Bamboo charcoal-based microelectrolysis porous ceramsite filler and preparing method thereof

A porous pottery and micro-electrolysis technology, which is applied in the field of environment-friendly materials and water treatment, can solve problems such as electrolysis cannot be carried out normally, water cannot pass through evenly, and the surrounding fillers are easy to fall off, etc., so as to improve the wastewater treatment effect and ensure long-term stable operation , high water absorption and the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

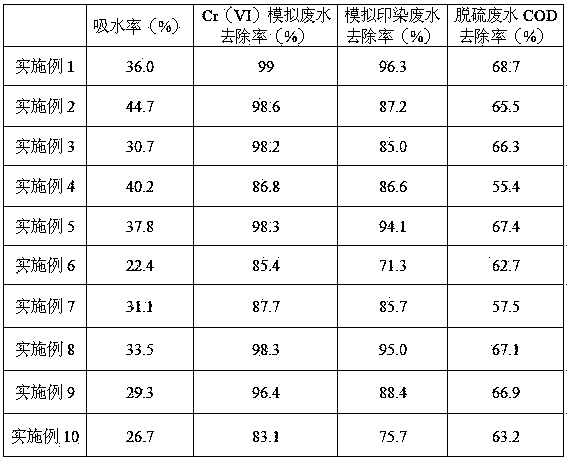

Examples

preparation example Construction

[0060] The preparation method comprises the following steps:

[0061] (1) Mix iron powder, bamboo powder, clay, activator, catalyst, pore-forming agent and binder, control the total moisture content of the green body to 25% to 40%, put the green body into the pelletizer to form ball;

[0062] (2) Put it in a muffle furnace for calcination, and pass through nitrogen protection, heat up to 150-250°C, pre-activate carbonization for 30-60 minutes, then continue to heat up to 500-800°C, keep it warm for 1-2 hours, and then cool down naturally to room temperature to prepare bamboo charcoal-based micro-electrolytic porous ceramsite filler.

Embodiment 1

[0064] 1. Preparation of raw materials

[0065] Bamboo chips are dried at 80°C and then finely crushed and passed through a 100-mesh sieve.

[0066] 2. Raw materials and dosage

[0067] Iron powder 40 parts

[0068] 10 parts of bamboo powder

[0069] 30 parts of clay

[0070] Activator 2 parts

[0071] Catalyst 3 parts

[0072] Pore builder 5 parts

[0073] 10 parts of binder

[0074] 3. Process

[0075] Mix the above raw materials evenly, select the corresponding template, and put it into the pelletizing machine to form balls. The prepared raw pellets were calcined in a muffle furnace and protected by nitrogen gas. Raise the temperature to 150°C and activate for 30 minutes, then continue to raise the temperature to 500°C and keep the temperature for 2 hours. Let it cool down to room temperature naturally, take it out and save it. The finished product has a rough surface and is a black spherical body.

[0076] The activator is a mixture of phosphoric acid and zin...

Embodiment 2

[0081] 1. Preparation of raw materials

[0082] Bamboo chips are dried at 90°C and then finely crushed and passed through a 100-mesh sieve.

[0083] 2. Raw materials and dosage

[0084] Iron powder 30 parts

[0085] 10 parts of bamboo powder

[0086] 20 parts clay

[0087] Activator 4 parts

[0088] Catalyst 1 part

[0089] Pore builder 5 parts

[0090] 10 parts of binder

[0091] 3. Process

[0092] Mix the above raw materials evenly, select the corresponding template, and put it into the pelletizing machine to form balls. The prepared raw pellets were calcined in a muffle furnace and protected by nitrogen gas. Raise the temperature to 160°C, activate for 35 minutes, then continue to raise the temperature to 600°C, and keep the temperature for 2 hours. Let it cool down to room temperature naturally, take it out and save it. The finished product has a rough surface and is a black spherical body.

[0093] The activator is zinc chloride.

[0094] The catalyst is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com