Bone china and preparation method thereof

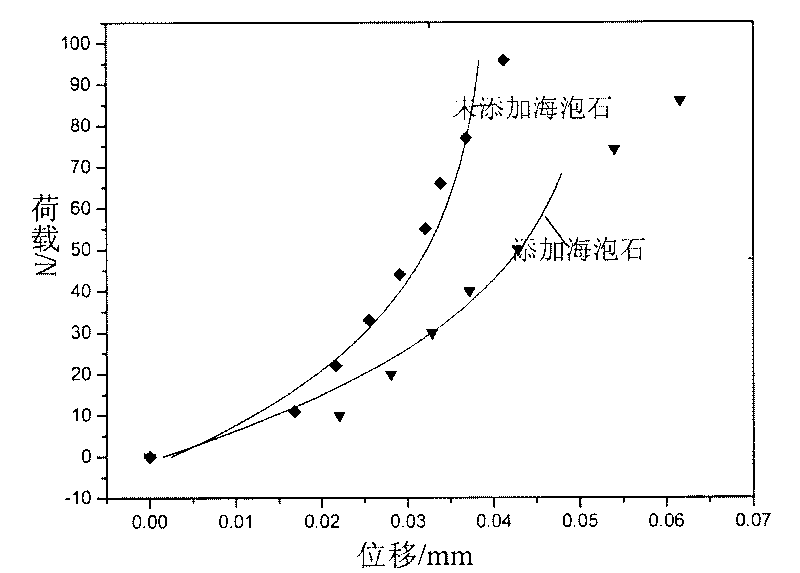

A technology of bone china and bone powder, applied in the field of ceramic molding products, can solve the problems of complex process and high production cost, achieve the effects of simple preparation process, improved strength and toughness, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

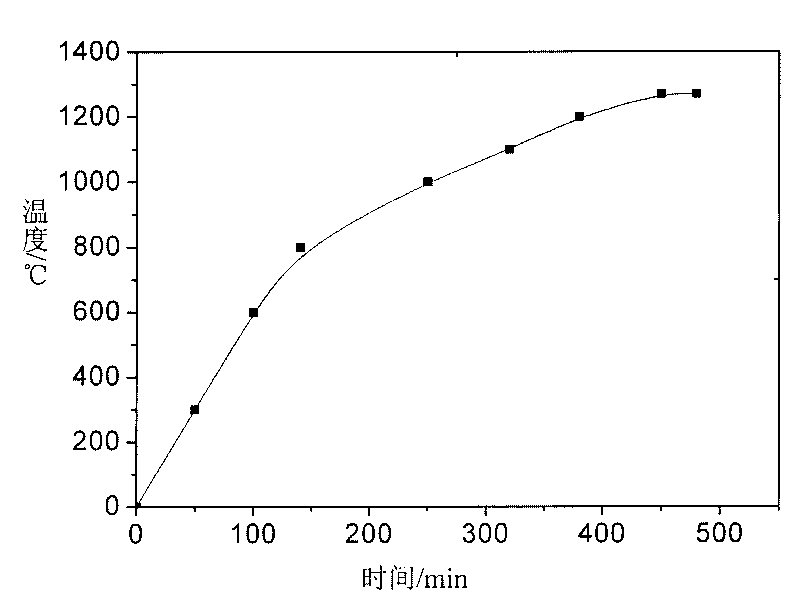

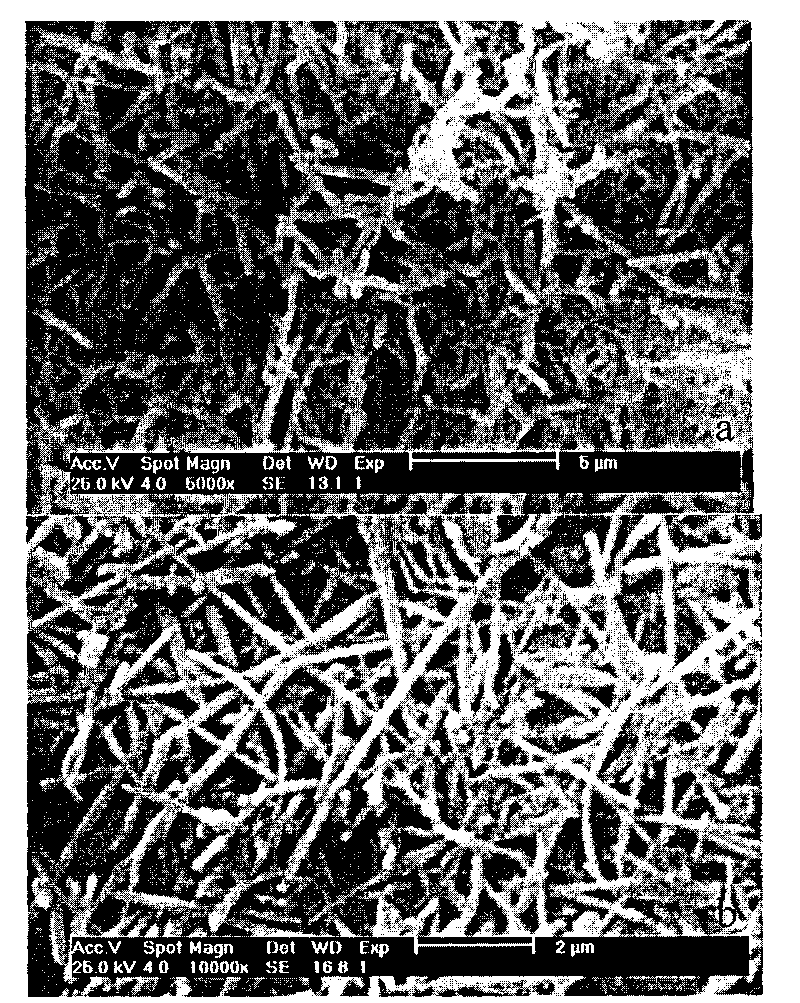

[0029] The first step, sepiolite pretreatment

[0030] The sepiolite raw ore is processed through ore dressing, washed with water, dried naturally, crushed into 10mm particles by a tooth crusher, and then processed by jet mill to obtain sepiolite mineral nanofibers with an average particle size of 7 μm;

[0031] The second step, the production of blanks and blanks

[0032] 30% bone meal, 15% Laiyang soil, 20% albite feldspar, 5% Datong soil, 8% Fangzi soil and 20% Longyan soil are used as raw materials in proportion by weight to form a billet, and the billet is prepared by weight ratio: Ball: water = 1: 2: 1 is put into the ball mill and added to the water ball mill, and after the raw material ball milling of the ratio is 60 μm, add 2% of the sepiolite mineral nanofiber obtained by the first step of sepiolite pretreatment, after adding Continue ball milling and mixing for 2 hours, then sieve through sieves with mesh size of 120 mesh, 180 mesh and 200 mesh for three times, rem...

Embodiment 2

[0036] The first step, sepiolite pretreatment

[0037] The sepiolite raw ore is processed through ore dressing, washed with water, dried naturally, crushed into 15mm particles by a tooth crusher, and then processed by jet mill to obtain sepiolite mineral nanofibers with an average particle size of 7 μm;

[0038] The second step, the production of blanks and blanks

[0039] Raw materials are prepared by proportioning 35% of bone meal, 12% of Laiyang soil, 17% of albite, 6% of Datong soil, 10% of Fangzi soil and 15% of Longyan soil to form a billet according to the weight percentage, and put the billet into a ball mill and add water for ball milling. After ball milling the proportioned raw materials to a particle size of 70 μm, add 5% of sepiolite mineral nanofibers obtained from the first step of sepiolite pretreatment, continue ball milling and mixing for 2.5 hours after adding, and then use sieves with mesh sizes of 120 mesh , 180 mesh and 200 mesh sieves were sieved three t...

Embodiment 3

[0043] The first step, sepiolite pretreatment

[0044] The sepiolite raw ore is processed through ore dressing, washed with water, dried naturally, crushed into 20mm particles by a tooth crusher, and then processed by a jet mill to obtain sepiolite mineral nanofibers with an average particle size of 7 μm;

[0045] The second step, the production of blanks and blanks

[0046] Raw materials are prepared by proportioning 40% of bone powder, 9% of Laiyang soil, 15% of albite, 8% of Datong soil, 5% of Fangzi soil and 15% of Longyan soil by weight to form a billet, and the billet is put into a ball mill and added with water for ball milling. After ball milling the proportioned raw materials to a particle size of 80 μm, add 8% of sepiolite mineral nanofibers obtained from the first step of sepiolite pretreatment. After adding, continue ball milling and mixing for 3 hours, and then use sieves with mesh sizes of 120 mesh , 180 mesh and 200 mesh sieves were sieved three times, iron rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com