Thin-gauge 1180MPa-grade dual-phase steel and processing method thereof

A processing method and dual-phase steel technology, applied in the field of steel rolling, can solve problems such as high energy consumption in the production process, high alloy cost, and long manufacturing process, and achieve the effects of shortening the manufacturing process, reducing production costs, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

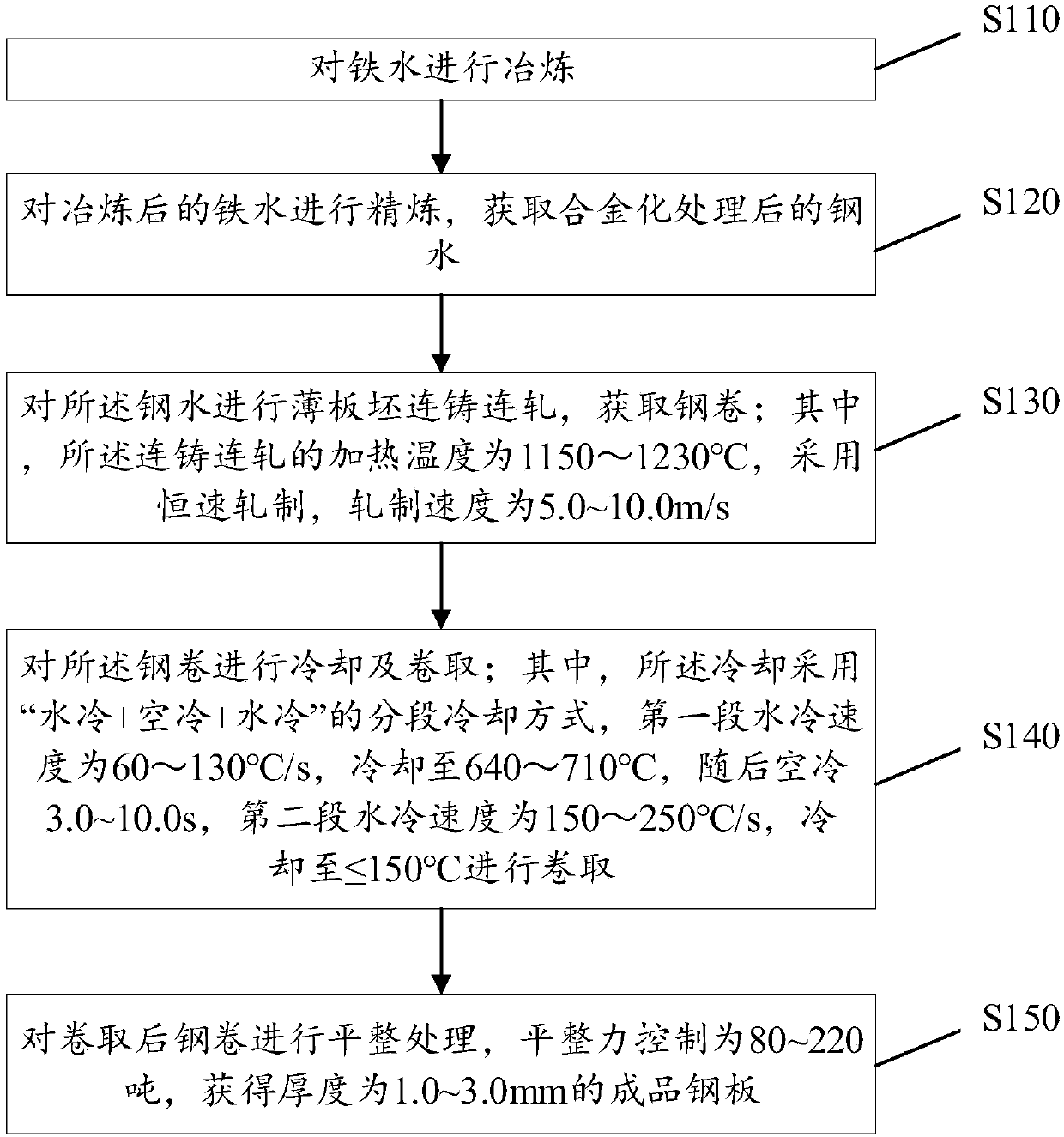

Method used

Image

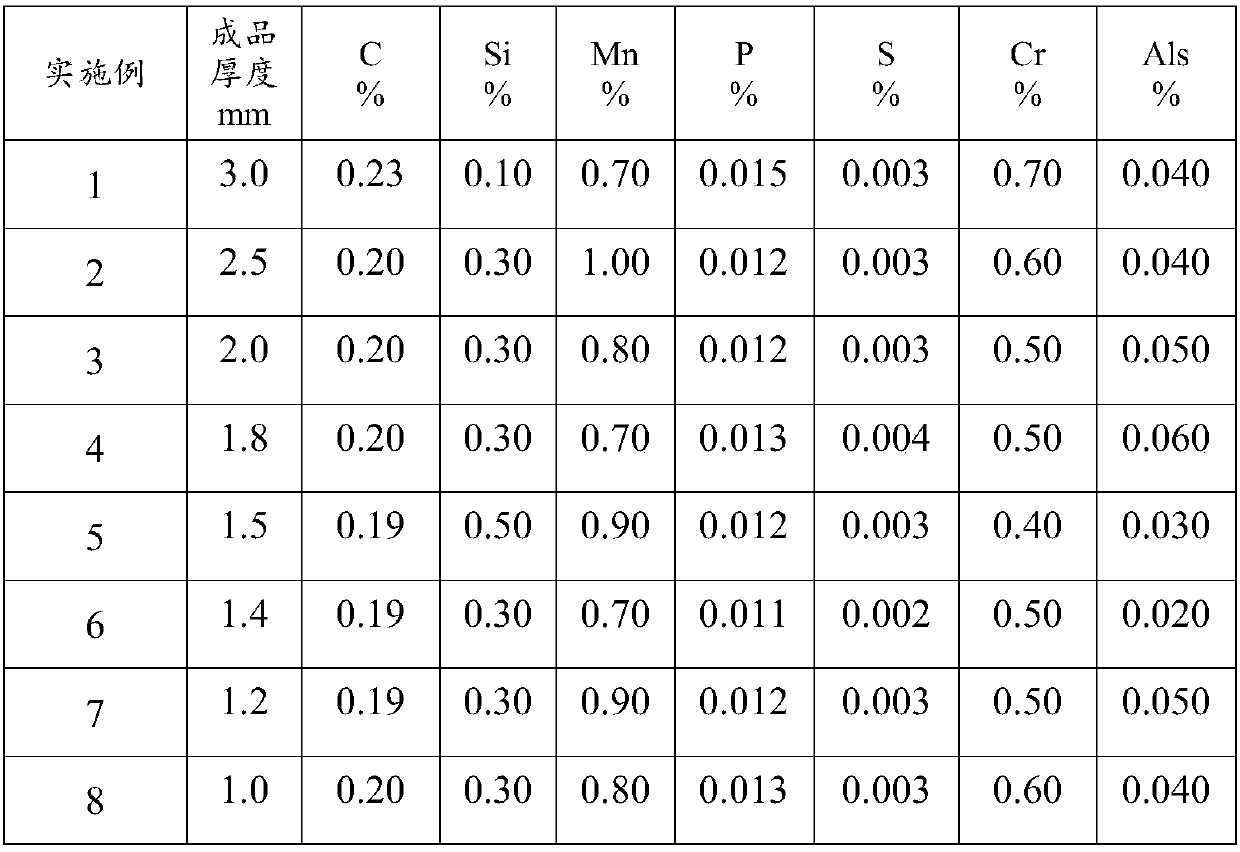

Examples

Embodiment Construction

[0026] The embodiment of the present application provides a thin-gauge 1180MPa dual-phase steel and its processing method. The thin-gauge dual-phase steel with a thickness of 1.0-3.0mm is produced by the thin slab continuous casting and rolling process, which reduces the production cost and has excellent comprehensive performance. mechanical properties.

[0027] The technical solution of the present application will be described in detail below through the accompanying drawings and specific embodiments. It should be understood that the embodiments of the present application and the specific features in the embodiments are detailed descriptions of the technical solution of the present application, rather than limitations on the technical solution of the present application. In the case of no conflict, the embodiments of the present application and the technical features in the embodiments may be combined with each other.

[0028] The term "and / or" in this article is just an ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com