High-performance waterborne epoxy anticorrosive coating

A water-based epoxy and anti-corrosion coating technology, used in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., to achieve excellent flexibility, improved strength, and good anti-corrosion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

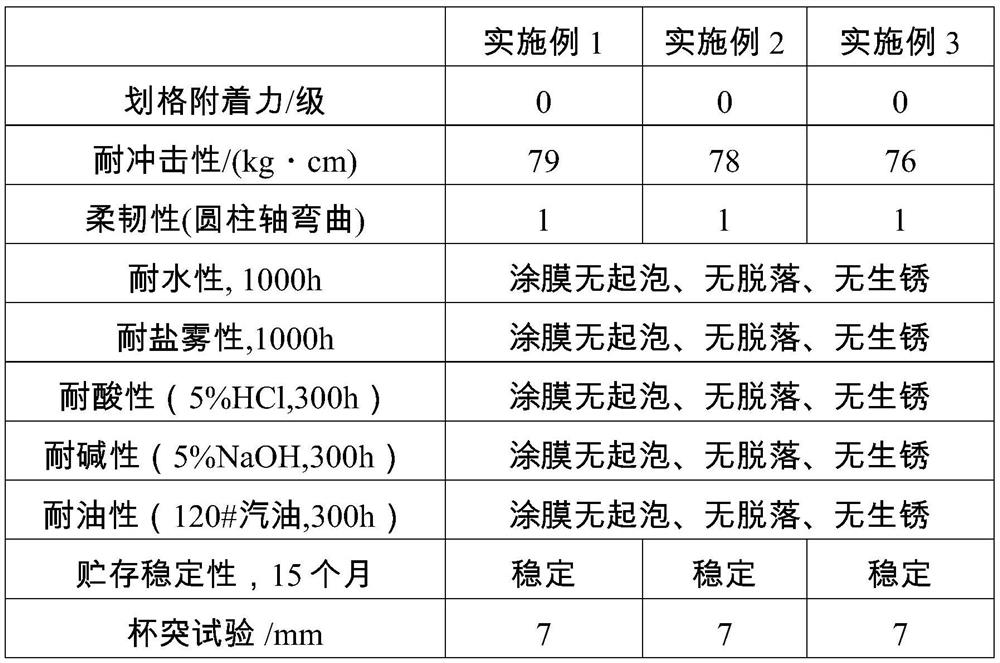

Examples

Embodiment 1

[0033] A high-performance water-based epoxy anti-corrosion coating, including component A and component B;

[0034] Component A is composed of the following components by weight: 67 parts of AB-EP-20 water-based epoxy resin emulsion, 6 parts of styrene-acrylic emulsion, 3 parts of zinc oxide / graphene oxide composite material, 0.9 parts of cerium-doped nano titanium dioxide, nano Attapulgite 1.2 parts, organic bentonite 4 parts, titanium dioxide 1 part, silane coupling agent KH550 0.35 parts, n-butanol 3 parts, dispersant BYK-9077 0.5 parts, defoamer BYK-025 0.4 parts, leveling agent 0.2 parts of BYK-310, 22 parts of deionized water.

[0035] Component B consists of the following components by weight: 33 parts of polyetheramine, 5 parts of diethylenetriamine, 30 parts of wet-process sericite powder, and 10 parts of talcum powder.

[0036] The solid content of the above-mentioned styrene-acrylic emulsion is 46.2%. The amine value of polyetheramine was 405 mgKOH / g. The mass fr...

Embodiment 2

[0038] A high-performance water-based epoxy anti-corrosion coating, including component A and component B;

[0039] Component A is composed of the following components by weight: 62 parts of AB-EP-20 water-based epoxy resin emulsion, 8.5 parts of styrene-acrylic emulsion, 3 parts of zinc oxide / graphene oxide composite material, 1 part of cerium-doped nano titanium dioxide, nano Attapulgite 1.3 parts, organic bentonite 3.5 parts, titanium dioxide 1 part, silane coupling agent KH570 0.5 parts, n-butanol 3 parts, dispersant BYK-9077 0.5 parts, defoamer BYK-025 0.3 parts, leveling agent 0.2 parts of BYK-310, 20 parts of deionized water.

[0040] Component B consists of the following ingredients in parts by weight: 32 parts of polyetheramine, 4.5 parts of diethylenetriamine, 30 parts of wet-process sericite powder, and 10 parts of talcum powder.

[0041] The solid content of the above-mentioned styrene-acrylic emulsion is 46.2%. The amine value of polyetheramine was 405 mgKOH / g. ...

Embodiment 3

[0043] A high-performance water-based epoxy anti-corrosion coating, including component A and component B;

[0044] Component A is composed of the following components by weight: 70 parts of AB-EP-20 water-based epoxy resin emulsion, 5 parts of styrene-acrylic emulsion, 3 parts of zinc oxide / graphene oxide composite material, 1 part of cerium-doped nano titanium dioxide, nano Attapulgite 2 parts, organic bentonite 5 parts, titanium dioxide 3 parts, silane coupling agent KH550 0.3 parts, n-butanol 3 parts, dispersant BYK-90770.6 parts, defoamer BYK-025 0.4 parts, leveling agent BYK -310 0.2 parts, deionized water 22 parts.

[0045] Component B consists of the following ingredients in parts by weight: 35 parts of polyetheramine, 5 parts of diethylenetriamine, 30 parts of wet-process sericite powder, and 10 parts of talcum powder.

[0046] The solid content of the above-mentioned styrene-acrylic emulsion is 48.5%. The amine value of polyetheramine was 465 mgKOH / g. The mass fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com