Single-component water-based dip-coating sealing white primer

A one-component, white primer technology, applied in the direction of coating, etc., can solve the problems of unsatisfactory defoaming, poor anti-settling, and affecting the effect of furniture coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A one-component water-based dip-coating and sealing white primer. When painting, the weight ratio of main paint to water is: main paint: water = 1:0.1-0.2;

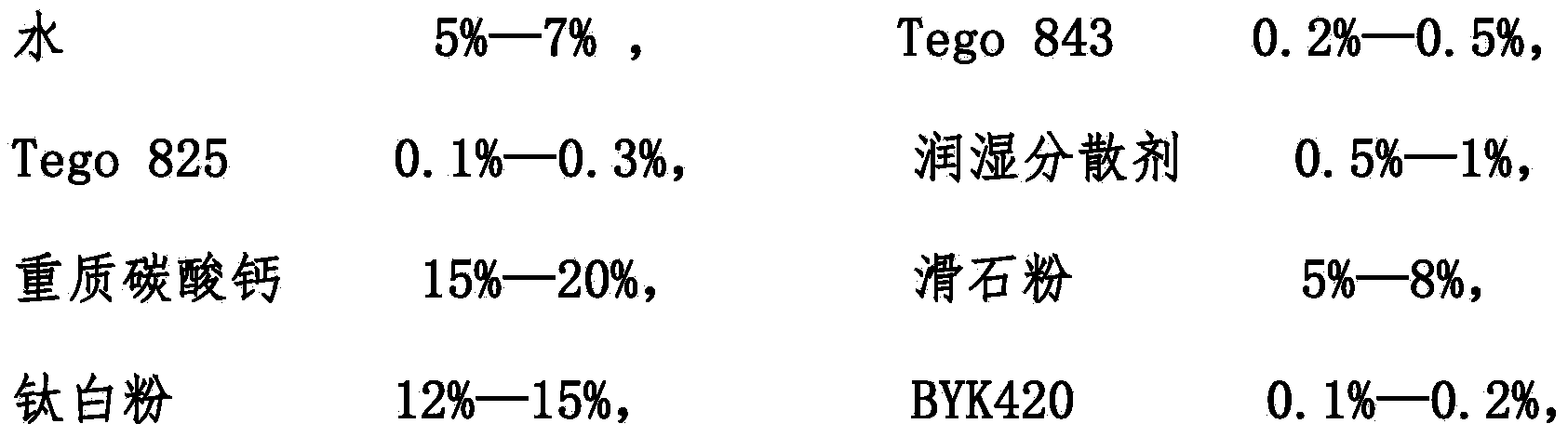

[0035] The weight percent of the composition of main paint:

[0036]

[0037]

[0038] Evenly dispersed to fineness≤40um, viscosity: 60-70s (coating 4 # coating test).

[0039] The preparation method based on the described one-component water-based dip-coating sealing white primer comprises the steps:

[0040] (1) Add water, defoamer, wetting and dispersing agent into the container, and stir at a low speed;

[0041] (2) Add heavy calcium carbonate, talc powder, titanium dioxide, anti-sedimentation agent, and disperse at high speed until the fineness is ≤40um;

[0042] (3) Then add acrylic emulsion and disperse for 5 minutes;

[0043] (4) Then add the mixture of film-forming aids and water, and disperse for 5 minutes;

[0044] (5) Add substrate wetting agent and leveling agent;

[0045] (6) Add thickener...

Embodiment 2

[0049] A one-component water-based dip-coating and sealing white primer. When painting, the weight ratio of main paint to water is: main paint: water = 1:0.1-0.2;

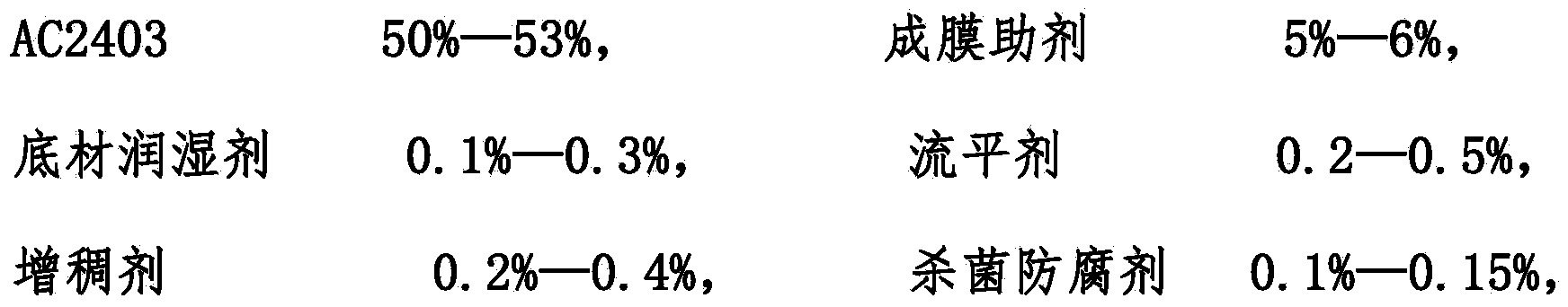

[0050] The weight percent of the composition of main paint:

[0051]

[0052]

[0053] Disperse evenly to fineness≤40um, viscosity: 60-70s (Tu4#Tu measurement).

Embodiment 3

[0055] A one-component water-based dip-coating and sealing white primer. When painting, the weight ratio of main paint to water is: main paint: water = 1:0.1-0.2;

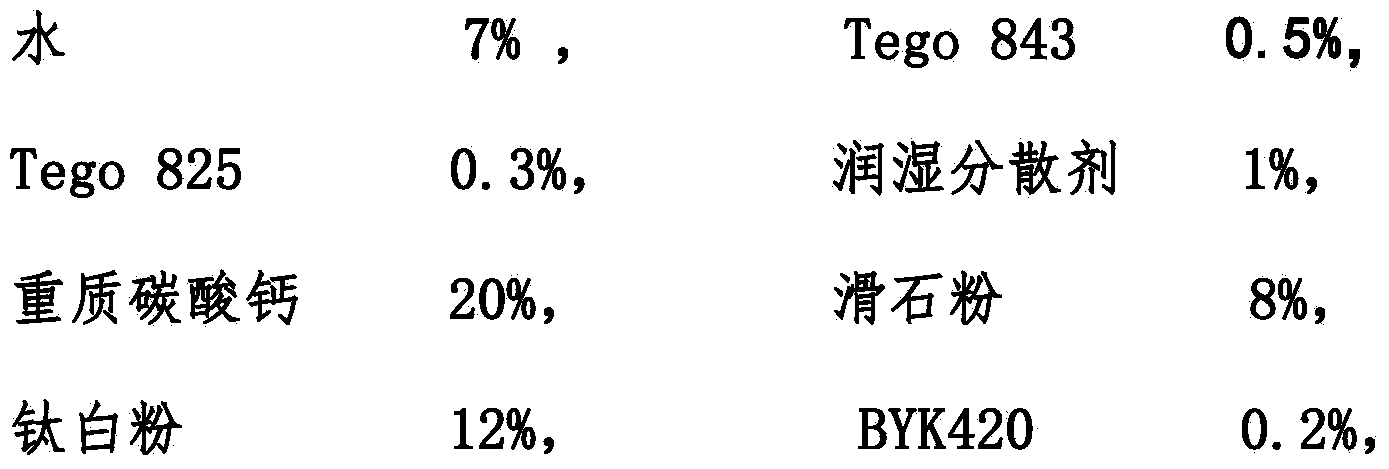

[0056] The weight percent of the composition of main paint:

[0057]

[0058] Evenly dispersed to fineness≤40um, viscosity: 60-70s (coating 4 # coating test).

[0059] Each performance index and the limited matter of the one-component water-based dipping and sealing white primer of the present invention are as follows:

[0060]

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com