High-performance water-based two-component finish paint composition as well as preparation method and use thereof

A water-based two-component, high-performance technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc. sagging and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

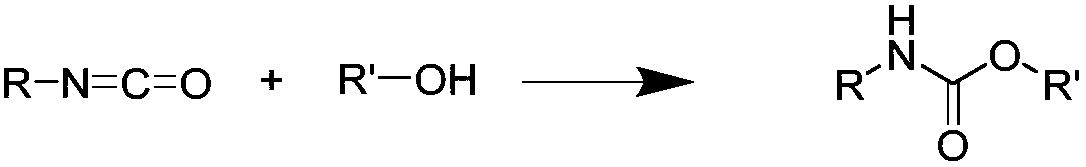

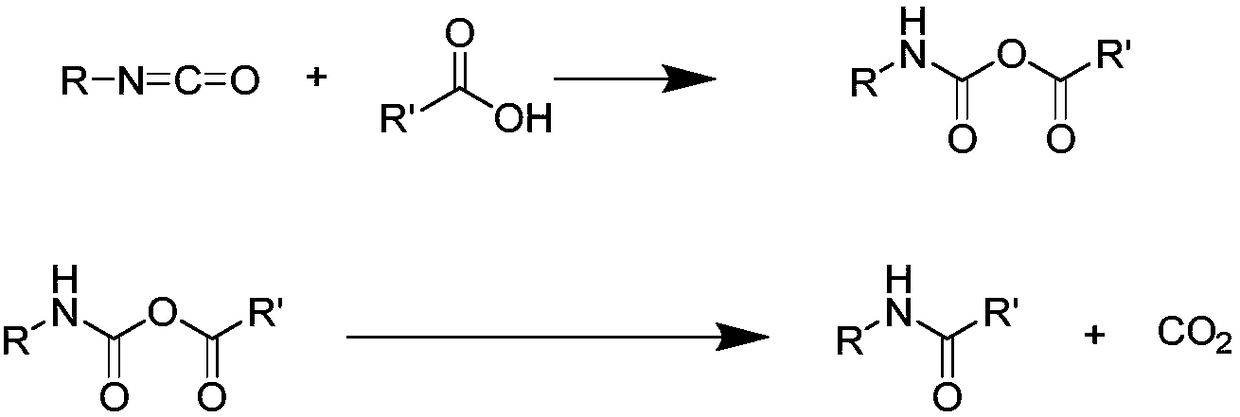

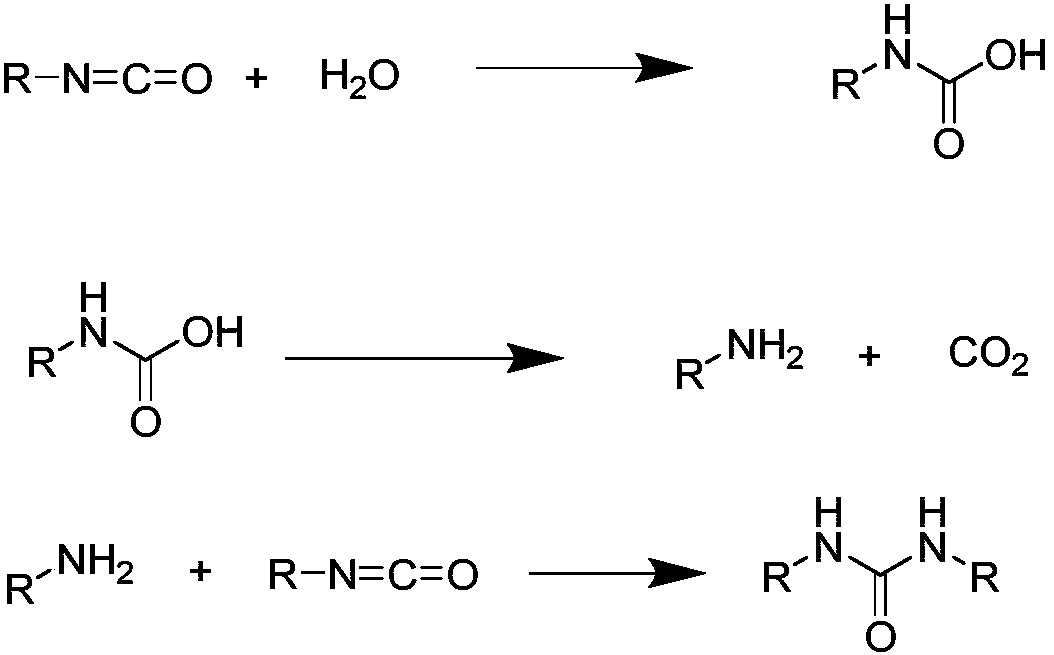

Method used

Image

Examples

Embodiment 1

[0064] In a container with a stirrer, add 2 parts of deionized water and add with stirring -2.5 parts of DISPERSANT-2010 dispersant, 30 parts of Neocryl XK-540 water-based acrylic resin, 0.2 parts of BYK 024 defoamer, 0.2 parts of BYK 346 silicone wetting agent, 30 parts of TIPURE R706, adjust the pH to 7.5-8.5, sanding to a fineness of ≤5 μm; add 30 parts of Neocryl XK-540 water-based acrylic resin, 0.1 part of BYK 331 silicone leveling agent, 0.7 part of BYK093 defoamer, 0.5 part of RHEOLATE 299 thickener, 0.1 part of preservative BESTCIDE-600, 3 parts of deionized water, and 0.1 part of triethanolamine to adjust the pH to 7.5-8.5. Stir well and strain through a 10 micron strainer to obtain the top coat.

[0065] Under nitrogen protection, control the water content of 45 parts of propylene glycol methyl ether acetate solvent to ≤0.05%, add 55 parts of Bayhydur XP2655 isocyanate and stir evenly to obtain a curing agent; mix and stir the topcoat and the curing agent evenly t...

Embodiment 2

[0068] In a container with a stirrer, add 5 parts of deionized water, add 4 parts of TEGO Dispers 757W dispersant, 0.5 parts of BYK 011 defoamer, 0.2 parts of BYK 346 silicone wetting agent, RAVEN 5000 carbon black 2 parts under stirring Use 0.05 parts of triethylamine to adjust the pH to 7.5-8.5, and sand to a fineness of ≤5 μm; add 75 parts of Macrynal SM 6810 water-based acrylic resin, 0.4 parts of Surfynol 440 wetting agent, and Tego Wet 280 under stirring 0.4 part of wet agent, 0.5 part of BYK 011 defoamer, 0.5 part of RHEOLATE 299 thickener, 10 parts of deionized water, adjust the pH to 7.5-8.5 with 0.1 part of triethylamine, stir well, and filter with 10 micron filter , to get the topcoat.

[0069] Under nitrogen protection, control the water content of 40 parts of 3-methoxybutyl propionate solvent to ≤0.05%, add 60 parts of Desmodur N3900 isocyanate and stir evenly to obtain a curing agent; mix and stir the topcoat and the curing agent evenly The high-performance wate...

Embodiment 3

[0072] In a container with a stirrer, add 4 parts of deionized water, add 1 part of TEGO Dispers 750W dispersant, 0.1 part of Foamstar ED2522 defoamer, 0.2 part of Tego Wet 500 wetting agent, 8 parts of BAYFERROX OXIDEYELLOW 3920 pigment under stirring , adjust the pH to 7.5-8.5 with 0.05 part of dimethylethanolamine adjustment agent, sand mill to fineness ≤ 5 μm; add 74 parts of Bayhydrol A2646 water-based acrylic resin, 0.4 part of Surfynol 440 wetting agent, and TegoWet 280 wetting agent under stirring 0.4 parts, 0.2 parts of Foamstar ST 2438 defoamer, 0.4 parts of Additol VXW6388 thickener, 3 parts of propylene glycol butyl ether, 8 parts of deionized water, adjust the pH to 7.5-8.5 with 0.1 part of dimethylethanolamine, and use a small amount of deionized Adjust the viscosity with water to pass. Stir well and strain through a 10 micron strainer to obtain the top coat.

[0073] Under the protection of nitrogen, control the water content of 25 parts of 3-methoxybutyl propi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com