Preparation method of flexible binding agent-free self-support combination electrode

A binder-free, composite electrode technology, applied in the field of electrochemistry, can solve the problems of low conductivity of activated carbon fiber cloth, low sulfur content, difficulty in improving mass specific energy and volume specific energy, and achieve stable cycle performance, High energy density, the effect of alleviating the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Take 60mg of graphene and add it to 220ml of distilled water, sonicate for 6h to obtain a concentration of 0.273gL -1 Graphene dispersion;

[0044] 2) According to the mass ratio of sulfur and graphene being 3:1, add sodium thiosulfate pentahydrate to the above solution, stir for 1 h to dissolve it, add dropwise 1M hydrochloric acid under stirring, and stir for 1 h;

[0045] 3) After adding 5 mg of graphene into 10 ml of water and ultrasonically dispersing for 3 hours, add it to the above solution, and stir to form a uniform dispersion.

[0046] 4) Suction filter the above dispersion through the mobile phase filter, wash with deionized water, and then vacuum dry at 60°C for 12h

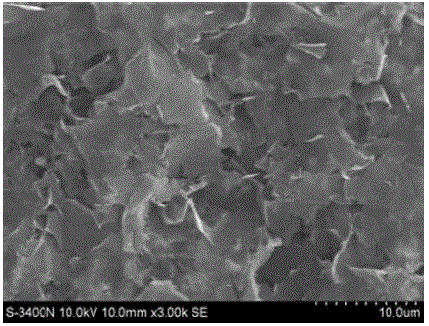

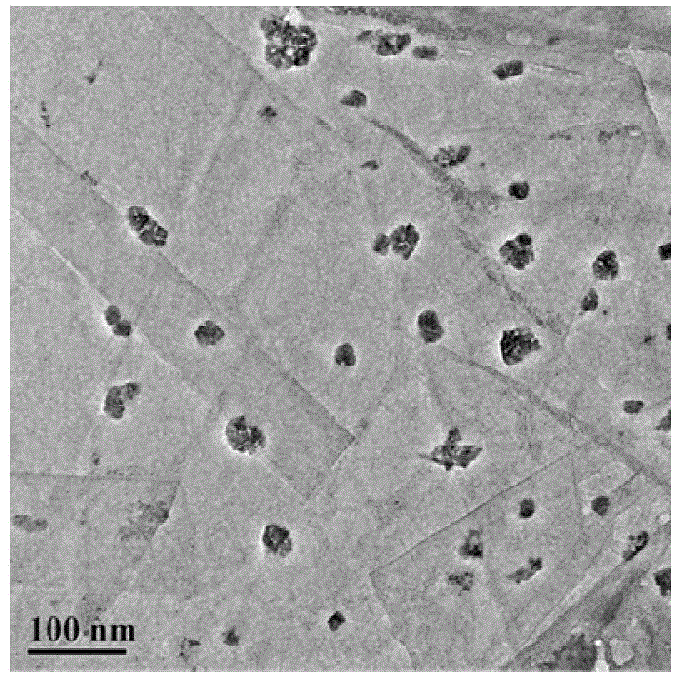

[0047] After peeling off from the filter paper, a flexible binder-free graphene-sulfur composite electrode is obtained. The obtained graphene-sulfur composite electrode film is shown in Figure 1, in which the sulfur content is 67wt%. The composite electrode was tested by TEM, and it can b...

Embodiment 2

[0050] 1) Add 50mg of graphene and 10mg of multi-walled carbon nanotubes (MWCNT) into 200ml of distilled water, and ultrasonicate for 5 hours to obtain a concentration of 0.25gL -1 Graphene dispersion;

[0051] 2) According to the mass ratio of sulfur and graphene being 3:1, add sodium thiosulfate pentahydrate to the above solution, stir for 1 h to dissolve it, add 1M nitric acid dropwise under stirring, and stir for 1 h.

[0052] 3) Add 2mg of silicon oxide into 20ml of water and disperse by ultrasonic for 3h, then add to the above solution, and stir to make a uniform dispersion.

[0053] 4) Suction filter the above-mentioned dispersion liquid through the mobile phase filtration device, wash with deionized water, then vacuum-dry at 60°C for 12 hours, and then peel off from the filter paper to obtain a binder-free graphene-multi-walled carbon nanometer with high toughness. Tube-sulfur composite electrode membrane. The obtained graphene-multi-walled carbon nanotubes-sulfur co...

Embodiment 3

[0055] 1) Take 100mg of single-walled carbon nanotubes and add them to 200ml of ethanol, sonicate for 3 hours to obtain a concentration of 0.5gL -1 Dispersion of carbon nanotubes;

[0056] 2) According to the mass ratio of lithium iron phosphate and carbon nanotubes being 10:1, add lithium iron phosphate to the above solution, and ultrasonically disperse it evenly for 3 hours.

[0057] 3) Add 5 mg of alumina to 20 ml of water and ultrasonically disperse for 3 hours, then add to the above solution, and stir to form a uniform dispersion.

[0058] The above-mentioned dispersion liquid was suction-filtered through a mobile phase filtration device, washed with deionized water, then vacuum-dried at 100° C. for 12 hours, and then peeled off from the filter paper to obtain a flexible binder-free lithium iron phosphate-carbon nanotube composite electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com