Process for preparing high-conductivity colloidal electrolyte of electric accumulator and pouring it

A colloidal electrolyte and battery technology, applied in lead-acid batteries, battery pack parts, circuits, etc., can solve the problems of long production cycle, high cost, waste of raw materials and working hours, etc., and achieve good thixotropy, good coagulation elasticity, and storage capacity. The effect of stable capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in detail below:

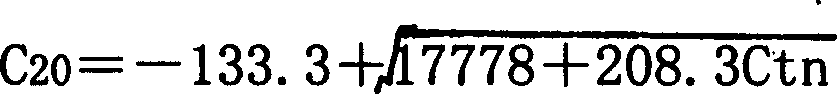

[0023] The contents of various technical indicators of the high-conductivity colloidal electrolyte for perfusion lead-acid storage battery of the present invention are: sulfuric acid 35-42%, glycerol 1-5%, silicon 4-5%, phosphoric acid 1-5%, potassium 0.01- 0.02%, sodium 0.01-0.02%, lithium 0.008-0.01%, germanium 0.1-0.2%, cadmium 0.06-0.1%, and the rest is water, in which the insoluble system indicators are: iron ≤ 0.00008%, sodium ≤ 0.01%, chlorine ≤ 0.0005%, arsenic ≤0.00002%, nitrogen compounds ≤0.0002%, carbonates ≤0.00001%, sulfates ≤0.00001%, ammonium ≤0.00008%, alkaline earth metal compounds ≤0.005%, nitrates and nitrites ≤0.0005%, Organic matter ≤0.0008%.

[0024] The high-conductivity colloidal electrolyte is composed of a mixture of various elements A, B 1 and A, B 2 The material is mixed again, and its preparation method is as follows:

[0025] 1. The preparation of A kind of material:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com