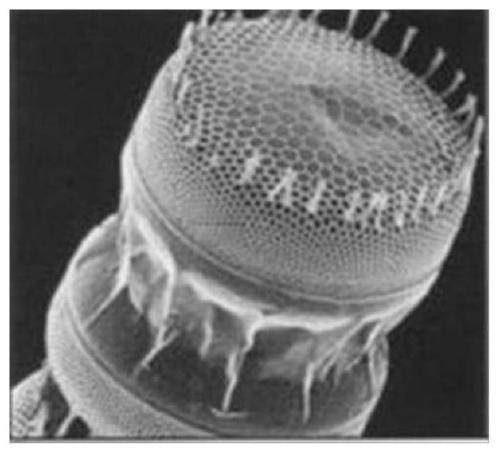

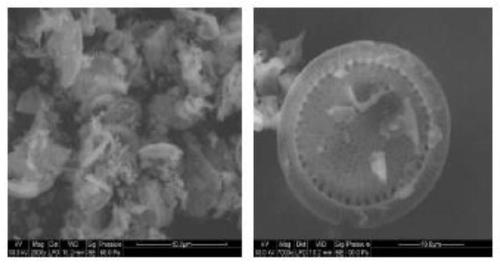

Diatom ooze decoration material and preparation method thereof

A technology of decorative materials and diatom mud, which is applied in the field of diatom mud decorative materials and its preparation, can solve problems such as lack of air purification performance and air pollution, and achieve the effects of easy polishing, easy application, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

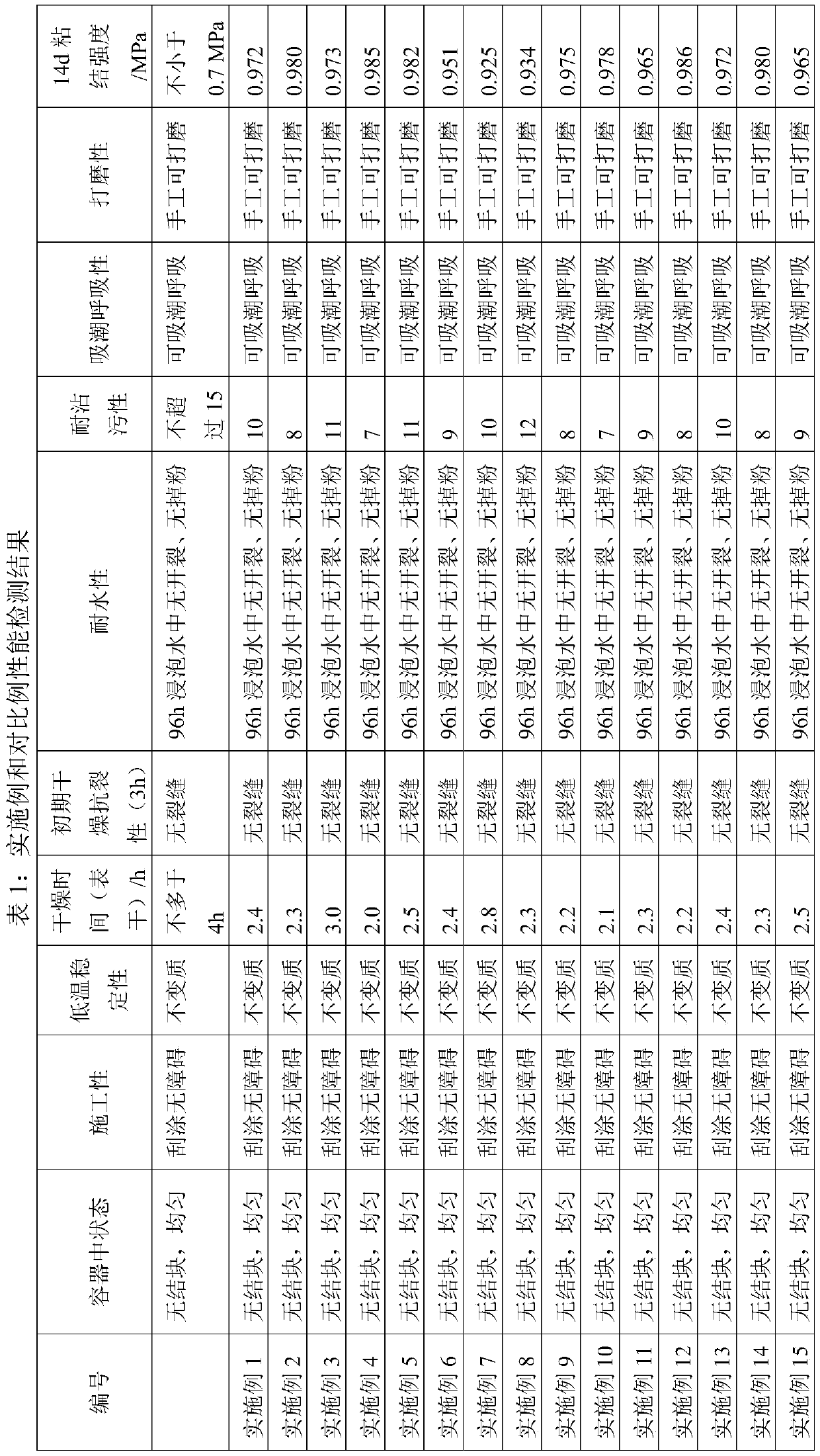

Examples

Embodiment 1

[0064] 1) Prepare the raw materials according to the following proportions by weight:

[0065] 100 parts of diatomite of 150-200 mesh, 50 parts of white cement, 270 parts of heavy calcium of 500-800 mesh, 220 parts of ash calcium of 550-850 mesh, 210 parts of quartz sand of 100-200 mesh, 20 parts of titanium dioxide of 0.2-0.5μm 3 parts, antifungal agent ammonium persulfate 3 parts, starch ether 4 parts, thixotropic lubricant (987) 6 parts, dispersant (SP-718) 0.5 parts, polyvinyl alcohol PVA (1788) 4 parts, inorganic pigment 4 parts , 30 parts of dispersible latex powder, 5 parts of hydroxypropyl methylcellulose ether, 4 parts of wood fiber and 740 parts of water.

[0066] 2) Put the diatomite, white cement, heavy calcium, gray calcium and quartz sand into the dry powder mixer first, and stir for 2-3 minutes;

[0067] 3) Then put the additives such as titanium dioxide, antifungal agent, starch ether, thixotropic agent, dispersant, polyvinyl alcohol, inorganic pigment, disper...

Embodiment 2

[0072] Except preparing raw material by following weight portion proportioning, all the other are with embodiment 1:

[0073]150 parts of diatomite, 60 parts of white cement, 270 parts of heavy calcium, 200 parts of gray calcium, 200 parts of quartz sand, 30 parts of titanium dioxide, 3 parts of antifungal agent, 3 parts of starch ether, thixotropic lubricant (987)5 1 part, 1 part of dispersant (718), 3 parts of polyvinyl alcohol PVA (1788), 3 parts of inorganic pigment, 50 parts of dispersible latex powder, 4 parts of cellulose ether, 3 parts of wood fiber and 735 parts of water.

Embodiment 3

[0075] Except preparing raw material by following weight portion proportioning, all the other are with embodiment 1:

[0076] 200 parts of diatomite, 50 parts of white cement, 280 parts of heavy calcium, 190 parts of gray calcium, 200 parts of quartz sand, 25 parts of titanium dioxide, 3 parts of antifungal agent, 4 parts of starch ether, thixotropic lubricant (987)5 2 parts, 2 parts of dispersant (718), 2 parts of polyvinyl alcohol PVA (1788), 2 parts of inorganic pigment, 50 parts of dispersible latex powder, 4 parts of cellulose ether, 5 parts of wood fiber and 740 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com