Diatom ooze wall material capable of efficiently purifying air or resisting against bacteria or automatically humidifying and preparation method of diatom ooze wall material

A technology for purifying air and diatom mud, applied in the field of new interior decoration materials, can solve the problems of unguaranteed air purification effect, weak ability to decompose harmful substances, unsatisfactory automatic humidity control ability, etc. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

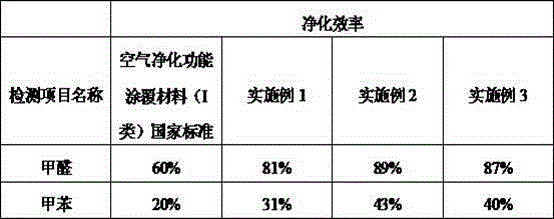

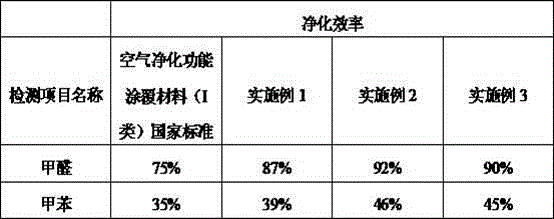

Examples

Embodiment 1

[0025] High-efficiency air purification / antibacterial / automatic humidity-adjusting diatom mud wall material components and quality components are: 34 parts of diatomite, 14 parts of sepiolite powder, 1 part of heavy calcium powder, 8 parts of calcium hydroxide, 1 part of quicklime, quartz 10 parts of sand, 22 parts of wollastonite powder, 2 parts of hydroxypropyl methylcellulose, 4 parts of EVA flexible rubber powder, 2.5 parts of titanium dioxide mesoporous molecular sieve, 3 parts of nano zinc oxide, 2 parts of silicone defoamer.

[0026] The titanium dioxide mesoporous molecular sieve mentioned above is made by modifying the mesoporous molecular sieve with silica (the same below), and the specific steps are as follows:

[0027] Put 0.12mol butyl titanate diacetylacetonate and 140mL solvent n-hexane into a 500mL round bottom flask respectively, add 4.0g calcined mesoporous molecular sieve MCM-41, and stir and reflux at 70°C for 24h under the protection of nitrogen At this ti...

Embodiment 2

[0032] Efficient air purification / antibacterial / automatic humidity control diatom mud wall material The mass ratio of each component is: 42 parts of diatomite, 14 parts of sepiolite powder, 1 part of heavy calcium powder, 10 parts of calcium hydroxide, 1 part of quicklime, quartz 10 parts of sand, 22 parts of wollastonite powder, 3 parts of hydroxypropyl methylcellulose, 5 parts of EVA flexible rubber powder, 3 parts of titanium dioxide mesoporous molecular sieve, 5 parts of nano-zinc oxide, and 2 parts of silicone defoamer.

[0033] The preparation method of highly efficient air-purifying / antibacterial / automatic humidity-regulating diatom mud wall material includes the following steps:

[0034] (1) Weigh each component material according to the mass ratio, and then put it into a high-speed disperser for uniform dispersion at a speed of 500 rpm, and disperse evenly for 5 minutes to form a mixed wall material powder.

[0035] (2) Add water to the mixed wall material powder acco...

Embodiment 3

[0037] Efficient air purification / antibacterial / automatic humidity control diatom mud wall material The mass ratio of each component is: 50 parts of diatomite, 18 parts of sepiolite powder, 3 parts of heavy calcium powder, 13 parts of calcium hydroxide, 2 parts of quicklime, quartz 13 parts of sand, 25 parts of wollastonite powder, 4 parts of hydroxypropyl methylcellulose, 5 parts of EVA flexible rubber powder, 3 parts of titanium dioxide mesoporous molecular sieve, 4 parts of nano-zinc oxide, and 3 parts of silicone defoamer.

[0038] The preparation method of highly efficient air-purifying / antibacterial / automatic humidity-regulating diatom mud wall material includes the following steps:

[0039] (1) Weigh each component material according to the mass ratio, and then put it into a high-speed disperser for uniform dispersion at a speed of 600 rpm, and disperse evenly for 5 minutes to form a mixed wall material powder.

[0040] (2) According to the mass ratio of water and wall ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com