Flame-retardant composite yarns and production method for same

A flame-retardant compounding and yarn manufacturing technology, which is applied in the direction of yarn, textiles and papermaking, can solve the disadvantages that are widely used in high temperature and fire-proof and flame-retardant fields. And other problems, to achieve the effect of wide range of use, high sewing processing efficiency, good fire and flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

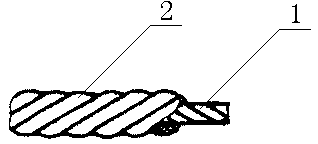

[0044] Specific embodiment one of the present invention: the denier of the central fiber 1 white staple fiber is 1.67 dtex, the fiber length is 45 mm, and the strength is 3.1 cN / dtex. The fineness of polyester filament is 49 dtex and the strength is 7 cN / dtex.

specific Embodiment 2

[0045] The second embodiment of the present invention: the denier of the central fiber 1 white staple fiber is 1.67 dtex, the fiber length is 50 mm, and the strength is 4 cN / dtex. The fineness of the polyester filament is 80 dtex and the strength is 7.3 cN / dtex.

specific Embodiment 3

[0046] Specific embodiment three of the present invention: the denier of the central fiber 1 white staple fiber is 1.67 dtex, the length of the fiber is 51 mm, and the strength is 5.3 cN / dtex. The fineness of the polyester filament is 140 dtex and the strength is 7.8 cN / dtex.

[0047] Specific embodiment four of the present invention: the denier of the central fiber 1 white staple fiber is 1.67 dtex, the length of the fiber is 58 mm, and the strength is 4.8 cN / dtex. The denier of polyester filament is 160 dtex and the strength is 7.6 cN / dtex.

[0048] The manufacturing method of the flame-retardant composite yarn of the present invention is as follows: first feed the aramid staple fiber into the blower, and then sequentially enter the carding machine, the draw frame and the roving frame for processing to form the aramid grit. The processed yarn is fed into the spinning frame for drafting. Let the polyester filaments pass through the additional unwinding device, tension control de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com