Plastering-free mechanically-sprayed putty powder, plastering-free mechanically-sprayed putty slurry as well as preparation method and application thereof

A technology that does not require plastering and putty powder. It is applied in the direction of filling slurry, construction, and building construction. It can solve problems such as spalling, wall efflorescence, and restrictions on safety and matching, and achieves reduced labor costs and good anti-sag performance. , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The present embodiment provides a kind of free plastering machine spray putty powder, described free plastering machine spray putty powder comprises the following components by weight percentage:

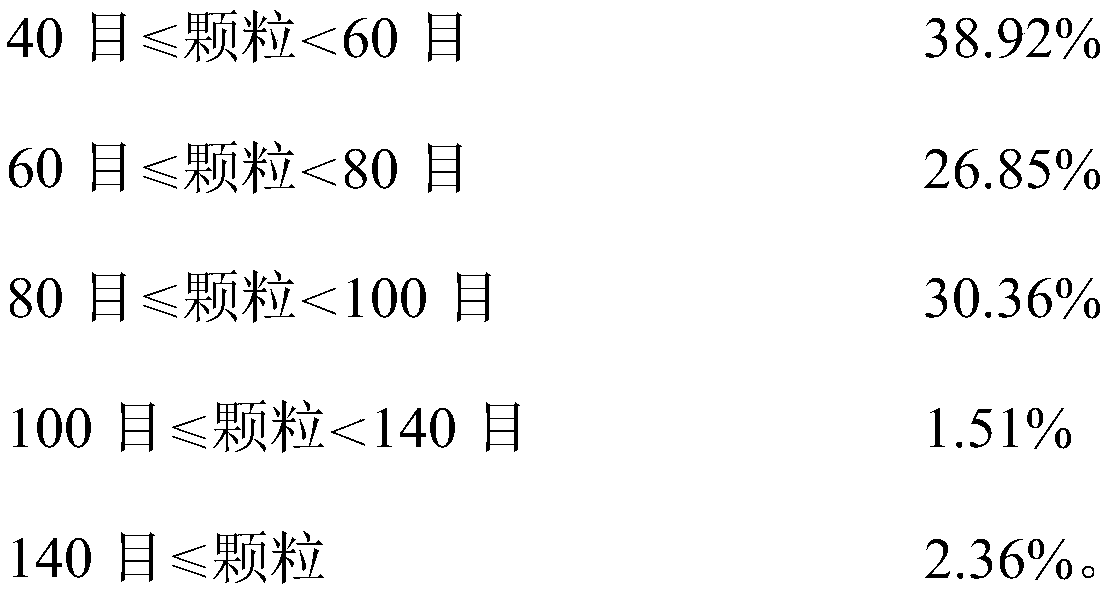

[0062] Inorganic gelling material 30.0%, aggregate 35.0%, filler 29.0%, anti-alkali additive 1.0%, redispersible latex powder 4.0%, hydroxypropyl methyl cellulose ether 0.4%, anti-crack fiber 0.2%, thixotropic 0.2% water reducing agent, 0.15% water reducing agent, 0.05% water repellent; inorganic gelling material is Portland cement with P.W32.5 or above; filler is 120-220 mesh quartz sand powder and 200-325 mesh heavy carbonic acid The combination of calcium, the mass ratio of the two is 1.8:1; the anti-alkali additive is a combination of metakaolin and Akzo Nobel ubiquitin inhibitor, the mass ratio of the two is 1.2:1; the redispersible latex powder is Wacker The combination of 5044N rubber powder and WACKER 8034H hydrophobic rubber powder, the mass ratio of the two is 4:1; ...

Embodiment 2

[0069] The present embodiment provides a kind of free plastering machine spray putty powder, described free plastering machine spray putty powder comprises the following components by weight percentage:

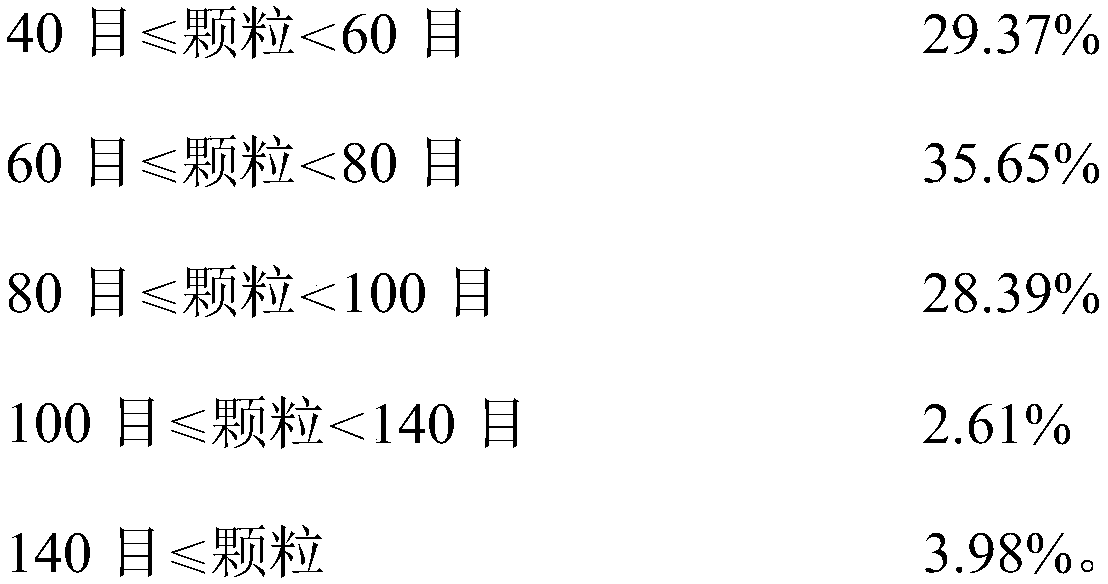

[0070] Inorganic gelling material 30.0%, aggregate 45.0%, filler 18.0%, anti-alkali additive 3.0%, redispersible latex powder 3.0%, hydroxypropyl methyl cellulose ether 0.3%, anti-crack fiber 0.3%, thixotropic 0.3% water reducing agent, 0.05% water reducing agent, 0.05% water repellent; inorganic gelling material is Portland cement with P.W32.5 or above; filler is 120-220 mesh quartz sand powder and 200-325 mesh heavy carbonic acid The combination of calcium, the mass ratio of the two is 1.5:1; the anti-alkali additive is a combination of metakaolin and Akzo Nobel ubiquitin inhibitor, the mass ratio of the two is 1:1; the redispersible latex powder is Wacker The combination of 5044N rubber powder and WACKER 8034H hydrophobic rubber powder, the mass ratio of the two is 3:1; th...

Embodiment 3

[0077] The present embodiment provides a kind of free plastering machine spray putty powder, described free plastering machine spray putty powder comprises the following components by weight percentage:

[0078]Inorganic gelling material 25.0%, aggregate 40.0%, filler 28.2%, anti-alkali additive 1.0%, redispersible latex powder 5.0%, hydroxypropyl methylcellulose ether 0.4%, anti-crack fiber 0.2%, thixotropic 0.1% water reducing agent, 0.09% water reducing agent, 0.01% water repellent; the inorganic gelling material is Portland cement with P.W32.5 or above; the filler is 120-220 mesh quartz sand powder and 200-325 mesh heavy carbonic acid The combination of calcium, the mass ratio of the two is 2:1; the anti-alkali additive is a combination of metakaolin and Akzo Nobel ubiquitin inhibitor, the mass ratio of the two is 1.5:1; the redispersible latex powder is Wacker The combination of 5044N rubber powder and WACKER 8034H hydrophobic rubber powder, the mass ratio of the two is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com