High-wet-strength wound dressing

A wound dressing and strength technology, applied in dressings, viscous dressings, medical science and other directions, can solve the problems of high temperature, affecting product comfort and softness, and achieve high strength and toughness, which is beneficial to wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

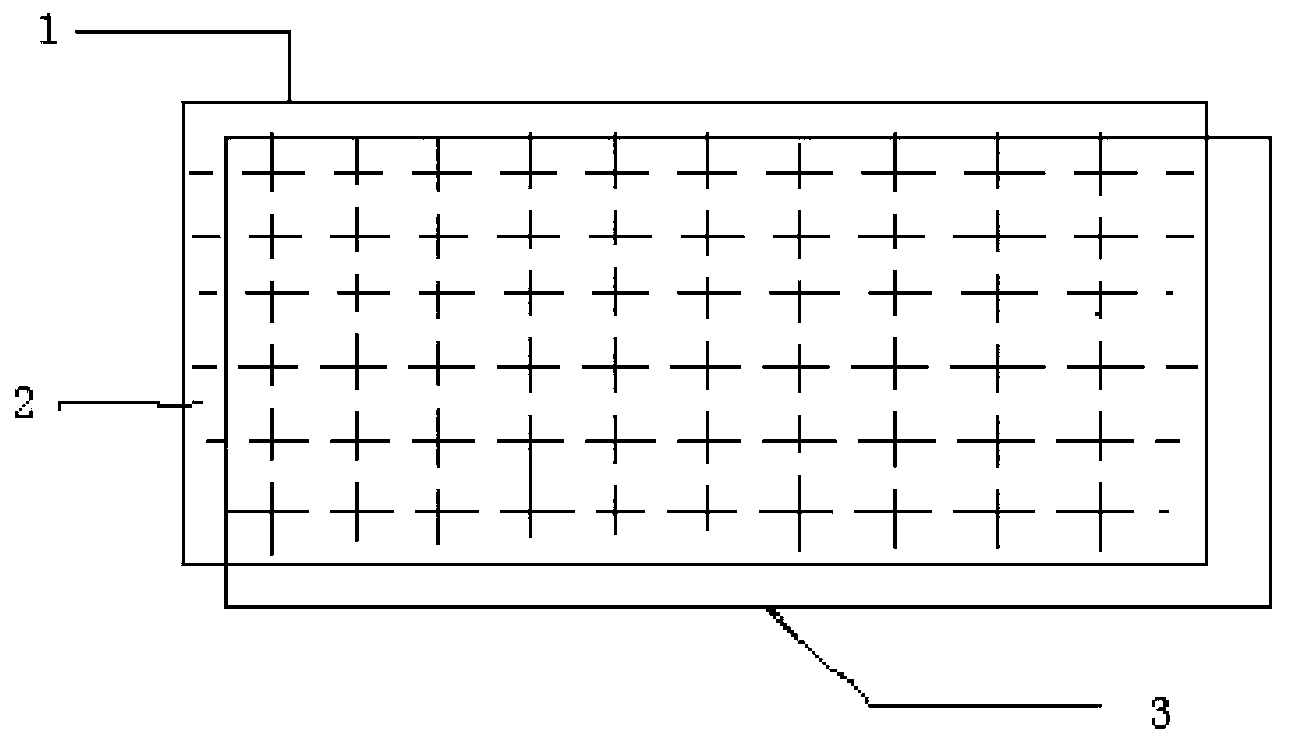

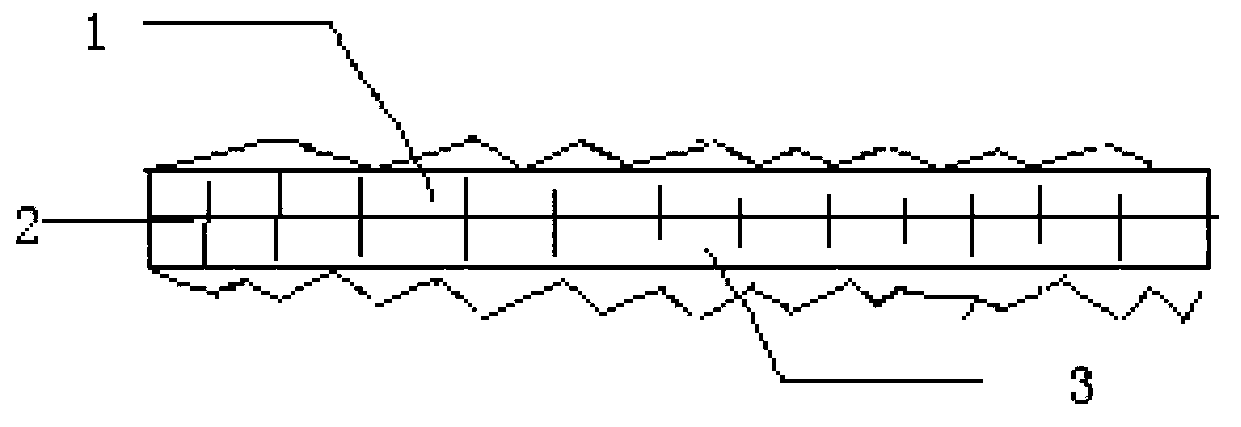

Image

Examples

Embodiment 1

[0028]Both the upper and lower layers of sol fiber use carboxymethyl cellulose fiber prepared from Lyocell fiber, the degree of substitution (DS) is 0.28~0.32, the fiber fineness is 2dtex, and the length is 50mm. The modified cellulose non-woven fabric was prepared by carding, laying and needling, with a grammage of 60 gsm. Stack two layers of such non-woven fabrics with ordinary cotton gauze (gram weight 60gsm), with the modified cellulose non-woven fabric on the outside and cotton gauze inside, and then bond the three layers of fabric together by needle punching, and then After being cut, packaged and sterilized, it is made into a dressing. The hygroscopicity of the dressing is 18g / 100cm 2 .

Embodiment 2

[0030] Both the upper and lower sol fibers use acylated chitosan prepared from chitosan, with a degree of substitution (DS) of 0.28-0.34, a fiber fineness of 2dtex, and a length of 50mm. Prepare acylated chitosan non-woven fabric by carding, laying and needle punching, with a gram weight of 70gsm. Lay two layers of such non-woven fabrics and polyester warp-knitted fabrics (gram weight 50gsm), with the modified chitosan non-woven fabric on the outside and polyester yarn warp-knitted fabrics on the inside, and then bond the three-layer fabric by needle punching. Put them together, then cut, package, and sterilize to make a dressing. The hygroscopicity of the dressing is 19g / 100cm 2 .

Embodiment 3

[0032] Both the upper and lower sol fibers use carboxymethylated chitosan prepared from chitosan, with a degree of substitution (DS) of 0.28-0.34, a fiber fineness of 2dtex, and a length of 55mm. The carboxymethylated chitosan non-woven fabric was prepared by carding, laying and needling, with a gram weight of 65 gsm. Lay two layers of such non-woven fabric and nylon warp-knitted fabric (gram weight 60gsm), carboxymethylated chitosan non-woven fabric on the outside, nylon warp-knitted fabric on the inside, and then three Layers of fabric are bonded together, and then cut, packaged, and sterilized to make a dressing. The hygroscopicity of the dressing is 21g / 100cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com