Salt-freezing-resisting high-performance repairing mortar for repairing road concrete bridge

A technology for repairing mortar and concrete, which is applied in the field of highway concrete bridge maintenance, can solve the problems of lack of salt freeze resistance durability, poor compatibility, and unimproved durability of concrete structures, etc., and achieve high salt freeze resistance and denudation performance , long operating time and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

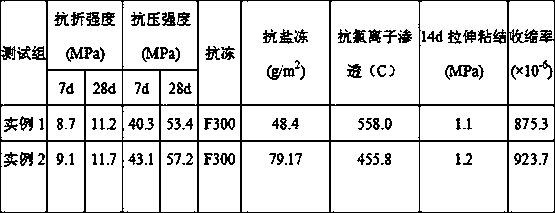

Embodiment 1

[0043] The components and parts of the anti-salt freeze-resistant high-performance polymer repair mortar are as follows:

[0044] 220 parts of ordinary Portland cement, 45 parts of granulated blast furnace slag powder, 45 parts of fly ash, 20 parts of silica fume, 650 parts of quartz sand (20~200 mesh) (of which 20~40 mesh 30%, 40~70 mesh 35%, 70~120 mesh 15%, 120~200 mesh 20%), modified sulfonated melamine 3.5 parts, redispersible latex powder 7.5 parts, defoamer 0.45 parts, starch ether 0.45 parts, polyacrylonitrile fiber 0.4 parts share.

[0045] Put the weighed ordinary Portland cement, granulated blast furnace slag powder, fly ash, and silica fume into the dry mixer and stir in turn. The stirring time is 5 minutes, and the stirring speed is 200r / min; after that, the modified sulfonated melamine , redispersible latex powder, defoamer, starch ether, and polyacrylonitrile fiber are put into the dry mixer and stirred in sequence, the stirring time is 5min, and the stirring s...

Embodiment 2

[0048] 274 parts of ordinary portland cement, 48 parts of granulated blast furnace slag powder, 48 parts of fly ash, 20 parts of silica fume, 590 parts of quartz sand (20~200 mesh) (of which, 20~40 mesh 30wt% (volume percentage weight ), 40~70 mesh 35%, 70~120 mesh 15%, 120~200 mesh 20%), modified (group) sulfonated melamine 4.0 parts, redispersible latex powder 8.0 parts, defoamer 0.5 parts ( specific components), 0.5 parts of starch ether, and 0.5 parts of polyacrylonitrile fiber. (list of ingredients)

[0049] Put the weighed ordinary Portland cement, granulated blast furnace slag powder, fly ash, and silica fume into the dry mixer and stir in turn. The stirring time is 7 minutes, and the stirring speed is 280r / min; after that, the modified sulfonated melamine, The redispersible latex powder, defoamer, starch ether, and polyacrylonitrile fiber are put into the dry mixer and stirred in sequence, and the stirring time is 7 minutes, and the stirring speed is 280r / min; finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com