Machine sprayed mortar for thin plastering system

A technology for machine-spraying mortar and thin plastering, which is used in the field of machine-spraying mortar for thin plastering systems and building materials, can solve the problem that the construction progress and strength have not been qualitatively improved or improved, the mortar performance cannot be satisfied at the same time, and the mortar is bonded. Low strength and other problems, to shorten the construction period, enhance sag resistance, and reduce equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

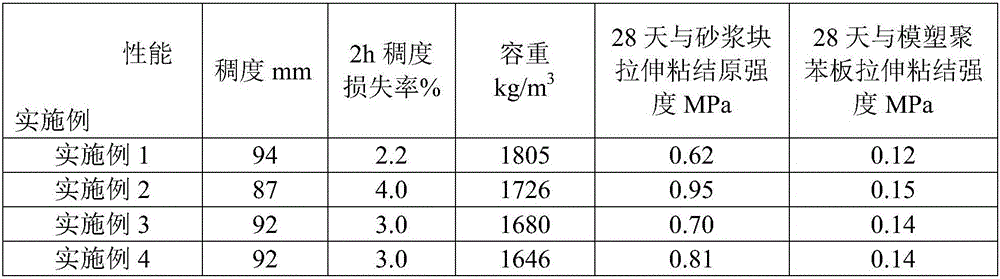

Embodiment 1

[0028] At room temperature, according to mass percentage, the ordinary Portland cement P.O42.5 20%, 40-120 mesh river sand 76.11%, heavy calcium 2%, water retention thickening material 1.83% (for redispersible latex powder 1.5%, hydroxypropyl methyl cellulose ether 0.2%, starch ether 0.03%, 3mm polypropylene fiber 0.1%), water reducing agent 0.05%, water repellent 0.01%, mixed evenly in the mixing equipment, namely Special machine blasting mortar for thin plastering system. Under normal temperature and pressure, 22% by weight of water is added to the blasted mortar for the special machine for thin plastering system and stirred to form slurry, which is directly used for the mechanized construction of the thin plastering system.

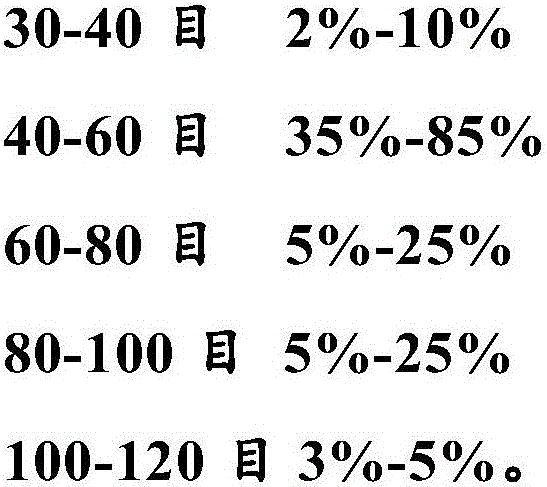

[0029] Wherein, the 40-120 mesh river sand has the following particle gradation:

[0030] 30-40 mesh 2%

[0031] 40-60 mesh 85%

[0032] 60-80 mesh 5%

[0033] 80-100 mesh 5%

[0034] 100-120 mesh 3%.

Embodiment 2

[0036] At room temperature, according to mass percentage, mix ordinary Portland cement P.O42.5 30%, 40-120 mesh river sand 58.65%, metakaolin 8%, water-retaining thickening material 3.15% (re-dispersible latex powder 2.5%, hydroxypropyl methyl cellulose ether 0.4%, starch ether 0.05%, 500μm wood fiber 0.2%), water reducing agent 0.15%, water repellent 0.05%. It is evenly mixed in the mixing equipment, which is the special machine blasting mortar for the thin plastering system. Under normal temperature and pressure, compared with the special machine-blasted mortar for the thin plastering system, 22% by weight of water is added to stir to form a slurry, which is directly used for the mechanized construction of the thin plastering system.

[0037] Wherein, the 40-120 mesh river sand has the following particle gradation:

[0038] 30-40 mesh 10%

[0039] 40-60 mesh 35%

[0040] 60-80 mesh 25%

[0041] 80-100 mesh 25%

[0042] 100-120 mesh 5%.

Embodiment 3

[0044] At room temperature, according to mass percentage, mix ordinary Portland cement P.O42. 25%, 40-120 mesh river sand 67.32%, mineral powder 5%, water retention thickening material 2.45% (re-dispersible latex powder 2.0 %, hydroxypropyl methyl cellulose ether 0.3%, starch ether 0.05%, 3mm polypropylene fiber 0.2%), thixotropic agent 0.05%, water reducing agent 0.15%, water repellent 0.03%. It is evenly mixed in the mixing equipment, which is the special machine blasting mortar for the thin plastering system. Under normal temperature and pressure, compared with the special machine-blasted mortar for the thin plastering system, 21% by weight of water is added to stir to form a slurry, which is directly used for the mechanized construction of the thin plastering system.

[0045] Wherein, the 40-120 mesh river sand has the following particle gradation:

[0046] 30-40 mesh 5%

[0047] 40-60 mesh 60%

[0048] 60-80 mesh 20%

[0049] 80-100 mesh 10%

[0050] 100-120 mesh 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com