Accelerating agent with good adaptability to cement with low alkali content and use method of accelerating agent

A quick-setting agent and adaptable technology, which is applied in civil engineering materials and civil engineering fields, can solve problems such as the incompatibility of the quick-setting agent, the inability of concrete to set quickly, and the impact on the construction progress and construction quality of shotcrete, and achieve the speed of strength development Ideal, less harmful to production and construction personnel and the environment, and low rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

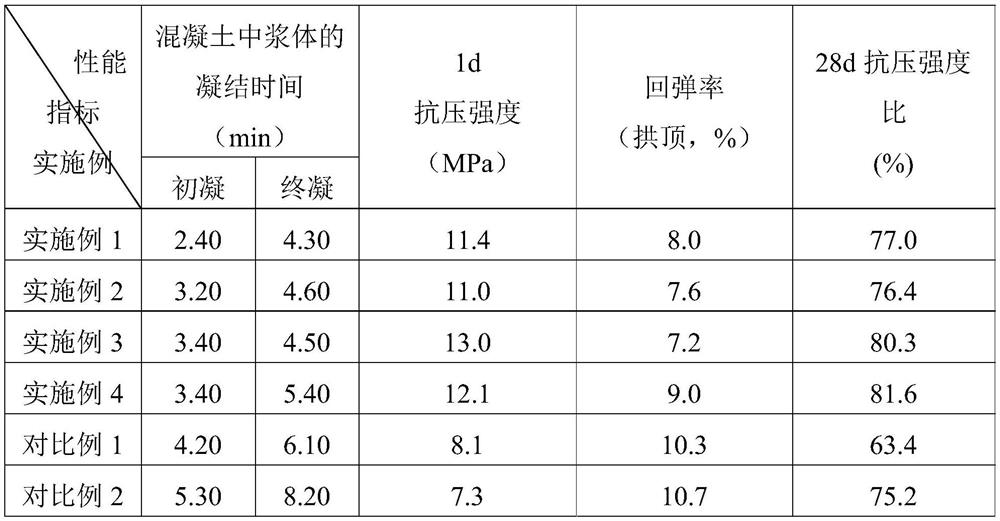

Examples

Embodiment 1

[0024] An accelerator with good adaptability to cement with low alkali content is composed of calcined alumite, sodium carbonate, shell calcined material separated during the preparation of machine-made sand, and diatomite, and the mass percentage of each composition is: calcined alum 20% of stone, 6% of sodium carbonate, 50% of calcined shell separated during the preparation of machine-made sand, and 24% of diatomaceous earth. The concrete prepared by mixing with low-alkali cement is sprayed for construction, and the dosage is 3% of the mass of the low-alkali cement.

Embodiment 2

[0026] An accelerator with good adaptability to cement with low alkali content is composed of calcined alumite, sodium carbonate, shell calcined material separated during the preparation of machine-made sand, and diatomite, and the mass percentage of each composition is: calcined alum 75% of stone, 2% of sodium carbonate, 20% of calcined shell separated during the preparation of machine-made sand, and 3% of expanded diatomaceous earth. The concrete prepared by mixing with low-alkali cement is sprayed for construction, and the dosage is 6% of the quality of the low-alkali cement.

Embodiment 3

[0028] An accelerator with good adaptability to cement with low alkali content is composed of calcined alumite, sodium carbonate, shell calcined material separated during the preparation of machine-made sand, and diatomite, and the mass percentage of each composition is: calcined alum 26% of stone, 4% of sodium carbonate, 30% of calcined shells separated during the preparation of machine-made sand, and 40% of expanded diatomaceous earth. The concrete prepared by mixing with low-alkali cement is sprayed for construction, and the mixing amount is 8% of the mass of the low-alkali cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com