parts of diatomaceous earth, 13 parts of aminopropyl isobutyl silsesquioxane, 12 parts of calcium carbonate, 12 parts of polyvinylidene fluoride, 12 parts of zinc oxide, 7 parts of stearic acid, 4 parts of polymethyl methacrylate, 1.5 parts of hydroxymethyl cellulose, 1.5 parts of polydimethylsiloxane, alcohol ester dodeca 1.3 parts, 1 part of barium sulfate.

[0043] Among them, the average molecular weight of polyethylene glycol is 400, the diatomite is 200 mesh diatomite, and the natural colored sand is 80-120 mesh natural colored sand.

[0044] S2. Add 30% of the formula amount of water, the ...

Embodiment 3

[0050] A kind of self-cleaning type imitation stone coating, its preparation method comprises the following steps:

[0051] S1. According to the following formula of self-cleaning stone imitation paint, weigh each component for later use;

[0052] 60 parts of natural colored sand, 60 parts of silicone acrylic emulsion, 40 parts of deionized water, 25 parts of polyethylene glycol, 25 parts of diatomaceous earth, 15 parts of aminopropyl isobutyl silsesquioxane, 15 parts of calcium carbonate, 15 parts of polyvinylidene fluoride, 15 parts of zinc oxide, 10 parts of stearic acid, 5 parts of polymethyl methacrylate, 2 parts of hydroxymethyl cellulose, 2 parts of polydimethylsiloxane, alcohol ester dodeca 1.5 parts, barium sulfate 1.3 parts.

[0053] Among them, the average molecular weight of polyethylene glycol is 400, the diatomite is 200 mesh diatomite, and the natural colored sand is 80-120 mesh natural colored sand.

[0054] S2. Add 30% of the formula amount of water, the who...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com