Automobile sound insulation pad and preparation method thereof

A technology for automobile sound insulation pads and sound insulation layers, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems of exposed fiber felt, strong smell of fiber felt, and easy pollution of the environment, and achieves improved strength and toughness, low mold shrinkage, and low mold shrinkage. Good sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

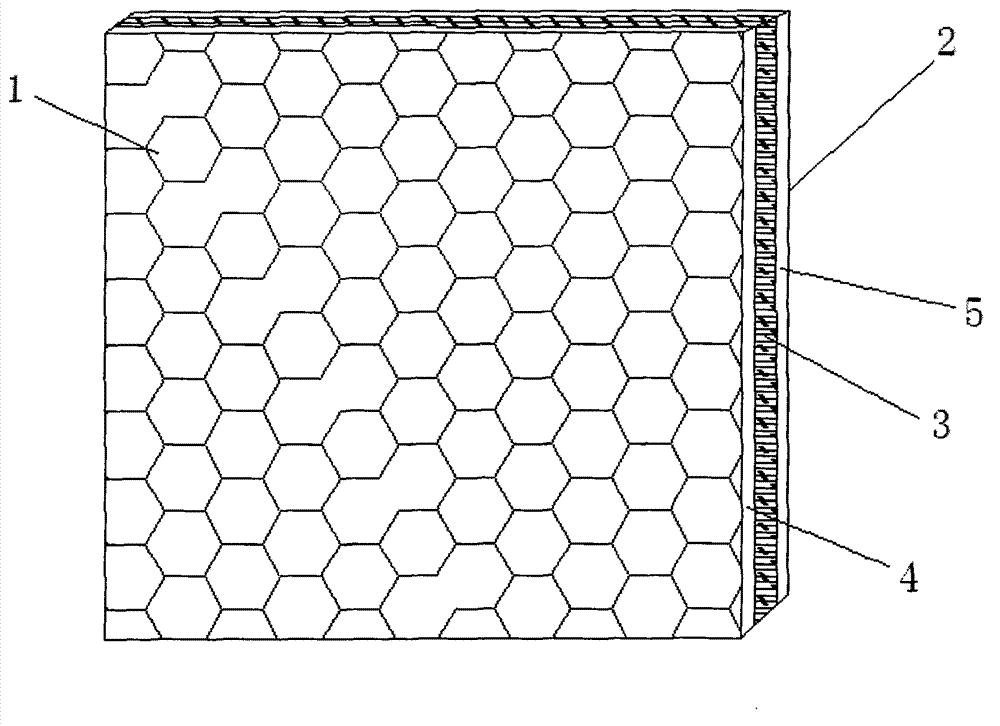

Image

Examples

Embodiment 1

[0027] S1, take by weighing 60 parts of PC resin, 39.5 parts of ABS resin, 5.5 parts of nano silicon dioxide, 0.55 part of dioctadecyl alcohol pentaerythritol diphosphite, 0.55 part of fatty acid amide, and the relative molecular weight of described PC resin is 17000g / mol, the glass transition temperature is 140°C;

[0028] S2. Dispersing nano silicon dioxide in pure water through an ultrasonic oscillation device to form an inorganic nano particle dispersion;

[0029] S3, injecting the dispersion obtained in step S2 into a twin-screw extruder through a liquid feeding pump, blending with ABS resin, evaporating all the water and leaving a mixture of inorganic nanoparticles and ABS resin;

[0030] S4. Add the mixture obtained in step S3, PC resin, dioctadecyl alcohol pentaerythritol diphosphite and fatty acid amide into a mixing mixer for mixing, and blend and granulate through a twin-screw extruder. The barrel temperature is 210°C , the screw speed is 320rpm, and the PC / ABS al...

Embodiment 2

[0040] S1, take by weighing 60 parts of PC resin, 39.5 parts of ABS resin, 5.5 parts of nano silicon dioxide, 0.55 part of dioctadecyl alcohol pentaerythritol diphosphite, 0.55 part of fatty acid amide, and the relative molecular weight of described PC resin is 30000g / mol, the glass transition temperature is 150°C;

[0041] S2. Dispersing nano silicon dioxide in pure water through an ultrasonic oscillation device to form an inorganic nano particle dispersion;

[0042] S3, injecting the dispersion obtained in step S2 into a twin-screw extruder through a liquid feeding pump, blending with ABS resin, evaporating all the water and leaving a mixture of inorganic nanoparticles and ABS resin;

[0043] S4. Add the mixture obtained in step S3, PC resin, dioctadecyl alcohol pentaerythritol diphosphite and fatty acid amide into a mixing mixer for mixing, and blend and granulate through a twin-screw extruder. The temperature of the barrel is 210~ 290°C, the screw speed is 320-620rpm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com