Industrial spinning oil agent for FDY chinlon 66 and preparation method thereof

A technology of spinning oil and production method, which is applied in the field of FDY nylon 66 industrial spinning oil, can solve the problems of spinnability, smoothness, low cohesion, easy occurrence of wool, broken ends, high use cost, etc. Achieve the effects of low end-breakage rate, good cohesion and low waste silk rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

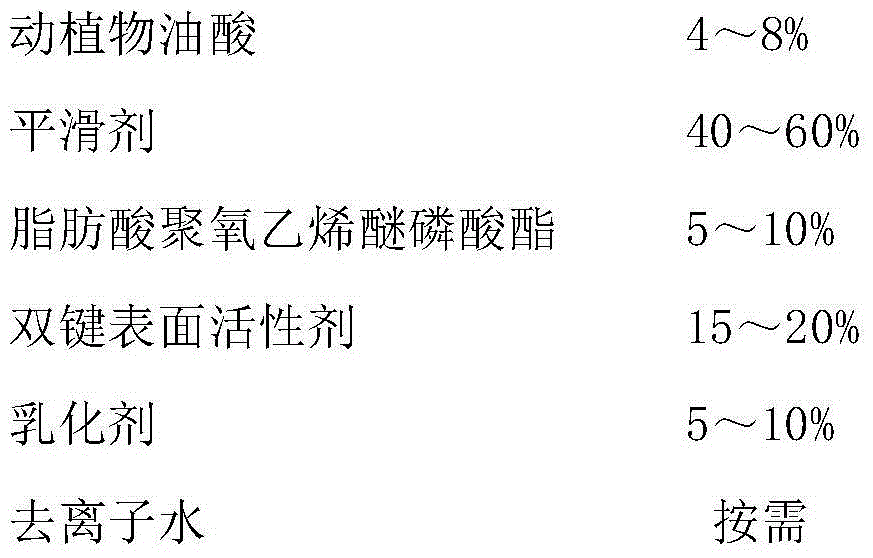

[0020] FDY nylon 66 industrial spinning oil, including the following components by weight percentage:

[0021]

[0022] The spinning oil agent of this embodiment adopts the following production method: put each component into the reaction kettle according to the ratio, add the measured deionized water, heat up to 40 ° C, keep stirring for 1 hour, so that the components are fully miscible, That is, the spinning finish is obtained.

Embodiment 2

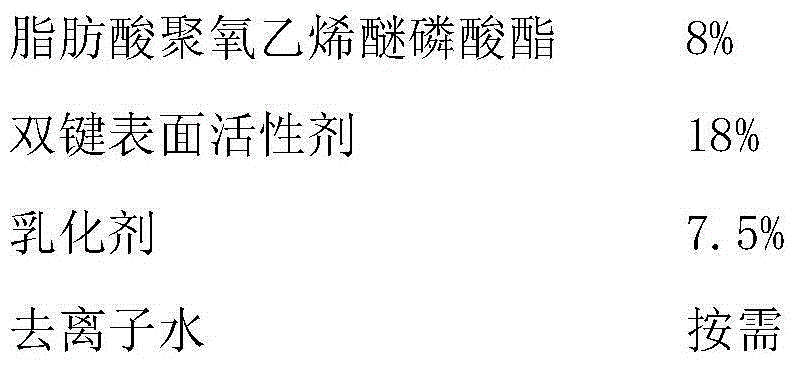

[0024] FDY nylon 66 industrial spinning oil, including the following components by weight percentage:

[0025]

[0026] The preparation method of the spinning finish of the present embodiment is the same as embodiment 1

Embodiment 3

[0028] FDY nylon 66 industrial spinning oil, including the following components by weight percentage:

[0029]

[0030]

[0031] The preparation method of the spinning finish of the present embodiment is the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com