Inner heater protection tube made of silicon carbide ceramic composite material and preparation method thereof

A technology of silicon carbide ceramics and composite materials, applied in the field of inorganic non-metallic materials, can solve the problems of short service life, poor corrosion resistance and high cost, and achieve the effects of long service life, reduced production cost, and improved toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a silicon carbide ceramic composite internal heater protection tube, the steps are as follows:

[0045] (1) Preform preparation

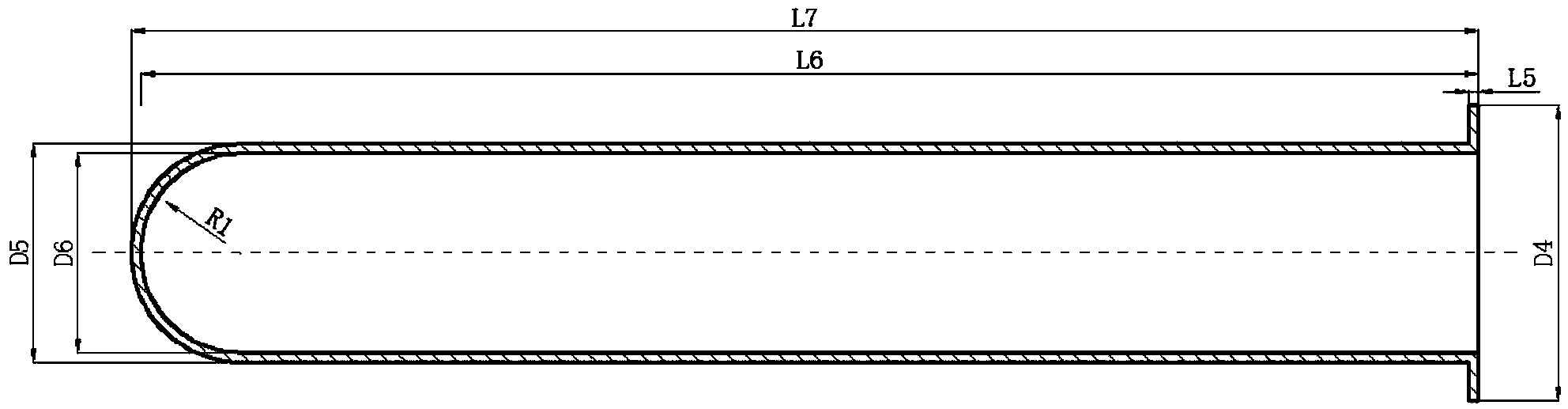

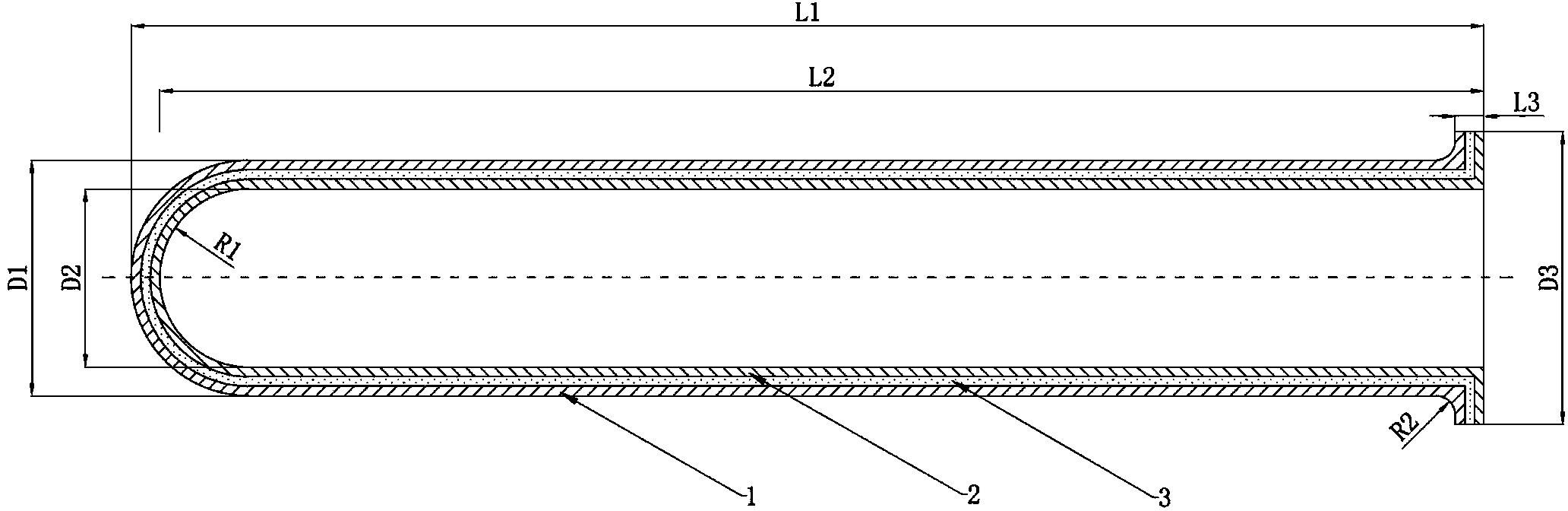

[0046] fixed carbon fiber figure 1 The prefabricated body in the shape of the silicon carbide ceramic composite inner heater protection tube is as follows: L7=840mm, L5=4mm, D5=150mm, D6=146mm, D4=156mm.

[0047] (2) Pretreatment

[0048] Calcining the preform treated in step (1) at 500°C for 60 minutes under a nitrogen protective atmosphere to obtain a pretreated preform;

[0049] (3) Coating carbon protective layer

[0050] Immerse the preform pretreated in step (2) into the impregnation solution, the mass fraction of carbon black in the impregnation solution is 45%, the mass fraction of phenolic resin is 5%, and the balance is ethanol, impregnated for 2.5h, Then dry at 50°C for 25 minutes to obtain a preform coated with a thin carbon layer;

[0051] (4) Grouting molding

[0052] Put the prefabricated body coate...

Embodiment 2

[0070] A method for preparing a silicon carbide ceramic composite internal heater protection tube, the steps are as follows:

[0071] (1) Preform preparation

[0072] Fix the graphite fibers as figure 1 The prefabricated body in the shape of the silicon carbide ceramic composite inner heater protection tube is as follows: L7=650mm, L5=4mm, D5=120mm, D6=114mm, D4=127mm.

[0073] (2) Pretreatment

[0074] Calcining the preform treated in step (1) at 500°C for 60 minutes under a nitrogen protective atmosphere to obtain a pretreated preform;

[0075] (3) Coating carbon protective layer

[0076] Immerse the preform pretreated in step (2) into the impregnation solution, the mass fraction of carbon black in the impregnation solution is 30%, the mass fraction of phenolic resin is 5%, and the balance is ethanol, impregnate for 2 hours, and then Drying at 50°C for 30 minutes to obtain a preform coated with a thin carbon layer;

[0077] (4) Grouting molding

[0078] Put the prefabr...

Embodiment 3

[0087] A method for preparing a silicon carbide ceramic composite internal heater protection tube, the steps are as follows:

[0088] (1) Preform preparation

[0089] Fix the carbon fiber felt as figure 1 The prefabricated body in the shape of the silicon carbide ceramic composite inner heater protection tube is as follows: L7=840mm, L5=4mm, D5=150mm, D6=146mm, D4=156mm.

[0090] (2) Pretreatment

[0091] Calcining the preform treated in step (1) at 500°C for 90 minutes under a nitrogen protective atmosphere to obtain a pretreated preform;

[0092] (3) Coating carbon protective layer

[0093] Immerse the preform pretreated in step (2) in the impregnating solution, the mass fraction of carbon black in the impregnating solution is 40%, the mass fraction of phenolic resin is 5%, and the balance is ethanol, impregnating for 3.5h, Then dry at 50°C for 35 minutes to obtain a preform coated with a thin carbon layer;

[0094] (4) Grouting molding

[0095] Put the prefabricated b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com