Polyurethane modified epoxy resin grouting material

An epoxy resin grouting and polyurethane modification technology, which is applied in the field of building materials, can solve the problems of high brittleness, fragility and high cost of epoxy resin grouting materials, improve toughness and strength, prolong service life, improve The effect of water and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is described in further detail.

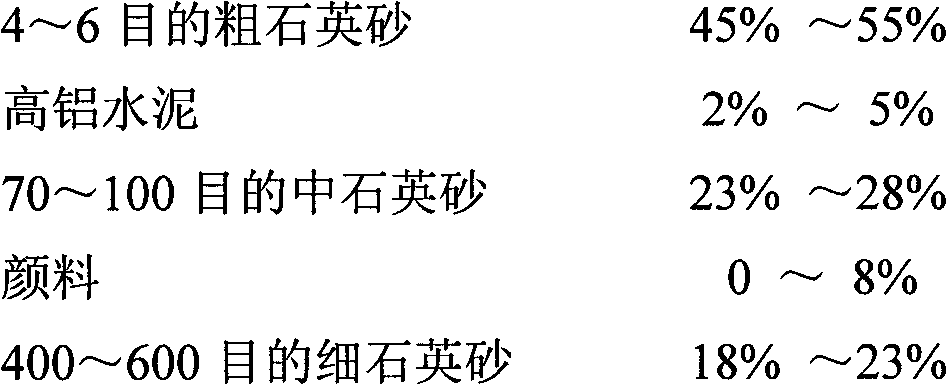

[0021] Prepare the solid material according to the following weight ratio:

[0022] 4~6 mesh coarse quartz sand 50%

[0023] High alumina cement: 3%

[0024] 70-100 mesh quartz sand 25%

[0025] Pigment: 2%

[0026] 400-600 mesh fine quartz sand 20%

[0027] The above-mentioned pigments can be selected from various colors as required, and the primary colors can be used without adding pigments.

[0028] Prepare the adhesive in the following weight ratios:

[0029] Polyurethane modified epoxy resin: 100%

[0030] Curing agent 45% C-1 type produced by Hunan Shenliling Manufacturing Co., Ltd.

[0031] Epoxy diluent 14% 660 type produced by Shanghai Resin Factory

[0032] Leveling agent 2% 3777 of Fuqua company in the Netherlands

[0033] Defoamer 2% Dutch Fuqua company type 2722

[0034] Dispersant 2% Holland Fuqua company 4010 type

[0035] The above-mentioned polyuretha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com